ASTM E1137/E1137M-08(2020)

(Specification)Standard Specification for Industrial Platinum Resistance Thermometers

Standard Specification for Industrial Platinum Resistance Thermometers

ABSTRACT

This specification establishes the physical, performance, and testing requirements, as well as resistance-temperature relationship and tolerances for metal-sheathed industrial platinum resistance thermometers (PRT) suitable for direct immersion temperature measurement. All materials including the sheath materials, sensing elements, insulation, connecting wire end closure materials, epoxy materials, and connecting wires shall be in accordance with specified requirements. The PRT shall be subjected to corresponding qualification tests to demonstrate conformance to the acceptance criteria of the following properties: insulation resistance; resistance versus temperature; minimum immersion length; pressure; thermal response time; vibration; self-heating; stability; thermoelectric effect; mechanical shock; and dimensions.

SIGNIFICANCE AND USE

4.1 This specification is written to provide common terminology, resistance versus temperature characteristics, accuracy classification, and inspection requirements for a specified configuration of a typical industrial platinum resistance thermometer (PRT).

4.2 This specification may be used as part of the documentation to support negotiations for the purchase and discussion of such thermometers.

SCOPE

1.1 This specification covers the requirements for metal-sheathed industrial platinum resistance thermometers (PRT's) suitable for direct immersion temperature measurement. It applies to PRT's with an average temperature coefficient of resistance between 0 and 100 °C of 0.385 %/°C and nominal resistance at 0 °C of 100 Ω or other specified value. This specification covers PRT's suitable for all or part of the temperature range −200 to 650 °C. The resistance-temperature relationship and tolerances are specified as well as physical, performance, and testing requirements.

1.2 The values of temperature in this specification are based on the International Temperature Scale of 1990 (ITS-90).2

1.3 The values stated in inch-pound units or SI (metric) units may be regarded separately as standard. The values stated in each system are not exact equivalents, and each system shall be independent of the other.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1137/E1137M −08 (Reapproved 2020)

Standard Specification for

Industrial Platinum Resistance Thermometers

ThisstandardisissuedunderthefixeddesignationE1137/E1137M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A269Specification for Seamless and Welded Austenitic

Stainless Steel Tubing for General Service

1.1 This specification covers the requirements for metal-

B167Specification for Nickel-Chromium-AluminumAlloys

sheathed industrial platinum resistance thermometers (PRT’s)

(UNS N06699), Nickel-Chromium-Iron Alloys (UNS

suitable for direct immersion temperature measurement. It

N06600, N06601, N06603, N06690, N06693, N06025,

applies to PRT’s with an average temperature coefficient of

N06045, and N06696), Nickel-Chromium-Cobalt-

resistance between 0 and 100 °C of 0.385%⁄°C and nominal

Molybdenum Alloy (UNS N06617), Nickel-Iron-

resistance at 0 °C of 100 Ω or other specified value. This

Chromium-Tungsten Alloy (UNS N06674), and

specification covers PRT’s suitable for all or part of the

E344Terminology Relating to Thermometry and Hydrom-

temperature range−200 to 650 °C. The resistance-temperature

etry

relationship and tolerances are specified as well as physical,

E644Test Methods for Testing Industrial Resistance Ther-

performance, and testing requirements.

mometers

1.2 Thevaluesoftemperatureinthisspecificationarebased

E1652Specification for Magnesium Oxide and Aluminum

on the International Temperature Scale of 1990 (ITS-90).

Oxide Powder and Crushable Insulators Used in the

1.3 The values stated in inch-pound units or SI (metric) Manufacture of Base Metal Thermocouples, Metal-

Sheathed Platinum Resistance Thermometers, and Noble

unitsmayberegardedseparatelyasstandard.Thevaluesstated

ineachsystemarenotexactequivalents,andeachsystemshall Metal Thermocouples

be independent of the other.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions:

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3.1.1 For definitions of terms used in this specification see

Terminology E344.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.2 Definitions of Terms Specific to This Standard:

1.5 This international standard was developed in accor- 3.2.1 connecting wire end closure, n—moisture barrier at

dance with internationally recognized principles on standard- the connecting wire end of the sheath.

ization established in the Decision on Principles for the 3.2.1.1 Discussion—The closure is intended to provide a

Development of International Standards, Guides and Recom- sealsufficienttopreventthesensor’sinsulationresistancefrom

mendations issued by the World Trade Organization Technical dropping below the minimum requirements.

Barriers to Trade (TBT) Committee.

3.2.2 connecting wires, n—wires that run from the element

through the connecting wire end closure and external to the

2. Referenced Documents

sheath.

2.1 ASTM Standards:

3.2.3 excitation, n—electrical current passing through the

element.

3.2.4 g-level, n—acceleration of an object relative to the

This specification is under the jurisdiction of ASTM Committee E20 on

local acceleration of gravity.

Temperature Measurement and is the direct responsibility of Subcommittee E20.03

3.2.4.1 Discussion—For example, a g-level of 5 is equiva-

on Resistance Thermometers.

Current edition approved May 1, 2020. Published May 2020. Originally lent to an acceleration of approximately

2 2

approved in 1987. Last previous edition approved in 2014 as E1137/E1137M–08

5×9.8 m⁄s =49.0 m⁄s .

(2014). DOI: 10.1520/E1137_E1137M-08R20.

3.2.5 minimum immersion length, n—depth that a thermom-

Preston-Thomas, H., “The International Temperature Scale of 1990 (ITS-90),”

Metrologia, Vol 27, No. 1, 1990, pp. 3–10, ibid, Vol 27, No. 2, 1990, p. 107

eter should be immersed, in a uniform temperature

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

environment, such that further immersion does not produce a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

change in indicated temperature greater than the specified

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. tolerance.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1137/E1137M − 08 (2020)

3.2.6 PRT design, n—generic term used to differentiate 6.1.6 Connection configuration; 2-Wire, 3-Wire, 4-Wire

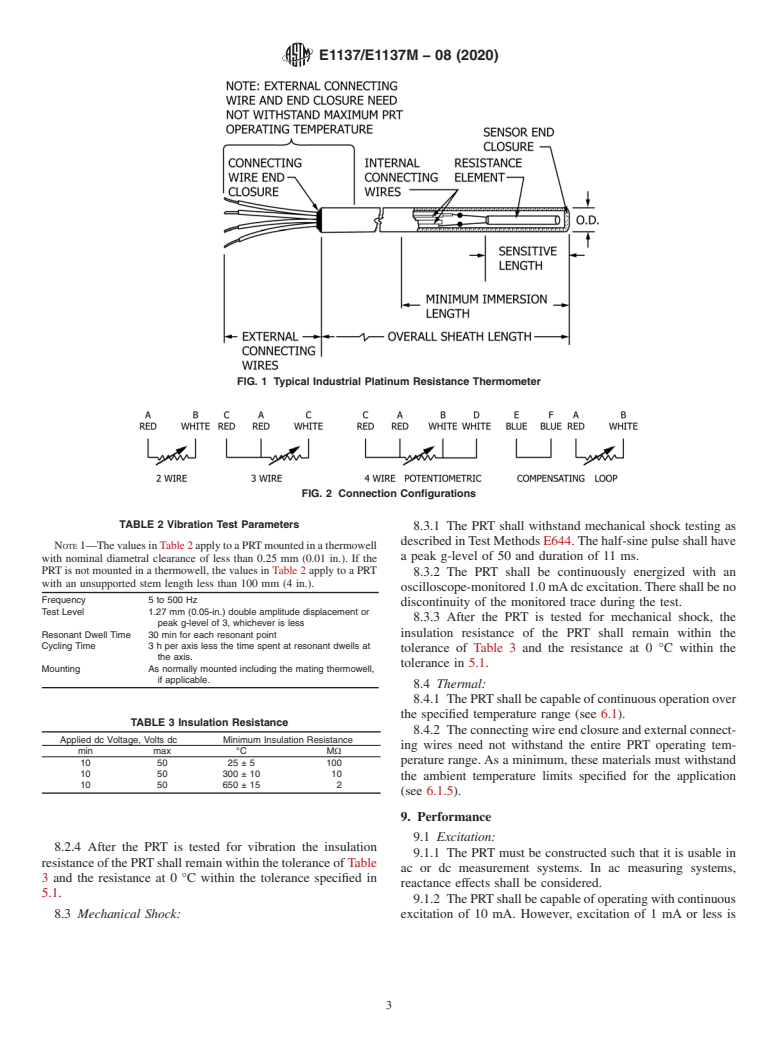

between different PRT construction details, such as element (potentiometric), and compensating loop (4-Wire) (see Fig. 2),

and connecting wire construction, insulation methods, sealing

6.1.7 Tolerance, (Grade A, or Grade B),

techniques,andmountingmethods(forexample,springloaded

6.1.8 Nominal resistance at 0 °C (100 Ω unless otherwise

or direct mounting).

specified), and

3.2.7 self-heating, n—change in temperature of the element

6.1.9 Serial Number identification requirement (mandatory

caused by the heating effect of the excitation.

if an individual calibration or test record will be maintained).

3.2.8 sheath, n—cylindrical metal tube with an integral

7. Materials and Manufacture

welded closure at the end in which the element is located.

7.1 All materials used shall be in accordance with the

4. Significance and Use

following requirements:

4.1 This specification is written to provide common

7.1.1 Sheath Materials—For temperatures not exceeding

terminology, resistance versus temperature characteristics, ac-

480 °C, austenitic stainless steel tubing, conforming to Speci-

curacy classification, and inspection requirements for a speci-

fication A269. For temperatures not exceeding 650 °C, high-

fied configuration of a typical industrial platinum resistance

nickel alloy tubing, conforming to Specification B167.

thermometer (PRT).

7.1.2 Sensing Element—Sensing element shall be platinum.

4.2 This specification may be used as part of the documen- 7.1.3 Insulation—The insulating material within the PRT

tation to support negotiations for the purchase and discussion

shallbecompatiblewiththetemperaturerange−200to650°C

of such thermometers. or as specified in 6.1.4. Magnesium oxide (MgO) and alumi-

numoxide(Al O )powdersandcrushableinsulatorsconform-

2 3

5. Classification of Tolerances

ing to Specification E1652 satisfy this requirement.

7.1.4 Connecting Wire End Closure Materials—Closure

5.1 The PRT shall conform to the resistance-temperature

materialsshallprovideabarrieragainstwaterandotherliquids

relation (see 9.2.1) within the following tolerances:

and generally prevent the penetration of water vapor. Any

Grade A56@0.1310.0017? t ? #°C (1)

material used shall be compatible with the ambient tempera-

Grade B56 0.2510.0042 ? t ? °C (2)

@ #

tures specified for the application (see 6.1.5).

where: 7.1.4.1 Typically, epoxy materials are used for ambient

temperatures less than 200 °C and moisture impervious ce-

| t | = value of temperature without regard to sign, °C.

ramic adhesives are used over 200 °C, but the connecting wire

5.1.1 The tolerances are given in Table 1 for a PRT with a

end closure shall not be limited to these materials if the end

nominal resistance of 100 Ω at 0 °C.

closure meets all other requirements of this specification.

7.1.5 Connecting Wires—Typically, materials of connecting

6. Ordering Information

wiresare:nickelplatedcopper,nickel,platinum,constantan,or

6.1 The purchase order documents shall specify the follow-

manganin. Individual connecting wires may be comprised of

inginformationtoensurethatthePRTisadequatelydescribed:

two or more different materials and sizes over their length to

6.1.1 The number of this specification,

accommodate different requirements internal and external to

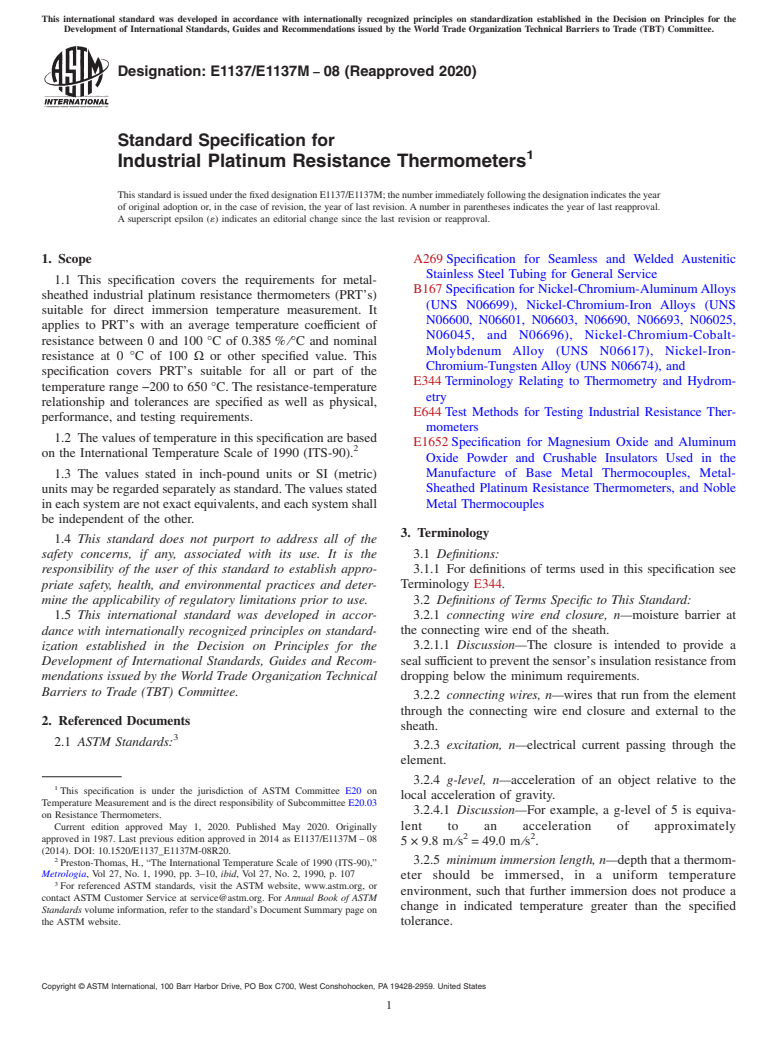

6.1.2 Sheath diameter and overall length (see Fig. 1),

thesensorsheath.Wheredifferentmaterialsareused,caremust

6.1.3 Sheath material,

be exercised in their selection to minimize thermoelectrically

6.1.4 Minimum and maximum sensed temperature,

induced measurement error (see 9.6). Any material used in

6.1.5 Maximum and minimum temperature at connecting

joining the connecting wires to the PRT element must with-

wire end closure,

stand the maximum operating temperature of the PRT.

8. Other Requirements

A,B

TABLE 1 Classification Tolerances

8.1 Pressure—The PRTshall withstand an external pressure

Temperature, t, Grade A Grade B

of 21 MPa (3000 psig) and shall be tested in accordance with

°C °C Ω °C Ω

−200 0.47 0.20 1.1 0.47 Test Methods E644 pressure test.The PRTshall remain within

−100 0.30 0.12 0.67 0.27

the tolerance specified in 5.1.

0 0.13 0.05 0.25 0.10

100 0.30 0.11 0.67 0.25

8.2 Vibration:

200 0.47 0.17 1.1 0.40

8.2.1 ThePRTshallwithstandvibrationtestingasdescribed

300 0.64 0.23 1.5 0.53

400 0.81 0.28 1.9 0.66 in Test Methods E644 using the test parameters in Table 2.

500 0.98 0.33 2.4 0.78

8.2.2 The PRT shall be mounted by installation in the

600 1.15 0.37 2.8 0.89

650 1.24 0.40 3.0 0.94 thermowell or by threaded connection to simulate normal

A

mounting procedure as limited by Table 2.

The table represents values for 3-wire and 4-wire PRT’s. Caution must be

exercised with 2-wire PRT’s because of possible errors caused by connecting

8.2.3 The PRT shall be continuously energized with an

wires.

B oscilloscope-monitored1.0mAdcexcitation.Thereshallbeno

Tabulated values are based on elements of 100.0 Ω (nominal) at 0 °C.

discontinuity of the monitored trace during the test.

E1137/E1137M − 08 (2020)

FIG. 1 Typical Industrial Platinum Resistance Thermometer

FIG. 2 Connection Configurations

TABLE 2 Vibration Test Parameters

8.3.1 The PRT shall withstand mechanical shock testing as

describedinTestMethodsE644.Thehalf-sinepulseshallhave

NOTE1—ThevaluesinTable2applytoaPRTmountedinathermowell

a peak g-level of 50 and duration of 11 ms.

with nominal diametral clearance of less than 0.25 mm (0.01 in.). If the

PRTis not mounted in a thermowell, the values in Table 2 apply to a PRT

8.3.2 The PRT shall be continuously energized with an

with an unsupported stem length less than 100 mm (4 in.).

oscilloscope-monitored1.0mAdcexcitation.Thereshallbeno

Frequency 5 to 500 Hz

discontinuity of the monitored trace during the test.

Test Level 1.27 mm (0.05-in.) double amplitude displacement or

8.3.3 After the PRT is tested for mechanical shock, the

peak g-level of 3, whichever is less

Resonant Dwell Time 30 min for each resonant point insulation resistance of the PRT shall remain within the

Cycling Time 3 h per axis less the time spent at resonant dwells at

tolerance of Table 3 and the resistance at 0 °C within the

the axis.

tolerance in 5.1.

Mounting As normally mounted including the mating thermowell,

if applicable.

8.4 Thermal:

8.4.1 ThePRTshallbecapableofcontinuousoperationover

the specified temperature range (see 6.1).

TABLE 3 Insulation Resistance

8.4.2 Theconnectingwireendclosureandexternalconnect-

Applied dc Voltage, Volts dc Minimum Insulation Resistance

ing wires need not withstand the entire PRT operating tem-

min max °C MΩ

perature range.As a minimum, these materials must withstand

10 50 25 ± 5 100

10 50 300 ± 10 10

the ambient temperature limits specified for the application

10 50 650 ± 15 2

(see 6.1.5).

9. Performance

9.1 Excitation:

8.2.4 After the PRT is tested for vibration the insulation

9.1.1 The PRT must be constructed such that it is usable in

resistanceofthePRTshallremainwithinthetoleranceofTable

ac or dc measurement systems. In ac measuring systems,

3 and the resistance at 0 °C within the tolerance specified in

reactance effects shall be considered.

5.1.

9.1.2 ThePRTshallbecapableofoperatingwithcontinuous

8.3 Mechanical Shock: excitation of 10 mA. However, excitation of 1 mA or less is

E1137/E1137M − 08 (2020)

recommendedtominimizemeasurementerrorsassociatedwith sion length shall be less than 51 mm (2 in.). The limit of

self-heating (see 9.4). uncertaintyshallbe0.13and0.25°CforGradeAandGradeB

PRT’s respectively.

9.2 Resistance Versus Temperature Relation:

9.2.1 Resistance-Temperature Equations—Within the speci- 9.9 End Seal Integrity—When tested in accordance with

fied tolerances (see 5.1), the PRT shall have resistance- Test Methods E644, the PRT shall meet the minimum insula-

temperature characteristics defined as follows: tion resistance value at 25 6 5 °C as specified in Table 3.

for the range−200 °C ≤ t < 0 °C:

10. Dimensions, Mass, and Permissible Variations

2 3

R 5 R 11At1Bt 1C t 2 100 t Ω (3)

@ ~ ! #

t o

10.1 A PRT without a process fitting or other means of

for the range 0 °C ≤ t ≤ 650 °C:

attachment is shown in Fig. 1.

R 5 R @11At1Bt # Ω (4)

t o

10.2 PRT’s manufactured in accordance with this specifica-

tion shall be able to pass through the straightness ring gauge

where:

with the gauge sizes listed in Table 6.

t = temperature (ITS-90), °C,

R = resistance at temperature (t),

t

11. Required Tests

R = resistance at 0 °C,

o

−3 −1

A = 3.9083×10 °C ,

11.1 Qualification Tests—The PRT shall be subjected to the

−7 −2

B = −5.775×10 °C , and

tests outlined in Table 7 to demonstrate conformance to this

−12 −4

C = −4.183×10 °C .

specification. The manufacturer shall perform these tests at

least one time to qualify the PRT design. Thereafter, it is

9.2.2 Resistance Table—Resistance values of the PRT ver-

recommended these tests be used on a periodic basis to verify

sus temperature using the equations of 9.2.1 and R of 100 Ω

o

process control.

are given in Table 4.

11.1.1 Qualification Test Report—The manufacturer shall

9.2.3 Inverse equations that may be used to compute values

prepare and retain a qualification test report applicable to the

of temperature (°C) as a function of resistance are given in

PRT design that documents the model number, test procedure

Appendix X1.

(byreferencetoTestMethodsE644andthisspecification),and

9.3 Insulation Resistance—The insulation resistance be-

the results obtained.

tween each connecting wire and the sheath shall meet the

11.2 Acceptance Tests—The manufacturer shall verify that

requirements of Table 3 when tested in accordance with Test

the PRT to be delivered satisfies the following minimum test

Methods E644. The PRT shall be tested with at least the

requirements: resistance at 0 °C (see 5.1), room temper

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.