ASTM D6948/D6948M-03(2011)e1

(Practice)Standard Practice for Application of Refined Coal Tar (Ready to Use, Commercial Grade)

Standard Practice for Application of Refined Coal Tar (Ready to Use, Commercial Grade)

SIGNIFICANCE AND USE

This practice is designed as a guide for architects, engineers, property owners or their representatives, or combination thereof. Its use helps ensure the satisfactory performance of the protective coating system when applied over bituminous concrete pavements.

SCOPE

1.1 This practice covers the application of emulsified refined coal tar slurry meeting the requirements of Specification D6945 Types I and II, by mechanized equipment as a weather protection and petroleum (aliphatic) solvent resistant sealer for use on bituminous concrete pavements. In order to clarify the differences between Types I and II, see 3.3 for standard definition of terms.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D6948/D6948M −03 (Reapproved 2011)

Standard Practice for

Application of Refined Coal Tar (Ready to Use, Commercial

Grade)

This standard is issued under the fixed designation D6948/D6948M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Units information was editorially revised in June 2011.

1. Scope combined at the contractor’s yard or at the job site. Refined

coal tar emulsion meeting Specification D5727 is concentrated

1.1 This practice covers the application of emulsified re-

when shipped from the manufacturer to the applicator.

fined coal tar slurry meeting the requirements of Specification

3.1.1 Specification D6945 Type I material—is Specification

D6945 Types I and II, by mechanized equipment as a weather

D5727 material diluted with water typically by the applicator

protection and petroleum (aliphatic) solvent resistant sealer for

after which aggregate is added.

use on bituminous concrete pavements. In order to clarify the

differences between Types I and II, see 3.3 for standard 3.1.2 Specification D6945 Type II material—is Specification

definition of terms.

D5727 material diluted with water typically by the applicator

after which additive and aggregate is added.

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in

3.2 The mixtures described in 3.1.1 and 3.1.2 can be

each system may not be exact equivalents; therefore, each

submitted to a laboratory approved by the owner for testing of

system shall be used independently of the other. Combining

their conformance to Specification D6945 Type I or Type II

values from the two systems may result in non-conformance

prior to their actual use on the job.

with the standard.

3.3 Definitions:

1.3 This standard does not purport to address all of the

3.3.1 additive—one or more ingredients that can be added to

safety concerns, if any, associated with its use. It is the

a specific refined coal tar emulsion, water, or sand (or combi-

responsibility of the user of this standard to establish appro-

nationthereof)mixturetoimprovethecoatings’durability,fuel

priate safety and health practices and determine the applica-

resistance, drying time, color uniformity, or length of time

bility of regulatory limitations prior to use.

required before opening the surface to traffic, or combination

thereof. This material can also be used to modify the wet

2. Referenced Documents

mixture’s viscosity to improve aggregate suspension. Because

2.1 ASTM Standards:

there is such a wide variance of additives on the market, the

D490 Specification for Road Tar

aforementioned results may not take place. If an additive is

D5727 Specification for Emulsified Refined Coal Tar (Min-

used, it is recommended that it be supplied by the same

eral Colloid Type)

manufacturer as the refined coal tar emulsion.

D6945 Specification for Emulsified Refined Coal-Tar

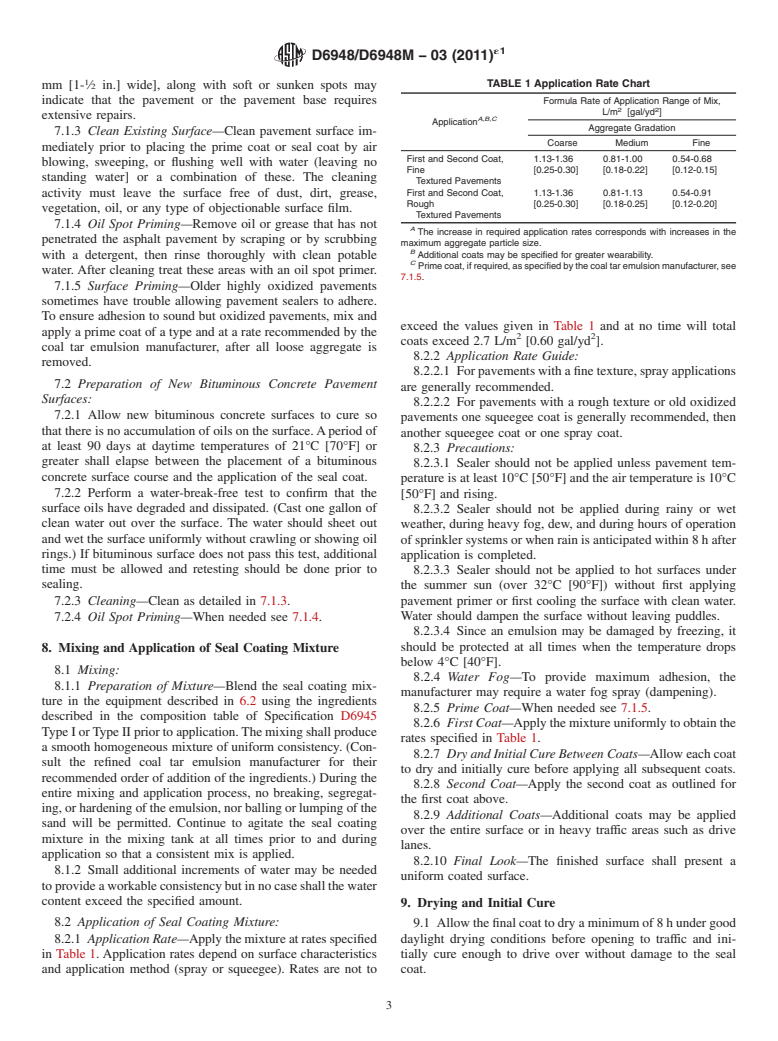

(Ready to Use, Commercial Grade) 3.3.2 application rate—the volume of mixed materials ap-

plied per area of pavement surface, usually expressed in liters

2 2

3. Terminology

per square meter (l/m ) [gallons per square yard (gal/yd )].

3.1 Two types of mixtures are defined in Specification

3.3.3 applied mixture—the combination of all ingredients

D6945.Theingredientsforbothtypesofmixturesarenormally

mixed together and ready for application to the pavement.Also

referred to as seal coat or sealer.

ThispracticeisunderthejurisdictionofASTMCommitteeD08onRoofingand

3.3.4 bituminous concrete pavements, new—pavements that

Waterproofing and is the direct responsibility of Subcommittee D08.09 on Bitumi-

nous Emulsions.

have been placed less than 90 days.

Current edition approved May 1, 2011. Published June 2011. Originally

3.3.5 bituminous concrete pavements, aged—pavements

approved in 2003. Last previous edition approved in 2003 as D2948 – 03. DOI:

10.1520/D6948_D6948M-03R11E01.

that weathered over at least one summer season and have

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

shown signs of one or more of the following: cracking,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

raveling, aggregate polishing or graying due to oxidation, or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. combination thereof.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6948/D6948M−03 (2011)

3.3.6 brush applicator—a hand type or mechanized brush nation thereof. Its use helps ensure the satisfactory perfor-

used to apply pavement sealer. mance of the protective coating system when applied over

bituminous concrete pavements.

3.3.7 crack filler—a material that is placed in a pavement

crack or joint to fill but not necessarily seal the void created by

5. Materials

the crack or joint.

5.1 Refined Coal Tar Emulsion (Seal Coating) Mixture—A

3.3.8 crack sealant—a material that has adhesive and cohe-

mixture of concentrated refined coal tar emulsion water and

sive properties to seal cracks, joints or other narrow openings

sand, with or without an additive, as specified in Specification

(less than 38.5 mm [1- ⁄2 in.] wide) in pavements against the

D6945.

entrance or passage of water or other debris.

5.2 Crack Sealant—As specified by the refined coal tar

3.3.9 crude coal tar—condensed material taken from the

coking process (high temperature heating of coal under a emulsion manufacturer.

vacuum) and containing all of the volatile constituents.

5.3 Oil Spot Primer—As specified by the refined coal tar

3.3.10 cure, final (of the seal coat)—the process of evapo-

emulsion manufacturer.

ration of water and volatiles of the applied seal coating mixture

5.4 Pavement Primer—As specified by the refined coal tar

over the period of days resulting in the coating reaching its

emulsion manufacturer.

ultimate strength. The duration of this process is dependent

upon ambient conditions.

6. Equipment

3.3.11 cure, initial (of the seal coat)—the condition of an

6.1 Use application equipment that is capable of applying

applied seal coating material that enables it to withstand

the required coating rates evenly over the entire width of the

vehicle traffic without damage to the seal coat.

application mechanism to provide a continuously coated sur-

3.3.12 drying (of the seal coat)—the process of evaporation

face. For spray units, this can be accomplished with either a

of water of the applied seal coating mixture resulting in the

spray bar or a wand-type application device. To ensure this,

coating being able to sustain light foot traffic.

equip all spray units with a pumping distribution system using

3.3.13 mechanized application equipment—equipment used

positive displacement pumps.All squeegee/brush units shall be

to mix and apply the refined coal tar emulsion mixture either properly adjusted and in condition for application of seal coat

with a spray or squeegee unit.

materials so that there are no streaks in the coating.

3.3.14 priming—application of an initial coat of a material

6.2 Bulk storage tanks shall be capable of mixing or

designed to assist the adhesion of the additional coats of seal

circulating, or both, the coat tar emulsion to a uniform

coating materials. Primers are always used as under coatings

consistency.

and are not designed to be used by themselves.

6.3 The mixing part of the application equipment must be

3.3.15 refined coal tar—a selectively distilled coal tar meet-

tank type with a mechanically powered, full sweep mixer

ing the requirements of Specification D490, grade RT-12.

capable of homogeneously mixing the entire contents of the

3.3.16 refined coal tar emulsion—astableandhomogeneous

tank.

dispersion of refined coal tar, clay, mineral fillers, and specialty

6.4 Use of hand squeegee or brush application will be

chemicals in water.

restricted to places not accessible to mechanized equipment, or

3.3.17 seal coating—process of applying a protective coat-

to accommodate neat trim work at curbs and so forth. Material

ing to a bituminous concrete pavement.

that is applied by hand application shall meet the same

3.3.18 spray unit—a piece of equipment equipped with a

standards as that applied by machine.

mixing tank and positive displacement pump that can homo-

geneously mix and apply protective coatings uniformly over 7. Surface Preparation

the entire width of a spray bar or wand type application device.

7.1 Preparation of Aged Asphalt Pavement Surfaces (see

3.3.19 squeegee unit—a piece of equipment equipped with a

3.3.5).

mixing tank and squeegeeing mechanism that can homoge-

7.1.1 Patching—Patch all bituminous c

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D6948–03 Designation: D6948/D6948M – 03 (Reapproved 2011)

Standard Practice for

Application of Refined Coal Tar (Ready to Use, Commercial

Grade)

This standard is issued under the fixed designation D6948/D6948M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Units information was editorially revised in June 2011.

1. Scope

1.1 This practice covers the application of emulsified refined coal tar slurry meeting the requirements of Specification D6945

Types I and II, by mechanized equipment as a weather protection and petroleum (aliphatic) solvent resistant sealer for use on

bituminous concrete pavements. In order to clarify the differences between Types I and II, see 3.3 for standard definition of terms.

1.2

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D490 Specification for Road Tar

D5727 Specification for Emulsified Refined Coal Tar (Mineral Colloid Type)

D6945 Specification for Emulsified Refined Coal-Tar (Ready to Use, Commercial Grade)

3. Terminology

3.1 TwotypesofmixturesaredefinedinSpecificationD6945.Theingredientsforbothtypesofmixturesarenormallycombined

at the contractor’s yard or at the job site. Refined coal tar emulsion meeting Specification D5727 is concentrated when shipped

from the manufacturer to the applicator.

3.1.1 Specification D6945 Type I material—is Specification D5727 material diluted with water typically by the applicator after

which aggregate is added.

3.1.2 Specification D6945 Type II material—is Specification D5727 material diluted with water typically by the applicator after

which additive and aggregate is added.

3.2 The mixtures described in 3.1.1 and 3.1.2 can be submitted to a laboratory approved by the owner for testing of their

conformance to Specification D6945 Type I or Type II prior to their actual use on the job.

3.3 Definitions:

3.3.1 additive—one or more ingredients that can be added to a specific refined coal tar emulsion, water, or sand (or combination

thereof)mixturetoimprovethecoatings’durability,fuelresistance,dryingtime,coloruniformity,orlengthoftimerequiredbefore

opening the surface to traffic, or combination thereof. This material can also be used to modify the wet mixture’s viscosity to

improve aggregate suspension. Because there is such a wide variance of additives on the market, the aforementioned results may

not take place. If an additive is used, it is recommended that it be supplied by the same manufacturer as the refined coal tar

emulsion.

3.3.2 application rate—the volume of mixed materials applied per area of pavement surface, usually expressed in liters per

This practice is under the jurisdiction of ASTM Committee D08 on Roofing and Waterproofing and is the direct responsibility of Subcommittee D08.09 on Bituminous

Emulsions.

Current edition approved July 10, 2003. Published August 2003. DOI: 10.1520/D6948-03.

Current edition approved May 1, 2011. Published June 2011. Originally approved in 2003. Last previous edition approved in 2003 as D2948 – 03. DOI:

10.1520/D6948_D6948M-03R11E01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D6948/D6948M – 03 (2011)

2 2

square meter (l/m ) (gallons[gallons per square yard (gal/yd )). )].

3.3.3 applied mixture—the combination of all ingredients mixed together and ready for application to the pavement. Also

referred to as seal coat or sealer.

3.3.4 bituminous concrete pavements, new—pavements that have been placed less than 90 days.

3.3.5 bituminous concrete pavements, aged—pavements that weathered over at least one summer season and have shown signs

of one or more of the following: cracking, raveling, aggregate polishing or graying due to oxidation, or combination thereof.

3.3.6 brush applicator—a hand type or mechanized brush used to apply pavement sealer.

3.3.7 crack filler—a material that is placed in a pavement crack or joint to fill but not necessarily seal the void created by the

crack or joint.

3.3.8 crack sealant—a material that has adhesive and cohesive properties to seal cracks, joints or other narrow openings (less

than 38.5 mm (1-[1- ⁄2 in.)in.] wide) in pavements against the entrance or passage of water or other debris.

3.3.9 crude coal tar—condensed material taken from the coking process (high temperature heating of coal under a vacuum) and

containing all of the volatile constituents.

3.3.10 cure, final (of the seal coat)—the process of evaporation of water and volatiles of the applied seal coating mixture over

the period of days resulting in the coating reaching its ultimate strength. The duration of this process is dependent upon ambient

conditions.

3.3.11 cure, initial (of the seal coat)—the condition of an applied seal coating material that enables it to withstand vehicle traffic

without damage to the seal coat.

3.3.12 drying (of the seal coat)—the process of evaporation of water of the applied seal coating mixture resulting in the coating

being able to sustain light foot traffic.

3.3.13 mechanized application equipment—equipment used to mix and apply the refined coal tar emulsion mixture either with

a spray or squeegee unit.

3.3.14 priming—application of an initial coat of a material designed to assist the adhesion of the additional coats of seal coating

materials. Primers are always used as under coatings and are not designed to be used by themselves.

3.3.15 refined coal tar—a selectively distilled coal tar meeting the requirements of Specification D490, grade RT-12.

3.3.16 refined coal tar emulsion—a stable and homogeneous dispersion of refined coal tar, clay, mineral fillers, and specialty

chemicals in water.

3.3.17 seal coating—process of applying a protective coating to a bituminous concrete pavement.

3.3.18 spray unit—a piece of equipment equipped with a mixing tank and positive displacement pump that can homogeneously

mix and apply protective coatings uniformly over the entire width of a spray bar or wand type application device.

3.3.19 squeegee unit—a piece of equipment equipped with a mixing tank and squeegeeing mechanism that can homogeneously

mix and apply protective coatings uniformly over the entire width of a rubber squeegee or brush type application device.

3.3.20 traffıcability—the ability of an applied seal coating material to withstand vehicle traffic without damage to the seal coat,

except for wear from traffic.

3.3.21 uniform coated surface—a surface that has an even distribution of seal coating material free of pinholes, streaks, or other

uneven characteristics, or combination thereof.

4. Significance and Use

4.1 This practice is designed as a guide for architects, engineers, property owners or their representatives, or combination

thereof. Its use helps ensure the satisfactory performance of the protective coating system when applied over bituminous concrete

pavements.

5. Materials

5.1 Refined Coal Tar Emulsion (Seal Coating) Mixture—A mixture of concentrated refined coal tar emulsion water and sand,

with or without an additive, as specified in Specification D6945.

5.2 Crack Sealant—As specified by the refined coal tar emulsion manufacturer.

5.3 Oil Spot Primer—As specified by the refined coal tar emulsion manufacturer.

5.4 Pavement Primer—As specified by the refined coal tar emulsion manufacturer.

6. Equipment

6.1 Use application equipment that is capable of applying the required coating rates evenly over the entire width of the

application mechanism to provide a continuously coated surface. For spray units, this can be accomplished with either a spray bar

or a wand-type application device. To ensure this, equip all spray units with a pumping distribution system using positive

displacement pumps.All squeegee/brush units shall be properly adjusted and in condition for application of seal coat materials so

that there are no streaks in the coating.

6.2 Bulk storage tanks shall be capabl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.