ASTM D1739-98(2004)

(Test Method)Standard Test Method for Collection and Measurement of Dustfall (Settleable Particulate Matter)

Standard Test Method for Collection and Measurement of Dustfall (Settleable Particulate Matter)

SIGNIFICANCE AND USE

This test method has the advantage of extreme simplicity. It is a crude and non-specific test method, but it is useful in the study of long-term trends. It requires very little investment in equipment and can be carried out without a large technically-skilled staff.

This test method is useful for obtaining samples of settleable particulate matter for further chemical analysis (1)5 .

SCOPE

1.1 This test method covers a procedure for collection of dustfall and its measurement. This test method is not appropriate for determination of the dustfall rate in small areas affected by specific sources. This test method describes determination of both water-soluble and insoluble particulate matter.

1.2 This test method is inappropriate for industrial hygiene use except where other more specific methods are also used.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1739–98 (Reapproved 2004)

Standard Test Method for

Collection and Measurement of Dustfall (Settleable

Particulate Matter)

This standard is issued under the fixed designation D1739; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers a procedure for collection of 3.1 Definitions—For definitions of terms used in this test

dustfall and its measurement. This test method is not appro- method, refer to Terminology D1356.An explanation of units,

priate for determination of the dustfall rate in small areas symbols, and conversion factors may be found in Practice

affected by specific sources. This test method describes deter- E380.

mination of both water-soluble and insoluble particulate mat- 3.2 Definition of Terms Specific to This Standard:

ter. 3.2.1 settleable particulate material—any material com-

1.2 This test method is inappropriate for industrial hygiene posed of particles small enough to pass through a 1-mm screen

use except where other more specific methods are also used. (see Specification E11) and large enough to settle by virtue of

1.3 The values stated in SI units are to be regarded as their weight into the container from the ambient air.

standard. No other units of measurement are included in this

4. Summary of Test Method

standard.

4.1 Containersofastandardsizeandshapearepreparedand

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the sealed in a laboratory and then opened and set up at appropri-

ately chosen sites so that particulate matter can settle into them

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- for periods of about 30 days. The containers are then closed

and returned to the laboratory.The masses of the water-soluble

bility of regulatory limitations prior to use.

and -insoluble components of the material collected are deter-

2. Referenced Documents

mined. The results are reported as grams per square metre per

2.1 ASTM Standards: 30 days g/(m·30d).

B57 Discontinued 1942; Specification for Copper-Alloy

3 5. Significance and Use

Condenser Tube Plates; Replaced by B 171

5.1 This test method has the advantage of extreme simplic-

D1193 Specification for Reagent Water

D1356 Terminology Relating to Sampling and Analysis of ity. It is a crude and non-specific test method, but it is useful in

the study of long-term trends. It requires very little investment

Atmospheres

E11 SpecificationforWovenWireTestSieveClothandTest in equipment and can be carried out without a large

technically-skilled staff.

Sieves

E380 Practice for the Use of the International System of 5.2 This test method is useful for obtaining samples of

4 5

settleable particulate matter for further chemical analysis (1) .

Units (SI) (the Modernized Metric System)

6. Interferences

This test method is under the jurisdiction of ASTM Committee D22 on

6.1 The results from this test method are obtained by

Sampling and Analysis of Atmospheres and is the direct responsibility of Subcom-

weighings.Any material that gets into the container and passes

mittee D22.03 on Ambient Atmospheres and Source Emissions.

Current edition approved October 1, 2004. Published December 2004. Originally through the sieve used in analysis, but which did not settle into

approved in 1960. Last previous edition approved in 1998 as D1739 - 98. DOI:

the container after air entrainment can be considered an

10.1520/D1739-98R04.

interferent.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org. The boldface numbers in parentheses refer to the list of references at the end of

Withdrawn. Replaced by IEEE/ASTM SI 10. this test method.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1739–98 (2004)

7. Apparatus

7.1 Container—An open-topped cylinder not less than 150

mm [6 in.] in diameter with height not less than twice its

diameter. Containers should be made of stainless steel or

weatherproof plastic. They shall be capable of accepting

legible, weatherproof, identification markings. A tight-fitting

lid is needed for each container.

7.2 Stand, for the container, which will hold the top of the

container at a height of 2 m above ground. It will also include

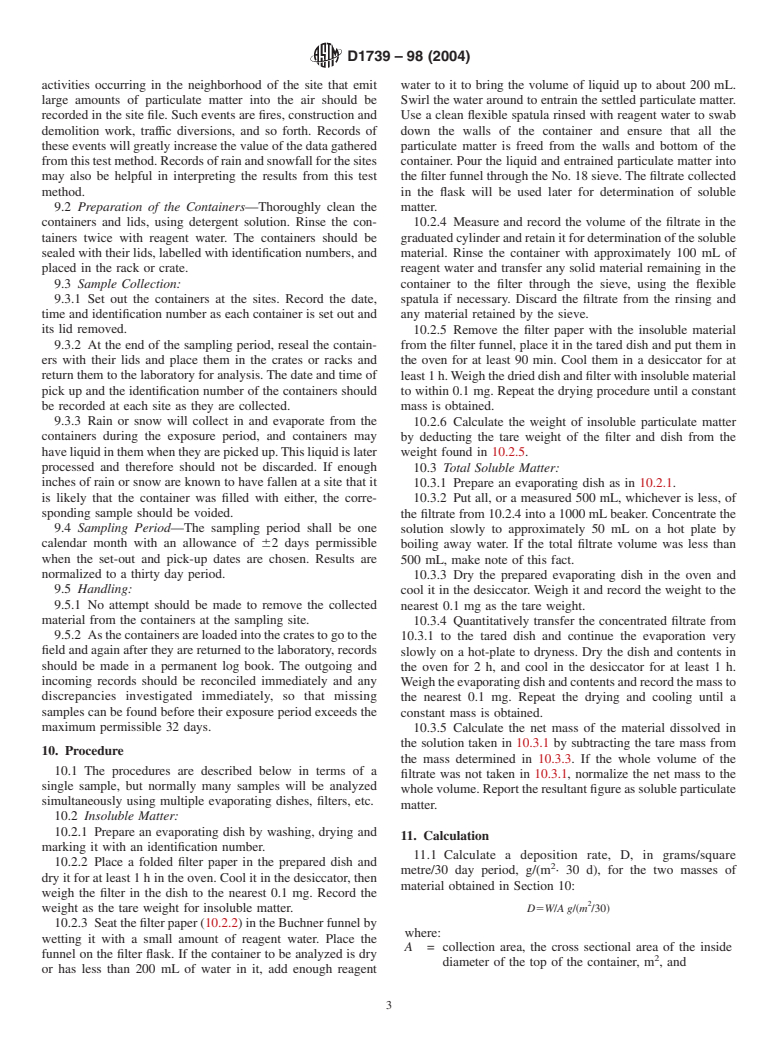

a wind shield constructed in accordance with Figs. 1 and 2.

Experiments reported in Kohler and Fleck (2) indicate that

much better precision is obtained when this simple aerody-

namic shield is provided, and that there is a wide variability in

the concentration of particles subject to settling at heights of

less than 2 m.

7.3 Sieve, 1 mm (No. 18), stainless steel.

7.4 Drying Oven, with temperature controlled at 105°C.

7.5 Buchner Funnel, and 2 L filtering flask.

FIG.2PlanViewofWindShield

7.6 Filter Paper, fast filtering type, circles to fit the Buchner

funnel.

9.1.1.1 These recommendations are a guide to the selection

7.7 Evaporating Dishes, 100-mL capacity, capable of being

unambiguously identified. of a site. In cases where these guidelines cannot be followed,

results should only be presented accompanied by an appropri-

7.8 Desiccators.

7.9 Analytical Balance, to weigh with a precision of 60.1 ate caveat.

9.1.1.2 The sampling site should be in an open area, free of

mg.

7.10 Flexible Spatula. structureshigherthan1mwithina20-mradiusofthecontainer

stand. It should be away from local sources of pollution and

7.11 Crate, or frame in which to carry the containers.

7.12 Graduated Cylinder, 1 L capacity, whose graduations objects that could affect the settling of particulate matter, such

astrees,andairexhaustsandintakes.Accessibilityandsecurity

have been checked for calibration accuracy, 65 mL, using, for

example, volumetric flasks or pipettes. from vandalism are major considerations in the selection of a

site.

8. Reagents 9.1.1.3 Elevations to higher objects within 20 m should not

exceed 30° from the horizontal.

8.1 Purity of Water—Unless otherwise indicated, reference

9.1.1.4 Open areas around police and fire stations and

to water shall be understood to mean reagent water as defined

libraries are often suitable because of their accessibility and

by Type II of Specification D1193.

security.

9.1.1.5 Avoid sitting the containers near chimneys. When-

9. Sampling

ever possible, the sampling site shall be more than ten

9.1 Sites (3, 4); for general sampling strategy, see Specifi-

stack-lengths from an operating stack and upwind from it in

cations B57.

accordance with the most frequent wind direction.

9.1.1 Location:

NOTE 1—Do not assume that stacks are unused without making direct

inquiry.

9.1.2 Number of Sites (5)—For each region to be surveyed,

a minimum of four sampling sites shall be provided, to allow

for rejected samples and to provide some evidence for quality

assurance checks.An orderly spacing of the stations should be

made approximately at the vertices of an equilateral triangular

grid.Theavailabilityofstaffwilloftenbeaconstrainingfactor,

but it is suggested that the spacing between sites be between 5

and 8 km.

9.1.3 Site Records—A file which will contain physical

information specific to each site, such as the approximate

elevation above sea level, map co-ordinates, and so forth,

should be maintained for each site. It should include a detailed

description, or photographs of the container stand that include

its surroundings. Also included should be photographs or

detailed descriptions of the surrounding area in the four

FIG. 1 Wind Shield for Dustfall Container compass point directions from the container stand. Unusual

D1739–98 (2004)

activities occurring in the neighborhood of the site that emit water to it to bring the volume of liquid up to about 200 mL.

large amounts of particulate matter into the air should be Swirl the water around to entrain the settled particulate matter.

recorded in the site file. Such events are fires, construction and Use a clean flexible spatula rinsed with reagent water to swab

demolition work, traffic diversions, and so forth. Records of down the walls of the container and ensure that all the

these events will greatly increase the value of the data gathered particulate matter is freed from the walls and bottom of the

fromthistestmethod.Recordsofrainandsnowfallforthesites container. Pour the liquid and entrained particulate matter into

may also be helpful in interpreting the results from this test the filter funnel through the No. 18 sieve. The filtrate collected

method. in the flask will be used later for determination of soluble

9.2 Preparation of the Containers—Thoroughly clean the matter.

containers and lids, using detergent solution. Rinse the con- 10.2.4 Measure and record the volume of the filtrate in the

tainers twice with reagent water. The containers should be graduatedcylinderandretainitfordeterminationofthesoluble

sealed with their lids, labelled with identification numbers, and material. Rinse the container with approximately 100 mL of

placed in the rack or crate. reagent water and transfer any solid material remaining in the

9.3 Sample Collection: container to the filter through the sieve, using the flexible

9.3.1 Set out the containers at the sites. Record the date, spatula if necessary. Discard the filtrate from the rinsing and

t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.