ASTM C1075-93(1997)

(Practice)Standard Practices for Sampling Uranium-Ore Concentrate

Standard Practices for Sampling Uranium-Ore Concentrate

SCOPE

1.1 These practices are intended to provide the nuclear industry with procedures for obtaining representative bulk samples from uranium-ore concentrates (UOC) (see Specification C967).

1.2 These practices also provide for obtaining a series of representative secondary samples from the original bulk sample for the determination of moisture and other test purposes, and for the preparation of pulverized analytical samples (see Test Methods C1022).

1.3 These practices consist of a number of alternative procedures for sampling and sample preparation which have been shown to be satisfactory through long experience in the nuclear industry. These procedures are described in the following order. Stage Procedure Section Primary Sampling One-stage falling stream 4 Two-stage falling stream 5 Auger 6 Secondary Sampling Straight-path (reciprocating) 7 Rotating (Vezin) 8, 9 Sample Preparation 10 Concurrent-drying 11 to 13 Natural moisture 14 to 16 Calcination 17, 18 Sample Packaging 19 Wax sealing 20 Vacuum sealing 21

1.3.1 The primary and secondary sampling stages can be organized in the following way: PRIMARY SAMPLING (sections 4 to 6) ------------------------------------

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: C 1075 – 93 (Reapproved 1997)

Standard Practices for

Sampling Uranium-Ore Concentrate

This standard is issued under the fixed designation C 1075; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope given stage, however, each procedure must be regarded as a

whole. It is highly inadvisable to mix elements belonging to

1.1 These practices are intended to provide the nuclear

different procedures.

industry with procedures for obtaining representative bulk

1.4 These procedures do not include requirements for

samples from uranium-ore concentrates (UOC) (see Specifica-

health, safety, and accountability. The observance of these

tion C 967).

practices does not relieve the user of the obligation to be aware

1.2 These practices also provide for obtaeining a series of

of and to conform to all applicable international, federal, state,

representative secondary samples from the original bulk

and local regulations pertaining to processing, shipping, or

sample for the determination of moisture and other test

using uranium-ore concentrates. (Guidance is provided in CFR,

purposes, and for the preparation of pulverized analytical

10, Chapter 1.)

samples (see Test Methods C 1022).

1.5 The values stated in SI units are to be regarded as the

1.3 These practices consist of a number of alternative

standard. The values given in parentheses are for information

procedures for sampling and sample preparation which have

only.

been shown to be satisfactory through long experience in the

1.6 This standard does not purport to address all of the

nuclear industry. These procedures are described in the follow-

safety problems, if any, associated with its use. It is the

ing order.

responsibility of the user of this standard to establish appro-

Stage Procedure Section

priate safety and health practices and determine the applica-

Primary Sampling One-stage falling stream 4

bility of regulatory limitations prior to use.

Two-stage falling stream 5

Auger 6

2. Referenced Documents

Secondary Sampling Straight-path (reciprocating) 7

Rotating (Vezin) 8, 9

2.1 ASTM Standards:

Sample Preparation 10

C 967 Specification for Uranium Ore Concentrate

Concurrent-drying 11-13

C 1022 Test Methods for Chemical and Atomic Absorption

Natural moisture 14-16

Calcination 17, 18

Analysis of Uranium-Ore Concentrate

Sample Packaging 19

2.2 Other Document:

Wax sealing 20

CFR 10 Nuclear Materials Licensing Code of Federal Regu-

Vacuum sealing 21

lations, Chapter 1

1.3.1 The primary and secondary sampling stages can be

organized in the following way:

3. General Requirements

3.1 Material Requirements:

3.1.1 The uranium-ore concentrates shall be free-flowing

and of a particle size not to exceed 6 mm (0.25 in.) or such

other limit agreed upon between contracting parties.

3.1.2 The average moisture content shall not exceed 5.0 %

weight of the uranium-ore concentrates.

3.1.3 The material shall be shipped to the sampling plant in

1.3.2 It is possible to combine the various elements of these

200-L (55-gal) standard steel drums that are fitted with steel

stages in different ways to give satisfactory results depending

lids and equipped with suitable gasket and sealing rings to

on the agreed requirements of the contracting parties. For a

ensure weatherproofing. The drums shall be constructed so that

the top of the drum is fully open when the lid is removed.

These practices are under the jurisdiction of ASTM Committee C26 on Nuclear

Fuel Cycle and are the direct responsibility of Subcommittee C26.02 on Fuel and

Fertile Material Specifications. Annual Book of ASTM Standards, Vol 12.01.

Current edition approved April 15, 1993. Published June 1993. Originally Available from Superintendent of Documents, U.S. Government Printing

published as C 1075 – 86. Last previous edition C 1075 – 86. Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1075

3.1.4 The number of drums in a sampling lot shall not freely at a uniform, controlled rate. All of the material in a lot

exceed 90 and the gross weight shall not exceed 45 metric tons passes through the system and is subject to incremental

(100 000 lb).

sampling.

3.1.5 A minimum number of drums in a sampling lot may be

4.2 Sampling Equipment Requirements:

established depending upon the sampling procedure used.

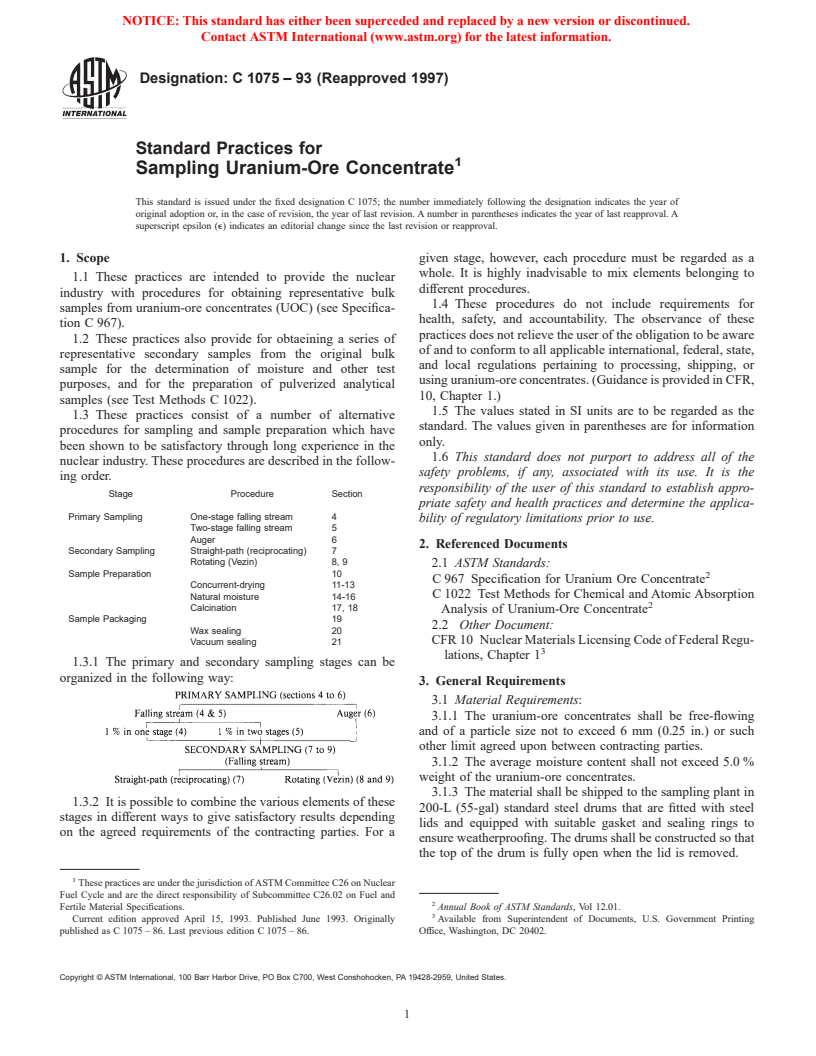

4.2.1 A schematic diagram of a typical falling-stream sam-

3.2 Sampling Equipment Requirements:

pling facility is shown in Fig. 1. Subsequent procedures are

3.2.1 Care shall be taken in the design and operation of the

described by reference to this equipment.

sampling and all associated equipment to minimize the ex-

4.2.2 The flow of material through the falling-stream system

changes of air between the atmosphere and the sampling

shall be controlled by a rotary valve discharging to the hopper

system. For obvious safety reasons dust-carrying internal air

or pan of the first stage vibrating feeder. The rate of flow should

must be prevented from escaping the system. This is achieved

−2 3 3

not exceed 4.5 3 10 ·m (1.6 ft )/min and also should be

by means of dust collectors. The latter, however, shall be

controlled so that the cutter obtains from the falling stream at

designed and operated in such a way that a minimum amount

−2 3 3

least 1 cut/2.8 3 10 ·m (1.0 ft ) of material.

of external air shall be allowed into the system. The purpose of

this is (1) to limit the exchanges of moisture between the

4.2.3 The first stage vibrating feeder should be adjusted so

atmosphere and the UOC and (2) to prevent a size-selective

that the depth of the material in the trough (pan) does not

dedusting. In any case, the amount of dust escaping the

exceed 50 mm (2.0 in.), and that the entire vertical cross

sampling operations must be kept to a minimum.

section of the falling stream is totally intercepted by the cutter

3.2.2 The scales for the gross and tare weighings of the

head.

drums shall be capable of reading to the nearest 0.2 kg (0.5 lb)

4.2.4 The samplers should be designed and constructed as

and shall be fitted with a print-out or data processing system, or

follows:

both. They shall have a capacity of 600 kg (1300 lb). The

4.2.4.1 Approximately 1 % of the falling stream shall be

weigh scale shall be calibrated and adjusted if required, at the

diverted by the cutter. With small lots (for example, less than

beginning, middle, and end of each lot weighed. Test weights

10 tonnes), however, a larger percentage may be implemented

shall be certified by a statutory authority and shall be traceable

in order to fulfill the requirements of the secondary sampling

to national or state standards.

stage.

3.2.3 All sampling containers shall be clean and dry before

usage. 4.2.4.2 The horizontal linear speed of cutter heads shall not

exceed 15 cm (6 in.)/s.

4. Primary Sampling, Falling Stream—1 % In One Stage

4.2.4.3 The width of the cutter head shall be no less than 30

4.1 Scope—The falling-stream procedure provides for re- mm (1.25 in.), that is, a minimum of five times the allowable

moving a large number of increments of the material as it falls particle size.

FIG. 1 Schematic Diagram of Falling-Stream Primary Sampler In One Stage

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1075

4.2.4.4 It is recommended that the cutter heads be con- 5. Primary Sampling, Falling Stream—1 % In Two

structed of stainless steel to improve their durability and Stages

reliability.

5.1 Scope—The falling-stream procedure provides for re-

4.2.4.5 The top edges of the cutter heads shall be beveled to

moving a large number of increments of the material as it falls

form knife edges.

freely at a uniform, controlled rate. All of the material in a lot

4.3 Procedure for Obtaining the Primary Sample:

passes through the system and is subject to incremental

sampling.

4.3.1 Clean and dry the tops of the drums if necessary,

transfer them by means of a roller conveyor to the weigh scale,

5.2 Special Sampling Equipment Requirements:

and record the gross weight to 60.2 kg (60.5 lb).

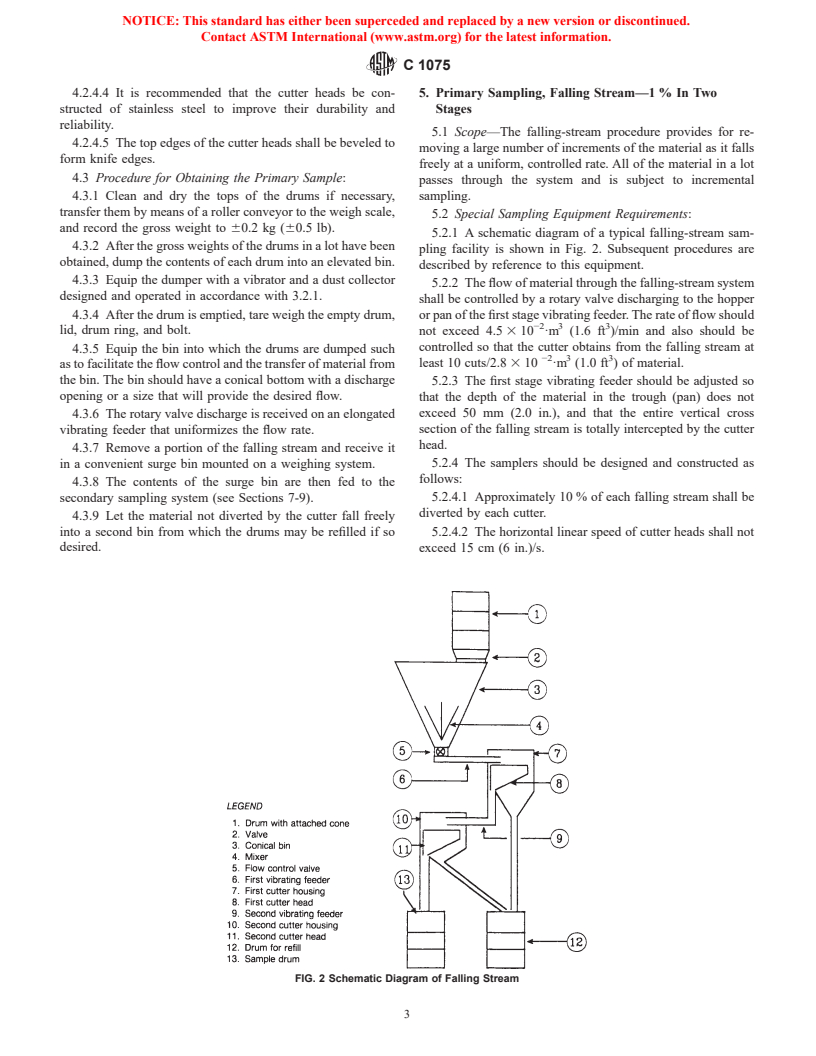

5.2.1 A schematic diagram of a typical falling-stream sam-

4.3.2 After the gross weights of the drums in a lot have been

pling facility is shown in Fig. 2. Subsequent procedures are

obtained, dump the contents of each drum into an elevated bin.

described by reference to this equipment.

4.3.3 Equip the dumper with a vibrator and a dust collector

5.2.2 The flow of material through the falling-stream system

designed and operated in accordance with 3.2.1.

shall be controlled by a rotary valve discharging to the hopper

4.3.4 After the drum is emptied, tare weigh the empty drum,

or pan of the first stage vibrating feeder. The rate of flow should

−2 3 3

lid, drum ring, and bolt.

not exceed 4.5 3 10 ·m (1.6 ft )/min and also should be

controlled so that the cutter obtains from the falling stream at

4.3.5 Equip the bin into which the drums are dumped such

−2 3 3

least 10 cuts/2.8 3 10 ·m (1.0 ft ) of material.

as to facilitate the flow control and the transfer of material from

the bin. The bin should have a conical bottom with a discharge

5.2.3 The first stage vibrating feeder should be adjusted so

opening or a size that will provide the desired flow.

that the depth of the material in the trough (pan) does not

exceed 50 mm (2.0 in.), and that the entire vertical cross

4.3.6 The rotary valve discharge is received on an elongated

section of the falling stream is totally intercepted by the cutter

vibrating feeder that uniformizes the flow rate.

head.

4.3.7 Remove a portion of the falling stream and receive it

in a convenient surge bin mounted on a weighing system. 5.2.4 The samplers should be designed and constructed as

follows:

4.3.8 The contents of the surge bin are then fed to the

secondary sampling system (see Sections 7-9). 5.2.4.1 Approximately 10 % of each falling stream shall be

diverted by each cutter.

4.3.9 Let the material not diverted by the cutter fall freely

into a second bin from which the drums may be refilled if so 5.2.4.2 The horizontal linear speed of cutter heads shall not

desired. exceed 15 cm (6 in.)/s.

FIG. 2 Schematic Diagram of Falling Stream

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

C 1075

5.2.4.3 The width of the cutter head shall be no less than 30 6.2.2.1 A conical top fitted with a flow-control valve if the

mm (1.25 in.), that is, a minimum of five times the allowable reciprocating cutter procedure is to be used for secondary

particle size. sampling, or

5.2.5 It is recommended that the cutter heads be constructed 6.2.2.2 A plain lid fixed by a metal band and bolt closure if

of stainless steel to improve their durability and reliability. the Vezin procedure is to be used for secondary sampling.

5.2.6 The top edges of the cutter heads shall be beveled to 6.2.3 In order to achieve the operating limits required for the

form knife edges. auger-sampling system the following design parameters are

5.3 Obtaining the Primary Sample Procedure: recommended:

5.3.1 Clean and dry the tops of the drums if necessary, 6.2.3.1 The auger shall be constructed of suitable material

transfer them by means of a roller conveyor to the weigh scale, (for example, tool or stainless steel) and shall have the

and record the gross weight to 60.2 kg (60.5 lb). following dimensions:

5.3.2 After the gross weights of the drums in a lot have been (1) Auger Tube—The outside diameter shall be 50 to 60 mm

obtained, dump the contents of each drum into an elevated bin. (1.968 to 2.375 in.) and the inside diameter shall be 43 mm

5.3.3 Equip the dumper with a vibrator and a dust collection (2.375 to 1.687 in.).

designed and operated in accordance with the conditions of (2) Length of Auger Helix Within the Auger Tube, shall be

3.2.1.

approximately 1400 mm (55 in.).

5.3.4 After the drum is emptied, tare weigh the empty drum,

(3) Pitch of Helix, shall be approximately 25 mm (1 in.)

lid, drum ring, and bolt.

apart.

5.3.5 Equip the bin into which the drums are dumped such

(4) In operation, the end of the auger should protrude 6 to 25

as to facilitate the flow control and the transfer of material from

mm (0.25 to 1.0 in.) below the auger tube.

the bin. The bin should have a conical bottom with a discharge

6.2.3.2 The auger shall be made to have a minimum

opening of a size that will provide the desired flow.

clearance allowing free rotation within the auger tube. The

5.3.6 Set the rotary valve to deliver approximately 4.2 to

auger shall be capable of being rotated electrically and, when

−2

3 3

4.5 3 10 ·m /min (1.5 to 1.6 ft /min). This rate should not

operating, shall turn at approximately 240 r/min.

vary during the course of sampling of the entire lot.

6.2.4 The auger sampling system may be used as a single or

5.3.7 Remove a portion of the falling stream and divert it to

double facility depending on design. In the latter case, two

a second vibrating elongated feeder and cutter of similar design

drums are sampled simultaneously with the two augers feeding

with a reciprocating cutter.

a common hopper that discharges by means of a 75-mm (3-in.)

5.3.8 Direct the material diverted by the second stage cutter

flexible tube into a single sample drum of 200-L (55-gal)

to a tared primary sample container, and close with a suitable

capacity.

lid depending on the secondary sampling procedure to be used

6.3 Obtaining the Primary Sample Procedure:

(see Sections 7-9).

6.3.1 Clean and dry the tops of the drums if necessary,

5.3.9 Let the material not diverted by the first- and second-

transfer them by means of a roller conveyor to the weigh scale,

stage cutters fall freely into a second bin from which the drums

and record the gross weight to 60.2 kg (60.5 lb). Pass the

may be refilled if so desired.

drums to the auger cabinet which shall be fitted with dust

5.3.10 Since approximately 10 % of each falling stream is

extraction and filtration equipment.

diverted, the primary sample container will contain approxi-

6.3.2 Remove the bolt and band from the drum, followed by

mately 1 % of the en

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.