ASTM C841-99

(Specification)Standard Specification for Installation of Interior Lathing and Furring

Standard Specification for Installation of Interior Lathing and Furring

SCOPE

1.1 This specification covers the minimum requirements for interior lathing and furring for full thick gypsum plastering. Other materials may be used provided that their physical characteristics and durability under conditions of usage are at least equal in performance to those described.

Note 1-To secure desirable results, this specification should be coordinated with the provisions of Specification C 842.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric values shown in parentheses are provided for information purposes only.

1.3 For specific degree of fire resistance and the specific degree of sound control requirements see Annex A1.2 and A1.3.

1.4 General information regarding matters of a contractual nature concerning lathing and furring is contained in Annex A1. Technical information relating to lathing and furring materials is provided in Annex A2. Erection data for door frames installed in lath and plaster hollow partitions using prefabricated steel studs or channel studs is provided in Annex A3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 841 – 99

Standard Specification for

Installation of Interior Lathing and Furring

This standard is issued under the fixed designation C 841; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * tion of Gypsum Panel Products or Metal Plaster Bases to

Steel Studs from 0.033 in. (0.84 mm) to 0.112 in. (2.84

1.1 This specification covers the minimum requirements for,

mm) in Thickness

and the methods of application of, interior lathing and furring

C 1002 Specification for Steel Drill Screws for the Appli-

to receive gypsum plaster applied in accordance with Specifi-

cation of Gypsum Board or Metal Plaster Bases

cation C 842. Other materials are not prohibited from being

C 1007 Specification for Installation of Load Bearing

used provided that their physical characteristics and durability

(Transverse and Axial) Steel Studs and Related Accesso-

under conditions of usage are at least equal in performance to

ries

those described.

C 1032 Specification for Woven Wire Plaster Base

1.2 The values stated in inch-pound units are to be regarded

D 1784 Specification for Rigid Poly Vinyl Chloride PVC

as the standard. The metric values shown in parentheses are

Compounds and Chlorinated Poly Vinyl Chloride CPVC

provided for information only.

Compounds

1.3 Details of construction for a specific assembly to

D 3678 Specification for Rigid Poly(Vinyl Chloride) (PVC)

achieve the required fire resistance shall be obtained from

Interior-Profile Extrusions

reports of fire-resistance tests, engineering evaluations, or

E 492 Method for Laboratory Measurement of Impact

listings from recognized fire testing laboratories.

Sound Transmission Through Floor-Ceiling Assemblies

1.4 Where a specific degree of sound control is required for

Using the Tapping Machine

plastered assemblies and constructions, details of construction

2.2 National Association of Architectural Metal Manufac-

shall be obtained from reports of sound tests of assemblies that

turers Standard

have met the requirements of Test Method E 492.

HMMA 840 Installation and Storage of Hollow Metal

2. Referenced Documents

Doors and Frames

2.1 ASTM Standards:

3. Terminology

A 641/A 641M Specification for Zinc-Coated (Galvanized)

3.1 Definitions—For definitions relating to ceilings and

Carbon Steel Wire

walls see Terminology C 11.

C 11 Terminology Relating to Gypsum and Related Build-

3.2 Definitions of Terms Specific to This Standard:

ing Materials and Systems

3.2.1 base coat, n—the sum of the scratch and brown coats

C 37 Specification for Gypsum Lath

or the total coats in place prior to application of finish coats.

C 514 Specification for Nails for the Application of Gyp-

3.2.2 contact ceiling, n—a ceiling in which the lath is

sum Board

attached in direct contact with the construction above, without

C 754 Specification for Installation of Steel Framing Mem-

the use of main runners or cross furring.

bers to Receive Screw-Attached Gypsum Panel Products

3.2.3 furred ceiling, n—a ceiling in which the furring used

C 842 Specification for Application of Interior Gypsum

for the support of the lath is attached directly to the structural

Plaster

3 members of the building.

C 847 Specification for Metal Lath

3.2.4 suspended ceiling, n—a ceiling in which the main

C 933 Specification for Welded Wire Lath

runners and cross furring are suspended below the structural

C 954 Specification for Steel Drill Screws for the Applica-

members of the building.

3.2.5 main runners, n—the members that are attached to or

This specification is under the jurisdiction of ASTM Committee C-11 on

Gypsum and Related Building Materials and Systems, and is the direct responsi-

bility of Subcommittee C11.03 on Specifications for Application of Gypsum and

Other Products in Assemblies. Annual Book of ASTM Standards, Vol 08.01.

Current edition approved Oct. 10, 1999. Published January 2000. Originally Annual Book of ASTM Standards, Vol 08.04.

published as C 841 – 76. Last previous edition C 841 – 98. Annual Book of ASTM Standards, Vol 04.06.

2 7

Annual Book of ASTM Standards, Vol 01.06. Available from NAAMM, 8 South Michigan Avenue, Suite 1000, Chicago, IL

Annual Book of ASTM Standards, Vol 04.01. 60603.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 841

suspended from the construction above for the support of cross corrosion resistance and strength. Wire diameters (uncoated)

furring. specified herein correspond with United States steel wire gage

3.2.6 cross furring, n—furring members that are attached at numbers as follows:

right angles to the underside of the main runners or construc-

Wire Gage (U.S. Steel

A

Diameter, in. mm Wire Gage)

tion above for support of the lath.

3.2.7 furring, n—spacer strips fastened to a wall, ceiling, or

0.0348 0.88 No. 20

planar element that create an even surface for the application of

0.0410 1.04 No. 19

0.0475 1.21 No. 18

metal plaster bases or gypsum lath.

0.0540 1.37 No. 17

3.2.8 primary members, n—the members (main runners or

0.0625 1.59 No. 16

structural supports) to which the cross furring is attached. 0.0800 2.03 No. 14

0.0915 2.32 No. 13

3.2.9 metal plaster bases, n—expanded metal lath, sheet

0.1055 2.68 No. 12

metal lath, welded or woven wire lath.

0.1205 3.06 No. 11

3.2.10 face side (gypsum lath), n—the side opposite the

0.1350 3.43 No. 10

0.1483 3.77 No. 9

paper cover seam laps.

0.1620 4.11 No. 8

3.2.11 surface transition, n—the change in width of a

_____________

surface, usually as a result of penetrations (doors, windows) or

A

Allowable variations in diameter shall be in accordance with tolerances as

architectural demands.

established in A 641/A 641M.

6.2 Gypsum Lath— Specification C 37.

4. Delivery of Materials

6.3 Expanded Metal Lath— Specification C 847.

4.1 All materials shall be delivered in the original packages,

6.4 Wire Lath:

containers, or bundles bearing the brand name and manufac-

6.4.1 Welded Wire Lath, Specification C 933.

turer’s (or supplier’s) identification.

6.4.2 Woven Wire Lath, Specification C 1032.

6.5 Fasteners:

5. Storage of Materials

6.5.1 Nails for Attaching Gypsum Lath— Specification

5.1 All materials shall be kept dry, preferably by being C 514. Nail size shall be in accordance with Table 1.

stored inside. Where necessary to be stored outside, materials

6.5.2 Nails for Attaching Metal Plaster Base—Galvanized

shall be stacked off the ground, supported on a level platform, roofing nails or common nails. length shall be as specified in 7.

and protected from the weather and surface contamination.

6.5.3 Screws—Specifications C 954 or C 1002.

5.2 Materials shall be neatly stacked flat with care taken to

6.5.3.1 Screws for attaching gypsum lath shall be sized in

avoid damage to edges, ends, or surfaces.

accordance with Table 1.

6.5.3.2 Screws for attaching metal plaster base shall have a

6. Materials

⁄16 in. (11.1 mm) diameter pan washer head and a 0.120 in.

6.1 Wire Specification A 641/A 641M, Class 1 coating (gal- (3.0 mm) diameter shank. The length shall be sufficient enough

vanized) soft temper. to allow for the threaded portion of the screw to project not less

6.1.1 Tie Wire and Hanger Wire—Zinc-coated (galvanized) than ⁄8 in. (9.5 mm) through steel framing when the lath is

soft-annealed steel, or a material having equivalent size, installed.

A,B

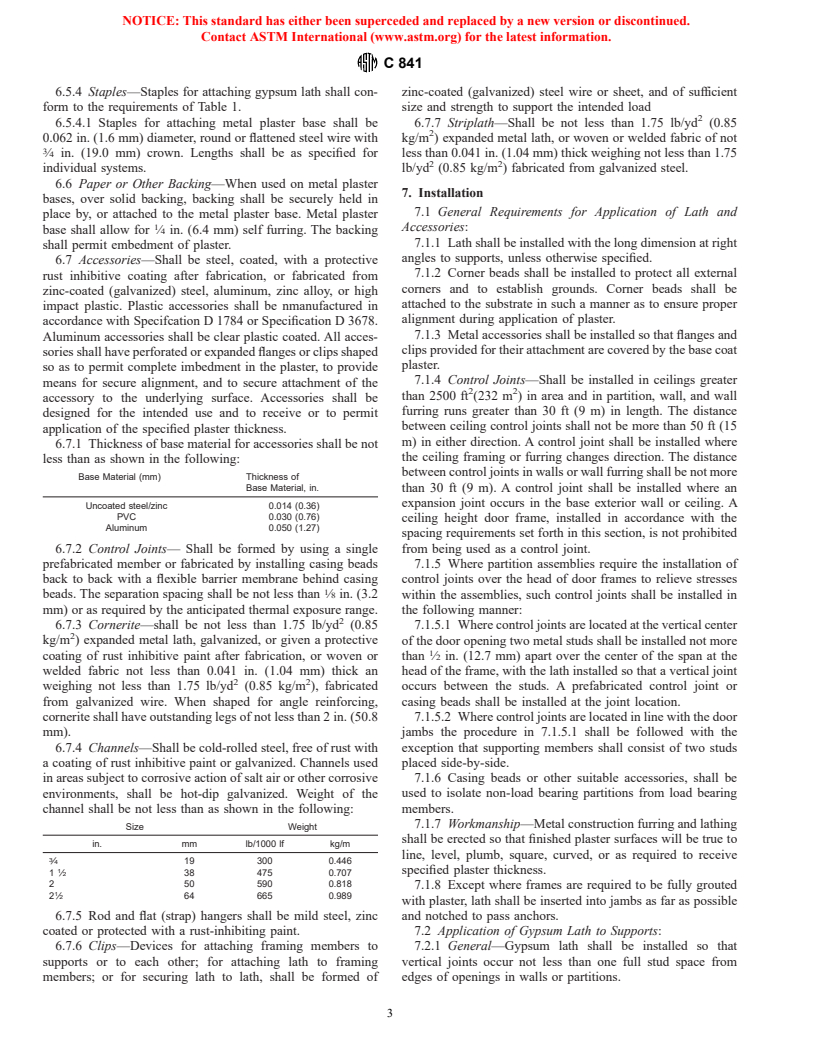

TABLE 1 Screws, Nails and Staples for Attaching Gypsum Lath to Horizontal and Vertical Wood Supports

Maximum Spacing, in. (mm) Minimum Gage Requirements, in. (mm)

Diameter of

Flat Head or Gage of

Distance Number of Approximate Depth of

Width of Thickness Length of Blued Nails Shank of

Between Attachments Spacing c to c of Support

Lath of Lath Leg or Crown Nails or

Supports per Bearing Attachments Penetration

A

Width of Staples

A

Staples

3 1 3 19

16 (406) ⁄8 (9.5) 16 (406) 4 5 (127) 1 ⁄8 (28.6) ⁄4(19) ⁄64 (7.5) 13

A A A A

5 7

1 (25.4) ⁄8(15.9) ⁄16 (11) 16

3 1 1 3 19

24 (610) ⁄8 (9.5) 16 (406) 6 4 ⁄2 (114) 1 ⁄8 (28.6) ⁄4 (19) ⁄64 (7.5) 13

A A A A

5 7

1 (25.4) ⁄8(15.9) ⁄16 (11) 16

1 1 3 19

16 (406) ⁄2 (12.7) 24 (610) 4 5 (127) 1 ⁄4 (32) ⁄4(19) ⁄64 (7.5) 13

A A A A

1 5 7

1 ⁄8 (28.6) ⁄8 (15.9) ⁄16(11) 16

1 1 1 3 19

24 (610) ⁄2 (12.7) 24 (610) 6 4 ⁄2 (114) 1 ⁄4 (32) ⁄4 (19) ⁄64 (7.5) 13 (330)

1 A 5 A 7 A A

1 ⁄8 (28.6) ⁄8 (15.9) ⁄16(11) 16

3 1 1 3

48 (1219) ⁄8 (9.5) 16 (406) 8 4 ⁄2 (114) 1 ⁄8 (28.6) ⁄4 (19)

A A

1 5

⁄2 (12.7) 24 (610) 1 (25.4) ⁄8 (15.9)

1 3

1 ⁄4 (32) ⁄4 (19)

A A

1 5

1 ⁄8 (28.6) ⁄8(15.9)

A

Galvanized staples.

B

Screws for attaching gypsum lath to wood supports shall be Type W as described in Specification C 1002.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 841

6.5.4 Staples—Staples for attaching gypsum lath shall con- zinc-coated (galvanized) steel wire or sheet, and of sufficient

form to the requirements of Table 1. size and strength to support the intended load

6.5.4.1 Staples for attaching metal plaster base shall be 6.7.7 Striplath—Shall be not less than 1.75 lb/yd (0.85

0.062 in. (1.6 mm) diameter, round or flattened steel wire with kg/m ) expanded metal lath, or woven or welded fabric of not

⁄4 in. (19.0 mm) crown. Lengths shall be as specified for less than 0.041 in. (1.04 mm) thick weighing not less than 1.75

2 2

individual systems. lb/yd (0.85 kg/m ) fabricated from galvanized steel.

6.6 Paper or Other Backing—When used on metal plaster

7. Installation

bases, over solid backing, backing shall be securely held in

7.1 General Requirements for Application of Lath and

place by, or attached to the metal plaster base. Metal plaster

Accessories:

base shall allow for ⁄4 in. (6.4 mm) self furring. The backing

7.1.1 Lath shall be installed with the long dimension at right

shall permit embedment of plaster.

angles to supports, unless otherwise specified.

6.7 Accessories—Shall be steel, coated, with a protective

7.1.2 Corner beads shall be installed to protect all external

rust inhibitive coating after fabrication, or fabricated from

corners and to establish grounds. Corner beads shall be

zinc-coated (galvanized) steel, aluminum, zinc alloy, or high

attached to the substrate in such a manner as to ensure proper

impact plastic. Plastic accessories shall be nmanufactured in

alignment during application of plaster.

accordance with Specifcation D 1784 or Specification D 3678.

7.1.3 Metal accessories shall be installed so that flanges and

Aluminum accessories shall be clear plastic coated. All acces-

clips provided for their attachment are covered by the base coat

sories shall have perforated or expanded flanges or clips shaped

plaster.

so as to permit complete imbedment in the plaster, to provide

7.1.4 Control Joints—Shall be installed in ceilings greater

means for secure alignment, and to secure attachment of the

2 2

than 2500 ft (232 m ) in area and in partition, wall, and wall

accessory to the underlying surface. Accessories shall be

furring runs greater than 30 ft (9 m) in length. The distance

designed for the intended use and to receive or to permit

between ceiling control joints shall not be more than 50 ft (15

application of the specified plaster thickness.

m) in either direction. A control joint shall be installed where

6.7.1 Thickness of base material for accessories shall be not

the ceiling framing or furring changes direction. The distance

less than as shown in the following:

between control joints in walls or wall furring shall be not more

Base Material (mm) Thickness of

Base Material, in. than 30 ft (9 m). A control joint shall be installed where an

expansion joint occurs in the base exterior wall or ceiling. A

Uncoated steel/zinc 0.014 (0.36)

PVC 0.030 (0.76)

ceiling height door frame, installed in accordance with the

Aluminum 0.050 (1.27)

spacing requirements set forth in this section, is not prohibited

6.7.2 Control Joints— Shall be formed by using a single from being used as a control joint.

prefabricated member or fabricated by installing casing beads

7.1.5 Where partition assemblies require the installation of

back to back with a flexible barrier membrane behind casing control joints over the head of door frames to relieve stresses

beads. The separation spacing shall be not less than ⁄8 in. (3.2 within the assemblies, such control joints shall be installed in

mm) or as required by the anticipated thermal exposure range. the following manner:

6.7.3 Cornerite—shall be not less than 1.75 lb/yd (0.85 7.1.5.1 Where control joints are located at the vertical center

kg/m ) expanded metal lath, galvanized, or given a protective of the door opening two metal studs shall be installed not more

coating of rust inhibitive paint after fabrication, or woven or than ⁄2 in. (12.7 mm) apart over the center of the span at the

welded fabric not less than 0.041 in. (1.04 mm) thick an head of the frame, with the lath installed so that a vertical joint

2 2

weighing not less than 1.75 lb/yd (0.85 kg/m ), fabricated occurs between the studs. A prefabricated control joint or

from galvanized wire. When shaped for angle reinforcing, casing beads shall be installed at the joint location.

cornerite shall have outstanding legs of not less than 2 in. (50.8 7.1.5.2 Where control joints are located in line with the door

mm). jambs the procedure in 7.1.5.1 shall be followed with the

6.7.4 Channels—Shall be cold-rolled steel, free of rust with exception that supporting members shall consist of two studs

a coating of rust inhibitive paint or galvanized. Channels used placed side-by-side.

in areas subject to corrosive action of salt air or other corrosive 7.1.6 Casing beads or other suitable accessories, shall be

environments, shall be hot-dip galvanized. Weight of the used to isolate non-load bearing partitions from load bearing

channel shall be not less than as shown in the following: members.

7.1.7 Workmanship—Metal construction furring and lathing

Size Weight

shall be erected so that finished plaster surfaces will be true to

in. mm lb/1000 lf kg/m

line, level, plumb, square, curved, or as required to receive

⁄4 19 300 0.446

specified plaster thickness.

1 ⁄2 38 475 0.707

2 50 590 0.818

7.1.8

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.