ASTM C1550-02

(Test Method)Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel)

Standard Test Method for Flexural Toughness of Fiber Reinforced Concrete (Using Centrally Loaded Round Panel)

SCOPE

1.1 This test method covers the determination of flexural toughness of fiber-reinforced concrete expressed as energy absorption in the post-crack range using a round panel supported on three symmetrically arranged pivots and subjected to a central point load. The performance of specimens tested by this method is quantified in terms of the energy absorbed between the onset of loading and selected values of central deflection.

1.2 This test method provides for the scaling of results whenever specimens do not comply with the target thickness and diameter, as long as dimensions do not fall outside of give limits.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1550 – 02

Standard Test Method for

Flexural Toughness of Fiber Reinforced Concrete (Using

Centrally Loaded Round Panel)

This standard is issued under the fixed designation C 1550; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope that excludes extraneous deformations of the load train and

local crushing of the panel at the point of load application and

1.1 This test method covers the determination of flexural

points of support.

toughness of fiber-reinforced concrete expressed as energy

3.2.2 compliance—a measure of the tendency of a structure

absorption in the post-crack range using a round panel sup-

to deflect under load, found as the inverse of stiffness or

ported on three symmetrically arranged pivots and subjected to

deflection divided by the corresponding load.

a central point load. The performance of specimens tested by

3.2.3 load train—those parts of a testing machine that

this method is quantified in terms of the energy absorbed

experience load and undergo straining during a mechanical

between the onset of loading and selected values of central

test, including the actuator, frame, support fixtures, load cell,

deflection.

and specimen.

1.2 This test method provides for the scaling of results

3.2.4 toughness—the energy absorbed by the specimen

whenever specimens do not comply with the target thickness

equivalent to the area under the load-deflection curve between

and diameter, as long as dimensions do not fall outside of given

the onset of loading and a specified central deflection.

limits.

1.3 The values stated in SI units are to be regarded as the

4. Summary of Test Method

standard.

4.1 Molded round panels of cast fiber-reinforced concrete or

1.4 This standard does not purport to address all of the

fiber-reinforced shotcrete are subjected to a central point load

safety concerns, if any, associated with its use. It is the

while supported on three symmetrically arranged pivots. The

responsibility of the user of this standard to establish appro-

load is applied through a hemispherical-ended steel piston

priate safety and health practices and determine the applica-

advanced at a prescribed rate of displacement. Load and

bility of regulatory limitations prior to use.

deflection are recorded simultaneously up to a specified central

2. Referenced Documents deflection. The energy absorbed by the panel up to a specified

central deflection is representative of the flexural toughness of

2.1 ASTM Standards:

the fiber-reinforced concrete panel.

C 125 Terminology Relating to Concrete and Concrete

Aggregates

5. Significance and Use

C 670 Practice for Preparing Precision and Bias Statements

2 5.1 The post-crack behavior of plate-like fiber-reinforced

for Test Methods for Construction Materials

concrete structural members is well represented by a centrally

3. Terminology loaded round panel test specimen that is simply supported on

three pivots symmetrically arranged around its circumference.

3.1 Definitions—For definitions of terms used in this test

Such a test panel experiences bi-axial bending in response to a

method, refer to Terminology C 125.

central point load and exhibits a mode of failure related to the

3.2 Definitions of Terms Specific to This Standard:

in situ behavior of structures such as concrete slabs-on-grade,

3.2.1 central deflection—the net deflection at the center of

shotcrete tunnel linings, and shotcrete embankment stabiliza-

the panel measured relative to a plane defined by the three

tion linings. The post-crack performance of round panels

pivots used to support the panel; this is a conditioned deflection

subject to a central point load can be represented by the energy

absorbed by the panel up to a specified central deflection. In

This test method is under the jurisdiction of ASTM Committee C09 on this test method, the energy absorbed up to a specified central

Concrete and Concrete Aggregates and is the direct responsibility of Subcommittee

deflection is taken to represent the ability of a fiber-reinforced

C09.42 on Fiber-Reinforced Concrete.

concrete to redistribute stress following cracking.

Current edition approved Sept. 10, 2002. Published October 2002.

Annual Book of ASTM Standards, Vol 04.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C1550–02

NOTE 1—The use of three pivoted point supports in the test configura-

6. Apparatus

tion results in determinate out-of-plane reactions prior to cracking,

6.1 Testing Machine—The testing machine shall be capable

however the support reactions are indeterminate after cracking due to the

of operating in a manner that produces a controlled and

unknown distribution of flexural resistance along each crack. There is also

constant rate of increase of deflection of the specimen without

a change in load resistance mechanism in the specimen as the test

the intervention of an operator. To avoid unstable behavior

proceeds, starting with predominantly flexural resistance and progressing

after cracking, the system stiffness of the testing machine

to tensile membrane action around the center as the imposed deflection is

increased. The energy absorbed up to a specified central deflection is

inclusive of load frame, load cell (if used), and support fixture

related to the toughness of the material but is specific to this specimen

shall exceed that of the specimen. The system stiffness of the

configuration because it is also determined by the support conditions and

testing machine can be determined in accordance with the

size of the specimen. Selection of the most appropriate central deflection

procedure described in Annex A1. A closed-loop testing

to specify depends on the intended application for the material. The energy

machine in which the measured deflection of the center of the

absorbed up to 5 mm central deflection is applicable to situations in which

specimen is used to automatically control the rate of increase of

the material is required to hold cracks tightly closed at low levels of

deflection of the loading device is acceptable. A testing

deformation. Examples include final linings in underground civil struc-

machine in which the displacement rate of the loading device

tures such as railway tunnels that may be required to remain water-tight.

The energy absorbed up to 40 mm is more applicable to situations in that

is constant is also acceptable provided the load train stiffness

the material is expected to suffer severe deformation in situ (for example,

exceeds the value listed above. Do not use a load-controlled

shotcrete linings in mine tunnels and temporary linings in swelling

test machine. The load-sensing device shall have a resolution

ground). Energy absorption up to intermediate values of central deflection

sufficient to record load to 6 50 N.

can be specified in situations requiring performance at intermediate levels

NOTE 3—Although it is commonly believed that closed-loop control

of deformation.

systems are capable of overcoming the disadvantages of a structurally

5.2 The motivation for use of a round panel with three

compliant testing machine, this will depend on the speed and sensitivity of

supports is based on the within-batch repeatability found in the feed-back loop and the mechanical response rate of the loading

3 4

apparatus. A more reliable configuration comprises a displacement-

laboratory and field experience. The consistency of the

controlled hydraulic actuator in a testing machine with high system

failure mode that arises through the use of three symmetrically

stiffness. Alternately, a stiff screw-driven machine in which the displace-

arranged support pivots results in low within-batch variability

ment of the cross-head is advanced at a constant rate is also acceptable.

in the energy absorbed by a set of panels up to a specified

This test method has been developed for use with displacement-controlled

central deflection. The use of round panels also eliminates the

machines so that the high cost of closed-loop machines can be avoided.

sawing that is required to prepare shotcrete beam specimens. Experience has indicated that the redistribution of stress that occurs in

fiber-reinforced concrete panels following cracking of the concrete matrix

5.3 The nominal dimensions of the panel are 75 mm in

generally results in stable post-crack behavior provided a testing machine

thickness and 800 mm in diameter. Thickness has been shown

complying with the requirements of this section is used.

to strongly influence panel performance in this test, while

6.2 Support Fixture—The fixture supporting the panel dur-

variations in diameter have been shown to exert a minor

ing testing shall consist of any configuration that includes three

influence on performance. Correction factors are provided to

symmetrically arranged pivot points on a pitch circle diameter

account for actual measured dimensions.

of 750 mm capable of supporting a load of 100 kN without

displacing in the radial direction by more than 0.5 mm relative

NOTE 2—The target dimensions of the panel specimen used in this test

are held constant regardless of the characteristics of aggregate and fibers

to the central axis. The three supports must be restrained

used in the concrete comprising the specimen. Post-crack performance

against radial or circumferential translation, and the pivots

may be influenced by size and boundary effects if large aggregate particles

shall not restrict rotation of the panel fragments after cracking.

or long fibers are used in the concrete. These influences are acknowledged

The support fixture must be configured so that the specimen

and accepted in this test method because issues of size effect and fiber

does not come into contact with any portion of the support

alignment arise in actual structures and no single test specimen can

fixture apart from the three pivots during a test. A photograph

suitably model structures of all sizes. Differences in post-crack behavior

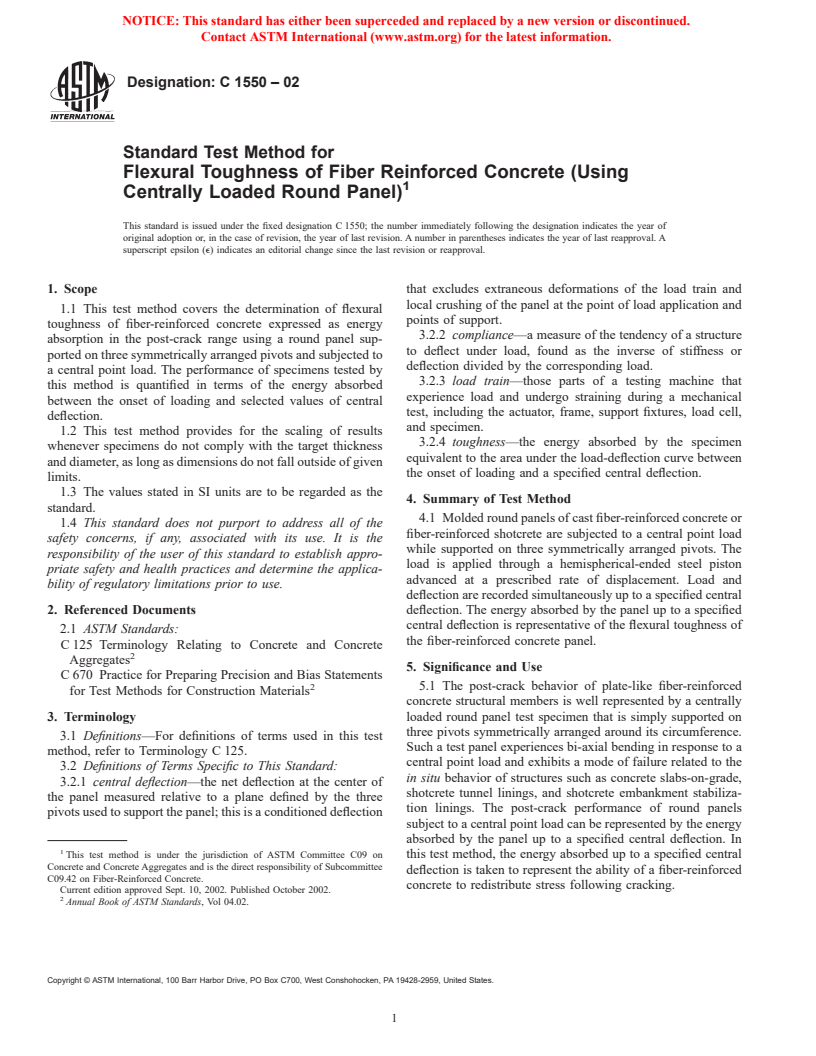

of a suggested design is shown in Fig. 1. The contact between

exhibited in this test method can be expected relative to cast fiber-

the specimen and each pivot shall comprise a steel transfer

reinforced concrete members thicker than 100 mm. Because fiber align-

ment is pronounced in structures produced by shotcreting, and the

maximum aggregate size in shotcrete mixtures is typically 10 mm,

post-crack behavior in specimens tested by this method are more

representative of in situ behavior when they are produced by spraying

rather than casting concrete.

Bernard, E. S. “Correlations in the Behaviour of Fibre Reinforced Shotcrete

Beam and Panel Specimens,” Materials and Structures, RILEM, Vol 35, April 2002,

pp. 156-164.

Hanke, S. A., Collis, A., and Bernard, E. S., “The M5 Motorway: An Education

in Quality Assurance for Fibre Reinforced Shotcrete,” Shotcrete: Engineering

Developments, Bernard (ed.), Swets & Zeitlinger, Lisse, 2001, pp. 145-156.

Bernard, E. S. and Pircher, M., 2001, “The Influence of Thickness on

Performance of Fiber-Reinforced Concrete in a Round Determinate Panel Test,”

Cement, Concrete, and Aggregates, CCAGDP, Vol 23, No. 1, June 2001, pp. 27–33. FIG. 1 Photograph of a Suggested Support Fixture

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C1550–02

NOTE 4—All components of the load train in a test system experience

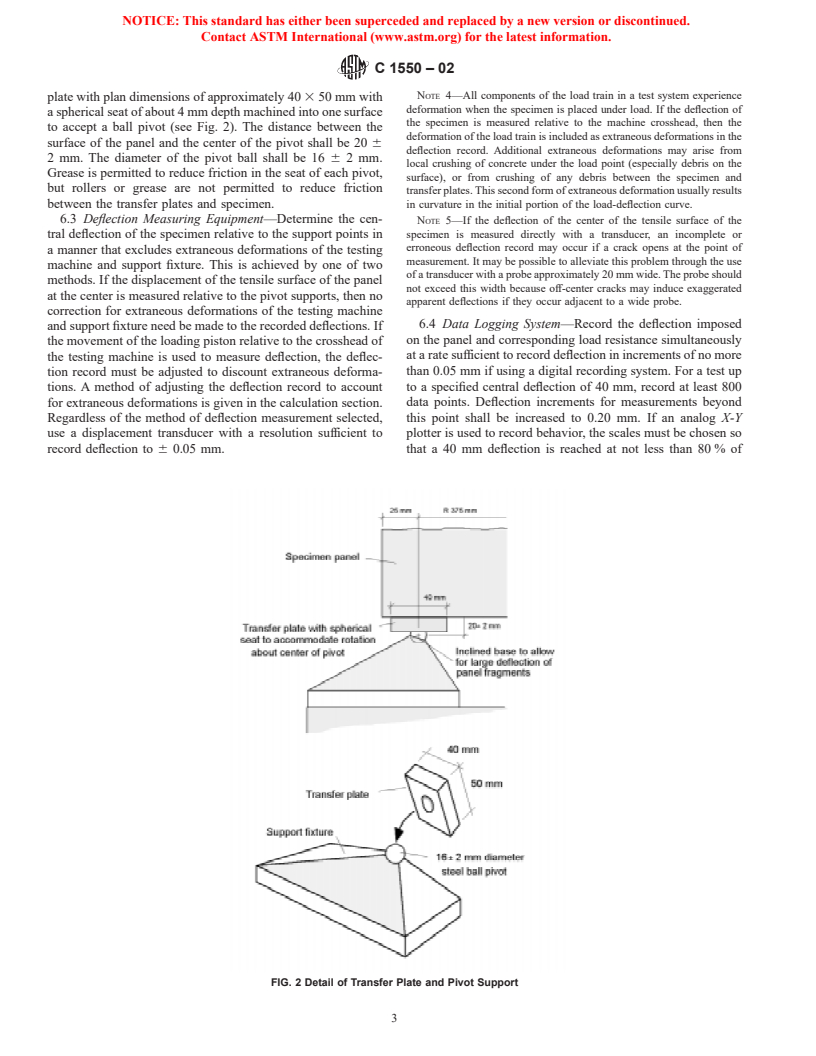

plate with plan dimensions of approximately 40 3 50 mm with

deformation when the specimen is placed under load. If the deflection of

a spherical seat of about 4 mm depth machined into one surface

the specimen is measured relative to the machine crosshead, then the

to accept a ball pivot (see Fig. 2). The distance between the

deformation of the load train is included as extraneous deformations in the

surface of the panel and the center of the pivot shall be 20 6

deflection record. Additional extraneous deformations may arise from

2 mm. The diameter of the pivot ball shall be 16 6 2 mm.

local crushing of concrete under the load point (especially debris on the

Grease is permitted to reduce friction in the seat of each pivot,

surface), or from crushing of any debris between the specimen and

but rollers or grease are not permitted to reduce friction

transfer plates. This second form of extraneous deformation usually results

between the transfer plates and specimen. in curvature in the initial portion of the load-deflection curve.

6.3 Deflection Measuring Equipment—Determine the cen-

NOTE 5—If the deflection of the center of the tensile surface of the

tral deflection of the specimen relative to the support points in specimen is measured directly with a transducer, an incomplete or

erroneous deflection record may occur if a crack opens at the point of

a manner that excludes extraneous deformations of the testing

measurement. It may be possible to alleviate this problem through the use

machine and support fixture. This is achieved by one of two

of a transducer with a probe approximately 20 mm wide. The probe should

methods. If the displacement of the tensile surface of the panel

not exceed this width because off-center cracks may induce exaggerated

at the center is measured relative to the pivot supports, then no

apparent deflections if they occur adjacent to a wide probe.

correction for extraneous deformations of the testing machine

6.4 Data Logging System—Record the deflection imposed

and support fixture need be made to the recorded deflections. If

on the panel and corresponding load resistance simultaneously

the movement of the loading piston relative to the crosshead of

at a rate sufficient to record deflection in increments of no more

the testing machine is used to measure deflection, the deflec-

than 0.05 mm if using a digital recording system. For a test up

tion record must be adjusted to discount extraneous deforma-

to a specified central deflection of 40 mm, record at least 800

tions. A method of adjusting the deflection record to account

for extraneous deformations is given in the calculation section. data points. Deflection increments for measurements beyond

Regardless of the method of deflection measurement selected, this point shall be increased to 0.20 mm. If an analog X-Y

use a displacement transducer with a resolution sufficient to plotter is used to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.