ASTM D2168-90(1996)e1

(Test Method)Standard Test Methods for Calibration of Laboratory Mechanical-Rammer Soil Compactors

Standard Test Methods for Calibration of Laboratory Mechanical-Rammer Soil Compactors

SCOPE

1.1 These test methods for the calibration of mechanical soil compactors are for use in checking and adjusting mechanical devices used in laboratory compaction of soil in accordance with Test Methods D698, D1557, and other methods of a similar nature which might specify these test methods. Calibration for use with one method does not qualify the equipment for use with another method.

1.2. The mass of the mechanical rammer is adjusted as described in 5.4 and 6.5 in order to provide that the mechanical compactor will produce the same result as the manual compactor.

1.3 Two alternative procedures are provided as follows: Section Test Method A Calibration based on the compaction of a 5 selected soil sample Test Method B Calibration based on the deformation of a 6 standard lead cylinder

1.4 If a mechanical compactor is calibrated in accordance with the requirements of either Test Method A or Test Method B, it is not necessary for it to meet the requirements of the other test method.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. >

General Information

Relations

Standards Content (Sample)

STD.ASTM D21b8-ENGL L=l=lO m 0759530 tlb110530 Tbl, I

Designation: D 2168 - 90 (Reapproved 1996)”

Standard Test Methods for

Calibration of Laboratory Mechanical-Rammer Soil

Compactors’

1. !kope D 1557 Test Method for Laboratory Compaction Chara~

teristics of Soil Using Modified Effort (56 000 ft-lbf/ft3

1.1 These test methods for the calibration of mechanical

(2700 kN-m/m3))Z

soil compactors are for use in checking and adjusting

D2487 ClassiBcation of Soils for Engineering Pmposes

mechanical devices used in laboratory compacting of soil

(Unified Soil ClassiBcation System)2

and soil-aggregate in accordance with Test Methods D 698,

E 11 Specification for Wire-Cloth Sieves for Testing

D 1557, and other methods of a similar nature which might

-3

specify these test methods. Calibration for use with one

E 145 Specification for Gravity-Convection and Forced-

method does not quali@ the equipment for use with another

Ventilation Ovens3

method.

1.2. The weight of the mechanical rammer is adjusted as

described in 5.4 and 6.5 in order to provide that the

3. siicance and use

mechanical compactor will produce the- same result as the

3.1 Mechanical compactors are commonly used to re-

manual compactor.

place the hand compactors required for Test Methods D 698

1.3 Two alternative procedures are provided as follows:

and D 1557 in cases where it is necessary to increase

!hliOll

production.

Test Method A Calibration based OD the compaclio~~ of a 5

3.2 The design of mechanical compactors is such that it is

se- soil sample

necessary to have a calibration process that goes beyond

Test Method B Calibration based on the deformation of a

determining the mass and drop of the hammer.

standard lead cylinder

1.4 If a mechanical compactor is calibrated in accordance

with the requirements of either Test Method A or Test

4. Apparatus

Method B, it is not necessary for it to meet the requirements

4.1 For Test Method A, in addition to the apparatus

of the other method.

requirements specified in Test Methods D 698 and D 1557,

1.5 The values stated in inch-pound units are to be

the following is required:

regarded as the standard. The values given in parentheses are

4.1.1 Drying Oven-Thermostatically controlled oven,

for information only.

preferably of the forced-draft type, meeting the requirements

1.6 This standard does not purport to address all of the of Specification E 145 and capable of maintaining a uniform

safpty concerns, if any, associated with its use. It is the temperture of 140 -C 5-F (60 f 12°C) throughout the drying

responsibility of the user of this standard to establish appru chamber.

priate safety and health practices and determine the applica- 4.2 For Test Method B, in addition to the apparatus

bility of regulatory limitations prior to use. requirements specified in Test Methods D 698 and D 1557,

the following are required:

4.2.1 Lead Dejzmation Apparatus-A lead deformation

2. Referenced Documents

apparatus consisting of an anvil, guide collar, and striking

pin, as shown in Fig 1.

2.1 ASTM Standark

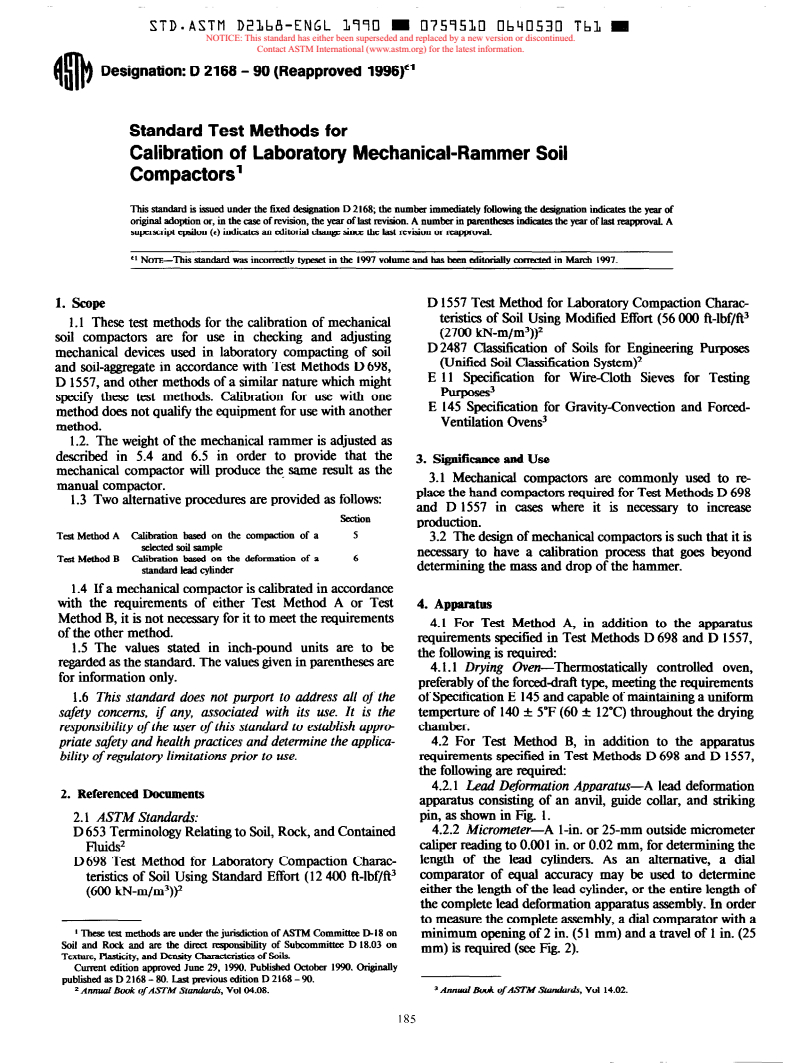

4.2.2 Micrometer--A l-in. or 25-mm outside micrometer

D 653 Terminology Relating to Soil, Rock, and Contained

caliper reading to 0.001 in. or 0.02 mm, for determining the

Fhlids2

length of the lead cylinders. As an alternative, a dial

D698 Test Method for Laboratory Compaction Charac-

comparator of equal accuracy may be used to determine

teristics of Soil Using Standard Effort (12 400 ft-lbf/fi3

either the length of the lead cylinder, or the entire length of

(600 kN-m/m3))2

the complete lead deformation apparatus assembly. In order

to measure the complete assembly, a dial comparator with a

‘ThsetestmethodsareunderthejurisdictionofASZU~~~D-18on

minimum opening of 2 in. (5 1 mm) and a travel of 1 in. (25

Soil and Rock and are the direct responsibility of Subcommittee D 18.03 on

mm) is required (see Fii 2).

Texture, Plasticity, and Density characteristics of Soii

Cunmt edition approved June 29,199O. F’ublisbed October 1990. originaur

publishedasD2168-80.LastpreviouseditionD2168-90.

2AnnuolBodro~ASTMStrmdonls,Vol04.08. 3 Ad Bad of ASTM .Ytan&rrls, Vol 14.02.

STD.ASTM DZLbB-ENGL L=l9Cl m 0759530 Ob’iCl53L 9T8 m

114” Ball Steel

Ream

~---j-O."'"" + "o:",",$:

Striking Pin

Guide Collar

l/4”

Anvil

in. rml

2.10 53.34

we 46

1%

1% ill

1.250 31.75

1243 31.70

0.626 15.30

0.625 15.68

;;",7 13 8.05

% 6.4

'h 32

'/la 1.6

'/x2 0.78

0.005 0.13

::E 0.10 0.05

0.001 0.02

NOTE l-The use of vemia calipers is not recommended since they

afengthof0.675+0.OO5in.(17.1 kO.1 mm)andadiameter

can produce eirromms reading if not zeroed correctly or if the vernier

of 0.310 + 0.002 in. (7.87 + 0.05 I@.~ A minimum of ten

caliper is not of high quality.

test cylinders is required for the calibration of one me&an-

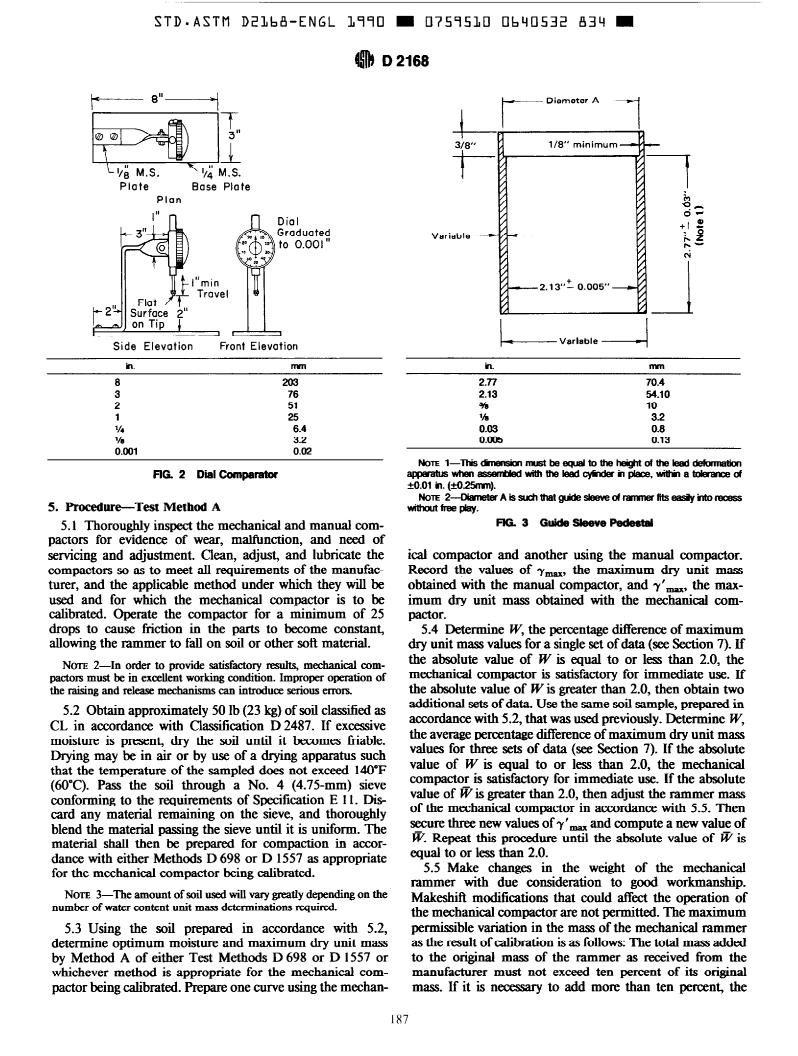

4.2.3 Guide Sleeve Pedestal-A guide sleeve pedestal for ical compactor. However, depending on circumstances, as

use with guide sleeves used to control the drop of the manual

many as 100 test cylinders may be required.

rammers in Test Methods D 698 and D 1557 (see Fg 3).

4.2.4 Test Cylinders-A supply of commercially pure

4LeadtertcylindasaFeavrikble~mtheHornady~~~,P.0.

lead test cylinders having individual masses such that the

Box l848,Grandl.slad,Nebr.688O1inlotsof5OO.

lightest cylinder is within 0.06 g of the heaviest, each having

STD.ASTM DZLbB-ENGL L=l=lll - 0757530 IJb1111532 83’4 -

D 2168

#lb

Plate Base Plate

Plan

Side Elevotion Front Elevation

in. Rm

In. mn

6 203 2.77 70.4

3 76 2.13 54.10

2 51 w 10

1 25 'hi 3.2

'14 6.4 0.03 0.6

'/a 3.2 0.005 0.13

0.001 0.02

NOTE l-l-hisdmensonmustbeequaltottleheigMofthelf!addelamatian

wilhthe~cyliderinpkw.wiltMatolmma3d

flG 2 DIM Ccnnpam aPI=-=--

Ml.01 in. (ko25ml).

NOTE 2-WneterAissuchthatguidesleeveoframner rltseasaybltoraeess

5. Procedure--Test Method A vilhoutlreeptay.

FKL3 GuideSkevePedestd

5.1 ThoroughIy inspect the mechanical and manual com-

pactors for evidence of wear, malfunction, and need of

servicing and adjustment. Clean, adjust, and lubricate the ical compactor and another using the manual compactor.

compactors so as to meet all requirements of the manufac- Record the values of ymax, the maximum dry unit mass

turer, and the applicable method under which they will be obtained with the manual compactor, and y’,, the max-

used and for which the mechanical compactor is to be

imum dry unit mass obtained with the mechanical com-

calibrated. Operate the compactor for a minimum of 25

pactor.

drops to cause friction in the parts to become constant,

5.4 Determine W, the percentage difference of maximum

allowing the rammer to fall on soil or other soft material.

dry unit maSS values for a single set of data (see Section 7). If

the absolute value of W is equal to or less than 2.0, the

NOTE 2-h order to provide satisfactory rrsdts, mechanical corn-

mechanical compactor is satisfactory for immediate use. If

paetors must be in excellent working condition. Improper operation of

the raising and release me&ankms can introduce serious errors. the absolute value of W is greatex than 2.0, then obtain two

additional sets of data. Use the same soil sample, prepared in

5.2 Obtain approximately 50 lb (23 kg) of soil classitied as

accordance with 5.2, that was used previously. Determine W,

CL in accordance with Classification D 2487. If excessive

the average percentage difference of maximum dry unit mass

moisture is present, dry the soil until it becomes fiiable.

values for three sets of data (see Section 7). If the absolute

Drying may be in air or by use of a drying apparatus such

value of W is equal to or less than 2.0, the mechanical

that the temperature of the sampled does not exceed 140°F

compactor is satisfactory for immediate use. If the absolute

(60°C). Pass the soil through a No. 4 (4.75-mm) sieve

value of w is greater than 2.0, then adjust the rammer mass

conforming to the requirements of Specification E 11. Dis-

of the mechanical compactor in accordance with 5.5. Then

card any material remaining on the sieve, and thoroughly

secure three new values of y’- and compute a new value of

blend the material passing the sieve until it is uniform. The

m Repeat this procedure until the absolute value of W is

material shall then be prepared for compaction in accor-

equal to or less than 2.0.

dance with either Methods D 698 or D 1557 as appropriate

5.5 Make changes in the weight of the mechanical

for the mechanical compactor being calibrated.

rammer with due consideration to good workmanship.

NOTE 3-The amount of soil used will vary greatly depending on the

Makeshift modifications that could affect the operation of

number of water content unit mass determinations required.

the mechanical compactor are not permitted. The maximum

permissible variation in the mass of the mechanical ramme

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.