ASTM C1495-16(2023)

(Test Method)Standard Test Method for Effect of Surface Grinding on Flexure Strength of Advanced Ceramics

Standard Test Method for Effect of Surface Grinding on Flexure Strength of Advanced Ceramics

SIGNIFICANCE AND USE

5.1 Surface grinding can cause a significant decrease4 in the flexure strength of advanced ceramic materials. The magnitude of the loss in strength is determined by the grinding conditions and the response of the material. This test method can be used to obtain a detailed characterization of the relationship between grinding conditions and flexure strength for an advanced ceramic material. The effect on flexure strength of varying a single grinding parameter or several grinding parameters can be measured. The method may also be used to compare and rank different materials according to their response to one or more different grinding conditions. Results obtained by this method can be used to develop an optimum grinding process with respect to maximizing material removal rate for a specified flexure strength requirement. The test method can assist in the development of improved grinding-damage-tolerant ceramic materials. It may also be used for quality control purposes to monitor and assure the consistency of a grinding process in the fabrication of parts from advanced ceramic materials. The test method is applicable to grinding methods that generate a planar surface and is not directly applicable to grinding methods that produce non-planar surfaces such as cylindrical and centerless grinding.

SCOPE

1.1 This test method covers the determination of the effect of surface grinding on the flexure strength of advanced ceramics. Surface grinding of an advanced ceramic material can introduce microcracks and other changes in the near surface layer, generally referred to as damage (see Fig. 1 and Ref. (1)).2 Such damage can result in a change—most often a decrease—in flexure strength of the material. The degree of change in flexure strength is determined by both the grinding process and the response characteristics of the specific ceramic material. This method compares the flexure strength of an advanced ceramic material after application of a user-specified surface grinding process with the baseline flexure strength of the same material. The baseline flexure strength is obtained after application of a surface grinding process specified in this standard. The baseline flexure strength is expected to approximate closely the inherent strength of the material. The flexure strength is measured by means of ASTM flexure test methods.

FIG. 1 Microcracks Associated with Grinding (Ref. (1))2

1.2 Flexure test methods used to determine the effect of surface grinding are C1161 Test Method for Flexure Strength of Advanced Ceramics at Ambient Temperatures and C1211 Test Method for Flexure Strength of Advanced Ceramics at Elevated Temperatures.

1.3 Materials covered in this standard are those advanced ceramics that meet criteria specified in flexure testing standards C1161 and C1211.

1.4 The flexure test methods supporting this standard (C1161 and C1211) require test specimens that have a rectangular cross section, flat surfaces, and that are fabricated with specific dimensions and tolerances. Only grinding processes that are capable of generating the specified flat surfaces, that is, planar grinding modes, are suitable for evaluation by this method. Among the applicable machine types are horizontal and vertical spindle reciprocating surface grinders, horizontal and vertical spindle rotary surface grinders, double disk grinders, and tool-and-cutter grinders. Incremental cross-feed, plunge, and creep-feed grinding methods may be used.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was develop...

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1495 − 16 (Reapproved 2023)

Standard Test Method for

Effect of Surface Grinding on Flexure Strength of Advanced

Ceramics

This standard is issued under the fixed designation C1495; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope and vertical spindle reciprocating surface grinders, horizontal

and vertical spindle rotary surface grinders, double disk

1.1 This test method covers the determination of the effect

grinders, and tool-and-cutter grinders. Incremental cross-feed,

of surface grinding on the flexure strength of advanced

plunge, and creep-feed grinding methods may be used.

ceramics. Surface grinding of an advanced ceramic material

can introduce microcracks and other changes in the near 1.5 The values stated in SI units are to be regarded as

surface layer, generally referred to as damage (see Fig. 1 and standard. No other units of measurement are included in this

Ref. (1)). Such damage can result in a change—most often a standard.

decrease—in flexure strength of the material. The degree of

1.6 This standard does not purport to address all of the

change in flexure strength is determined by both the grinding

safety concerns, if any, associated with its use. It is the

process and the response characteristics of the specific ceramic

responsibility of the user of this standard to establish appro-

material. This method compares the flexure strength of an

priate safety, health, and environmental practices and deter-

advanced ceramic material after application of a user-specified

mine the applicability of regulatory limitations prior to use.

surface grinding process with the baseline flexure strength of

1.7 This international standard was developed in accor-

the same material. The baseline flexure strength is obtained

dance with internationally recognized principles on standard-

after application of a surface grinding process specified in this

ization established in the Decision on Principles for the

standard. The baseline flexure strength is expected to approxi-

Development of International Standards, Guides and Recom-

mate closely the inherent strength of the material. The flexure

mendations issued by the World Trade Organization Technical

strength is measured by means of ASTM flexure test methods.

Barriers to Trade (TBT) Committee.

1.2 Flexure test methods used to determine the effect of

2. Referenced Documents

surface grinding are C1161 Test Method for Flexure Strength

of Advanced Ceramics at Ambient Temperatures and C1211

2.1 ASTM Standards:

Test Method for Flexure Strength of Advanced Ceramics at

C1145 Terminology of Advanced Ceramics

Elevated Temperatures.

C1161 Test Method for Flexural Strength of Advanced

Ceramics at Ambient Temperature

1.3 Materials covered in this standard are those advanced

C1211 Test Method for Flexural Strength of Advanced

ceramics that meet criteria specified in flexure testing standards

Ceramics at Elevated Temperatures

C1161 and C1211.

C1239 Practice for Reporting Uniaxial Strength Data and

1.4 The flexure test methods supporting this standard

Estimating Weibull Distribution Parameters for Advanced

(C1161 and C1211) require test specimens that have a rectan-

Ceramics

gular cross section, flat surfaces, and that are fabricated with

C1322 Practice for Fractography and Characterization of

specific dimensions and tolerances. Only grinding processes

Fracture Origins in Advanced Ceramics

that are capable of generating the specified flat surfaces, that is,

C1341 Test Method for Flexural Properties of Continuous

planar grinding modes, are suitable for evaluation by this

Fiber-Reinforced Advanced Ceramic Composites

method. Among the applicable machine types are horizontal

3. Terminology

3.1 Materials Related:

This test method is under the jurisdiction of ASTM Committee C28 on

Advanced Ceramics and is the direct responsibility of Subcommittee C28.01 on

Mechanical Properties and Performance.

Current edition approved Jan. 1, 2023. Published February 2023. Originally

approved in 2001. Last previous edition approved in 2016 as C1495 – 16. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/C1495-16R23. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1495 − 16 (2023)

FIG. 2 Machine Axes for Horizontal Spindle Reciprocating Sur-

FIG. 1 Microcracks Associated with Grinding (Ref. (1))

face Grinder

3.1.6 materials lot or batch, n—a single billet or several

3.1.1 advanced ceramic, n—a highly engineered, high-

billets prepared from defined homogeneous quantities of raw

performance, predominately nonmetallic, inorganic, ceramic

materials passing simultaneously through each processing step

material having specific functional attributes. C1145

to the end product is often referred to as belonging to a single

3.1.2 baseline flexure strength, n—in the context of this

lot or batch.

standard, refers to the flexure strength value obtained after

3.1.6.1 Discussion—There is no assurance that a single

application of a grinding procedure specified in this standard.

billet is internally homogenous or that billets belonging to the

3.1.2.1 Discussion—For the advanced ceramics to which

same lot or batch are identical.

this standard is applicable, the baseline flexure strength is

3.2 Grinding Process Related—Definitions in this section

expected to be a close approximation to the inherent flexure

apply to grinding machines and modes that generate planar

strength.

surfaces. Applicable grinding machines types are identified in

3.1.3 ceramic matrix composite, n—a material consisting of

(1.4). Some definitions may not be applicable when used in

two or more materials (insoluble in one another) in which the

connection with non-planar grinding modes such as centerless

major, continuous component (matrix component) is a ceramic,

and cylindrical modes which are outside of the scope of this

while the secondary component(s) (reinforcing component)

standard.

may be ceramic, glass-ceramic, glass, metal, or organic in

3.2.1 blanchard grinding, n—a type of rotary grinding in

nature. These components are combined on a macroscale to

which the workpiece is held on a rotating table with an axis of

form a useful engineering material possessing certain proper-

rotation that is parallel to the (vertical) spindle axis.

ties or behavior not possessed by the individual constituents.

3.2.2 coolant, n—usually a liquid that is applied to the

C1341

workpiece or wheel, or both, during grinding for cooling,

3.1.4 grinding damage, n—any change in a material that is

removal of grinding swarf, and for lubrication.

a result of the application of a surface grinding process. Among

3.2.3 coolant flow rate, n—volume of coolant per unit time

the types of damage are microcracks (Fig. 1), dislocations,

delivered to the wheel and workpiece during grinding.

twins, stacking faults, voids, and transformed phases.

3.2.4 creep-feed grinding, n—a mode of grinding character-

3.1.4.1 Discussion—Although they do not represent internal

changes in microstructure, chips and surface pits, which are a ized by a relatively large wheel depth-of-cut and correspond-

ingly low rate of feed.

manifestation of microfracture, and abnormally large grinding

striations are often referred to as grinding damage. Residual

3.2.5 cross-feed, n—increment of displacement or feed in

stresses that result from microstructural changes may also be

the cross-feed direction.

referred to as grinding damage.

3.2.6 cross-feed direction, n—direction in the plane of

3.1.5 inherent flexure strength, n—the flexure strength of a

grinding which is perpendicular to the principal direction of

material in the absence of any effects of surface grinding or

grinding. (Fig. 2)

other surface finishing process, or of extraneous damage that

3.2.7 down-feed, n—increment of displacement or feed in

may be present. The measured inherent flexure strength may

the down feed direction. (Fig. 2)

depend on the flexure test method, test conditions, and test

3.2.8 down-feed direction, n—direction perpendicular to the

specimen size.

plane of grinding for a machine configuration in which the

3.1.5.1 Discussion—Flaws due to surface finishing or extra-

grinding wheel is located above the workpiece. (Fig. 2)

neous damage may be present but their effect on flexure

strength is negligible compared to that of “inherent” flaws in 3.2.9 down-grinding, n—A condition of down-grinding is

the material. said to hold when the velocity vector tangent to the surface of

C1495 − 16 (2023)

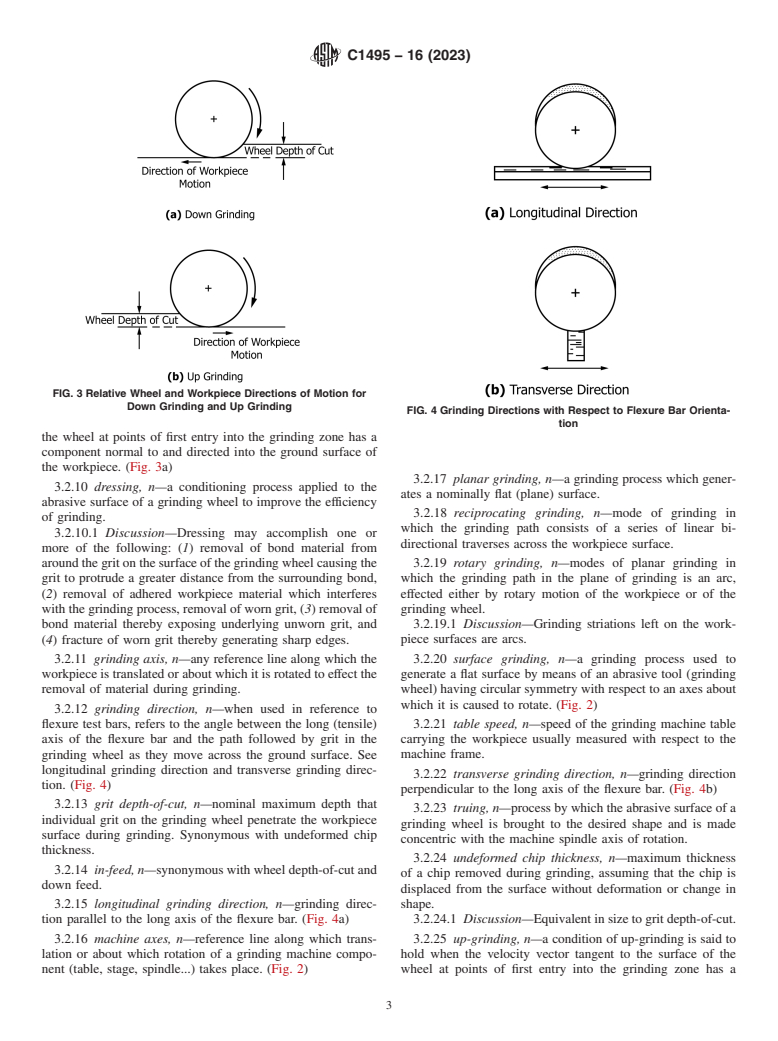

FIG. 3 Relative Wheel and Workpiece Directions of Motion for

Down Grinding and Up Grinding

FIG. 4 Grinding Directions with Respect to Flexure Bar Orienta-

tion

the wheel at points of first entry into the grinding zone has a

component normal to and directed into the ground surface of

the workpiece. (Fig. 3a)

3.2.17 planar grinding, n—a grinding process which gener-

3.2.10 dressing, n—a conditioning process applied to the

ates a nominally flat (plane) surface.

abrasive surface of a grinding wheel to improve the efficiency

3.2.18 reciprocating grinding, n—mode of grinding in

of grinding.

which the grinding path consists of a series of linear bi-

3.2.10.1 Discussion—Dressing may accomplish one or

directional traverses across the workpiece surface.

more of the following: (1) removal of bond material from

around the grit on the surface of the grinding wheel causing the 3.2.19 rotary grinding, n—modes of planar grinding in

grit to protrude a greater distance from the surrounding bond, which the grinding path in the plane of grinding is an arc,

(2) removal of adhered workpiece material which interferes effected either by rotary motion of the workpiece or of the

with the grinding process, removal of worn grit, (3) removal of grinding wheel.

bond material thereby exposing underlying unworn grit, and 3.2.19.1 Discussion—Grinding striations left on the work-

(4) fracture of worn grit thereby generating sharp edges. piece surfaces are arcs.

3.2.11 grinding axis, n—any reference line along which the 3.2.20 surface grinding, n—a grinding process used to

workpiece is translated or about which it is rotated to effect the generate a flat surface by means of an abrasive tool (grinding

removal of material during grinding. wheel) having circular symmetry with respect to an axes about

which it is caused to rotate. (Fig. 2)

3.2.12 grinding direction, n—when used in reference to

flexure test bars, refers to the angle between the long (tensile) 3.2.21 table speed, n—speed of the grinding machine table

carrying the workpiece usually measured with respect to the

axis of the flexure bar and the path followed by grit in the

grinding wheel as they move across the ground surface. See machine frame.

longitudinal grinding direction and transverse grinding direc-

3.2.22 transverse grinding direction, n—grinding direction

tion. (Fig. 4)

perpendicular to the long axis of the flexure bar. (Fig. 4b)

3.2.13 grit depth-of-cut, n—nominal maximum depth that

3.2.23 truing, n—process by which the abrasive surface of a

individual grit on the grinding wheel penetrate the workpiece

grinding wheel is brought to the desired shape and is made

surface during grinding. Synonymous with undeformed chip

concentric with the machine spindle axis of rotation.

thickness.

3.2.24 undeformed chip thickness, n—maximum thickness

3.2.14 in-feed, n—synonymous with wheel depth-of-cut and

of a chip removed during grinding, assuming that the chip is

down feed.

displaced from the surface without deformation or change in

3.2.15 longitudinal grinding direction, n—grinding direc- shape.

tion parallel to the long axis of the flexure bar. (Fig. 4a) 3.2.24.1 Discussion—Equivalent in size to grit depth-of-cut.

3.2.16 machine axes, n—reference line along which trans- 3.2.25 up-grinding, n—a condition of up-grinding is said to

lation or about which rotation of a grinding machine compo- hold when the velocity vector tangent to the surface of the

nent (table, stage, spindle.) takes place. (Fig. 2) wheel at points of first entry into the grinding zone has a

C1495 − 16 (2023)

component normal to and directed out of the ground surface of applied surface grinding process with the baseline flexure

the workpiece. (Fig. 3b) strength for the same material. The baseline flexure strength is

obtained after application of a grinding process specified in this

3.2.26 wheel depth-of-cut, n—depth of penetration of the

standard and is expected to approximate closely the inherent

grinding wheel into the workpiece surface as it moves parallel

flexure strength of the material. The user-applied surface

to the surface to remove a layer of material. (Fig. 3)

grinding process may result in a decrease in flexure strength,

3.2.26.1 Discussion—Often abbreviated to depth-of-cut.

no change in flexure strength, or in certain cases an increase in

3.2.27 wheel specifications, n—description of the grinding

flexure strength. Two procedures, A and B, are available

wheel dimensions, grit type, grit size, grit concentration, bond

depending on the objective of the measurement. Procedure A is

type, and any other properties provided by the wheel manu-

restricted to linear grinding processes obtained, for example,

facturer that characterize the grinding wheel.

by a horizontal spindle, reciprocating-table surface grinder. In

3.2.28 wheel surface speed, n—circumferential speed of the

linear grinding processes, the surface finish is usually charac-

grinding wheel surface at points which engage the workpiece

terized by straight, parallel striations. Procedure A compares

during the process of grinding.

the baseline flexure strength of a material with the flexure

3.3 Surface Finish Related:

strength (1) after grinding parallel (termed longitudinal) to the

3.3.1 lay, n—refers to the direction a non-random pattern of

long axis of the flexure test specimen and (2) after grinding

surface roughness in the plane of the surface, for example, the

perpendicular (termed transverse) to the long axis of the flexure

direction of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.