ASTM F1157-04

(Practice)Standard Practice for Classifying the Relative Performance of the Physical Properties of Security Seals

Standard Practice for Classifying the Relative Performance of the Physical Properties of Security Seals

ABSTRACT

This practice covers methods for testing the physical properties of mechanical (passive) security seals. Where appropriate, the various tests include particular apparatus or procedural specifications required for different types of security seals. A security seal shall be evaluated in accordance with its classification into one of five general groups and its performance in the following six tests: pull (tensile) shear, bending, impact, low temperature impact, and high temperature pull (tensile). A security seal shall receive a grade designation based upon its measured performance in each of the required tests. The seals shall be classified according to groups: Group 1; Group 2; Group 3; Group 4; and Group 5. Pull test, shear test, bending test, impact test, and extreme temperature tests shall be performed to conform with the specified requirements.

SCOPE

1.1 This practice presents methods for testing the physical properties of security seals. Where appropriate, the various tests include particular apparatus or procedural specifications required for different types of security seals.

1.2 This practice will serve as a basis for comparing the response of various security seals under different modes of attack. The security seal to be evaluated shall first be placed in an appropriate classification, and then tested in the manner designated as most suitable for that class of seal, in accordance with Classification F832.

Note 1--See Guide F1158 for procedures on the inspection and evaluation of tampering of security seals.

1.3 A security seal is a device intended to detect tampering or entry. Single use locking devices are to be evaluated under this specification. Therefore, the following procedures are to reflect the relative performance of security seals when subject to various physical attacks.

1.4 This practice is not intended to be fully comprehensive, since certain types of security seals, such as labels, are not addressed. Further, it is the responsibility of users of this practice to interpret their specific security needs concerning the application of seals, and to determine the grade of seal appropriate for their particular application. ASTM assumes no responsibility for losses occurring as a result of a defeated seal whether the defeat is apparent or the seal is not suited for its application.

1.5 The values as stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only.

1.6 The following safety hazards caveat pertains only to the test procedures portion, Section 6, of this practice. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F1157 – 04

Standard Practice for

Classifying the Relative Performance of the Physical

1

Properties of Security Seals

This standard is issued under the fixed designation F1157; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 The following safety hazards caveat pertains only to the

test procedures portion, Section 6, of this practice. This

1.1 This practice covers methods for testing the physical

standard does not purport to address all of the safety concerns,

properties of mechanical (passive) security seals. Where ap-

if any, associated with its use. It is the responsibility of the user

propriate, the various tests include particular apparatus or

of this standard to establish appropriate safety and health

procedural specifications required for different types of secu-

practices and determine the applicability of regulatory limita-

rityseals.Thispracticedoesnotaddressadhesive(tapeorlabel

tions prior to use.

style) or electronic types of security seals.

1.2 This practice will serve as a basis for comparing the

2. Referenced Documents

response of various security seals under different simulated

2

2.1 ASTM Standards:

modes of attack. The security seal to be evaluated shall first be

F832 Classification for Security Seals

classified into established groupings, and then tested in the

F883 Performance Specification for Padlocks

manner designated as most suitable for that class of seal, in

F946 Guide for Establishing Security Seal Control and

accordance with Classification F832.

Accountability Procedures

1.3 A mechanical security seal is a single use, passive

F1158 Guide for Inspection and Evaluation ofTampering of

device intended to detect tampering or entry into the sealed

Security Seals

item. Removal of the security seal requires permanent and

irreversible damage to the seal. The following procedures

3. Terminology

reflect the relative performance of security seals when subject

3.1 Definitions:

to various destructive physical attacks. These tests simulate

3.1.1 locked seal—condition, as intended by the manufac-

known and likely security seal implementation and attack

turer, which secures the sealed item and cannot be reversed or

methods.

opened without physical destruction of the security seal.

1.4 Security seals often contain unique identification mark-

3.1.2 open condition—condition which could allow entry

ings for authentication purposes to discourages duplication and

into the sealed item and, for the purposes of this practice, a

to prevent reapplication. This practice does not address unique

failed security seal.

identifiers or vulnerabilities of security seals.

3.1.3 security seal—passive, one-time locking device used

NOTE 1—See Guide F1158 for procedures on the inspection and

to indicate tampering or entry, and may be designed to offer

evaluation of tampering of security seals.

limitedresistancetoforcedentry.Securitysealsrequireinspec-

1.5 It is the responsibility of users of this practice to tion to determine a tampering or entry event.

interpret their specific security needs concerning the applica-

4. Summary of Practice

tion of seals, and to determine the grade of seal appropriate for

their particular application. ASTM assumes no responsibility 4.1 Asecurity seal shall be evaluated in accordance with its

for losses occurring as a result of a defeated seal, whether the classification into one of five general groups and its perfor-

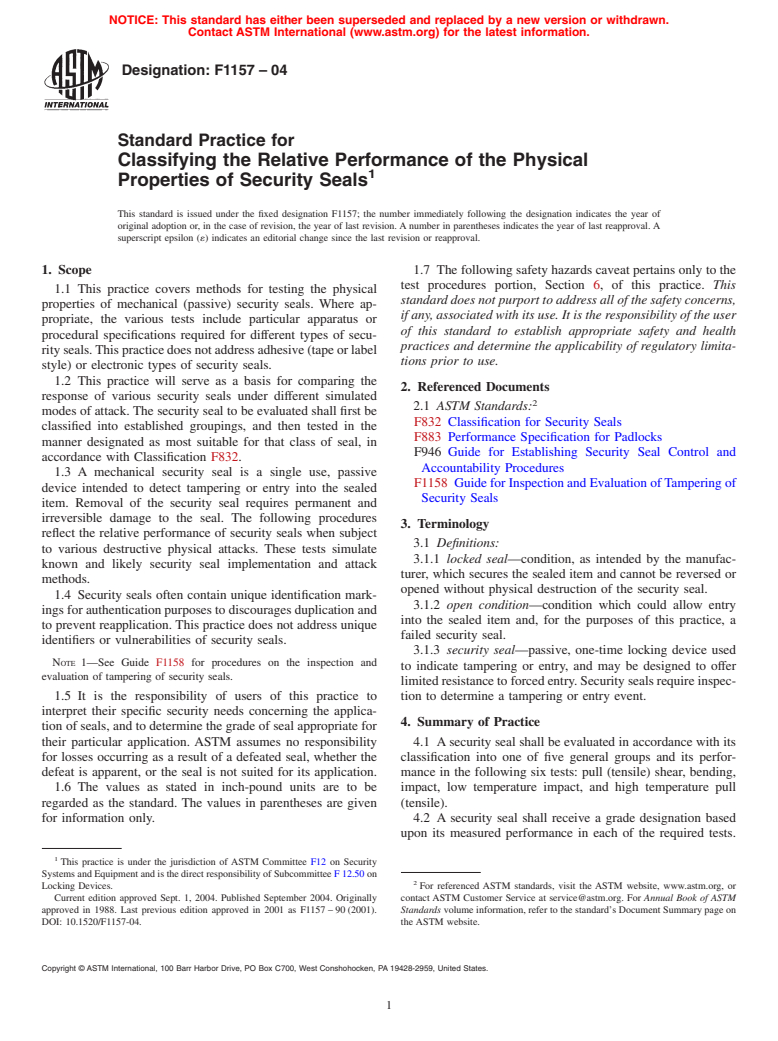

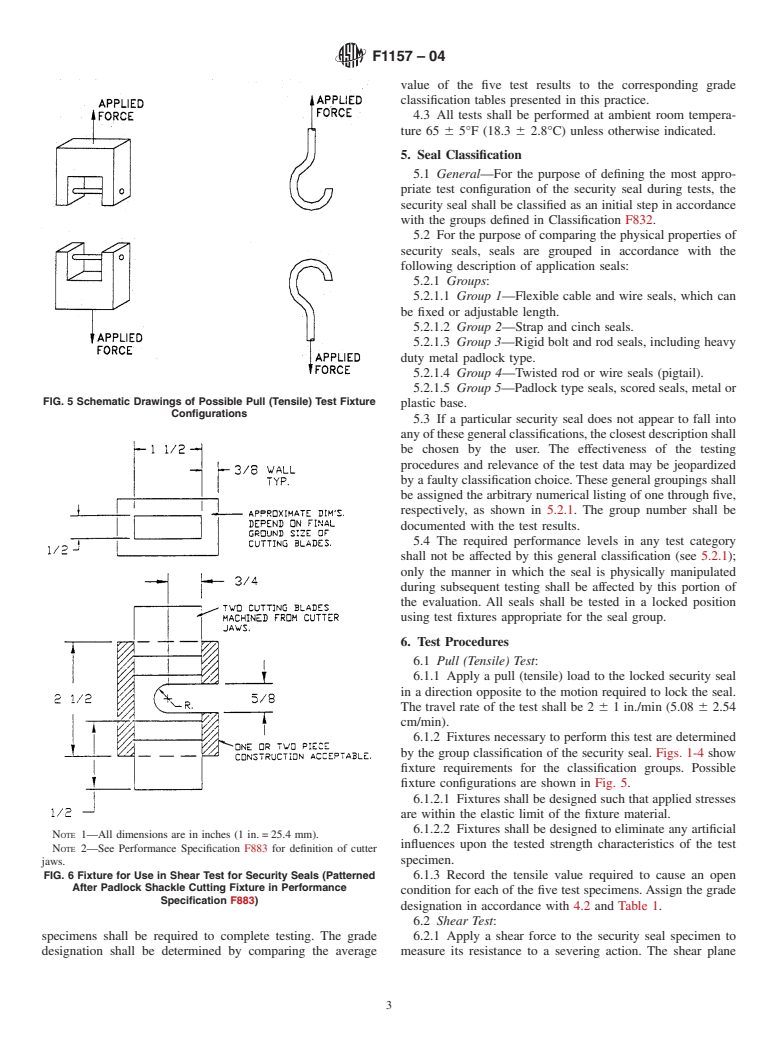

defeat is apparent, or the seal is not suited for its application. mance in the following six tests: pull (tensile) shear, bending,

1.6 The values as stated in inch-pound units are to be impact, low temperature impact, and high temperature pull

regarded as the standard. The values in parentheses are given (tensile).

for information only. 4.2 A security seal shall receive a grade designation based

upon its measured performance in each of the required tests.

1

This practice is under the jurisdiction of ASTM Committee F12 on Security

Systems and Equipment and is the direct responsibility of Subcommittee F 12.50 on

2

Locking Devices. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Sept. 1, 2004. Published September 2004. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1988. Last previous edition approved in 2001 as F1157 – 90 (2001). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/F1157-04. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United Stat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.