ASTM C1134-90(2001)

(Test Method)Standard Test Method for Water Retention of Rigid Thermal Insulations Following Partial Immersion

Standard Test Method for Water Retention of Rigid Thermal Insulations Following Partial Immersion

SCOPE

1.1 This test method determines the amount of water retained (including surface water) by rigid block and board thermal insulations used in building construction applications after these materials have been partially immersed in liquid water for prescribed time intervals under isothermal conditions. This test method is intended to be used for the characterization of materials in the laboratory. It is not intended to simulate any particular environmental condition that may be encountered in building construction applications.

1.2 This test method does not address all the possible mechanisms of water intake and retention and related phenomena for rigid thermal insulations. It relates only to those conditions outlined in 1.1. Determination of moisture accumulation in thermal insulations due to complete immersion, water vapor transmission, internal condensation, freeze-thaw cycling, or a combination of these effects requires different test procedures.

1.3 Each partial immersion interval is followed by a brief free-drainage period. This test method does not address or attempt to quantify the drainage characteristics of materials. Therefore, results for materials with different internal structure and porosity, such as cellular materials and fibrous materials, may not be directly comparable. Also, test results for specimens of different thickness may not be directly comparable because of porosity effects. The surface characteristics of a material also affect drainage. Specimens with rough surfaces may retain more surface water than specimens with smooth surfaces, and surface treatment during specimen preparation may affect water intake and retention. Therefore, results for materials with different surface characteristics may not be directly comparable.

1.4 For most materials the size of the test specimens is small compared with the size of the products actually installed in the field. If the surface-to-volume ratios for the test specimens and the corresponding products are different, the test results may be misleading.

1.5 The values stated in SI units are to be regarded as standard, but the results may also be reported in inch-pound (I-P) units. In this standard I-P units are given in parentheses for information purposes and may be approximate.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1134–90(Reapproved2001)

Standard Test Method for

Water Retention of Rigid Thermal Insulations Following

Partial Immersion

This standard is issued under the fixed designation C 1134; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 The values stated in SI units are to be regarded as

standard, but the results may also be reported in inch-pound

1.1 This test method determines the amount of water re-

(I-P) units. In this standard I-P units are given in parentheses

tained (including surface water) by rigid block and board

for information purposes and may be approximate.

thermal insulations used in building construction applications

1.6 This standard does not purport to address all of the

after these materials have been partially immersed in liquid

safety concerns, if any, associated with its use. It is the

water for prescribed time intervals under isothermal condi-

responsibility of the user of this standard to establish appro-

tions. This test method is intended to be used for the charac-

priate safety and health practices and determine the applica-

terization of materials in the laboratory. It is not intended to

bility of regulatory limitations prior to use.

simulate any particular environmental condition that may be

encountered in building construction applications.

2. Referenced Documents

1.2 This test method does not address all the possible

2.1 ASTM Standards:

mechanisms of water intake and retention and related phenom-

C 168 Terminology Relating to Thermal Insulation

ena for rigid thermal insulations. It relates only to those

E 691 Practice for Conducting an Interlaboratory Study to

conditions outlined in 1.1. Determination of moisture accumu-

Determine the Precision of a Test Method

lation in thermal insulations due to complete immersion, water

vaportransmission,internalcondensation,freeze-thawcycling,

3. Terminology

or a combination of these effects requires different test proce-

3.1 Definitions—Terminology C 168 applies to terms used

dures.

in this test method.

1.3 Each partial immersion interval is followed by a brief

3.2 Descriptions of Terms Specific to This Standard:

free-drainage period. This test method does not address or

3.2.1 WR —short-term water retention rating, the average

S

attempt to quantify the drainage characteristics of materials.

of the water retained following the 0.75-h and 3.00-h partial

Therefore, results for materials with different internal structure

immersion intervals, kilograms per square metre (percent by

and porosity, such as cellular materials and fibrous materials,

volume) (for materials tested at 25.4 mm (1.00 in.) thickness).

may not be directly comparable. Also, test results for speci-

(See 4.2.)

mens of different thickness may not be directly comparable

3.2.2 WR —long-term water retention rating, the water

L

because of porosity effects. The surface characteristics of a

retained following the 168-h partial immersion interval, kilo-

material also affect drainage. Specimens with rough surfaces

grams per square metre (percent by volume) (for materials

may retain more surface water than specimens with smooth

tested at 25.4 mm (1.00 in.) thickness). (See 4.2.)

surfaces, and surface treatment during specimen preparation

may affect water intake and retention. Therefore, results for

4. Significance and Use

materials with different surface characteristics may not be

4.1 Materials less than or equal to 15.0 mm (0.59 in.) in

directly comparable.

thickness shall not be tested in accordance with this test

1.4 Formostmaterialsthesizeofthetestspecimensissmall

method in order to avoid complete immersion of the speci-

compared with the size of the products actually installed in the

mens. This type of exposure is beyond the scope of this test

field. If the surface-to-volume ratios for the test specimens and

method.

thecorrespondingproductsaredifferent,thetestresultsmaybe

4.2 Materials shall be tested at both actual product thickness

misleading.

and 25.4 mm (1.00 in.) thickness provided the materials can be

cut to a thickness of 25.4 mm without changing the original

This test method is under the jurisdiction ofASTM Committee C16 onThermal

Insulation and is the direct responsibility of Subcommittee C16.33 on Thermal

Insulation Finishes and Vapor Transmission. Annual Book of ASTM Standards, Vol 04.06.

Current edition approved Jan. 10, 1990. Published February 1990. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1134

character of the materials. If a product cannot be cut without

changing the original character of the material, the test report

shall contain an appropriate note to this effect. Results shall be

reportedonthebasisofequalnominalwettedspecimensurface

area (in units of kilograms per square metre) for materials

tested at actual product thickness and on the basis of equal

specimen volume (in units of percent by volume) for materials

tested at 25.4 mm thickness. If a product cannot be cut to a

thickness of 25.4 mm or if the actual product thickness is less

than 25.4 mm but greater than 15.0 mm (0.59 in.), the product

(a) Typical dimensions for an immersion tank

shall only be tested at actual product thickness and results only

reportedonthebasisofequalnominalwettedspecimensurface

area.

4.2.1 By reporting results on the basis of equal nominal

wetted specimen surface area, specimens of different thick-

nesses can be compared equitably. For some specimens, the

water intake and retention primarily may depend on the

nominal wetted surface area available for water intake.

4.2.2 By reporting results on the basis of equal specimen

(b) Typical dimensions for a noncorrosive support for the specimens

volume, specimens can be compared equitably using units that

FIG. 1 Immersion Tank

commonly are selected to represent results of water intake

testing (percent by volume). For some materials, water intake

than is required, in which case a sensitivity of at least 0.1 % of

and retention primarily may depend on the volume of the

the total mass of the specimen after immersion and the

specimen available for water intake.

weighing container is acceptable. See 7.4.1. To achieve these

4.2.3 In most cases water retention is a secondary perfor-

sensitivities, two different balances may be required.

mance characteristic that has an influence on a primary

5.4 Weighing Container—The weighing container shall be

performance characteristic, such as thermal performance, sur-

made of a nonabsorbent, waterproof, lightweight material and

face accumulation of moisture (that may contribute to fungal

shall be large enough to allow a specimen to be laid flat in the

growth), localized collection of electrolytes (that may contrib-

container.

ute to corrosion), etc. Depending on the primary performance

5.5 Linear Measuring Instrument—The linear measuring

characteristic that is of interest, the preferred units for use in

instrument shall be capable of measuring specimen dimensions

comparing the water retention of different materials may be

to the nearest 0.2 mm (0.01 in.).

either kilograms per square metre or percent by volume.

5.6 Distilled or Deionized Water—Distilled or deionized

4.3 Immersion times in addition to those required by this

water shall be used for testing.

test method may be selected provided that all parties involved

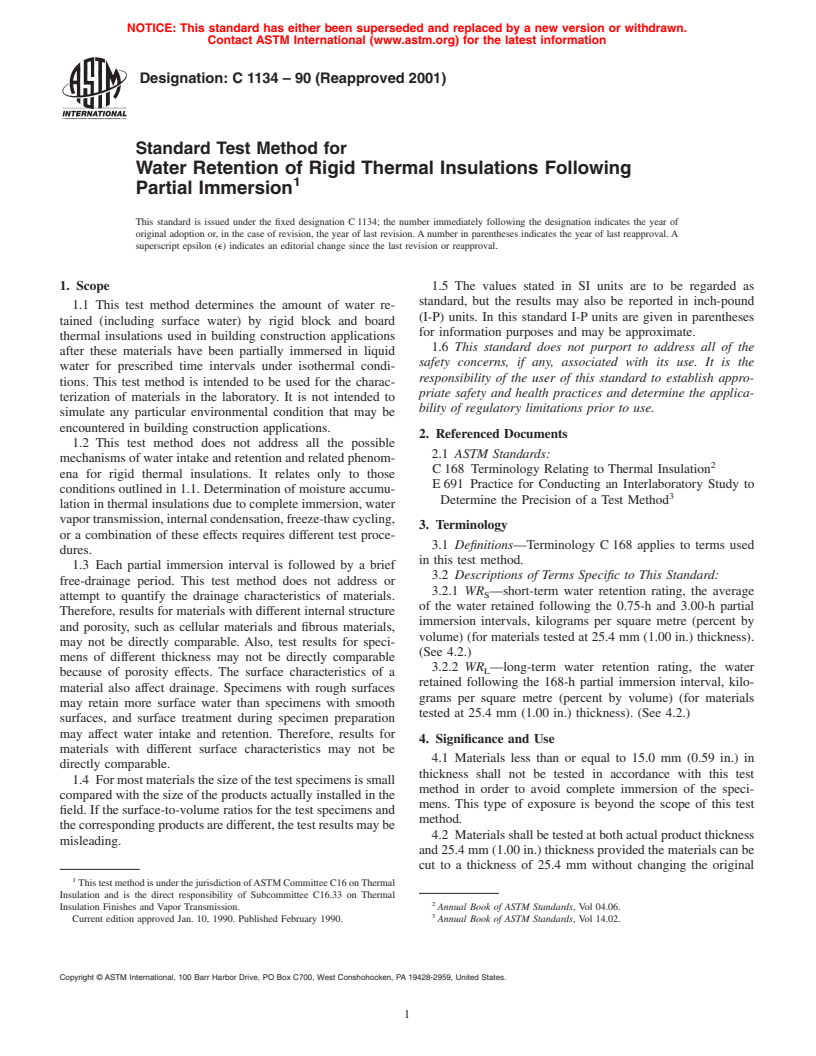

5.7 Drainage Rack—The drainage rack shall be similar to

are in agreement.

that shown in Figs. 2 and 3.

4.4 The water retention characteristics of materials may be

affected by conditions such as elevated temperatures or chemi-

6. Test Specimens

cal exposures.

6.1 Six test specimens shall be selected randomly from each

5. Apparatus

sample. Only three specimens are required if the product is

5.1 Test Chamber—Thetestchamberorroomwherethetest only to be tested at the actual product thickness or if the actual

product thickness is 25.4 mm (1.00 in.). See 4.2.

is to be run shall be maintained at a temperature of 236 2°C

(73 6 4°F) and a relative humidity of 50 65%. 6.2 The test specimens shall be square with a length and

width of 3006 10 mm (11.8 6 0.4 in.). The thickness of three

5.2 Immersion Tank—The immersion tank shall consist of

an open tank of sufficient size to accommodate at least three of the specimens shall be the same as that of the product or

specimens. Included in the construction of the tank shall be a sample from which the specimens are taken. The thickness of

means for securing the specimens in a level position, that is, a the other three specimens shall be 25.4 6 1.6 mm (1.00 6 0.06

noncorrosive support for the bottom surface of the specimens in.),providedthematerialisgreaterthan25.4mminthickness.

and a similar constraining device for the top surface. The Specimens shall be cut to this size from thicker stock if

support and constraining devices shall not contact more than appropriate. See 4.2.

15 % of the specimen surfaces. The pressure exerted on the 6.3 Specimen Preparation:

specimens by the constraining device for the top surface shall 6.3.1 Materials normally produced with natural skins or

be limited to that required to counteract any buoyant force specially cut surfaces shall be tested with at least one skin or

exerted by the specimens at the beginning of the test. The surface intact, and that skin or surface shall be placed in

immersion tank shall be provided with a water overflow level, contact with the water when the test is conducted. The test

as shown in Fig. 1. report shall contain an appropriate note.

5.3 Balance—The balance shall have a sensitivity of at least 6.3.2 Composite materials normally produced with facings

0.1 g. For some measurements such a sensitivity may be more or laminates may be tested with or without facings, as required

C1134

FIG. 2 Drainage Rack for Three Specimens

FIG. 4 Measurement Locations for Determining Test Specimen

Dimensions

FIG. 3 Test Specimen in Drainage Rack

relative humidity of 506 5 %.Allow at least 24 h for the initial

by the appropriate material specification. The test report shall

conditioning period and then at least 4 h for each additional

contain an appropriate note.

period as needed. Continue conditioning until specimens reach

6.3.3 Care must be taken to avoid making indentations

constant mass as indicated by a change in mass of 0.2 g or less

when handling specimens. Any specimens having surface

between successive weighings. Record the dry mass, M,of

indentations greater than 5.0 mm (0.20 in.) in depth or any

each specimen to the nearest 0.1 g.

specimens damaged during preparation shall be rejected and

7.3 Using nonabsorbent dummy blocks of the same size as

replaced by new specimens prior to testing.

the test specimens, adjust the support and constraining devices

7. Procedure

so that the dummy blocks are horizontal and level. Make

certain that the immersion tank is also level. Adjust the water

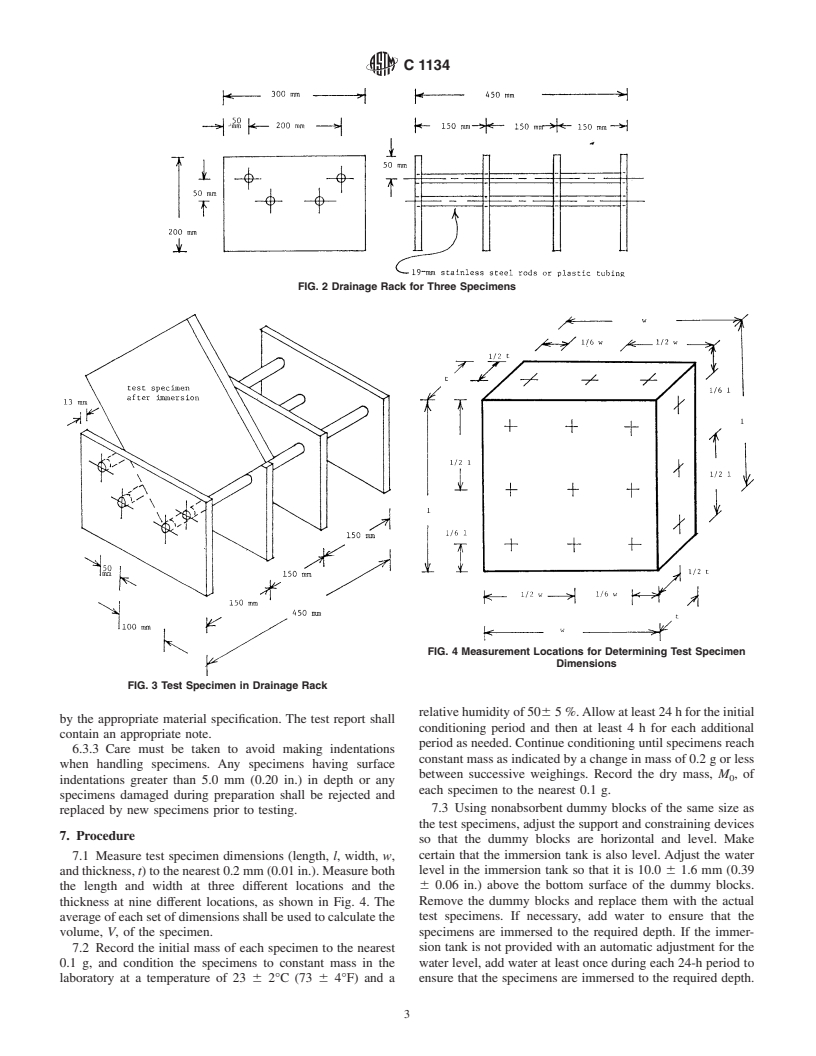

7.1 Measure test specimen dimensions (length, l, width, w,

level in the immersion tank so that it is 10.0 6 1.6 mm (0.39

and thickness, t) to the nearest 0.2 mm (0.01 in.). Measure both

the length and width at three different locations and the 6 0.06 in.) above the bottom surface of the dummy blocks.

Remove the dummy blocks and replace them with the actual

thickness at nine different locations, as shown in Fig. 4. The

average of each set of dimensions shall be used to calculate the test specimens. If necessary, add water to ensure that the

specimens are immersed to the required depth. If the immer-

volume, V, of the specimen.

7.2 Record the initial mass of each specimen to the nearest sion tank is not provided with an automatic adjustment for the

water level, add water at least once during each 24-h period to

0.1 g, and condition the specimens to constant mass in the

laboratory at a temperature of 23 6 2°C (73 6 4°F) and a ensure that the specimens are immersed to the required depth.

C1134

7.4 Remove and weigh the specimens at the following time

WR 2) = water retention of the specimen for time, t,

t(kg/m

intervals: 0.75 6 0.03 h, 3.00 6 0.15 h, and 168 6 4 h. These

kg/m ,

times are required. Longer or intermediate immersion times

M = mass of the specimen after immersion time,

t

may be used to provide more information.

t,g,and

M = mass of the conditioned specimen, g.

7.4.1 Determine the mass of the weighing container to the

8.3.2 For each specimen tested at a thickness of 25.4 mm

nearest 0.1 g. Place each specimen on the drainage rack, as

(1.00 in.), calculate the water retention, WR , expressed in

shown in Fig. 3. Allow 6.0 6 0.5 min. for the drainage of

t(%)

percent by volume, for each immersion time, t, as follows:

water. Remove each specimen from the drainage rack and

place it in the weighing container with the wet side down.

M 2 M

t 0

WR 5 ·100 (4)

t~%!

Weigh each specimen and its container to the nearest 0.1 g or

V

to within 0.1 % of the total mass of the specimen and the

where:

weighing container. (Choose the sensitivity that is largest in

WR = water retention of the specimen for time, t,

magnitude or most convenient to use.) Subtract the mass of the t(%)

percent by volume.

weighing container from the total mass, and record the mass of

each specimen in grams to the appropriate sensitivity. Data

NOTE 1—The density of water is assumed to be 1.00 g/cm at 23°C

should be clearly identified by the letter M with the subscript (73°F).

t

indicating the immersion time, for example M for the mass

0.75

8.4 Calculate the short-term water retention rating, WR , for

S

after a 0.75-h immersion time. Clean and dry the weighing

each specimen, expressed in kilogram per square metre and

container if it is going to be reused, and reweigh it before

percent by volume (for materials tested at 25.4 mm (1.00 in.)

proceeding with the next specimen.

thickness) by averaging the water retention for the 0.75-h and

7.4.2 Return the specimens to the immersion tank, making

3.00-h partial-immersion intervals, determined for each speci-

sure each specimen is placed in the tank with the wet side

men in accordance with 8.3, as follows:

down. Total time elapsed between removal and return of the

WR 2 1 WR 2

0.75~kg/m ! 3~kg/m !

specimens shall not be longer than 8 min.

WR 5 (5)

S~kg/m !

7.4.3 Repeat the procedures given in 7.4.1 and 7.4.2 for

each immersion time.

where:

WR ) = short-term water retention rating of the

S(kg/m

specimen, kg/m .

8.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.