ASTM D4672-00

(Test Method)Standard Test Methods for Polyurethane Raw Materials Determination of Water Content of Polyols

Standard Test Methods for Polyurethane Raw Materials Determination of Water Content of Polyols

SCOPE

1.1 These test methods measure water content of polyols and many other organic compounds.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1--ISO Standard 14897 is equivalent to these test methods.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:D4672–00

Standard Test Methods for

Polyurethane Raw Materials: Determination of Water

Content of Polyols

This standard is issued under the fixed designation D 4672; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Methods

1.1 These test methods measure water content of polyols 4.1 Test MethodsAand B are based essentially on volumet-

and many other organic compounds. ric or coulometric titrations that follow the reduction of iodine

1.2 The values stated in SI units are to be regarded as the by sulfur dioxide in the presence of water. This reaction

standard. The values given in parentheses are for information proceeds quantitatively when methanol or another alcohol

only. (ROH) and pyridine (C H N) or a similar amine (R8N) are

5 5

1.3 This standard does not purport to address all of the present to react with the sulfur trioxide (SO ) and hydriodic

safety concerns, if any, associated with its use. It is the acid (HI) produced according to the following reactions:

responsibility of the user of this standard to establish appro- ROH+SO +R8N→ [R8NH]SO R

2 3

priate safety and health practices and determine the applica- H O+I +[R8NH]SO R+2R8N→ [R8NH]SO R + 2[R8NH]I

2 2 3 4

bility of regulatory limitations prior to use. 4.2 To determine water, Karl Fischer reagent (a solution of

iodine, sulfur dioxide, imidazole, and pyridine or a pyridine

NOTE 1—ISO Standard 14897 is equivalent to these test methods.

substitute) is added to a solution of the sample in methanol or

other alcohol until all the water present has been consumed.

2. Referenced Documents

2 The titrant can either be added by buret (volumetry) or

2.1 ASTM Standards:

generated electrochemically in the titration cell (coulometry).

D 1193 Specification for Reagent Water

Coulometric titrations eliminate the need for standardizing the

D 883 Terminology Relating to Plastics

reagent.

E 180 Practice for Determining the Precision of ASTM

Methods for Analysis and Testing of Industrial and Spe-

5. Significance and Use

cialty Chemicals

5.1 These test methods are suitable for quality control, as a

specification test, and for research. The water content of a

3. Terminology

polyol is important since isocyanates react with water.

3.1 Definition:

3.1.1 polyurethane, n—a polymer prepared by the reaction

TEST METHOD A: MANUAL PROCEDURE

of an organic diisocyanate with compounds containing hy-

NOTE 2—Commercially available automated Karl Fischer titrators are

droxyl groups.

used extensively.

3.1.1.1 Discussion—Polyurethanes, or urethanes, as they

5.2 The description of the manual systems presented below

are sometimes called, may be thermosetting, thermoplastic,

is for reference purposes and has been included in order to

rigid or soft and flexible, cellular or solid. (See Terminology

better define the principles of the Karl Fischer measurement.

D 883.)

6. Apparatus

6.1 Titration Vessel—A vessel of approximately 300-mL

These test methods are under the jurisdiction of ASTM Committee D20 on

capacity, such as a tall-form, lipless beaker, provided with a

Plastics and are the direct responsibility of Subcommittee D20.22 on Cellular

tight-fitting closure to protect the reaction mixture from atmo-

Plastics. It was recommended to ASTM by the American Plastics Council.

spheric moisture.The vessel shall also be fitted with a nitrogen

Current edition approved Nov. 10, 2000. Published February 2001. Originally

published as D 4672 – 91. Last previous edition D 4672 – 95.

inlet tube, a 10-mLburet, a stirrer (preferably magnetic), and a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

port that may be opened momentarily for sample and solvent

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

addition or removal of electrodes. It is convenient to provide a

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. vacuum line leading to a 1-L trap bottle for drawing off the

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D4672–00

titrated solution. Pass the nitrogen through a drying tube 8. Sampling

containing anhydrous calcium sulfate before it enters the

8.1 It is essential to avoid changes in the water content of

titration vessel.

the material during sampling operations. Many polyols are

6.2 Instrument Electrodes—Platinum with a surface equiva-

quite hygroscopic and errors from this source are particularly

lent of two No. 26 wires, 4.762 mm (0.19 in.) long. The wires

significant in the determination of the small amount of water

should be 3 to 8 mm apart and inserted in the vessel so that 75

usually present. Use almost-filled, tightly capped containers

mL of solution will cover them.

and limit as much as possible contact of the sample with air

6.3 Instrument Depolarization Indicator—Having an inter-

when transferring the sample to the titration vessel. Avoid

nal resistance of less than 5000 V and consisting of a means of

intermediate sample containers, if possible. If several different

impressing and showing a voltage of 20 to 50 mV across the

analyses are to be performed on the same sample, determine

electrodes and capable of indicating a current flow of 10 to 20

the water first and do not open the sample prior to the actual

µA by means of a galvanometer or ratio tuning circuit.

analysis.

6.4 BuretAssembly—ForKarlFischerreagent,consistingof

a 10-mL buret with 0.05-mL subdivisions connected by means

9. Standardization of Reagent

of glass or polyethylene (not rubber) connectors to a source of

9.1 Standardize the Karl Fischer reagent daily using the

reagent. Several types of automatic dispensing burets may be

same procedures as used for titrating the sample.

used. Since the reagent loses strength when exposed to moist

9.1.1 Add 100 mLof titration solvent to the flask and titrate

air,allventsmustbeprotectedagainstatmosphericmoistureby

theresidualmoistureasdescribedinSection10.Tothistitrated

adequate drying tubes containing anhydrous calcium sulfate.

solvent, immediately add 1 drop of water from a weighing

All stopcocks and joints should be lubricated with an inert

pipet. Weigh the pipet to 60.1 mg. Complete the titration with

lubricant.

Karl Fischer reagent as described in Section 10. It may be

necessary to refill the buret during the titration.

7. Reagents

9.1.2 Calculate the equivalence factor, F, in terms of milli-

7.1 Purity of Reagents—Use reagent-grade chemicals in all

grams of water per millilitre of reagent as follows:

tests. Unless otherwise indicated, it is intended that all reagents

equivalency factor, F 5 A/B (1)

shall conform to the specifications of the Committee on

Analytical Reagents of the American Chemical Society where

such specifications are available. Other grades may be used,

where:

provided it is first ascertained that the reagent is of sufficiently

A = water added, mg, and

high purity to permit its use without lessening the accuracy of

B = Karl Fischer reagent required, mL.

the determination.

7.2 Purity of Water—Unless otherwise indicated, references

10. Procedure

to water shall be understood to mean reagent water as defined

10.1 Adjust the nitrogen valve so that dry nitrogen flows

by Type I of Specification D 1193.

into the titration vessel at a slow rate (20 to 50 mL/min).

7.3 Karl Fischer Reagent—Equivalent to 2.5 to 3.0 mg of

Introduce approximately 100 mL of titration solvent into the

water/mL. Dilute commercially available stabilized Karl Fis-

titration vessel, making sure that the electrodes are covered

cher reagent (6 mg of water/mL) with an equal volume of

withsolvent.Adjustthestirrertogiveadequatemixingwithout

anhydrous ethylene glycol monomethyl ether (containing less

splashing. Titrate the mixture with Karl Fischer reagent to the

than 0.1 % water). (See Note 3.)

end point. (See Note 4.)

NOTE 3—Improved, pyridine-free Karl Fischer reagents have been 10.2 To the prepared titration mixture, add the amount of

made available and are now highly recommended as a replacement for the

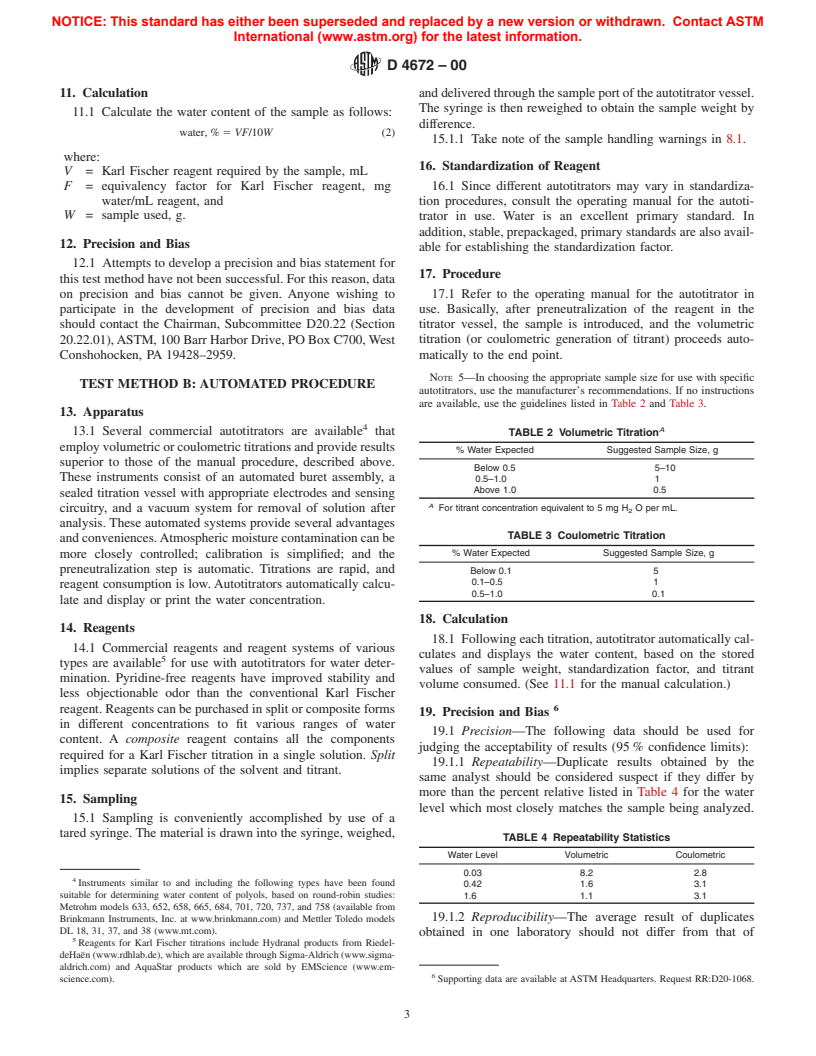

sample as indicated in Table 1. Exercise care when the sample

previous reagents. See Section 14, under Test Method B, Automated

is transferred so that water is not absorbed from the air,

Procedure.

particularly under conditions of high humidity. Allow the

7.4 Titration Solvent, Anhydrous Methanol—Unless the

solution to stir 1 or 2 minutes until dissolution is complete.

methanol is extremely dry it will require a large amount of

10.3 Titrate the mixture again with Karl Fischer reagent to

dilute Karl Fischer solution to react with its residual water. For

thesameendpointpreviouslyemployed.Recordtheamountof

this reason the solvent shall be further dried by adding

reagent used to titrate the water in the sample.

undiluted Karl Fischer reagent (6 mg of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.