ASTM A381-96(2012)

(Specification)Standard Specification for Metal-Arc-Welded Steel Pipe for Use With High-Pressure Transmission Systems

Standard Specification for Metal-Arc-Welded Steel Pipe for Use With High-Pressure Transmission Systems

ABSTRACT

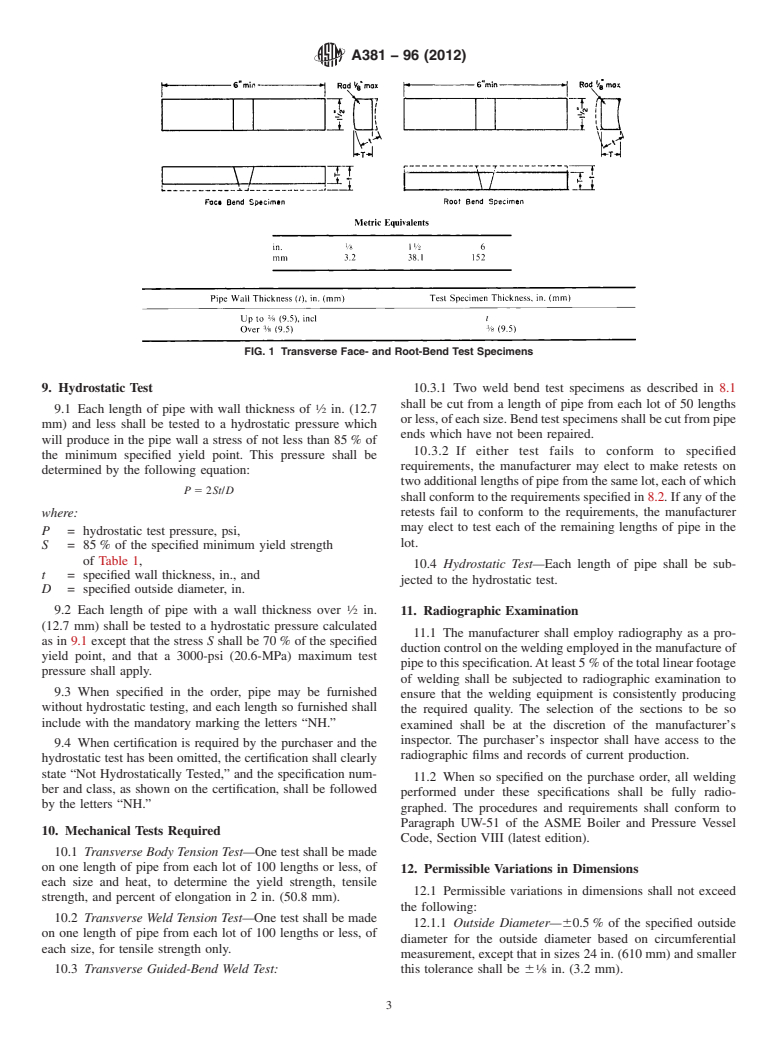

This specification covers metal-arc-welded steel pipe for use with high pressure transmission systems. The pipe is intended for fabrication of fittings and accessories for compressor or pump-station piping. The required chemical compositions for carbon steel, and the tensile properties of finished pipes are presented. Mechanical testing requirements namely transverse body tension test and transverse weld tension test shall be performed on each length of pipe from each lot of 100 lengths, and transverse guided-bend weld test cut from a length of pipe from each lot of 50 length, also hydrostatic test from each length of pipes shall be performed. A radiographic examination shall also be performed to ensure that the welding equipment is consistently producing the required quality.

SCOPE

1.1 This specification covers straight seam, double-submerged-arc-welded steel pipe (Note 1) suitable for high-pressure service, 16 in. (406 mm) and larger in outside diameter, with wall thicknesses from 5/16 to 11/2 in. (7.9 to 38 mm). The pipe is intended for fabrication of fittings and accessories for compressor or pump-station piping. Pipe ordered to this specification shall be suitable for bending, flanging (vastoning), corrugating, and similar operations. Note 1—A comprehensive listing of standardized pipe dimensions is contained in ANSI B36.10. Note 2—The term “double welded” is commonly used in the gas and oil transmission industry, for which this pipe is primarily intended, to indicate welding with at least two weld passes, of which one is on the outside of the pipe and one on the inside. For some sizes of the pipe covered by this specification, it becomes expedient to use manual welding, in which case the provisions of Note 3 shall be followed.

1.2 Nine classes of pipe, based on minimum yield point requirements, are covered as indicated in Table 1. TABLE 1 Tensile Requirements

Class

Yield Strength,

min, psi (MPa)

Tensile Strength,

min, psi (MPa)

Elongation in 2 in.

(50.8 mm),

min, %

Y 35

35 000 (240)

60 000 (415)

26

Y 42

42 000 (290)

60 000 (415)

25

Y 46

46 000 (316)

63 000 (435)

23

Y 48

48 000 (330)

62 000 (430)

21

Y 50

50 000 (345)

64 000 (440)

21

Y 52

52 000 (360)

66 000 (455)

20

Y 56

56 000 (385)

71 000 (490)

20

Y 60

60 000 (415)

75 000 (515)

20

Y 65

65 000 (450)

77 000 (535)

20

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following caveat applies to the test methods portion, Sections 9 and 10, only. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A381 −96 (Reapproved 2012)

Standard Specification for

Metal-Arc-Welded Steel Pipe for Use With High-Pressure

1

Transmission Systems

This standard is issued under the fixed designation A381; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A370 Test Methods and Definitions for Mechanical Testing

of Steel Products

1.1 This specification covers straight seam, double-

A530/A530M Specification for General Requirements for

submerged-arc-welded steel pipe (Note 1) suitable for high-

Specialized Carbon and Alloy Steel Pipe

pressure service, 16 in. (406 mm) and larger in outside

E30 Test Methods for ChemicalAnalysis of Steel, Cast Iron,

5 1

diameter, with wall thicknesses from ⁄16 to 1 ⁄2 in. (7.9 to 38

3

Open-Hearth Iron, and Wrought Iron (Withdrawn 1995)

mm). The pipe is intended for fabrication of fittings and

4

2.2 ASME Boiler and Pressure Vessel Code:

accessories for compressor or pump-station piping. Pipe or-

Section VIII Pressure Vessels

dered to this specification shall be suitable for bending,

Section IX Welding Qualifications

flanging (vastoning), corrugating, and similar operations.

5

2.3 ANSI Standard:

NOTE 1—A comprehensive listing of standardized pipe dimensions is

ANSI B36.10 Welded and Seamless Wrought Steel Pipe

contained in ANSI B36.10.

NOTE 2—The term “double welded” is commonly used in the gas and

oil transmission industry, for which this pipe is primarily intended, to

3. Ordering Information

indicate welding with at least two weld passes, of which one is on the

3.1 Orders for material to this specification should include

outside of the pipe and one on the inside. For some sizes of the pipe

coveredbythisspecification,itbecomesexpedienttousemanualwelding, the following, as required, to describe the desired material

in which case the provisions of Note 3 shall be followed.

adequately:

3.1.1 Quantity (feet, centimetres, or number of lengths),

1.2 Nine classes of pipe, based on minimum yield point

3.1.2 Name of material (metal-arc welded pipe),

requirements, are covered as indicated in Table 1.

3.1.3 Class (Table 1),

1.3 The values stated in inch-pound units are to be regarded

3.1.4 Material (carbon or alloy steel, Section 5),

as standard. The values given in parentheses are mathematical

3.1.5 Size (outside diameter and wall thickness),

conversions to SI units that are provided for information only

3.1.6 Length (specific or random) (Section 13),

and are not considered standard.

3.1.7 Ends (Section 14),

1.4 The following caveat applies to the test methods

3.1.8 Heat treatment (stress-relieved or normalized) (see

portion, Sections 9 and 10, only. This standard does not

5.6),

purport to address all of the safety concerns, if any, associated

3.1.9 Optional requirements (see 5.2 (Note 3), Sections 11

with its use. It is the responsibility of the user of this standard

and 15),

to establish appropriate safety and health practices and

3.1.10 Specification number, and

determine the applicability of regulatory limitations prior to

3.1.11 Special requirements or exceptions to this specifica-

use.

tion.

2. Referenced Documents

4. General Requirements

2

2.1 ASTM Standards:

4.1 Material furnished to this specification shall conform to

the applicable requirements of the current edition of Specifi-

1

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

cation A530/A530M, unless otherwise provided herein.

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.09 on Carbon Steel Tubular Products.

Current edition approved March 1, 2012. Published November 2012. Originally

3

approved in 1954. Last previous edition approved in 2005 as A381 – 96 (2005). The last approved version of this historical standard is referenced on

DOI: 10.1520/A0381-96R12. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Society of Mechanical Engineers, 345 E. 47th St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM New York, NY 10017.

5

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A381−96 (2012)

TABLE 1 Tensile Requirements TABLE 2 Chemical Requirements for Carbon Steels on Product

Analysis

Class Yield Strength, Tensile Strength, Elongat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.