ASTM D6926-04

(Practice)Standard Practice for Preparation of Bituminous Specimens Using Marshall Apparatus

Standard Practice for Preparation of Bituminous Specimens Using Marshall Apparatus

SIGNIFICANCE AND USE

Compacted bituminous mixture specimens molded by this procedure are used for various physical tests such as stability, flow, indirect tensile strength, fatigue, creep, and modulus. Density and voids analysis are also conducted on specimens for mixture design and evaluation of field compaction.

Note 1—Uncompacted mixtures are used for determination of theoretical maximum specific gravity.

SCOPE

1.1 This practice covers preparation and compaction of 102 mm (4 in.) diameter by nominal 64 mm (2.5 in.) high cylindrical bituminous paving mixture specimens by means of the original manual Marshall method and subsequent variations of the method. This practice is intended for use with laboratory and plant produced bituminous mixtures with aggregate up to 25 mm (1 in.) maximum size and for recompaction of asphalt pavement samples.

1.2 There are three types of Marshall compaction apparatus in use. The following types of hammer arrangements are included in this practice:

1.2.1 Manually held hammer handle attached to a flat compaction foot through a spring loaded swivel and is hand operated (original standard developed by the Corps of Engineers).

1.2.2 Hammer handle restrained laterally (fixed) but not vertically attached to a flat compaction foot through a spring loaded swivel and is either mechanically or hand operated. There may or may not be a constant surcharge on top of the hammer handle. Mechanical hammers are available that operate at (1) nominal 55 blows per minute and (2) equal to or greater than 75 blows per minute.

1.2.3 Hammer handle restrained laterally (fixed) with constant surcharge on top of hammer, a slanted compaction foot, rotating mold base, and is mechanically operated.

1.3 Although the mass and height of mass drop for each apparatus are the same, density achieved in compacted specimens with the same number of blows will be different. It is up to the user to establish the specific required number of blows to be used for compaction of the specimen in relation to the field.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6926–04

Standard Practice for

Preparation of Bituminous Specimens Using Marshall

Apparatus

This standard is issued under the fixed designation D6926; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2171 Test Method for Viscosity of Asphalts by Vacuum

Capillary Viscometer

1.1 This practice covers preparation and compaction of 102

D2493 Standard Viscosity-Temperature Chart for Asphalts

mm (4 in.) diameter by nominal 64 mm (2.5 in.) high

D4402 Test Method for Viscosity Determination ofAsphalt

cylindrical bituminous paving mixture specimens by means of

at Elevated Temperatures Using a Rotational Viscometer

theoriginalmanualMarshallmethodandsubsequentvariations

E11 SpecificationforWovenWireTestSieveClothandTest

of the method.This practice is intended for use with laboratory

Sieves

and plant produced bituminous mixtures with aggregate up to

25 mm (1 in.) maximum size and for recompaction of asphalt

3. Significance and Use

pavement samples.

3.1 Compacted bituminous mixture specimens molded by

1.2 There are three types of Marshall compaction apparatus

this procedure are used for various physical tests such as

in use. The following types of hammer arrangements are

stability, flow, indirect tensile strength, fatigue, creep, and

included in this practice:

modulus. Density and voids analysis are also conducted on

1.2.1 Manually held hammer handle attached to a flat

specimens for mixture design and evaluation of field compac-

compaction foot through a spring loaded swivel and is hand

tion.

operated (original standard developed by the Corps of Engi-

neers).

NOTE 1—Uncompacted mixtures are used for determination of theo-

1.2.2 Hammer handle restrained laterally (fixed) but not retical maximum specific gravity.

vertically attached to a flat compaction foot through a spring

4. Apparatus

loaded swivel and is either mechanically or hand operated.

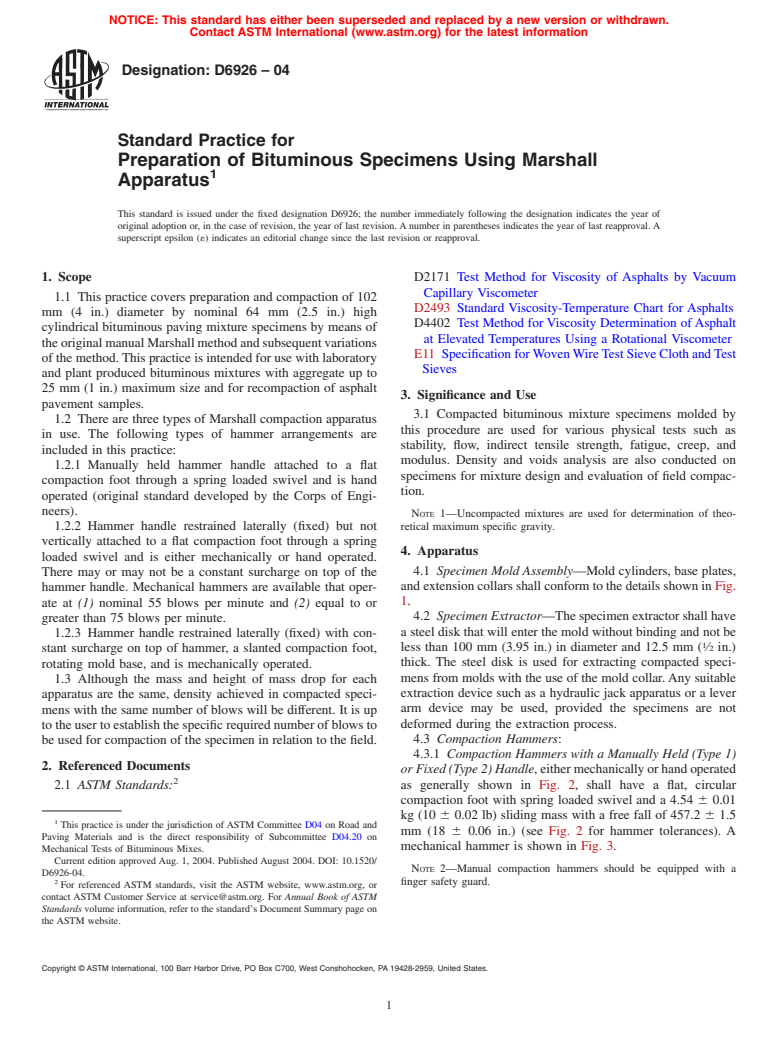

4.1 Specimen Mold Assembly—Mold cylinders, base plates,

There may or may not be a constant surcharge on top of the

and extension collars shall conform to the details shown in Fig.

hammer handle. Mechanical hammers are available that oper-

1.

ate at (1) nominal 55 blows per minute and (2) equal to or

4.2 SpecimenExtractor—The specimen extractor shall have

greater than 75 blows per minute.

a steel disk that will enter the mold without binding and not be

1.2.3 Hammer handle restrained laterally (fixed) with con-

less than 100 mm (3.95 in.) in diameter and 12.5 mm ( ⁄2 in.)

stant surcharge on top of hammer, a slanted compaction foot,

thick. The steel disk is used for extracting compacted speci-

rotating mold base, and is mechanically operated.

mens from molds with the use of the mold collar.Any suitable

1.3 Although the mass and height of mass drop for each

extraction device such as a hydraulic jack apparatus or a lever

apparatus are the same, density achieved in compacted speci-

arm device may be used, provided the specimens are not

mens with the same number of blows will be different. It is up

deformed during the extraction process.

to the user to establish the specific required number of blows to

4.3 Compaction Hammers:

be used for compaction of the specimen in relation to the field.

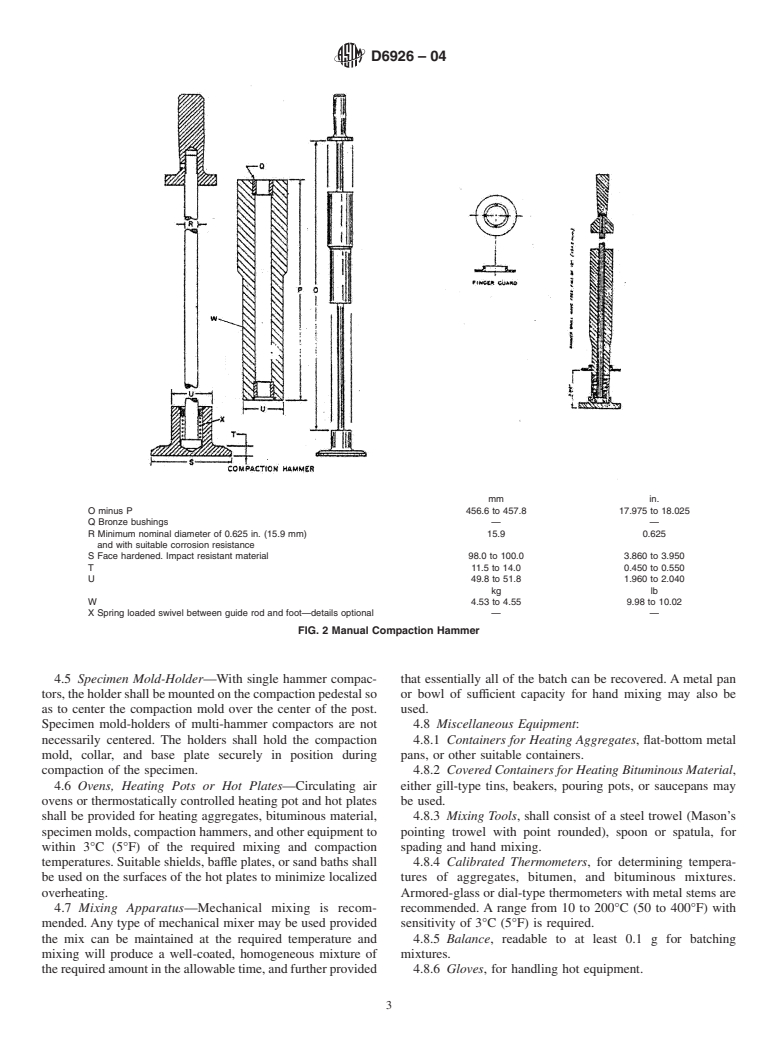

4.3.1 Compaction Hammers with a Manually Held (Type 1)

2. Referenced Documents

orFixed(Type2)Handle,eithermechanicallyorhandoperated

2.1 ASTM Standards: as generally shown in Fig. 2, shall have a flat, circular

compaction foot with spring loaded swivel and a 4.54 6 0.01

kg (10 6 0.02 lb) sliding mass with a free fall of 457.2 6 1.5

This practice is under the jurisdiction of ASTM Committee D04 on Road and

mm (18 6 0.06 in.) (see Fig. 2 for hammer tolerances). A

Paving Materials and is the direct responsibility of Subcommittee D04.20 on

mechanical hammer is shown in Fig. 3.

Mechanical Tests of Bituminous Mixes.

Current edition approved Aug. 1, 2004. Published August 2004. DOI: 10.1520/

NOTE 2—Manual compaction hammers should be equipped with a

D6926-04.

finger safety guard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6926–04

mm in.

A 104.1 to 105.4 4.100 to 4.150

B 109.1 to 110.2 4.295 to 3.439

C 114.0 to 115.8 4.490 to 4.560

D 107.0 to 109.7 4.211 to 4.320

E 101.3 to 101.7 3.990 to 4.005

F 119.9 to 121.4 4.720 to 4.780

G 101.1 to 101.3 3.980 to 3.990

H 69.3 to 70.4 2.730 to 2.770

J 7.0 to 7.2 0.235 to 0.285

K 6.1 to 6.7 0.235 to 0.265

L 86.9 to 87.9 3.420 to 3.460

M 3.0 to 4.8 0.120 to 0.190

N 12.3 to 14.9 0.485 to 0.585

FIG. 1 Compaction Mold

ing all specimens with the same hammer and with no other hammers

4.3.2 Compaction Hammers with a Fixed Hammer Handle,

operating.

surcharge on top of handle, constantly rotating base, and

mechanically operated (Type 3) as generally shown in Fig. 4

4.4 Compaction Pedestal—The compaction pedestal shall

shallhaveaslanted,circulartampingfaceanda4.54 60.01kg

consist of a nominal 203.2 by 203.2 mm (8 by 8 in.) wooden

(10 6 0.02 lb) sliding weight with a free fall of 457.2 6 1.5

post approximately 457 mm (18 in.) long capped with a steel

mm (18 6 0.06 in.) (see Fig. 2 and Fig. 4 for hammer and

plateapproximately304.8by304.8mm(12by12in.)and25.4

tamping face bevel angle and tolerances, respectively). A

mm (1 in.) thick. The wooden post shall be oak, yellow pine,

rotating mechanism is incorporated in the base. The base

or other wood having an average dry density of 670 to 770

3 3

rotation rate and hammer blow rate shall be 18 to 30 rpm and

kg/m (42 to 48 lb/ft ). The wooden post shall be secured by

64 6 4 blows per minute, respectively.

bolts through four angle brackets to a solid concrete slab. The

steel cap shall be firmly fastened to the post. The pedestal

NOTE 3—Type 3 Marshall hammer apparatus are available in versions

assemblyshallbeinstalledsothatthepostisplumbandthecap

with more than one hammer. Multiple hammer operation will affect

specimen density. Best comparative results will be obtained by compact- is level.

D6926–04

mm in.

O minus P 456.6 to 457.8 17.975 to 18.025

Q Bronze bushings ——

R Minimum nominal diameter of 0.625 in. (15.9 mm) 15.9 0.625

and with suitable corrosion resistance

S Face hardened. Impact resistant material 98.0 to 100.0 3.860 to 3.950

T 11.5 to 14.0 0.450 to 0.550

U 49.8 to 51.8 1.960 to 2.040

kg lb

W 4.53 to 4.55 9.98 to 10.02

X Spring loaded swivel between guide rod and foot—details optional — —

FIG. 2 Manual Compaction Hammer

4.5 Specimen Mold-Holder—With single hammer compac- that essentially all of the batch can be recovered. A metal pan

tors,theholdershallbemountedonthecompactionpedestalso or bowl of sufficient capacity for hand mixing may also be

as to center the compaction mold over the center of the post. used.

Specimen mold-holders of multi-hammer compactors are not 4.8 Miscellaneous Equipment:

necessarily centered. The holders shall hold the compaction 4.8.1 Containers for Heating Aggregates, flat-bottom metal

mold, collar, and base plate securely in position during pans, or other suitable containers.

compaction of the specimen. 4.8.2 Covered Containers for Heating Bituminous Material,

4.6 Ovens, Heating Pots or Hot Plates—Circulating air either gill-type tins, beakers, pouring pots, or saucepans may

ovens or thermostatically controlled heating pot and hot plates be used.

shall be provided for heating aggregates, bituminous material, 4.8.3 Mixing Tools, shall consist of a steel trowel (Mason’s

specimen molds, compaction hammers, and other equipment to pointing trowel with point rounded), spoon or spatula, for

within 3°C (5°F) of the required mixing and compaction spading and hand mixing.

temperatures. Suitable shields, baffle plates, or sand baths shall 4.8.4 Calibrated Thermometers, for determining tempera-

be used on the surfaces of the hot plates to minimize localized tures of aggregates, bitumen, and bituminous mixtures.

overheating. Armored-glass or dial-type thermometers with metal stems are

4.7 Mixing Apparatus—Mechanical mixing is recom- recommended. A range from 10 to 200°C (50 to 400°F) with

mended. Any type of mechanical mixer may be used provided sensitivity of 3°C (5°F) is required.

the mix can be maintained at the required temperature and 4.8.5 Balance, readable to at least 0.1 g for batching

mixing will produce a well-coated, homogeneous mixture of mixtures.

therequiredamountintheallowabletime,andfurtherprovided 4.8.6 Gloves, for handling hot equipment.

D6926–04

FIG. 4 Slanted Foot, Rotating Base Compactor

25 to 19 mm (1 to ⁄4 in.)

FIG. 3 Mechanical Hammer

3 1

19 to 12.5 mm ( ⁄4 to ⁄2 in.)

1 3

12.5 to 9.5 mm ( ⁄2 to ⁄8 in.)

9.5to4.75mm( ⁄8 to No. 4)

4.75 to 2.36 mm (No. 4 to No. 8)

4.8.7 Marking Crayons, for identifying specimens.

2.36 mm (Passing No. 8)

4.8.8 Scoop, flat bottom, for batching aggregates.

5.2 Determination of Mixing and Compacting Tempera-

4.8.9 Spoon, large, for placing the mixture in the specimen

tures:

molds.

5.2.1 The asphalt cement used in preparing the samples

must be heated to produce viscosities of 0.17 6 0.02 Pa·s and

5. Test Specimens

0.28 6 0.03 Pa·s for mixing and compacting, respectively. An

5.1 Preparation of Aggregates—Dry aggregates to constant

example of a viscosity temperature chart is given in F

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.