ASTM F970-22

(Test Method)Standard Test Method for Measuring Recovery Properties of Floor Coverings after Static Loading

Standard Test Method for Measuring Recovery Properties of Floor Coverings after Static Loading

SIGNIFICANCE AND USE

3.1 This test method is a meaningful test for determining the indentation recovery properties of uninstalled resilient floor covering.3

3.2 This test method is intended solely for the purpose of determining compliance, where applicable, with static load requirements set forth in resilient flooring product specifications under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings.

3.3 As testing is conducted on uninstalled flooring, results are not an indicator of the floor covering's installed performance.3

SCOPE

1.1 This test method is intended for use in determining the recovery properties of uninstalled resilient floor covering after long-term indentation test, 24 h under the load specified in the detail specification. The reported value, residual indentation, is the depth of the depression remaining 24 h after removal of the specified load.

1.2 This test method is intended to evaluate ex-factory floor covering and is not intended to evaluate the performance of installed floor coverings.

1.3 This test method is not intended for use in evaluating the long-term indentation resistance or recovery properties, or both, of resilient floor coverings at loads above those listed in the Precision and Bias statement as described in Section 10.

1.3.1 Testing at loads above 250 psi is outside the scope of this test method.

1.4 Testing with any other indentor plate other than the exact plates listed in Section 4 is outside the scope of this test method.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F970 − 22

Standard Test Method for

Measuring Recovery Properties of Floor Coverings after

1

Static Loading

ThisstandardisissuedunderthefixeddesignationF970;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method is intended for use in determining the 2.1 ASTM Standards:

recovery properties of uninstalled resilient floor covering after E691 Practice for Conducting an Interlaboratory Study to

long-term indentation test, 24 h under the load specified in the Determine the Precision of a Test Method

detail specification. The reported value, residual indentation, is F386 Test Method for Thickness of Resilient Flooring Ma-

the depth of the depression remaining 24 h after removal of the terials Having Flat Surfaces

specified load. F387 Test Method for Measuring Thickness of Resilient

Floor Covering With Foam Layer

1.2 This test method is intended to evaluate ex-factory floor

F1914 Test Methods for Short-Term Indentation and Re-

covering and is not intended to evaluate the performance of

sidual Indentation of Resilient Floor Covering

installed floor coverings.

1.3 Thistestmethodisnotintendedforuseinevaluatingthe

3. Significance and Use

long-term indentation resistance or recovery properties, or

3.1 Thistestmethodisameaningfultestfordeterminingthe

both, of resilient floor coverings at loads above those listed in

indentation recovery properties of uninstalled resilient floor

the Precision and Bias statement as described in Section 10.

3

covering.

1.3.1 Testing at loads above 250 psi is outside the scope of

3.2 This test method is intended solely for the purpose of

this test method.

determining compliance, where applicable, with static load

1.4 Testing with any other indentor plate other than the

requirements set forth in resilient flooring product specifica-

exact plates listed in Section 4 is outside the scope of this test

tions under the jurisdiction of ASTM Committee F06 on

method.

Resilient Floor Coverings.

1.5 The values stated in inch-pound units are to be regarded

3.3 As testing is conducted on uninstalled flooring, results

as standard. The values given in parentheses are mathematical

are not an indicator of the floor covering’s installed perfor-

conversions to SI units that are provided for information only

3

mance.

and are not considered standard.

1.6 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

4.1 The following apparatus shall be used:

responsibility of the user of this standard to establish appro-

4.2 Conditioning Room, providing the standard laboratory

priate safety, health, and environmental practices and deter-

atmosphere of 50 % 6 5 % relative humidity at a temperature

mine the applicability of regulatory limitations prior to use.

of 73.4 °F 6 3.6 °F (23 °C 6 2.0 °C).

1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4.3 Indentation Machine, as described in Section 12 and

ization established in the Decision on Principles for the

pictured in Fig. 2 of Test Method F1914.

Development of International Standards, Guides and Recom-

4.4 Indentor Plates, each constructed of a piece of 2 in.

mendations issued by the World Trade Organization Technical

(50.8 mm) square stainless steel, 0.240 in. 6 0.005 in.

Barriers to Trade (TBT) Committee.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

1

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Floor Coverings and is the direct responsibility of Subcommittee F06.20 on Test Standards volume information, refer to the standard’s Document Summary page on

Methods. the ASTM website.

3

Current edition approved Oct. 1, 2022. Published October 2022. Originally For additional information, see Resilient Floor Covering Institute (RFCI)

approved in 1987. Last previous edition approved in 2017 as F970–17. DOI: document, Static LimitTesting of Resilient Flooring Products, available from RFCI,

10.1520/F0970–22. 115 Broad Street, Suite 201, La Grange, GA 30240, www.rfci.com.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

1

---------------------- Page: 1 ----------------------

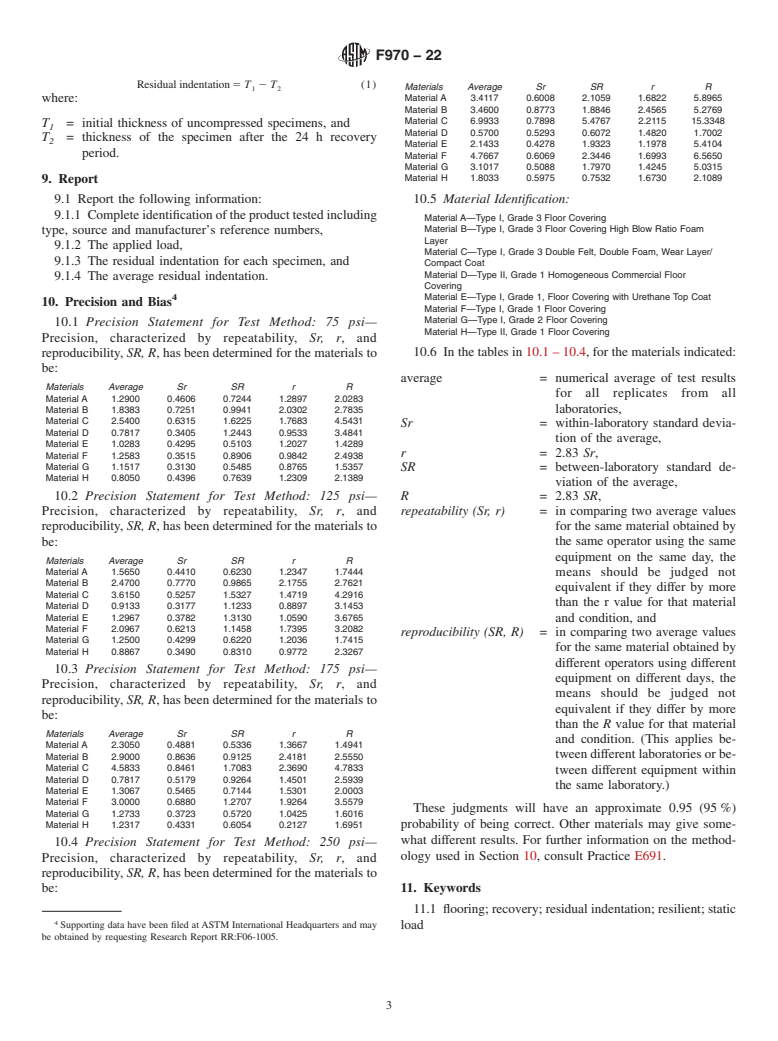

F970 − 22

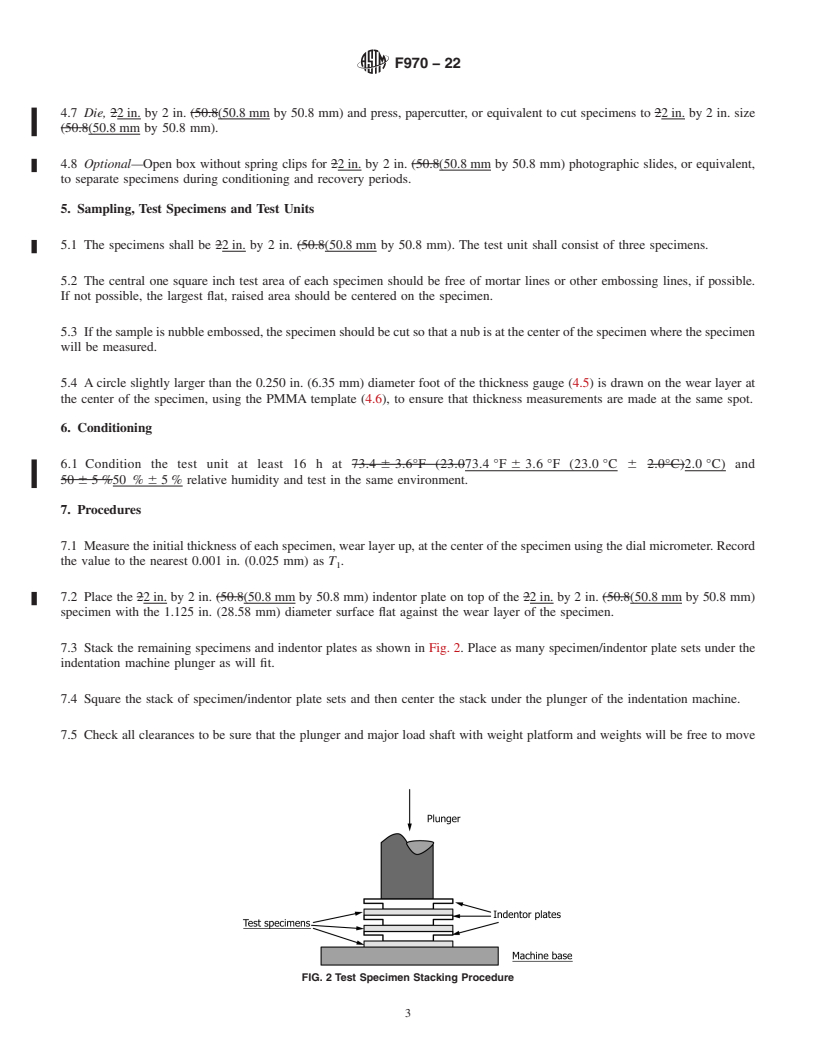

(6.1 mm 6 0.1 mm) thick, with one side turned to 1.125 in. 6. Conditionin

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F970 − 17 F970 − 22

Standard Test Method for

Measuring Recovery Properties of Floor Coverings after

1

Static Loading

This standard is issued under the fixed designation F970; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is intended for use in determining the recovery properties of uninstalled resilient floor covering after

long-term indentation test, 24 h under the load specified in the detail specification. The reported value, residual indentation, is the

depth of the depression remaining 24 h after removal of the specified load.

1.2 This test method is intended to evaluate ex-factory floor covering and is not intended to evaluate the performance of installed

floor coverings.

1.3 This test method is not intended for use in evaluating the long-term indentation resistance or recovery properties, or both, of

resilient floor coverings at loads above those listed in the Precision and Bias statement as described in Section 10.

1.3.1 Testing at loads above 250 psi is outside the scope of this test method.

1.4 Testing with any other indentor plate other than the exact plates listed in Section 4 is outside the scope of this test method.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

F386 Test Method for Thickness of Resilient Flooring Materials Having Flat Surfaces

F387 Test Method for Measuring Thickness of Resilient Floor Covering With Foam Layer

1

This test method is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.20 on Test Methods.

Current edition approved May 1, 2017Oct. 1, 2022. Published May 2017October 2022. Originally approved in 1987. Last previous edition approved in 20152017 as

F970–15.–17. DOI: 10.1520/F0970–17.10.1520/F0970–22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F970 − 22

F1914 Test Methods for Short-Term Indentation and Residual Indentation of Resilient Floor Covering

3. Significance and Use

3.1 This test method is a meaningful test for determining the indentation recovery properties of uninstalled resilient floor

3

covering.

3.2 This test method is intended solely for the purpose of determining compliance, where applicable, with static load requirements

set forth in resilient flooring product specifications under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings.

3

3.3 As testing is conducted on uninstalled flooring, results are not an indicator of the floor covering’s installed performance.

4. Apparatus

4.1 The following apparatus shall be used:

4.2 Conditioning Room, providing the standard laboratory atmosphere of 50 6 5 %50 % 6 5 % relative humidity at a temperature

of 73.4 6 3.6°F (23 6 2.0°C).73.4 °F 6 3.6 °F (23 °C 6 2.0 °C).

4.3 Indentation Machine, as described in Section 12 and pictured in Fig. 2 of Test Method F1914.

4.4 Indentor Plates, each constructed of a piece of 2-in.2 in. (50.8 mm) square stainless steel, 0.240 6 0.005 in. (6.1 6 0.1 mm)

0.240 in. 6 0.005 in. (6.1 mm 6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.