ASTM C613-19

(Test Method)Standard Test Method for Constituent Content of Composite Prepreg by Soxhlet Extraction

Standard Test Method for Constituent Content of Composite Prepreg by Soxhlet Extraction

SIGNIFICANCE AND USE

5.1 The prepreg volatiles content, matrix content, reinforcement content, and filler content of composite prepreg materials are used to control material manufacture and subsequent fabrication processes, and are key parameters in the specification and production of such materials, as well as in the fabrication of products made with such materials.

5.2 The extraction products resulting from this test method (the extract, the residue, or both) can be analyzed to assess chemical composition and degree of purity.

SCOPE

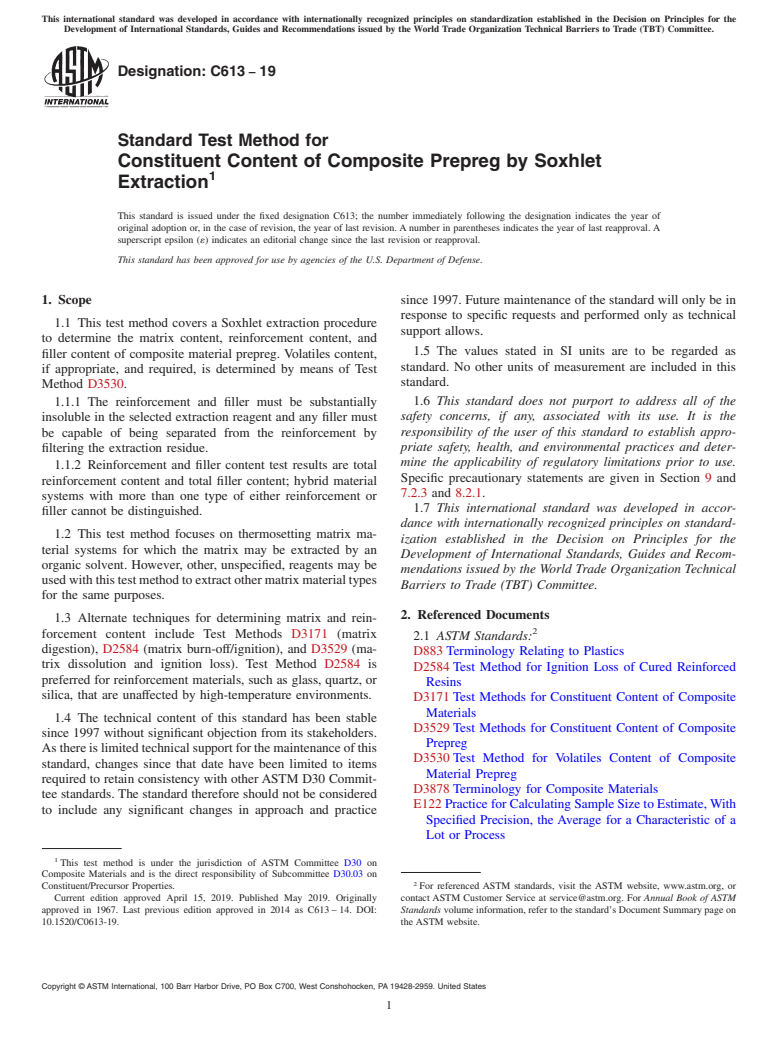

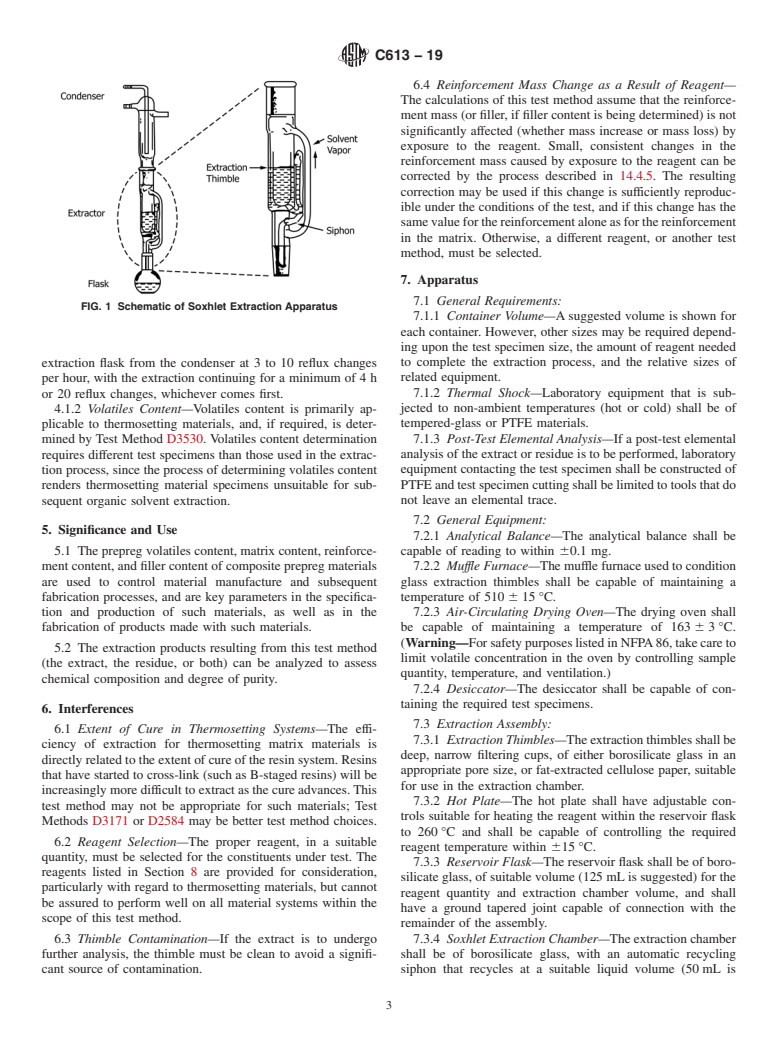

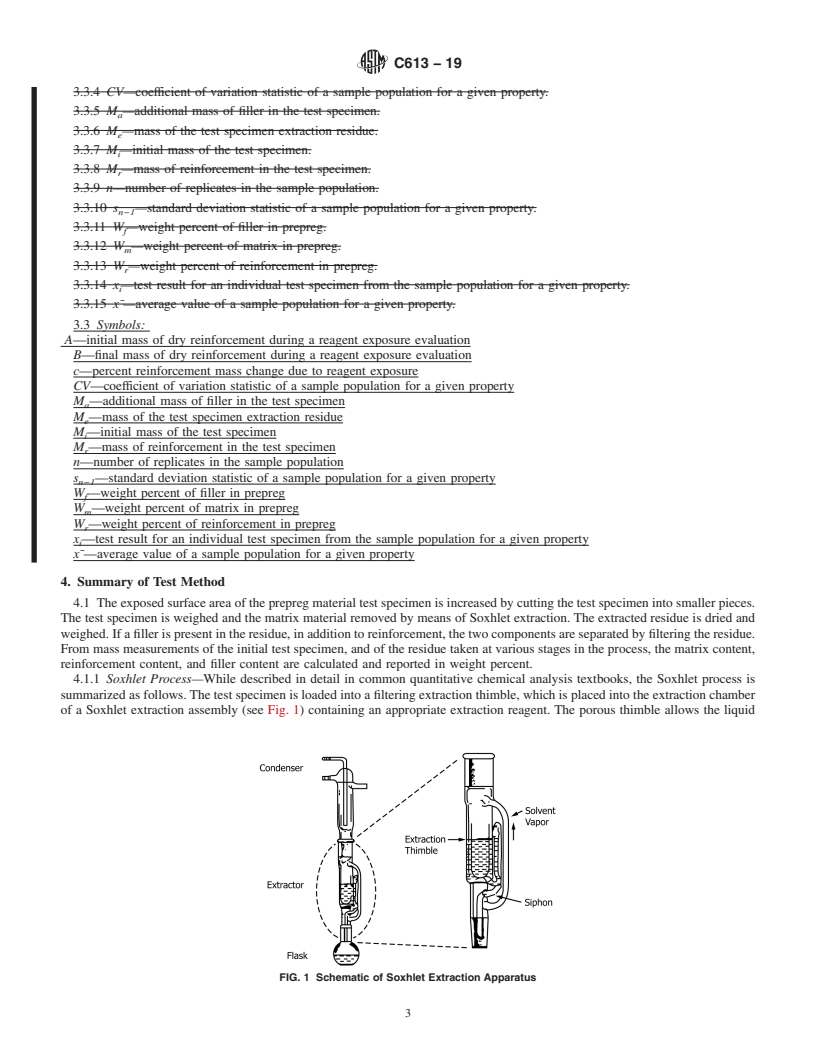

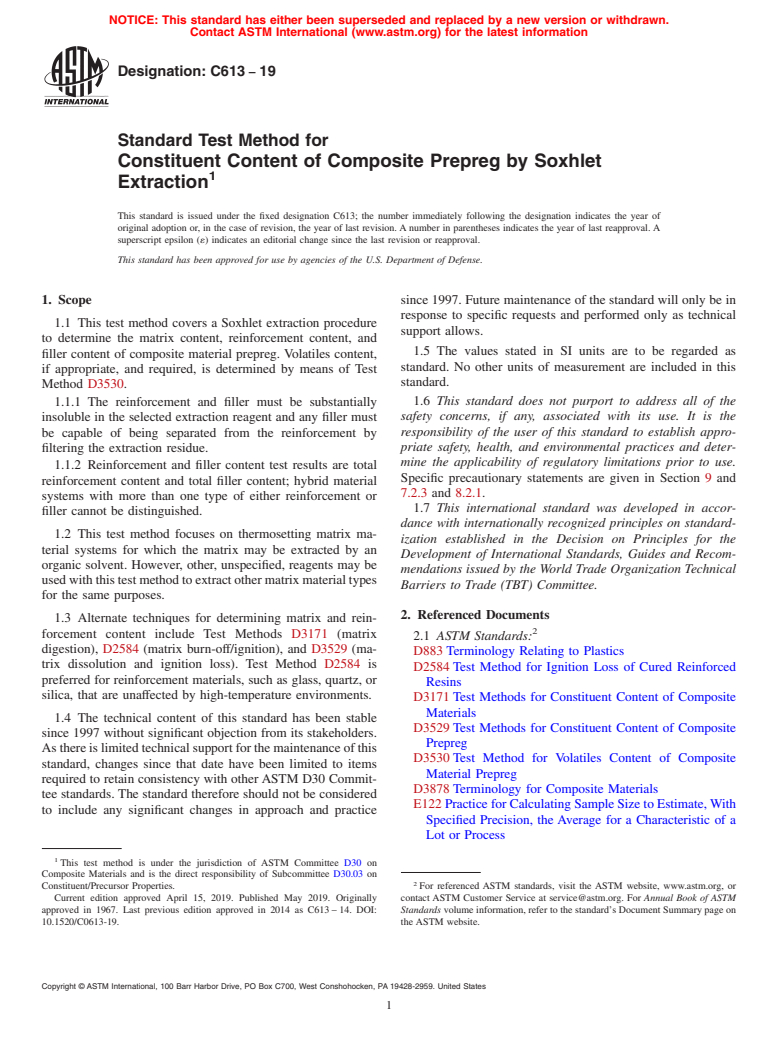

1.1 This test method covers a Soxhlet extraction procedure to determine the matrix content, reinforcement content, and filler content of composite material prepreg. Volatiles content, if appropriate, and required, is determined by means of Test Method D3530.

1.1.1 The reinforcement and filler must be substantially insoluble in the selected extraction reagent and any filler must be capable of being separated from the reinforcement by filtering the extraction residue.

1.1.2 Reinforcement and filler content test results are total reinforcement content and total filler content; hybrid material systems with more than one type of either reinforcement or filler cannot be distinguished.

1.2 This test method focuses on thermosetting matrix material systems for which the matrix may be extracted by an organic solvent. However, other, unspecified, reagents may be used with this test method to extract other matrix material types for the same purposes.

1.3 Alternate techniques for determining matrix and reinforcement content include Test Methods D3171 (matrix digestion), D2584 (matrix burn-off/ignition), and D3529 (matrix dissolution and ignition loss). Test Method D2584 is preferred for reinforcement materials, such as glass, quartz, or silica, that are unaffected by high-temperature environments.

1.4 The technical content of this standard has been stable since 1997 without significant objection from its stakeholders. As there is limited technical support for the maintenance of this standard, changes since that date have been limited to items required to retain consistency with other ASTM D30 Committee standards. The standard therefore should not be considered to include any significant changes in approach and practice since 1997. Future maintenance of the standard will only be in response to specific requests and performed only as technical support allows.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 9 and 7.2.3 and 8.2.1.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C613 − 19

Standard Test Method for

Constituent Content of Composite Prepreg by Soxhlet

1

Extraction

This standard is issued under the fixed designation C613; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope since 1997. Future maintenance of the standard will only be in

response to specific requests and performed only as technical

1.1 This test method covers a Soxhlet extraction procedure

support allows.

to determine the matrix content, reinforcement content, and

1.5 The values stated in SI units are to be regarded as

filler content of composite material prepreg. Volatiles content,

standard. No other units of measurement are included in this

if appropriate, and required, is determined by means of Test

standard.

Method D3530.

1.1.1 The reinforcement and filler must be substantially 1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

insoluble in the selected extraction reagent and any filler must

be capable of being separated from the reinforcement by responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

filtering the extraction residue.

mine the applicability of regulatory limitations prior to use.

1.1.2 Reinforcement and filler content test results are total

Specific precautionary statements are given in Section 9 and

reinforcement content and total filler content; hybrid material

7.2.3 and 8.2.1.

systems with more than one type of either reinforcement or

1.7 This international standard was developed in accor-

filler cannot be distinguished.

dance with internationally recognized principles on standard-

1.2 This test method focuses on thermosetting matrix ma-

ization established in the Decision on Principles for the

terial systems for which the matrix may be extracted by an

Development of International Standards, Guides and Recom-

organic solvent. However, other, unspecified, reagents may be

mendations issued by the World Trade Organization Technical

usedwiththistestmethodtoextractothermatrixmaterialtypes

Barriers to Trade (TBT) Committee.

for the same purposes.

2. Referenced Documents

1.3 Alternate techniques for determining matrix and rein-

2

forcement content include Test Methods D3171 (matrix

2.1 ASTM Standards:

digestion), D2584 (matrix burn-off/ignition), and D3529 (ma-

D883Terminology Relating to Plastics

trix dissolution and ignition loss). Test Method D2584 is

D2584Test Method for Ignition Loss of Cured Reinforced

preferred for reinforcement materials, such as glass, quartz, or

Resins

silica, that are unaffected by high-temperature environments.

D3171Test Methods for Constituent Content of Composite

Materials

1.4 The technical content of this standard has been stable

D3529Test Methods for Constituent Content of Composite

since 1997 without significant objection from its stakeholders.

Prepreg

Asthereislimitedtechnicalsupportforthemaintenanceofthis

D3530Test Method for Volatiles Content of Composite

standard, changes since that date have been limited to items

Material Prepreg

required to retain consistency with otherASTM D30 Commit-

D3878Terminology for Composite Materials

tee standards. The standard therefore should not be considered

E122PracticeforCalculatingSampleSizetoEstimate,With

to include any significant changes in approach and practice

Specified Precision, the Average for a Characteristic of a

Lot or Process

1

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of Subcommittee D30.03 on

2

Constituent/Precursor Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 15, 2019. Published May 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1967. Last previous edition approved in 2014 as C613–14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0613-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C613 − 19

E177Practice for Use of the Terms Precision and Bias in 3.2.10 wet resin content, n—prepreg resin content deter-

ASTM Test Methods mine

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C613 − 14 C613 − 19

Standard Test Method for

Constituent Content of Composite Prepreg by Soxhlet

1

Extraction

This standard is issued under the fixed designation C613; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This test method covers a Soxhlet extraction procedure to determine the matrix content, reinforcement content, and filler

content of composite material prepreg. Volatiles content, if appropriate, and required, is determined by means of Test Method

D3530.

1.1.1 The reinforcement and filler must be substantially insoluble in the selected extraction reagent and any filler must be

capable of being separated from the reinforcement by filtering the extraction residue.

1.1.2 Reinforcement and filler content test results are total reinforcement content and total filler content; hybrid material systems

with more than one type of either reinforcement or filler cannot be distinguished.

1.2 This test method focuses on thermosetting matrix material systems for which the matrix may be extracted by an organic

solvent. However, other, unspecified, reagents may be used with this test method to extract other matrix material types for the same

purposes.

1.3 Alternate techniques for determining matrix and reinforcement content include Test Methods D3171 (matrix digestion),

D2584 (matrix burn-off/ignition), and D3529MD3529 (matrix dissolution and ignition loss). Test Method D2584 is preferred for

reinforcement materials, such as glass, quartz, or silica, that are unaffected by high-temperature environments.

1.4 The technical content of this standard has been stable since 1997 without significant objection from its stakeholders. As there

is limited technical support for the maintenance of this standard, changes since that date have been limited to items required to

retain consistency with other ASTM D30 Committee standards. The standard therefore should not be considered to include any

significant changes in approach and practice since 1997. Future maintenance of the standard will only be in response to specific

requests and performed only as technical support allows.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 9 and 7.2.3 and 8.2.1.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

D2584 Test Method for Ignition Loss of Cured Reinforced Resins

D3171 Test Methods for Constituent Content of Composite Materials

D3529MD3529 Test Methods for Constituent Content of Composite Prepreg

D3530 Test Method for Volatiles Content of Composite Material Prepreg

1

This test method is under the jurisdiction of ASTM Committee D30 on Composite Materials and is the direct responsibility of Subcommittee D30.03 on

Constituent/Precursor Properties.

Current edition approved Oct. 15, 2014April 15, 2019. Published November 2014May 2019. Originally approved in 1967. Last previous edition approved in 20032014

ε2

as C613 – 97C613 – 14.(2003) . DOI: 10.1520/C0613-14.10.1520/C0613-19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C613 − 19

D3878 Terminology for Composite Materials

E122 Practice for Calc

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C613 − 19

Standard Test Method for

Constituent Content of Composite Prepreg by Soxhlet

1

Extraction

This standard is issued under the fixed designation C613; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope since 1997. Future maintenance of the standard will only be in

response to specific requests and performed only as technical

1.1 This test method covers a Soxhlet extraction procedure

support allows.

to determine the matrix content, reinforcement content, and

1.5 The values stated in SI units are to be regarded as

filler content of composite material prepreg. Volatiles content,

standard. No other units of measurement are included in this

if appropriate, and required, is determined by means of Test

standard.

Method D3530.

1.6 This standard does not purport to address all of the

1.1.1 The reinforcement and filler must be substantially

insoluble in the selected extraction reagent and any filler must safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

be capable of being separated from the reinforcement by

filtering the extraction residue. priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1.2 Reinforcement and filler content test results are total

Specific precautionary statements are given in Section 9 and

reinforcement content and total filler content; hybrid material

7.2.3 and 8.2.1.

systems with more than one type of either reinforcement or

1.7 This international standard was developed in accor-

filler cannot be distinguished.

dance with internationally recognized principles on standard-

1.2 This test method focuses on thermosetting matrix ma-

ization established in the Decision on Principles for the

terial systems for which the matrix may be extracted by an

Development of International Standards, Guides and Recom-

organic solvent. However, other, unspecified, reagents may be

mendations issued by the World Trade Organization Technical

used with this test method to extract other matrix material types

Barriers to Trade (TBT) Committee.

for the same purposes.

2. Referenced Documents

1.3 Alternate techniques for determining matrix and rein-

2

forcement content include Test Methods D3171 (matrix

2.1 ASTM Standards:

digestion), D2584 (matrix burn-off/ignition), and D3529 (ma-

D883 Terminology Relating to Plastics

trix dissolution and ignition loss). Test Method D2584 is

D2584 Test Method for Ignition Loss of Cured Reinforced

preferred for reinforcement materials, such as glass, quartz, or

Resins

silica, that are unaffected by high-temperature environments.

D3171 Test Methods for Constituent Content of Composite

Materials

1.4 The technical content of this standard has been stable

D3529 Test Methods for Constituent Content of Composite

since 1997 without significant objection from its stakeholders.

Prepreg

As there is limited technical support for the maintenance of this

D3530 Test Method for Volatiles Content of Composite

standard, changes since that date have been limited to items

Material Prepreg

required to retain consistency with other ASTM D30 Commit-

D3878 Terminology for Composite Materials

tee standards. The standard therefore should not be considered

E122 Practice for Calculating Sample Size to Estimate, With

to include any significant changes in approach and practice

Specified Precision, the Average for a Characteristic of a

Lot or Process

1

This test method is under the jurisdiction of ASTM Committee D30 on

Composite Materials and is the direct responsibility of Subcommittee D30.03 on

2

Constituent/Precursor Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 15, 2019. Published May 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1967. Last previous edition approved in 2014 as C613 – 14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0613-19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C613 − 19

E177 Practice for Use of the Terms Precision and Bias in 3.2.10 wet resin content, n—prepreg resin content deter-

ASTM Test Methods mined by considering volatiles as part of the resin mass.

E456 Terminology Relating to Quality and Statist

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.