ASTM C1358-96(2000)

(Test Method)Standard Test Method for Monotonic Compressive Strength Testing of Continuous Fiber-Reinforced Advanced Ceramics with Solid Rectangular Cross-Section Specimens at Ambient Temperatures

Standard Test Method for Monotonic Compressive Strength Testing of Continuous Fiber-Reinforced Advanced Ceramics with Solid Rectangular Cross-Section Specimens at Ambient Temperatures

SCOPE

1.1 This test method covers the determination of compressive strength including stress-strain behavior under monotonic uniaxial loading of continuous fiber-reinforced advanced ceramics at ambient temperatures. This test method addresses, but is not restricted to, various suggested test specimen geometries as listed in the appendix. In addition, specimen fabrication methods, testing modes (load, displacement, or strain control), testing rates (load rate, stress rate, displacement rate, or strain rate), allowable bending, and data collection and reporting procedures are addressed. Compressive strength as used in this test method refers to the compressive strength obtained under monotonic uniaxial loading where monotonic refers to a continuous nonstop test rate with no reversals from test initiation to final fracture.

1.2 This test method applies primarily to advanced ceramic matrix composites with continuous fiber reinforcement: uni-directional (1-D), bi-directional (2-D), and tri-directional (3-D) or other multi-directional reinforcements. In addition, this test method may also be used with glass (amorphous) matrix composites with 1-D, 2-D, 3-D, and other multi-directional continuous fiber reinforcements. This test method does not directly address discontinuous fiber-reinforced, whisker-reinforced, or particulate-reinforced ceramics, although the test methods detailed here may be equally applicable to these composites.

1.3 The values stated in SI units are to be regarded as the standard and are in accordance with Practice E380.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Refer to Section 7 for specific precautions.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1358–96 (Reapproved 2000)

Standard Test Method for

Monotonic Compressive Strength Testing of Continuous

Fiber-Reinforced Advanced Ceramics with Solid Rectangular

Cross-Section Specimens at Ambient Temperatures

This standard is issued under the fixed designation C1358; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of compres- 2.1 ASTM Standards:

sive strength including stress-strain behavior under monotonic C1145 Terminology of Advanced Ceramics

uniaxial loading of continuous fiber-reinforced advanced ce- D695M Test Method for Compressive Properties of Rigid

ramics at ambient temperatures. This test method addresses, Plastics [Metric]

but is not restricted to, various suggested test specimen D3379 Test Method for Tensile Strength and Young’s

geometries as listed in the appendix. In addition, specimen Modulus for High-Modulus Single-Filament Materials

fabrication methods, testing modes (load, displacement, or D3410/D3410M TestMethodforCompressiveProperties

straincontrol),testingrates(loadrate,stressrate,displacement ofPolymerMatrixCompositeMaterialsWithUnsupported

rate, or strain rate), allowable bending, and data collection and Gage Section by Shear Loading

reporting procedures are addressed. Compressive strength as D3479 Test Methods for Tension-Tension Fatigue of Ori-

used in this test method refers to the compressive strength ented Fiber, Resin Matrix Composites

obtained under monotonic uniaxial loading where monotonic D3878 Terminology of High Modulus Reinforcing Fibers

refers to a continuous nonstop test rate with no reversals from and Their Composites

test initiation to final fracture. E4 Practices for Force Verification of Testing Machines

1.2 This test method applies primarily to advanced ceramic E6 Terminology Relating to Methods of Mechanical Test-

matrix composites with continuous fiber reinforcement: uni- ing

directional (1–D), bi-directional (2–D), and tri-directional E83 Practice for Verification and Classification of Exten-

(3–D) or other multi-directional reinforcements. In addition, someters

this test method may also be used with glass (amorphous) E337 TestMethodforMeasuringHumiditywithPsychom-

matrix composites with 1–D, 2–D, 3–D, and other multi- eter (the Measurement of Wet-and Dry-Bulb Tempera-

directional continuous fiber reinforcements. This test method tures)

does not directly address discontinuous fiber-reinforced, E380 PracticeforUseofInternationalSystemofUnits(SI)

whisker-reinforced, or particulate-reinforced ceramics, al- (the Modernized Metric System)

though the test methods detailed here may be equally appli- E1012 Practice for Verification of Specimen Alignment

cable to these composites. Under Tensile Loading

1.3 The values stated in SI units are to be regarded as the

3. Terminology

standard and are in accordance with Practice E380.

1.4 This standard does not purport to address all of the 3.1 Definitions:

3.1.1 The definitions of terms relating to compressive test-

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- ing, advanced ceramics, and fiber-reinforced composites, ap-

pearing in Terminology E6, Test Method D695M, Practice

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. Refer to Section 7 E1012, Terminology C1145, Test Method D3410, and Ter-

minology D3878 apply to the terms used in this test method.

for specific precautions.

Annual Book of ASTM Standards, Vol 15.01.

1 3

This test method is under the jurisdiction of ASTM Committee C–28 on Annual Book of ASTM Standards, Vol 08.01.

Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on Annual Book of ASTM Standards, Vol 15.03.

Ceramic Matrix Composites. Annual Book of ASTM Standards, Vol 03.01.

Current edition approved Dec. 10, 1996. Published December 1997. Annual Book of ASTM Standards, Vols 07.02, 11.03, and 15.09.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1358

Pertinent definitions are shown as follows with the appropriate mechanisms as environmentally-assisted stress corrosion or

source given in parentheses.Additional terms used in conjunc- diffusive crack growth.

tion with this test method are defined in 3.2.

4. Significance and Use

3.2 Definitions of Terms Specific to This Standard:

4.1 Thistestmethodmaybeusedformaterialdevelopment,

3.2.1 advanced ceramic, n—a highly engineered, high-

material comparison, quality assurance, characterization, reli-

performance predominantly non-metallic, inorganic, ceramic

ability assessment, and design data generation.

material having specific functional attributes. (See Terminol-

4.2 Continuous fiber-reinforced ceramic matrix composites

ogy C1145.)

(CFCCs) are generally characterized by fine-grain sized (<50

−1

3.2.2 axial strain [LL ], n—the average longitudinal

µm) matrices and ceramic fiber reinforcements. In addition,

strains measured at the surface on opposite sides of the

continuous fiber-reinforced glass (amorphous) matrix compos-

longitudinal axis of symmetry of the specimen by two strain-

itescanalsobeclassifiedasCFCCs.Uniaxial-loadedcompres-

sensing devices located at the mid length of the reduced

sivestrengthtestsprovideinformationonmechanicalbehavior

section. (See Practice E1012.)

and strength for a uniformly stressed CFCC.

−1

3.2.3 bending strain [LL ], n—the difference between the

4.3 Generally, ceramic and ceramic matrix composites have

strainatthesurfaceandtheaxialstrain.Ingeneral,thebending

greater resistance to compressive loads than tensile loads.

strain varies from point to point around and along the reduced

Ideally, ceramics should be compressively stressed in use,

section of the specimen. (See Practice E1012.)

although engineering applications may frequently introduce

3.2.4 breaking load [F], n—the load at which fracture

tensile stresses in the component. Nonetheless, compressive

occurs. (See Terminology E6.)

behavior is an important aspect of mechanical properties and

3.2.5 ceramic matrix composite, n—amaterialconsistingof

performance. The compressive strength of ceramic and ce-

two or more materials (insoluble in one another), in which the

ramic composites may not be deterministic Therefore, test a

major,continuouscomponent(matrixcomponent)isaceramic,

sufficient number of specimens to gain an insight into strength

while the secondary component(s) (reinforcing component)

distributions.

may be ceramic, glass-ceramic, glass, metal, or organic in

4.4 Compression tests provide information on the strength

nature. These components are combined on a macroscale to

and deformation of materials under uniaxial compressive

form a useful engineering material possessing certain proper-

stresses. Uniform stress states are required to effectively

ties or behavior not possessed by the individual constituents.

evaluate any nonlinear stress-strain behavior that may develop

−2

3.2.6 compressive strength [FL ], n—the maximum com- as the result of cumulative damage processes (for example,

pressive stress which a material is capable of sustaining. matrixcracking,matrix/fiberdebonding,fiberfracture,delami-

Compressive strength is calculated from the maximum load nation, etc.) that may be influenced by testing mode, testing

during a compression test carried to rupture and the original rate, effects of processing or combination of constituent mate-

cross-sectional area of the specimen. (See Terminology E6.)

rials, or environmental influences. Some of these effects may

beconsequencesofstresscorrosionorsub-critical(slow)crack

3.2.7 continuous fiber-reinforced ceramic matrix composite

growth which can be minimized by testing at sufficiently rapid

(CFCC), n—aceramicmatrixcompositeinwhichthereinforc-

rates as outlined in this test method.

ing phase consists of a continuous fiber, continuous yarn, or a

4.5 Theresultsofcompressiontestsofspecimensfabricated

woven fabric.

to standardized dimensions from a particulate material or

3.2.8 gage length [L], n—the original length of that portion

selected portions of a part, or both, may not totally represent

of the specimen over which strain or change of length is

the strength and deformation properties of the entire, full-size

determined. (See Terminology E6.)

−2

product or its in-service behavior in different environments.

3.2.9 modulus of elasticity [FL ], n—the ratio of stress to

4.6 For quality control purposes, results derived from stan-

corresponding strain below the proportional limit. (See Termi-

dardized compressive test specimens may be considered in-

nology E6.)

dicative of the response of the material from which they were

−2

3.2.10 proportional limit stress in compression [FL ],

taken for given primary processing conditions and post-

n—the greatest stress that a material is capable of sustaining

processing heat treatments.

without any deviation from proportionality of stress to strain

4.7 The compressive behavior and strength of a CFCC are

(Hooke’s law).

dependent on, and directly related to, the material.Analysis of

3.2.10.1 Discussion—Many experiments have shown that

fracturesurfacesandfractography,thoughbeyondthescopeof

valuesobservedfortheproportionallimitvarygreatlywiththe

this test method, are recommended.

sensitivity and accuracy of the testing equipment, eccentricity

of loading, the scale to which the stress-strain diagram is 5. Interferences

plotted, and other factors. When determination of proportional

5.1 Test environment (vacuum, inert gas, ambient air, etc.)

limit is required, specify the procedure and sensitivity of the

including moisture content (for example, relative humidity)

test equipment. (See Terminology E6)

may have an influence on the measured compressive strength.

3.2.11 percent bending, n—the bending strain times 100

In particular, the behavior of materials susceptible to slow

divided by the axial strain. (See Practice E1012).

crack growth will be strongly influenced by test environment,

3.2.12 slow crack growth, n—sub-critical crack growth testing rate, and test temperature. Conduct tests to evaluate the

(extension) that may result from, but is not restricted to, such maximum strength potential of a material in inert environment

C1358

or at sufficiently rapid testing rates, or both, to minimize slow so as to artificially increase the load required to produce

crack growth effects. Conversely, conduct tests in environ- compressive failure. In addition, the lateral supports and

ments or at test modes, or both, and rates representative of attendant frictional stresses may invalidate the assumption of

service conditions to evaluate material performance under use uniaxial stress state. When lateral supports are used, the

frictional effect should be quantified to ensure that its contri-

conditions. Monitor and report relative humidity and ambient

temperaturewhentestingisconductedinuncontrolledambient butionissmall,andthemeansfordoingsoreportedalongwith

the quantity of the frictional effect.

air with the intent of evaluating maximum strength potential.

Testing at humidity levels >65% relative humidity (RH) is not

6. Apparatus

recommended.

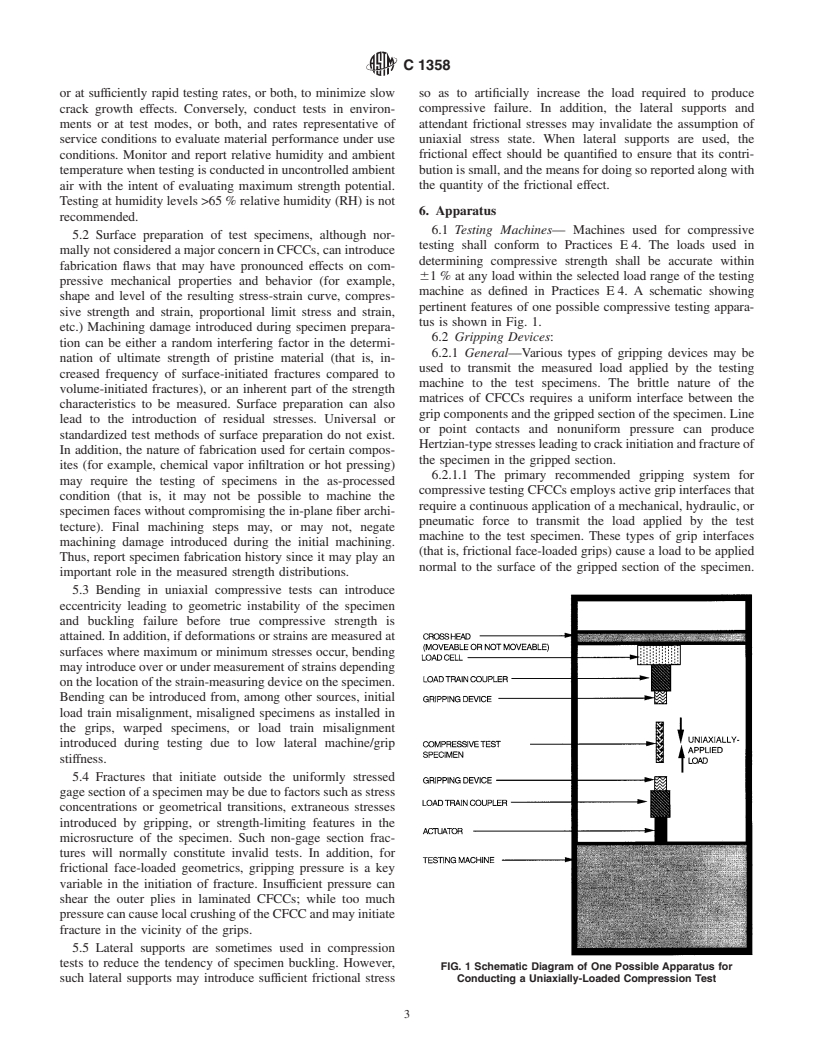

6.1 Testing Machines— Machines used for compressive

5.2 Surface preparation of test specimens, although nor-

testing shall conform to Practices E4. The loads used in

mallynotconsideredamajorconcerninCFCCs,canintroduce

determining compressive strength shall be accurate within

fabrication flaws that may have pronounced effects on com-

61% at any load within the selected load range of the testing

pressive mechanical properties and behavior (for example,

machine as defined in Practices E4. A schematic showing

shape and level of the resulting stress-strain curve, compres-

pertinent features of one possible compressive testing appara-

sive strength and strain, proportional limit stress and strain,

tus is shown in Fig. 1.

etc.) Machining damage introduced during specimen prepara-

6.2 Gripping Devices:

tion can be either a random interfering factor in the determi-

6.2.1 General—Various types of gripping devices may be

nation of ultimate strength of pristine material (that is, in-

used to transmit the measured load applied by the testing

creased frequency of surface-initiated fractures compared to

machine to the test specimens. The brittle nature of the

volume-initiated fractures), or an inherent part of the strength

matrices of CFCCs requires a uniform interface between the

characteristics to be measured. Surface preparation can also

gripcomponentsandthegrippedsectionofthespecimen.Line

lead to the introduction of residual stresses. Universal or

or point contacts and nonuniform pressure can produce

standardized test methods of surface preparation do not exist.

Hertzian-typestressesleadingtocrackinitiationandfractureof

In addition, the nature of fabrication used for certain compos-

the specimen in the gripped section.

ites (for example, chemical vapor infiltration or hot pressing)

6.2.1.1 The primary recommended gripping system for

may require the testing of specimens in the as-processed

compressive testing CFCCs employs active grip interfaces that

condition (that is, it may not be possible to machine the

require a continuous application of a mechanical, hydraulic, or

specimen faces without compromising the in-plane fiber archi-

pneumatic force to transmit the load applied by the test

tecture). Final machining steps may, or may not, negate

machine to the test specimen. These types of grip interfaces

machining damage introduced during the initial machining.

(that is, frictional face-loaded grips) cause a load to be applied

Thus, report specimen fabrication history since it may play an

normal to the surface of the gripped section of the specimen.

important role in the measured strength distributions.

5.3 Bending in uniaxial compressive tests can introduce

eccentricity leading to geometric instability of the specimen

and buckling failure before true compressive strength is

attained. In addition, if deformations or strains are measured at

surfaces where maximum or minimum stresses occur, bending

mayintroduceoverorundermeasurementofstrainsdepending

onthelocationofthestrain-measuringdeviceonthespecimen.

Bending can be introduced from, among other sources, initial

load train misalignment, misaligned specimens as installed in

the grips, warped specimens, or load train

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.