ASTM D2416-84(1999)

(Test Method)Standard Test Method for Coking Value of Tar and Pitch (Modified Conradson)

Standard Test Method for Coking Value of Tar and Pitch (Modified Conradson)

SCOPE

1.1 This test method covers the determination of the coking value of tar and pitch having an ash content not over 0.5% as determined by Test Method D2415.

1.2 Coking values by this method are practically the same as those obtained by Test Method D189, but results are more reproducible. The apparatus used is identical, except that an electric furnace is substituted for the gas flame.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2416 – 84 (Reapproved 1999)

Standard Test Method for

Coking Value of Tar and Pitch (Modified Conradson)

This standard is issued under the fixed designation D 2416; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ing tars and pitches. The method can also be used as one

element in establishing the uniformity of shipments or sources

1.1 This test method covers the determination of the coking

of supply.

value of tar and pitch having an ash content not over 0.5 % as

determined by Test Method D 2415.

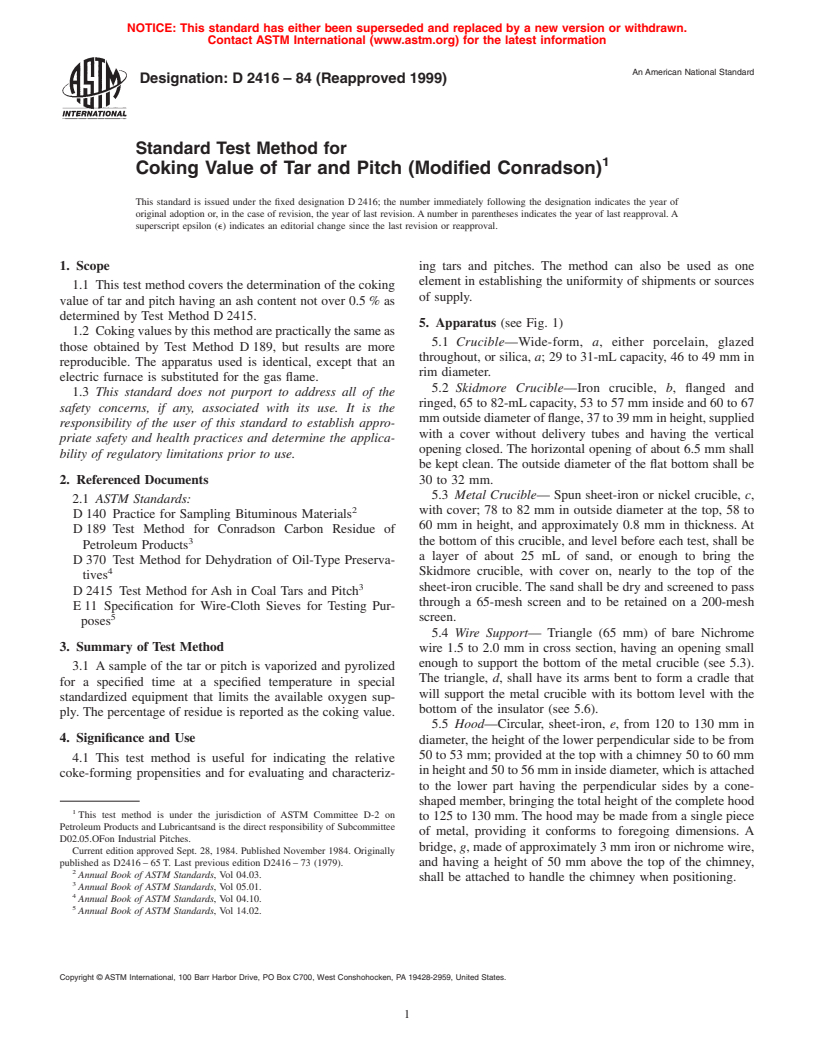

5. Apparatus (see Fig. 1)

1.2 Cokingvaluesbythismethodarepracticallythesameas

5.1 Crucible—Wide-form, a, either porcelain, glazed

those obtained by Test Method D 189, but results are more

throughout, or silica, a; 29 to 31-mL capacity, 46 to 49 mm in

reproducible. The apparatus used is identical, except that an

rim diameter.

electric furnace is substituted for the gas flame.

5.2 Skidmore Crucible—Iron crucible, b, flanged and

1.3 This standard does not purport to address all of the

ringed, 65 to 82-mLcapacity, 53 to 57 mm inside and 60 to 67

safety concerns, if any, associated with its use. It is the

mmoutsidediameterofflange,37to39mminheight,supplied

responsibility of the user of this standard to establish appro-

with a cover without delivery tubes and having the vertical

priate safety and health practices and determine the applica-

opening closed. The horizontal opening of about 6.5 mm shall

bility of regulatory limitations prior to use.

be kept clean. The outside diameter of the flat bottom shall be

2. Referenced Documents 30 to 32 mm.

5.3 Metal Crucible— Spun sheet-iron or nickel crucible, c,

2.1 ASTM Standards:

with cover; 78 to 82 mm in outside diameter at the top, 58 to

D 140 Practice for Sampling Bituminous Materials

60 mm in height, and approximately 0.8 mm in thickness. At

D 189 Test Method for Conradson Carbon Residue of

the bottom of this crucible, and level before each test, shall be

Petroleum Products

a layer of about 25 mL of sand, or enough to bring the

D 370 Test Method for Dehydration of Oil-Type Preserva-

Skidmore crucible, with cover on, nearly to the top of the

tives

3 sheet-iron crucible. The sand shall be dry and screened to pass

D 2415 Test Method for Ash in Coal Tars and Pitch

through a 65-mesh screen and to be retained on a 200-mesh

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

5 screen.

poses

5.4 Wire Support— Triangle (65 mm) of bare Nichrome

3. Summary of Test Method wire 1.5 to 2.0 mm in cross section, having an opening small

enough to support the bottom of the metal crucible (see 5.3).

3.1 A sample of the tar or pitch is vaporized and pyrolized

The triangle, d, shall have its arms bent to form a cradle that

for a specified time at a specified temperature in special

will support the metal crucible with its bottom level with the

standardized equipment that limits the available oxygen sup-

bottom of the insulator (see 5.6).

ply. The percentage of residue is reported as the coking value.

5.5 Hood—Circular, sheet-iron, e, from 120 to 130 mm in

4. Significance and Use

diameter, the height of the lower perpendicular side to be from

50 to 53 mm; provided at the top with a chimney 50 to 60 mm

4.1 This test method is useful for indicating the relative

in height and 50 to 56 mm in inside diameter, which is attached

coke-forming propensities and for evaluating and characteriz-

to the lower part having the perpendicular sides by a cone-

shaped member, bringing the total height of the complete hood

This test method is under the jurisdiction of ASTM Committee D-2 on

to 125 to 130 mm. The hood may be made from a single piece

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

of metal, providing it conforms to foregoing dimensions. A

D02.05.OFon Industrial Pitches.

bridge, g, made of approximately 3 mm iron or nichrome wire,

Current edition approved Sept. 28, 1984. Published November 1984. Originally

published as D2416 – 65 T. Last previous edition D2416 – 73 (1979). and having a height of 50 mm above the top of the chimney,

Annual Book of ASTM Standards, Vol 04.03.

shall be attached to handle the chimney when positioning.

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 04.10.

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 2416

open container until the surface is free from foam. Take care

not to overheat, and remove heat source immediately when

foam subsides.

7.3 Tar—Dehydrate a representative portion of the bulk

sample in accordance with Test Method D 370, but stop the

distillation when the temperature reaches 170°C. Separate any

oilfromthewaterthathasdistilledover(ifcrystalsarepresent,

warm sufficiently to ensure their solution), and thoroughly mix

the oil with the residual tar in the still after the latter has cooled

to a moderate temperature.

8. Preparation of Working Sample

8.1 Hard Pitch—If the pitch can be crushed at room

temperature, prepare a 20-g working sample by suitable

crushing, mixing, and quartering of a representative portion of

the dry sample. The crushing can be done with a small jaw

crusher and a mortar and pestle. No particle in the representa-

tive sample should be larger than 5 mm in any dimension.

CrushthissamplesothatallofitwillpasstheNo.30(600-µm)

sieve but have a minimum of fine particles.

8.2 Soft Pitch—If the pitch is too soft to grind and to sticky

FIG. 1 Apparatus for Determining Carbon Residue

to mix, heat a representative portion of the dry sample to the

lowest temperature that will permit passage through the No. 30

5.6 Insulator—Ceram

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.