ASTM C1052-01(2007)

(Practice)Standard Practice for Bulk Sampling of Liquid Uranium Hexafluoride

Standard Practice for Bulk Sampling of Liquid Uranium Hexafluoride

SIGNIFICANCE AND USE

Uranium hexafluoride is normally produced and handled in large (typically 1- to 14-ton) quantities and must, therefore, be characterized by reference to representative samples. The quantities involved, physical properties, chemical reactivity, and hazardous nature of UF6 are such that for representative sampling, specially designed equipment must be used and operated in accordance with the most carefully controlled and stringent procedures. This practice indicates appropriate principles, equipment, and procedures currently in use for bulk sampling of liquid UF6. It is used by UF6 converters, enrichers, and fuel fabricators to review the effectiveness of existing procedures or as a guide to the design of equipment and procedures for future use. Other sampling procedures such as UF6 vapor sampling are not directly representative of the quality of liquid UF6.

It is emphasized that this practice is not meant to address conventional or nuclear criticality safety issues.

SCOPE

1.1 This practice covers methods for withdrawing representative samples of liquid uranium hexafluoride (UF6) from bulk quantities of the material. Such samples are used for determining compliance with the applicable commercial specification, for example Specification C787 and Specification C996.

1.2 It is assumed that the bulk liquid UF6 being sampled comprises a single quality and quantity of material. This practice does not address any special additional arrangements that might be required for taking proportional or composite samples, or when the sampled bulk material is being added to UF6 residues already in a container (“heels recycle”).

1.3 The number of samples to be taken, their nominal sample weight, and their disposition shall be agreed upon between the parties.

1.4 The scope of this practice does not include provisions for preventing criticality incidents.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1052 −01(Reapproved 2007)

Standard Practice for

Bulk Sampling of Liquid Uranium Hexafluoride

This standard is issued under the fixed designation C1052; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Documents:

USEC-651 Uranium Hexafluoride: A Manual of Good Han-

1.1 This practice covers methods for withdrawing represen-

dling Practices

tative samples of liquid uranium hexafluoride (UF ) from bulk

ANSI N14.1 Uranium Hexafluoride: Packaging for Trans-

quantities of the material. Such samples are used for determin-

port

ing compliance with the applicable commercial specification,

ISO/DIS 7195 Packaging of Uranium Hexafluoride (UF )

for example Specification C787 and Specification C996.

for Transport

1.2 It is assumed that the bulk liquid UF being sampled

3. Terminology

comprises a single quality and quantity of material. This

practice does not address any special additional arrangements

3.1 Definitions of Terms Specific to This Standard:

that might be required for taking proportional or composite

3.1.1 container—the bulk vessel either holding or receiving

samples, or when the sampled bulk material is being added to

by transfer, the UF to be sampled; it may consist of, for

UF residues already in a container (“heels recycle”).

6 example, a fixed vessel in a UF handling plant or a cylinder to

be used for the transport of UF .

1.3 The number of samples to be taken, their nominal 6

sample weight, and their disposition shall be agreed upon

3.1.2 sample bottle—the small vessel into which the sample

between the parties.

of UF is withdrawn for transfer to the laboratory for charac-

terization.

1.4 The scope of this practice does not include provisions

for preventing criticality incidents.

4. Summary of Practice

1.5 This standard does not purport to address all of the

4.1 Two methods of withdrawing a sample are described,

safety concerns, if any, associated with its use. It is the

namely: (1) direct withdrawal from a filled container and (2)

responsibility of the user of this standard to establish appro-

withdrawal from the inlet-line during the filling of a container

priate safety and health practices and determine the applica-

by liquid transfer. The first method involves tilting or turning

bility of regulatory limitations prior to use.

the container in such a way that its valve is below the surface

of the liquefied UF , and dependent on the equipment, this

2. Referenced Documents

requires that the container holds more than a specified mini-

2.1 ASTM Standards:

mum quantity of UF . Liquid UF is withdrawn into a

6 6

C787 Specification for Uranium Hexafluoride for Enrich-

graduatedvolumeandthentransferredtotherespectivesample

ment

bottle(s). In the second method, a small proportion of the UF

C996 Specification for Uranium Hexafluoride Enriched to

flowing from one container to another is withdrawn into a

Less Than 5 % U

graduatedvolumeandthentransferredtotherespectivesample

bottle(s).

1 4.2 For both methods of sampling, the presence of residues

This practice is under the jurisdiction of ASTM Committee C26 on Nuclear

may have significant implications for the quality of the UF .

Fuel Cycle and is the direct responsibility of Subcommittee C26.02 on Fuel and

Fertile Material Specifications.

For safety and quality reasons, containers and bottles shall be

CurrenteditionapprovedJune1,2007.PublishedJuly2007.Originallyapproved

clean, dry, and empty before filling.

in 1985. Last previous edition approved in 2001 as C1052 – 01. DOI: 10.1520/

C1052-01R07.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or AvailablefromUnitedStatesEnrichmentCorp.,6903RockledgeDr.,Bethesda,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM MD 20817.

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 11 W. 42nd St., 13th

the ASTM website. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

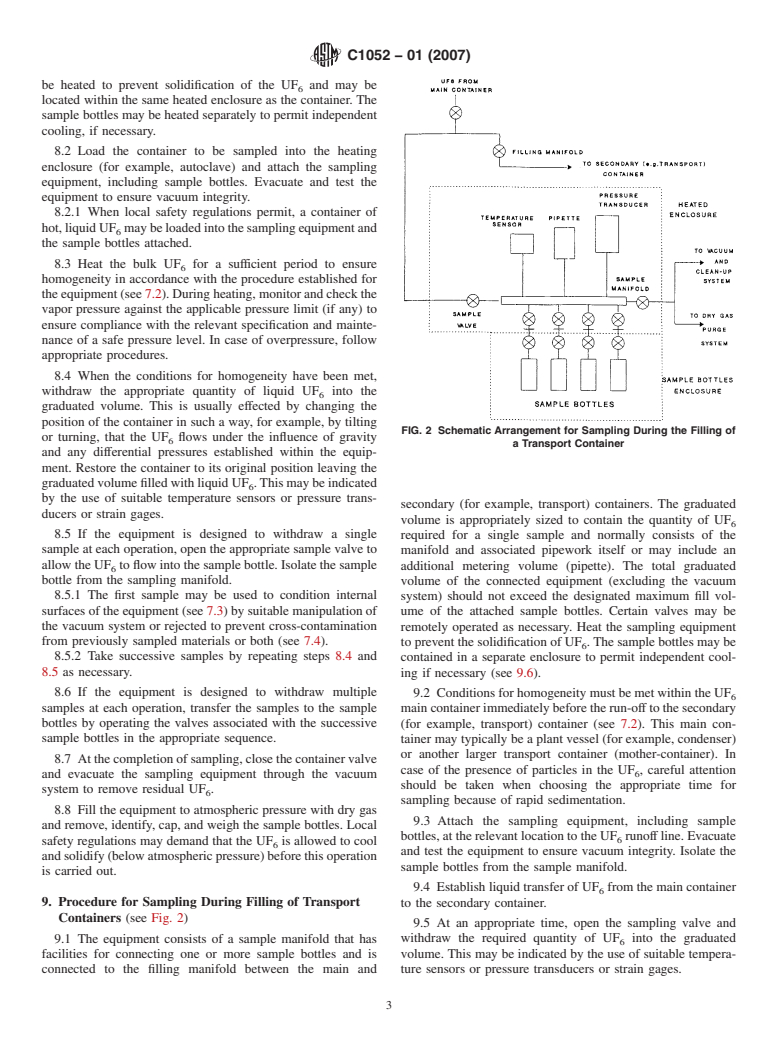

C1052−01 (2007)

4.3 Various types of sample bottles are in use and are nents in direct contact with UF are made from nickel,

described in detail in the applicable national and international high-nickel alloys, or materials having equivalent resistance to

standards, for example,ANSI N14.1 and ISO/DIS 7195. For a UF corrosion. The formation of an inert fluoride layer is often

given type of sample bottle, the detailed configuration, for an important feature of UF corrosion resistance, and hence,

example, valve orientation, terminal fittings, and the like, may internal surfaces are generally conditioned with a suitable

vary.Hence,thetypeandconfigurationofbottlestobeusedfor fluorinating agent, sometimes UF itself.

the withdrawal of samples shall be agreed upon between the

7.4 Cross-contamination may occur between subsequent

parties.

samples taken using the same equipment, and appropriate

precautions must be taken to prevent this. It is therefore

5. Significance and Use

recommended that, before taking definitive samples, the equip-

5.1 Uraniumhexafluorideisnormallyproducedandhandled

ment is flushed through with an aliquot of the material to be

in large (typically 1- to 14-ton) quantities and must, therefore,

sampled. This is normally accomplished by taking an initial

be characterized by reference to representative samples. The

volume which is then rejected and not used for definitive

quantities involved, physical properties, chemical reactivity,

analysis. Alternative procedures to prevent cross-

and hazardous nature of UF are such that for representative

contamination are possible and should be validated individu-

sampling, specially designed equipment must be used and

ally.

operated in accordance with the most carefully controlled and

7.5 If the sample bottles are taken for an analytical need

stringent procedures. This practice indicates appropriate prin-

such as liquid UF6 subsampling for P10 tubes or liquid UF6

ciples, equipment, and procedures currently in use for bulk

transfer for FTIR quantification, it is recommended, in order to

sampling of liquid UF . It is used by UF converters, enrichers,

6 6

minimize the gas phase contribution to the sample bottle, to fill

and fuel fabricators to review the effectiveness of existing

the bottle with more than 10% of its total volume.

procedures or as a guide to the design of equipment and

procedures for future use. Other sampling procedures such as

8. Procedure for Sampling Directly from Filled

UF vapor sampling are not directly representative of the

Containers (see Fig. 1)

quality of liquid UF .

8.1 The equipment consists of a sample manifold that is

5.2 Itisemphasizedthatthispracticeisnotmeanttoaddress

connected directly to the valve of the transport container and

conventional or nuclear criticality safety issues.

has facilities for connecting one or more sample bottles. The

graduated volume is appropriately sized so that when filled

6. Hazards

either completely or visually to a predetermined level it will

6.1 Because of its chemical, radiochemical, and toxic prop- contain a known quantity of UF . The graduated volume may

consist of the manifold and associated pipework, or may

erties, UF is a hazardous material. Suitable handling proce-

dures are described in USEC-651. include an additional metering volume (pipette). The equip-

ment may be designed to withdraw either single or multiple

7. Principles

sample quantities of UF at each operation.The total graduated

volume of the connected equipment (excluding the vacuum

7.1 The essential purpose of the sample is to be represen-

system) should not exceed the designated maximum fill vol-

tative of the bulk material for the purpose of determining

ume of the connected sample bottles. Certain valves may be

compliance with the applicable material specification. To

remotely operated as necessary. The sampling equipment must

ensurethatthesampleisrepresentativeforthispurpose,certain

principles, as described below, must be observed.

7.2 Special attention must be given to ensuring that the bulk

material from which the sample is withdrawn is homogeneous,

particular

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.