ASTM D6710-01

(Guide)Standard Guide for Evaluation of Hydrocarbon-Based Quench Oil

Standard Guide for Evaluation of Hydrocarbon-Based Quench Oil

SCOPE

1.1 This guide covers information without specific limits, for selecting standard test methods for testing hydrocarbon-based quench oils for quality and aging.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Standards Content (Sample)

Designation: D 6710 – 01 An American National Standard

Standard Guide for

1

Evaluation of Hydrocarbon-Based Quench Oil

This standard is issued under the fixed designation D 6710; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 6200 Test Method for Cooling Characteristics of Quench

4

Oils by Cooling Curve Analysis

1.1 This guide covers information without specific limits,

D 6304 Test Method for Determination of Water in Petro-

for selecting standard test methods for testing hydrocarbon-

leum Products, Lubricating Oils, and Additives by Coulo-

based quench oils for quality and aging.

4

metric Karl Fisher Titration

1.2 This standard does not purport to address all of the

5

2.2 ISO Standards:

safety concerns, if any, associated with its use. It is the

ISO 9950 - “Industrial Quenching Oils – Determination of

responsibility of the user of this standard to establish appro-

Cooling Characteristics – Nickel-Alloy Probe Test

priate safety and health practices and determine the applica-

Method,” 1995-95-01.

bility of regulatory limitations prior to its use.

3. Terminology

2. Referenced Documents

3.1 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.1.1 Quench Processing:

D 91 Test Method for Precipitation Number of Lubrication

2 3.1.1.1 austenitization, n—heating a steel containing less

Oils

than the eutectoid concentration of carbon (about 0.8 mass %)

D 92 Test Method for Flash Point and Fire Points by

2 to a temperature just above the eutectoid temperature to

Cleveland Open Cup

decompose the pearlite microstructure to produce a face-

D 94 Test Method for Saponification Number of Petroleum

2 centered cubic (fcc) austenite-ferrite mixture.

Products

3.1.1.2 dragout—solution carried out of a bath on the metal

D 95 Test Method for Water in Petroleum Products and

2 being quenched and associated handling equipment.

Bituminous Materials by Distillation

3.1.1.3 martempering, n—cooling steel from the austeniti-

D 189 Test Method for Conradson Carbon Residue of

2

zation temperature to a temperature just above the start of

Petroleum Products

mertensite transformation (M ) for a time sufficient for the

s

D 445 Test Method for Kinematic Viscosity of Transparent

temperature to equalize between the surface and the center of

and Opaque Liquids (the Calculation of Dynamic Viscos-

2

the steel, at which point the steel is removed from the quench

ity)

6

2

bath and air cooled as shown in Fig. 1. (1)

D 482 Test Method for Ash from Petroleum Products

3.1.1.4 protective atmosphere, n—any atmosphere that will

D 524 Test Method for Ramsbottom Carbon Residue of

2

inhibit oxidation of the metal surface during austenitization, or

Petroleum Products

it may be used to protect the quenching oil, which may be an

D 664 Test Method for Acid Number of Petroleum Products

2

inert gas such as nitrogen or argon or a gas used for a heat

by Potentiometric Titration

treating furnace.

D 974 Test Method for Acid and Base Number by Color-

2

3.1.1.5 quenching, n—cooling process from a suitable el-

Indicator Titration

evated temperature used to facilitate the formation of the

D 1298 Practice for Density, Relative Density (Specific

desired microstructure and properties of a metal as shown in

Gravity) or API Gravity of Crude Petroleum and Liquid

2 Fig. 2.

Petroleum Products by Hydrometer Method

3.1.1.6 quench severity, n—the ability of a quenching oil to

D 4052 Test Method for Density and Relative Density of

3 extract heat from a hot metal traditionally defined by the

Liquids by Digital Density Meter

quenching speed (cooling rate) at 1300°F (705°C) which was

D 4530 Test Method for Determination of Carbon Residue

3 related to a Grossmann H-Value or Quench Severity Factor

(Micro Method)

(H-Factor). (2)

1

This guide is under the jurisdiction of ASTM Committee D02 on Petroleum

4

Products and Lubricants and is the direct responsibility of Subcommittee D02.L0.06 Annual Book of ASTM Standards, Vol 05.04.

5

on Nonlubricating Process Fluids. Available from American National Standards Institute, 11 W. 42nd St., 13th

Current edition approved Aug. 10, 2001. Published October 2001. floor, New York, NY 10036.

2 6

Annual Book of ASTM Standards, Vol 05.01. The boldface numbers in parentheses refer to the list of references at the end of

3

Annual Book of ASTM Standards, Vol 05.02. this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 6710

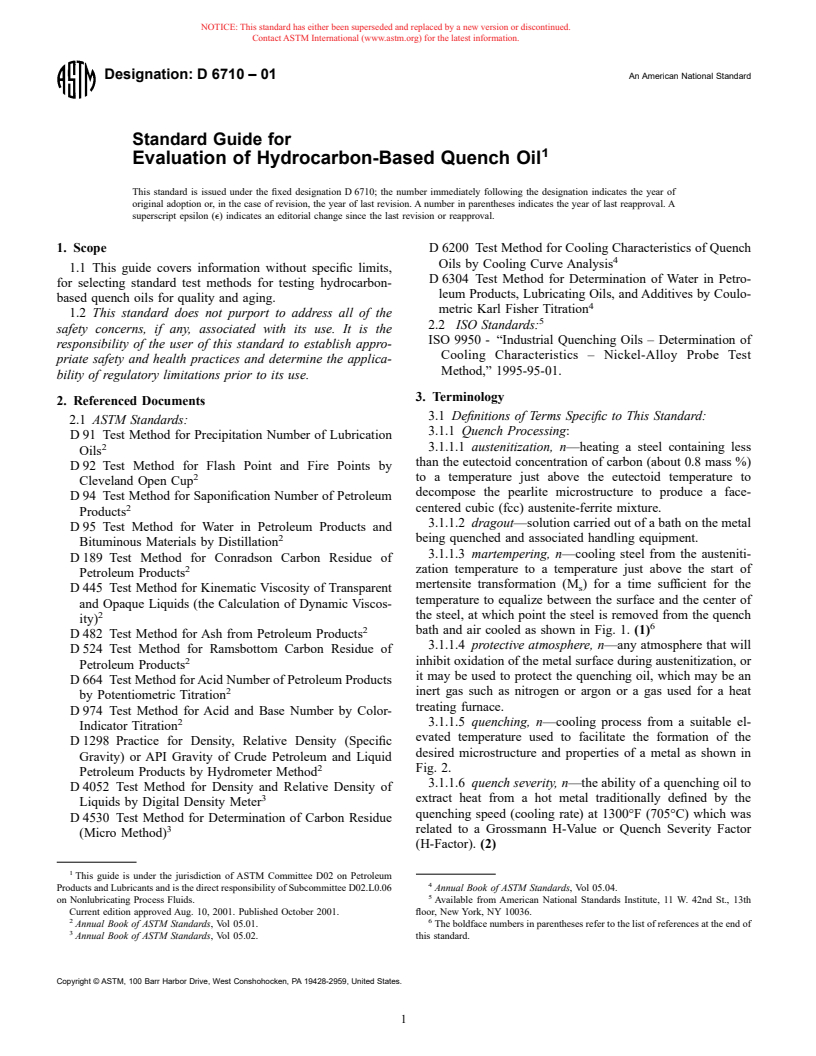

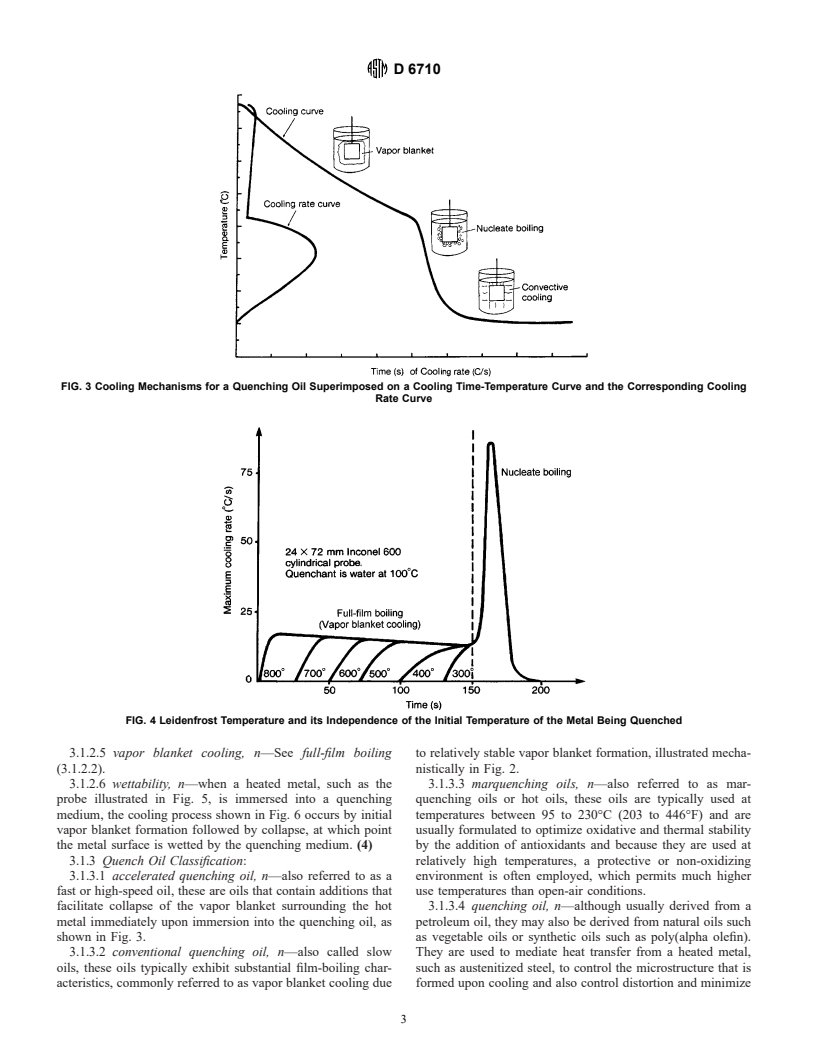

FIG. 1 (A) Conventional Quenching Cycle (B) Martempering

FIG. 2 Transformation Diagram for a Low-Alloy Steel with Cooling Curves for Various Quenching Media (A) High Speed Oil (B)

Conventional Oil

3.1.1.7 quench media, n—any medium, either liquid (water, the quenc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.