ASTM F1157-04(2010)

(Practice)Standard Practice for Classifying the Relative Performance of the Physical Properties of Security Seals

Standard Practice for Classifying the Relative Performance of the Physical Properties of Security Seals

ABSTRACT

This practice covers methods for testing the physical properties of mechanical (passive) security seals. Where appropriate, the various tests include particular apparatus or procedural specifications required for different types of security seals. A security seal shall be evaluated in accordance with its classification into one of five general groups and its performance in the following six tests: pull (tensile) shear, bending, impact, low temperature impact, and high temperature pull (tensile). A security seal shall receive a grade designation based upon its measured performance in each of the required tests. The seals shall be classified according to groups: Group 1; Group 2; Group 3; Group 4; and Group 5. Pull test, shear test, bending test, impact test, and extreme temperature tests shall be performed to conform with the specified requirements.

SCOPE

1.1 This practice covers methods for testing the physical properties of mechanical (passive) security seals. Where appropriate, the various tests include particular apparatus or procedural specifications required for different types of security seals. This practice does not address adhesive (tape or label style) or electronic types of security seals.

1.2 This practice will serve as a basis for comparing the response of various security seals under different simulated modes of attack. The security seal to be evaluated shall first be classified into established groupings, and then tested in the manner designated as most suitable for that class of seal, in accordance with Classification F832.

1.3 A mechanical security seal is a single use, passive device intended to detect tampering or entry into the sealed item. Removal of the security seal requires permanent and irreversible damage to the seal. The following procedures reflect the relative performance of security seals when subject to various destructive physical attacks. These tests simulate known and likely security seal implementation and attack methods.

1.4 Security seals often contain unique identification markings for authentication purposes to discourages duplication and to prevent reapplication. This practice does not address unique identifiers or vulnerabilities of security seals.

Note 1—See Guide F1158 for procedures on the inspection and evaluation of tampering of security seals. See also Guide F946.

1.5 It is the responsibility of users of this practice to interpret their specific security needs concerning the application of seals, and to determine the grade of seal appropriate for their particular application. ASTM assumes no responsibility for losses occurring as a result of a defeated seal, whether the defeat is apparent, or the seal is not suited for its application.

1.6 The values as stated in inch-pound units are to be regarded as the standard. The values in parentheses are given for information only.

1.7 The following safety hazards caveat pertains only to the test procedures portion, Section 6, of this practice. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1157 − 04(Reapproved 2010)

Standard Practice for

Classifying the Relative Performance of the Physical

Properties of Security Seals

This standard is issued under the fixed designation F1157; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope for losses occurring as a result of a defeated seal, whether the

defeat is apparent, or the seal is not suited for its application.

1.1 This practice covers methods for testing the physical

properties of mechanical (passive) security seals. Where 1.6 The values as stated in inch-pound units are to be

appropriate, the various tests include particular apparatus or regarded as the standard. The values in parentheses are given

procedural specifications required for different types of secu- for information only.

rityseals.Thispracticedoesnotaddressadhesive(tapeorlabel

1.7 The following safety hazards caveat pertains only to the

style) or electronic types of security seals.

test procedures portion, Section 6, of this practice. This

standard does not purport to address all of the safety concerns,

1.2 This practice will serve as a basis for comparing the

if any, associated with its use. It is the responsibility of the user

response of various security seals under different simulated

of this standard to establish appropriate safety and health

modes of attack. The security seal to be evaluated shall first be

practices and determine the applicability of regulatory limita-

classified into established groupings, and then tested in the

tions prior to use.

manner designated as most suitable for that class of seal, in

accordance with Classification F832.

2. Referenced Documents

1.3 A mechanical security seal is a single use, passive

2.1 ASTM Standards:

device intended to detect tampering or entry into the sealed

F832 Classification for Security Seals

item. Removal of the security seal requires permanent and

F883 Performance Specification for Padlocks

irreversible damage to the seal. The following procedures

F946 Guide for Establishing Security Seal Control and

reflect the relative performance of security seals when subject

Accountability Procedures

to various destructive physical attacks. These tests simulate

F1158 Guide for Inspection and Evaluation of Tampering of

known and likely security seal implementation and attack

Security Seals

methods.

3. Terminology

1.4 Security seals often contain unique identification mark-

ings for authentication purposes to discourages duplication and

3.1 Definitions:

to prevent reapplication. This practice does not address unique

3.1.1 locked seal—condition, as intended by the

identifiers or vulnerabilities of security seals.

manufacturer, which secures the sealed item and cannot be

NOTE 1—See Guide F1158 for procedures on the inspection and

reversed or opened without physical destruction of the security

evaluation of tampering of security seals. See also Guide F946.

seal.

1.5 It is the responsibility of users of this practice to

3.1.2 open condition—condition which could allow entry

interpret their specific security needs concerning the applica-

into the sealed item and, for the purposes of this practice, a

tion of seals, and to determine the grade of seal appropriate for

failed security seal.

their particular application. ASTM assumes no responsibility

3.1.3 security seal—passive, one-time locking device used

to indicate tampering or entry, and may be designed to offer

This practice is under the jurisdiction of ASTM Committee F12 on Security

Systems and Equipment and is the direct responsibility of Subcommittee F12.50 on

Locking Devices. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2010. Published May 2010. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1988. Last previous edition approved in 2004 as F1157 – 04. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1157-04R10. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1157 − 04 (2010)

limitedresistancetoforcedentry.Securitysealsrequireinspec- 5.2.1.1 Group 1—Flexible cable and wire seals, which can

tion to determine a tampering or entry event. be fixed or adjustable length.

5.2.1.2 Group 2—Strap and cinch seals.

4. Summary of Practice

5.2.1.3 Group 3—Rigid bolt and rod seals, including heavy

4.1 Asecurity seal shall be evaluated in accordance with its duty metal padlock type.

5.2.1.4 Group 4—Twisted rod or wire seals (pigtail).

classification into one of five general groups and its perfor-

mance in the following six tests: pull (tensile) shear, bending, 5.2.1.5 Group 5—Padlock type seals, scored seals, metal or

plastic base.

impact, low temperature impact, and high temperature pull

(tensile).

5.3 If a particular security seal does not appear to fall into

4.2 A security seal shall receive a grade designation based anyofthesegeneralclassifications,theclosestdescriptionshall

upon its measured performance in each of the required tests. be chosen by the user. The effectiveness of the testing

This grade shall be obtained by testing five individual seals in procedures and relevance of the test data may be jeopardized

each of the six specific tests. A minimum of 30 security seal by a faulty classification choice. These general groupings shall

specimens shall be required to complete testing. The grade be assigned the arbitrary numerical listing of one through five,

designation shall be determined by comparing the average respectively, as shown in 5.2.1. The group number shall be

value of the five test results to the corresponding grade documented with the test results.

classification tables presented in this practice.

5.4 The required performance levels in any test category

4.3 All tests shall be performed at ambient room tempera- shall not be affected by this general classification (see 5.2.1);

ture 65 6 5°F (18.3 6 2.8°C) unless otherwise indicated. only the manner in which the seal is physically manipulated

during subsequent testing shall be affected by this portion of

5. Seal Classification

the evaluation. All seals shall be tested in a locked position

using test fixtures appropriate for the seal group.

5.1 General—For the purpose of defining the most appro-

priate test configuration of the security seal during tests, the

6. Test Procedures

security seal shall be classified as an initial step in accordance

with the groups defined in Classification F832.

6.1 Pull (Tensile) Test:

5.2 For the purpose of comparing the physical properties of 6.1.1 Apply a pull (tensile) load to the locked security seal

security seals, seals are grouped in accordance with the in a direction opposite to the motion required to lock the seal.

following description of application seals: The travel rate of the test shall be 2 6 1 in./min (5.08 6 2.54

5.2.1 Groups: cm/min).

NOTE 1—Pin diameter 0.250 in. (6.35 mm) for smallest cross section dimension less than or equal to 0.125 in. (318 mm).

NOTE 2—Pin diameter 0.500 in. (12.7 mm) for smallest cross section dimension greater than 0.125 in. (3.18 mm).

NOTE 3—Tolerance: 60.010 in. (0.254 mm).

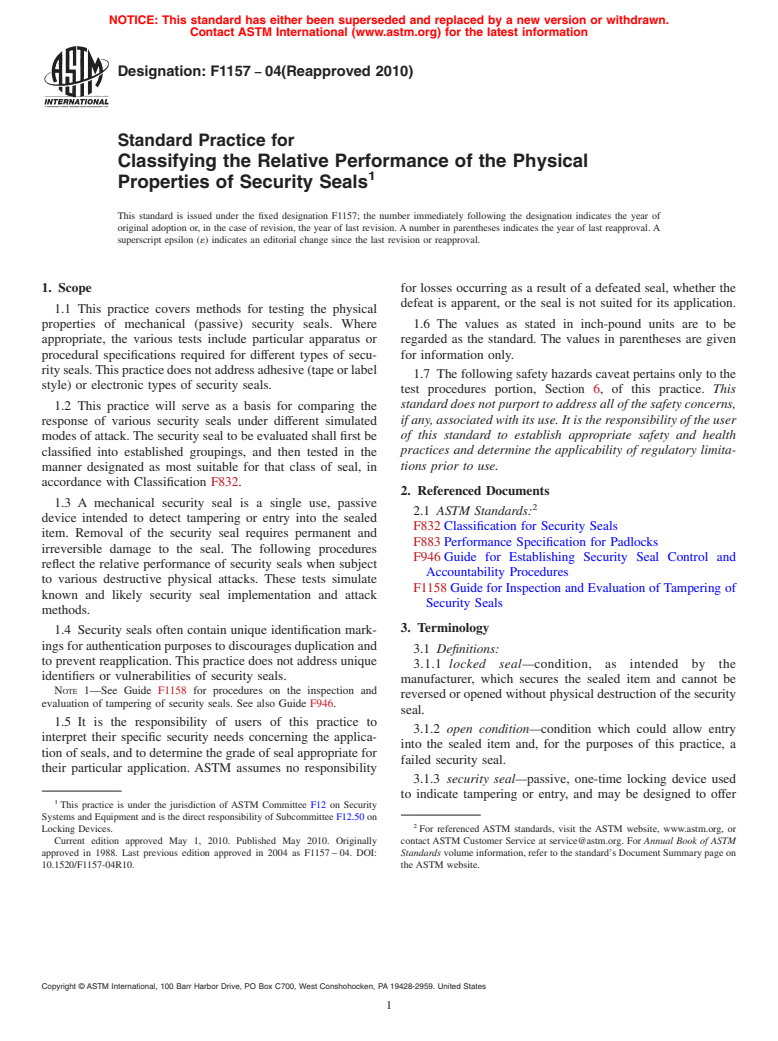

FIG. 1 Schematic Drawings of Pull (Tensile) Test Fixture Requirements for Groups 1 and 2

F1157 − 04 (2010)

FIG. 2 Schematic Drawings of Pull (Tensile) Test Fixture Requirements for Group 3

FIG. 3 Schematic Drawings of Pull (Tensile) Test Fixture Require-

ments for Group 4

FIG. 5 Schematic Drawings of Possible Pull (Tensile) Test Fix-

ture Configurations

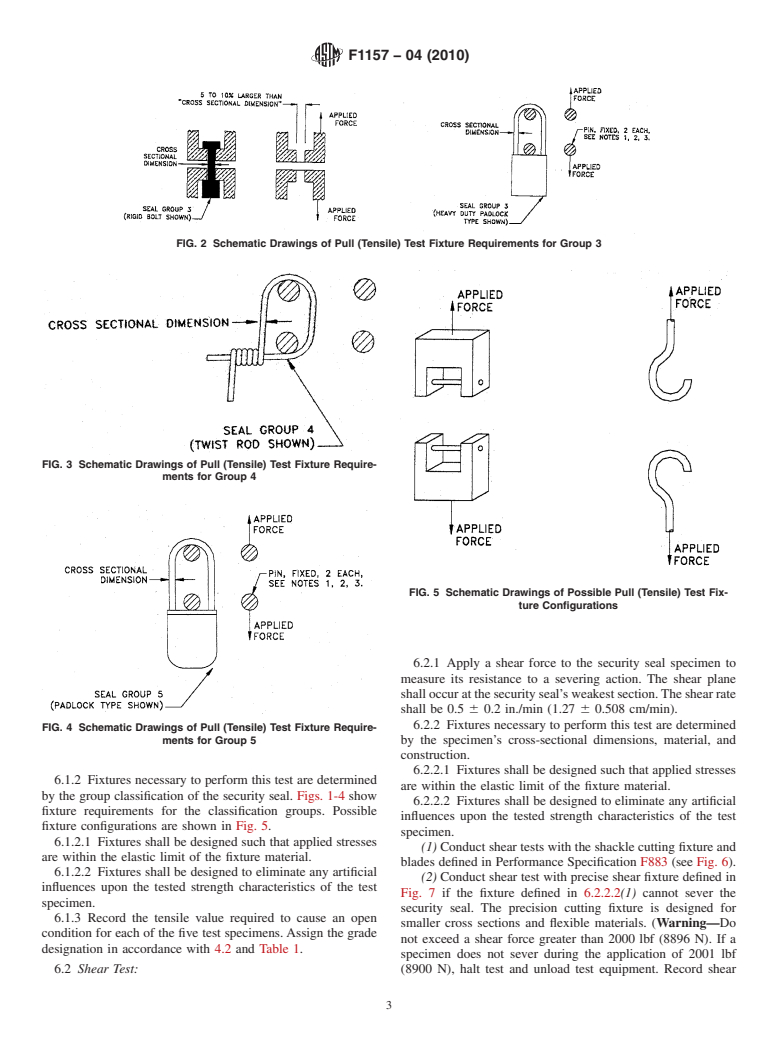

6.2.1 Apply a shear force to the security seal specimen to

measure its resistance to a severing action. The shear plane

shalloccuratthesecurityseal’sweakestsection.Theshearrate

shall be 0.5 6 0.2 in./min (1.27 6 0.508 cm/min).

6.2.2 Fixtures necessary to perform this test are determined

FIG. 4 Schematic Drawings of Pull (Tensile) Test Fixture Require-

ments for Group 5 by the specimen’s cross-sectional dimensions, material, and

construction.

6.2.2.1 Fixtures shall be designed such that applied stresses

6.1.2 Fixtures necessary to perform this test are determined

are within the elastic limit of the fixture material.

by the group classification of the security seal. Figs. 1-4 show

6.2.2.2 Fixtures shall be designed to eliminate any artificial

fixture requirements for the classification groups. Possible

influences upon the tested strength characteristics of the test

fixture configurations are shown in Fig. 5.

specimen.

6.1.2.1 Fixtures shall be designed such that applied stresses

(1) Conduct shear tests with the shackle cutting fixture and

are within the elastic limit of the fixture material.

blades defined in Performance Specification F883 (see Fig. 6).

6.1.2.2 Fixtures shall be designed to eliminate any artificial

(2) Conduct shear test with precise shear fixture defined in

influences upon the tested strength characteristics of the test

Fig. 7 if the fixture defined in 6.2.2.2(1) cannot sever the

specimen.

security seal. The precision cutting fixture is designed for

6.1.3 Record the tensile value required to cause an open

smaller cross sections and flexible materials. (Warning—Do

condition for each of the five test specimens. Assign the grade

not exceed a shear force greater than 2000 lbf (8896 N). If a

designation in accordance with 4.2 and Table 1.

specimen does not sever during the application of 2001 lbf

6.2 Shear Test: (8900 N), halt test and unload test equipment. Record shear

F1157 − 04 (2010)

6.3.2.4 Record the bending cycles required to cause an open

condition for each of the five test specimens. A bending cycle

is defined as one complete arc of 180°. Assign the grade

designation in accordance with 4.2 and Table 3.

6.3.3 Rigid security seals include rigid bolt, rod and heavy

duty metal padlock security seals (Group 3), and twisted rod or

wire seals (Group 4), and shall be subjected to bending. Fig. 9

shows necessary fixture requirements.

6.3.3.1 Fixtures shall be designed such that applied stresses

are within the elastic limit of the fixture material.

6.3.3.2 Fixtures shall be designed to eliminate any artificial

influences upon the tested strength characteristics of the test

specimen.

6.3.3.3 The pre-test orientation shall be considered 0°. Bend

the security seal and measure the moment necessary to bend

from 0° to 90°. Reverse the applied bending and measure the

moment necessary to cause a bend from 90° to 0°. Repeat this

range of motion, until the security seal exhibits an open

condition. For calculation purposes, the moment arm is defined

as the perpendicular distance between line of action of the

applied force and the point of bend.

6.3.3.4 Record the maximum bending moment required to

cause an open condition for each of the five test specimens.

Assign the grade designation in accordance with 4.2 and Table

4.

NOTE 1—All dimensions are in inches (1 in. = 25.4 mm).

6.3.4 Metallichasppadlocksecurityseals(Group5)shallbe

NOTE 2—See Performance Specification F883 for definition of cutter

subjected to a twisting or torsional moment. Fig. 10 shows

jaws.

FIG. 6 Fixture for Use in Shear Test for Security Seals (Patterned necessary fixture requirements.

After Padlock Shackle Cutting Fixture in Performance Specifica-

6.3.4.1 Fixtures shall be designed such that applied stresses

tion F883)

are within the elastic limit of the fixture material.

6.3.4.2 Fixtures shall be designed to eliminate any artificial

influences upon the tested strength characteristics of the test

force of 2000 lbf (8896 N). Do not test specimen to failure.

specimen.

Sudden and violent rupture of the test specimen can endanger

6.3.4.3 Apply a moment to the security seal body until the

personnel, equipment, and property.)

seal exhibits an open condition.

6.2.3 Record the shear force required to cause an open

6.3.4.4 Record the maximum moment required to cause an

condition for each of the five test specimens. Assign the grade

open condition for each of the five test specimens. Assign the

designation in accordance with 4.2 and Table 2.

grade designation in accordance with 4.2 and Table 4.

6.3 Bending Test:

6.3.5 Non-metallic hasp padlock security seals (Group 5)

6.3.1 Apply a moment to the security seal specimen to

shall be subjected to a twisting or torsional moment. Fig. 11

measure its resistance to a bending or twisting action. For the

shows necessary fixture requirements.

purpose of the bending test, security seals are categorized as

6.3.5.1 Fixtures shall be designed such that applied stresses

flexible (Groups 1 and 2), rigid (Groups 3 and 4), padlocks

are within the elastic limit of the fixture material.

with metallic hasps (Group 5), and padlocks with non-metallic

6.3.5.2 Fixtures shall be designed to eliminate any artificial

hasps (Group 5).

influences upon the tested strength characteristics of the test

6.3.2 Flexible security seals include cable and wire seals

specimen.

(Group 1), and strap and cinch seals (Group 2) and shall be

6.3.5.3 The pre-test orientation with the torsion bar contact-

subjected to bending. Fig. 8 shows necessary fixture require-

ing both shackle legs shall be considered 0°. Rotate the torsion

ments.

bar from 0° to 90° so the bar is in constant contact with the

6.3.2.1 Fixtures shall be designed such that applied stresses

shackle legs. Reverse the motion and rotate the bar from 90° to

are within the elastic limit of the fixture material.

0°. Repeat this arc of 90° until the security seal exhibits an

6.3.2.2 Fixtures shall be designed to eliminate any artificial

open condition.

influences upon the tested strength characteristics of the test

6.3.5.4 Record the bending cycles required to cause an open

specimen.

condition for each of the five test specimens. A bending cycle

6.3.2.3 The pre-test orientation shall be considered 0°. Bend

is defined as a rotation from 0° to 90° to 0°. Assign the grade

the security seal from 0° to 90°. Reverse the motion and bend

designation in accordance with 4.2 and Table 3.

the security seal from 90° to -90°, an arc of 180°. Repeat this

180° arc until the security seal exhibits an open condition. 6.4 Impact Test:

F1157 − 04 (2010)

NOTE 1—Hole through specimen holder shall not exceed 10 % of the cross section dimension(s) of specimen.

NOTE 2—Hardness of cutting jaw 60 to 62 Rockwell “C” scale.

NOTE 3—Cutting jaw shall remain parallel 60.005 in. (0.127 mm) to specimen holder.

NOTE 4—Tolerance 60.005 i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.