ASTM B23-00(2005)

(Specification)Standard Specification for White Metal Bearing Alloys (Known Commercially as "Babbitt Metal")

Standard Specification for White Metal Bearing Alloys (Known Commercially as "Babbitt Metal")

ABSTRACT

This specification deals with eight typical white metal bearing alloys, in bar or ingot form, known commercially as "Babbitt metal." Covered in this specification are tin-based alloys, namely, UNS-L13910 (alloy no. 1), UNS-L13890 (alloy no. 2), UNS-L13840 (alloy no. 3), and UNS-L13870 (alloy no. 11); and lead-based alloys, namely, UNS-L53585 (alloy no. 7), UNS-L53565 (alloy no. 8), UNS-L53346 (alloy no. 13), and UNS-L53620 (alloy no. 15). Materials shall be manufactured in accordance with such practice as to obtain the chemical composition, weight, and dimensions as prescribed herein.

SCOPE

1.1 This specification covers eight typical white metal bearing alloys, in bar or ingot form, known commercially as "babbitt metal." The alloys are specified, covering the range commercially used, and are designated by the alloy numbers shown in .

1.2 &inch-pound-units;

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B23 – 00 (Reapproved 2005)

Standard Specification for

White Metal Bearing Alloys

(Known Commercially as “Babbitt Metal”)

This standard is issued under the fixed designation B23; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.2 Form and nominal weight of individual bars,

3.1.3 Quantity,

1.1 This specification covers eight typical white metal

3.1.4 Alloy number,

bearing alloys, in bar or ingot form, known commercially as

3.1.5 Inspection required (Section 9),

“babbitt metal.” The alloys are specified, covering the range

3.1.6 Certification required (Section 10),

commercially used, and are designated by the alloy numbers

3.1.7 Marking required (Section 11), and

shown in Table 1.

3.1.8 ASTM designation and year of issue.

1.2 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are mathematical

4. Materials and Manufacture

conversions to SI units that are provided for information only

4.1 The bars or ingots shall be made in accordance with

and are not considered standard.

such practice as to obtain the chemical composition, weight,

1.3 This standard does not purport to address all of the

and dimensions as prescribed in this specification.

safety concerns, if any, associated with its use. It is the

4.2 The bars or ingots shall be as uniform in quality as

responsibility of the user of this standard to become familiar

practicable.

with all hazards including those identified in the appropriate

Material Safety Data Sheet (MSDS) for this product/material

5. Chemical Composition

as provided by the manufacturer, to establish appropriate

5.1 Thealloyscoveredbythisspecificationshallconformto

safety and health practices, and determine the applicability of

the requirements for chemical composition prescribed in Table

regulatory limitations prior to use.

1.

2. Referenced Documents 5.2 By agreement between manufacturer and purchaser,

2 analysis may be required and limits established for elements

2.1 ASTM Standards:

not specified in Table 1.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

6. Dimensions and Weights

E57 Methods for Chemical Analysis of White Metal Bear-

3 6.1 The babbitt shall be furnished in bars of a convenient

ing Alloys

weightandsizeforhandling.Unlessotherwiseagreedupon,no

3. Ordering Information unnotched bar shall exceed 10 lb (4.5 kg) in weight, nor

notched bar exceed 15 lb (6.8 kg).

3.1 Orders for materials under this specification shall in-

6.2 By mutual agreement, babbitt may be furnished in small

clude the following information:

round bars about 3.5 in. (90 mm) in diameter.

3.1.1 Name of material (white metal bearing alloy),

7. Sampling

This specification is under the jurisdiction of ASTM Committee B02 on

7.1 Three bars shall be selected to represent a shipment of

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

less than 1000 lb (450 kg), five bars to represent a shipment of

B02.02 on Refined Lead, Tin, Antimony, and Their Alloys.

1000 lb to 10 000 lb (4500 kg) inclusive, and ten bars to

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1926. Last previous edition approved in 2000 as B23 – 00. DOI: represent a shipment of over 10 000 lb to one carload.

10.1520/B0023-00R05.

7.2 Saw cuts shall be made at points in the bars as indicated

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

in Fig. 1. No lubricants shall be used for sawing. The sawings

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

shallbecarefullytreatedwithamagnettoremoveanyparticles

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

of steel introduced in taking the sample.

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B23 – 00 (2005)

A

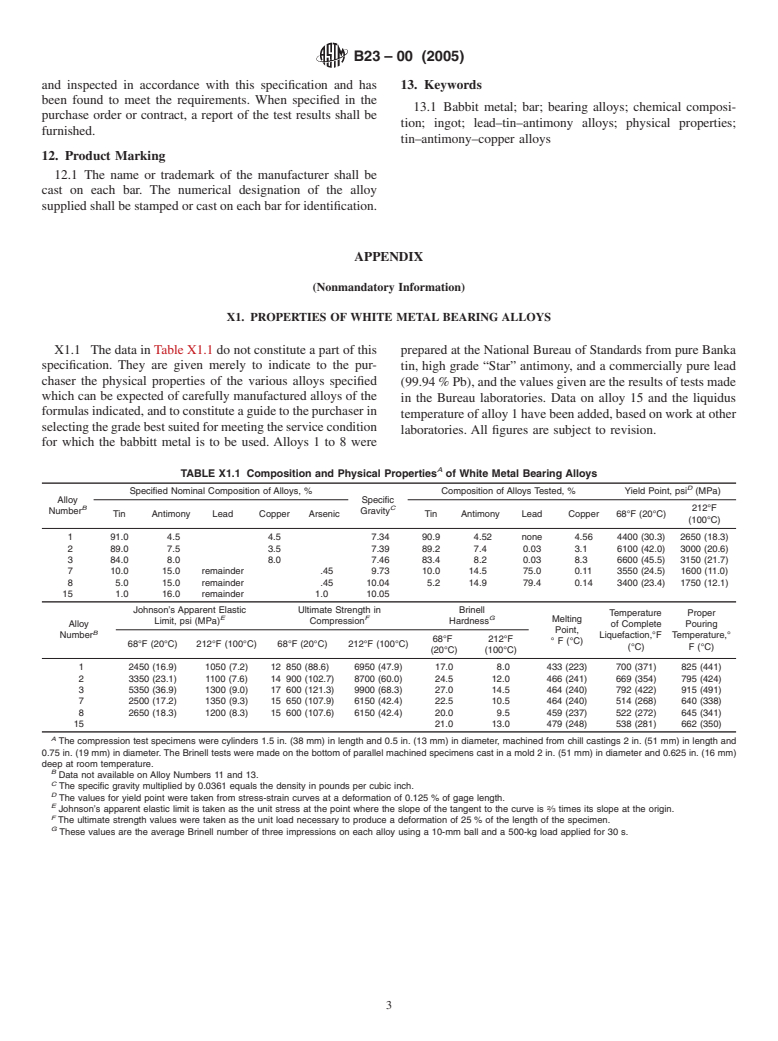

TABLE 1 Chemical Composition —wt% (range or maximum)

Alloy Number

Tin Base Lead Base

Chemical

Composition, %

1 2 3 11 7 8 13 15

UNS—L13910 UNS—L13890 UNS—L13840 UNS—L13870 UNS—L53585 UNS—L53565 UNS—L53346 UNS—L53620

B B B B

Tin remainder remainder remainder remainder 9.3–10.7 4.5–5.5 5.5–6.5 0.8–1.2

Antimony 4.0–5.0 7.0–8.0 7.5–8.5 6.0–7.5 14.0–16.0 14.0–16.0 9.5–10.5 14.5–17.5

B B B B

Lead 0.35 0.35 0.35 0.50 remainder remainder remainder remainder

Copper 4.0–5.0 3.0–4.0 7.5–8.5 5.0–6.5 0.50 0.50 0.50 0.6

Iron 0.08 0.08 0.08 0.08 0.10 0.10 0.10 0.10

Arsenic 0.10 0.10 0.10 0.10 0.30–0.60 0.30–0.60 0.25 0.8–1.4

Bismuth 0.08 0.08 0.08 0.08 0.10 0.10 0.10 0.10

Zinc 0.005 0.005 0.005 0.005 0.005 0.005 0.005 0.005

Aluminum 0.005 0.005 0.005 0.005 0.005 0.005 0.005 0.005

Cadmium 0.05 0.05 0.05 0.05 0.05 0.05 0.05 0.05

Total named 99.80 99.80 99.80 99.80

elements,

min

A

Alloy Number 9 was discontinued in 1946 and numbers 4, 5, 6, 10, 11, 12, 16, and 19 were discontinued in 1959. A new number 11, similar to SAE Grade 11, was

added in 1966.

B

To be determined by difference.

NOTE 1—With notched bars the saw cuts shall be distributed along the bar in a similar manner, avoiding if possible, saw cuts directly through a notch.

FIG. 1 Method of Sampling Unnotched Bar

7.3 When babbitt is furnished in bars under 5 lb (2.3 kg) in 8.3 For purposes of compliance with the specified chemical

weight, three bars shall be considered the equivalent of one bar composition limits, the reported analysis shall be rounded to

(6.1) for sampling purposes. These may be remelted in a clean the nearest unit in the right hand place of figures used in

utensil at a temperature slightly above the liquidus point of the expressing the limiting value, in accordance with the rounding

alloy, mixed thoroughly, poured into a cold mold forming a method of Practice E29.

convenient size bar, and then handled in accordance with 6.2.

9. Inspection

7.4 Sawings,thoroughlymixed,shallbeseparatedintothree

equal portions, each of which shall be placed in a sealed 9.1 Inspection of the material shall be made as agreed upon

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.