ASTM D2168-10(2018)

(Practice)Standard Practices for Calibration of Laboratory Mechanical-Rammer Soil Compactors

Standard Practices for Calibration of Laboratory Mechanical-Rammer Soil Compactors

SIGNIFICANCE AND USE

3.1 Mechanical compactors are commonly used to replace the hand compactors required for Test Methods D698 and D1557 in cases where it is necessary to increase production.

3.2 The design of mechanical compactors is such that it is necessary to have a calibration process that goes beyond determining the mass and drop of the hammer.

Note 1: The quality of the result produced by this standard is dependent on the competence of the personnel performing it, and the suitability of the equipment and facilities used. Agencies that meet the criteria in Practice D3740 are generally considered capable of competent and objective testing/sampling/inspection/and the like. Users of this standard are cautioned that compliance with Practice D3740 does not in itself assure reliable results. Reliable results depend on many factors; Practice D3740 provides a means of evaluating some of those factors.

SCOPE

1.1 These practices for the calibration of mechanical soil compactors are for use in checking and adjusting mechanical devices used in laboratory compacting of soil and soil-aggregate in accordance with Test Methods D698, D1557, Practice D6026, and other methods of a similar nature that might specify these practices. Calibration for use with one practice does not qualify the equipment for use with another practice.

1.2 The weight of the mechanical rammer is adjusted as described in 5.4 and 6.5 in order to provide for the mechanical compactor to produce the same result as the manual compactor.

1.3 Two alternative procedures are provided as follows:

Section

Practice A

Calibration based on the compaction of a

selected soil sample

5

Practice B

Calibration based on the deformation of a

standard lead cylinder

6

1.4 If a mechanical compactor is calibrated in accordance with the requirements of either Practice A or Practice B, it is not necessary for the mechanical compactor to meet the requirements of the other practice.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5.1 It is common practice in the engineering profession to concurrently use pounds to represent both a unit of mass (lbm) and a force (lbf). This implicitly combines two separate systems of units; that is, the absolute system and the gravitational system. It is scientifically undesirable to combine the use of two separate sets of inch-pound units within a single standard. This standard has been written using the gravitational system of units when dealing with the inch-pound system. In this system, the pound (lbf) represents a unit of force (weight). However, the use of balances or scales recording pounds of mass (lbm) or the recording of density in lbm/ft3 shall not be regarded as a nonconformance with this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D2168 − 10 (Reapproved 2018)

Standard Practices for

Calibration of Laboratory Mechanical-Rammer Soil

Compactors

This standard is issued under the fixed designation D2168; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope However, the use of balances or scales recording pounds of

mass (lbm) or the recording of density in lbm/ft shall not be

1.1 These practices for the calibration of mechanical soil

regarded as a nonconformance with this standard.

compactors are for use in checking and adjusting mechanical

1.6 This standard does not purport to address all of the

devices used in laboratory compacting of soil and soil-

safety concerns, if any, associated with its use. It is the

aggregate in accordance with Test Methods D698, D1557,

responsibility of the user of this standard to establish appro-

Practice D6026, and other methods of a similar nature that

priate safety, health, and environmental practices and deter-

might specify these practices. Calibration for use with one

mine the applicability of regulatory limitations prior to use.

practice does not qualify the equipment for use with another

1.7 This international standard was developed in accor-

practice.

dance with internationally recognized principles on standard-

1.2 The weight of the mechanical rammer is adjusted as

ization established in the Decision on Principles for the

described in 5.4 and 6.5 in order to provide for the mechanical

Development of International Standards, Guides and Recom-

compactortoproducethesameresultasthemanualcompactor.

mendations issued by the World Trade Organization Technical

1.3 Two alternative procedures are provided as follows:

Barriers to Trade (TBT) Committee.

Section

Practice A Calibration based on the compaction of a 5

2. Referenced Documents

selected soil sample

Practice B Calibration based on the deformation of a 6 2.1 ASTM Standards:

standard lead cylinder

D653 Terminology Relating to Soil, Rock, and Contained

1.4 If a mechanical compactor is calibrated in accordance

Fluids

with the requirements of either Practice A or Practice B, it is

D698 Test Methods for Laboratory Compaction Character-

not necessary for the mechanical compactor to meet the

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

requirements of the other practice.

kN-m/m ))

D1557 Test Methods for Laboratory Compaction Character-

1.5 The values stated in inch-pound units are to be regarded

istics of Soil Using Modified Effort (56,000 ft-lbf/ft

as the standard. The values given in parentheses are for

(2,700 kN-m/m ))

information only.

D2487 Practice for Classification of Soils for Engineering

1.5.1 It is common practice in the engineering profession to

Purposes (Unified Soil Classification System)

concurrently use pounds to represent both a unit of mass (lbm)

D3740 Practice for Minimum Requirements for Agencies

and a force (lbf). This implicitly combines two separate

Engaged in Testing and/or Inspection of Soil and Rock as

systems of units; that is, the absolute system and the gravita-

Used in Engineering Design and Construction

tional system. It is scientifically undesirable to combine the use

D6026 Practice for Using Significant Digits in Geotechnical

of two separate sets of inch-pound units within a single

Data

standard.This standard has been written using the gravitational

E11 Specification for Woven Wire Test Sieve Cloth and Test

system of units when dealing with the inch-pound system. In

Sieves

this system, the pound (lbf) represents a unit of force (weight).

E145 Specification for Gravity-Convection and Forced-

Ventilation Ovens

ThesepracticesareunderthejurisdictionofASTMCommitteeD18onSoiland

Rock and are the direct responsibility of Subcommittee D18.03 on Texture,

Plasticity and Density Characteristics of Soils. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2018. Published July 2018. Originally appr- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

roved in 1990. Last previous edition approved in 2010 as D2168–10. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D2168-10R18. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2168 − 10 (2018)

3. Significance and Use 5. Procedure—Practice A

3.1 Mechanical compactors are commonly used to replace 5.1 Evaluate the mechanical and manual compactors for

the hand compactors required for Test Methods D698 and evidence of wear, malfunction, and need of servicing and

D1557 in cases where it is necessary to increase production. adjustment.Clean,adjust,andlubricatethecompactorssoasto

meet all requirements of the manufacturer, and the applicable

3.2 The design of mechanical compactors is such that it is

method under which they will be used and for which the

necessary to have a calibration process that goes beyond

mechanical compactor is to be calibrated. Operate the compac-

determining the mass and drop of the hammer.

tor for a minimum of 25 drops to cause friction in the parts to

NOTE 1—The quality of the result produced by this standard is

become constant, allowing the rammer to fall on soil or other

dependent on the competence of the personnel performing it, and the

suitability of the equipment and facilities used. Agencies that meet the

soft material.

criteria in Practice D3740 are generally considered capable of competent

NOTE 3—In order to provide satisfactory results, mechanical compac-

and objective testing/sampling/inspection/and the like. Users of this

tors must be in excellent working condition. Improper operation of the

standard are cautioned that compliance with Practice D3740 does not in

raising and release mechanisms can introduce serious errors.

itself assure reliable results. Reliable results depend on many factors;

Practice D3740 provides a means of evaluating some of those factors.

5.2 Obtain approximately 50 lb (23 kg) of soil classified as

CL in accordance with Classification D2487. If excessive

4. Apparatus

moistureispresent,drythesoiluntilitbecomesfriable.Drying

4.1 For PracticeA, in addition to the apparatus requirements

may be in air or by use of a drying apparatus such that the

specified in Test Methods D698 and D1557, the following is

temperature of the sample does not exceed 140°F (60°C). Pass

required:

the soil through a No. 4 (4.75-mm) sieve conforming to the

4.1.1 DryingOven—Thermostatically controlled oven, pref-

requirements of Specification E11. Discard any material re-

erably of the forced-draft type, meeting the requirements for

maining on the sieve, and thoroughly blend the material

Specification E145 and capable of maintaining a uniform

passing the sieve until it is uniform. The material shall then be

temperature of 140 6 5°F (60 6 3°C) throughout the drying

prepared for compaction in accordance with either Methods

chamber.

D698 or D1557 as appropriate for the mechanical compactor

4.2 For Practice B, in addition to the apparatus requirements

being calibrated.

specified in Test Methods D698 and D1557, the following are

NOTE 4—The amount of soil used will vary greatly depending on the

required:

number of water content unit mass determinations required.

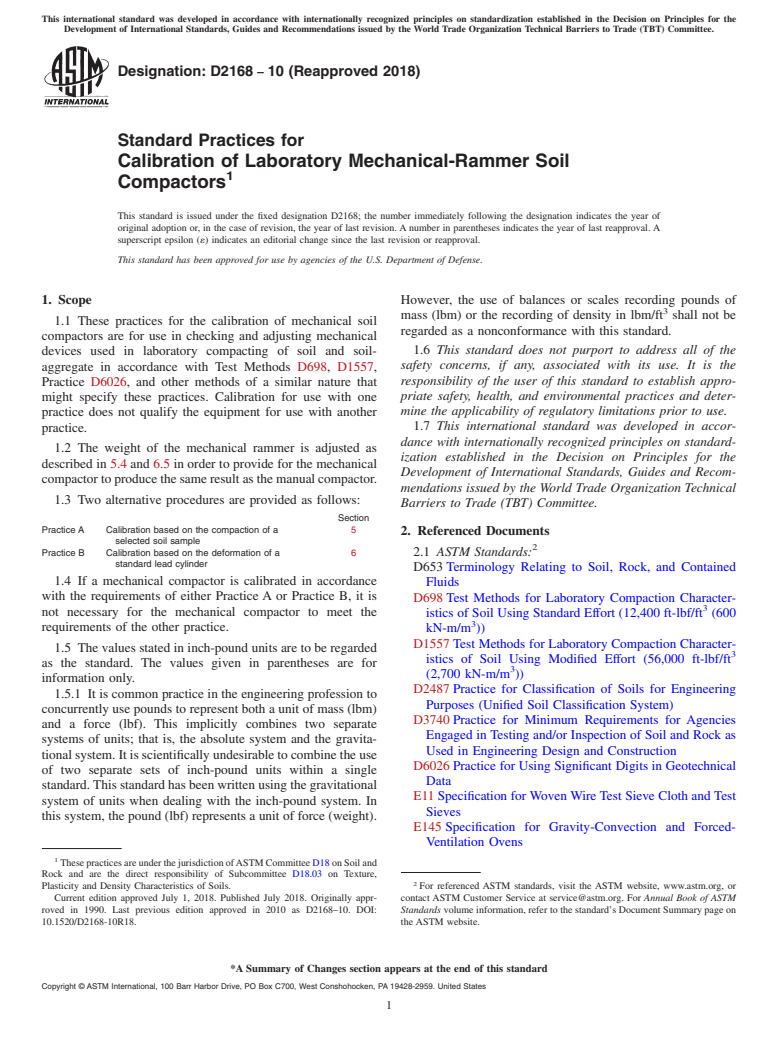

4.2.1 Lead Deformation Apparatus—A lead deformation

5.3 Using the soil prepared in accordance with 5.2, deter-

apparatus consisting of an anvil, guide collar, and striking pin,

mine optimum moisture and maximum dry unit weight by

as shown in Fig. 1.

MethodAof eitherTest Methods D698 or D1557 or whichever

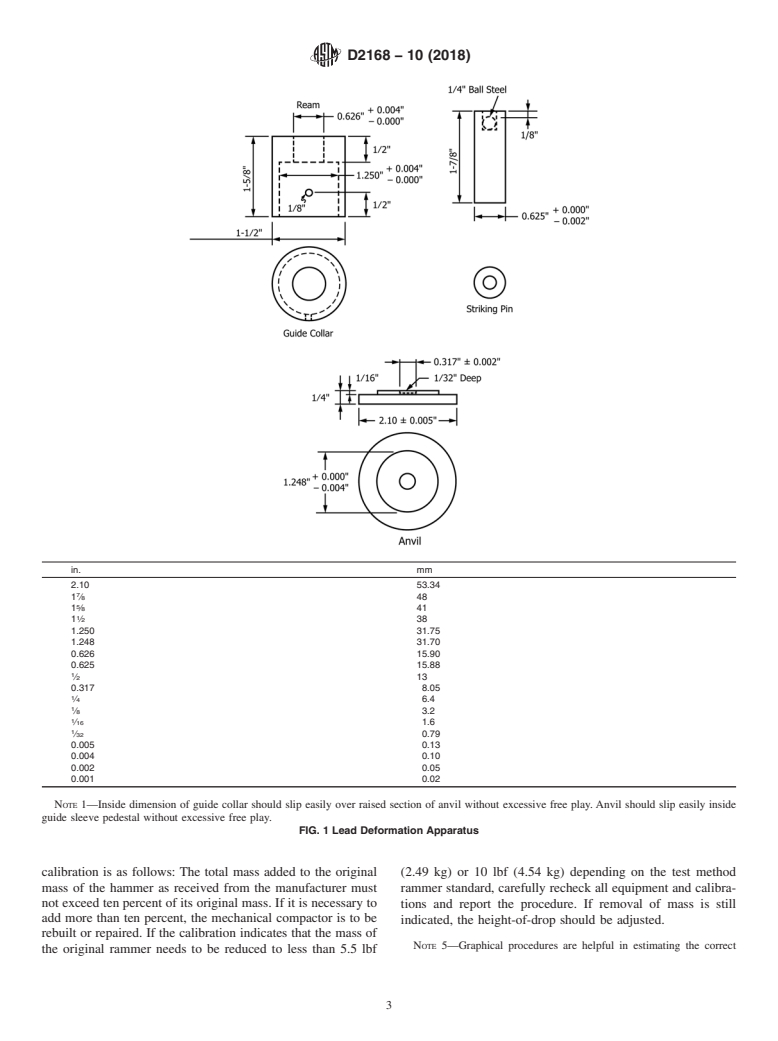

4.2.2 Micrometer—Aone-inch (25-mm) outside micrometer

method is appropriate for the mechanical compactor being

or caliper reading to 0.001 in. (0.02 mm), for determining the

calibrated. Prepare one curve using the mechanical compactor

length of the lead cylinders. As an alternative, a one-inch

and another using the manual compactor. Record the values of

(25-mm) dial comparator reading to 0.001 in. (0.02 mm) may

γ , the maximum dry unit weight obtained with the manual

max

be used to determine either the length of the lead cylinder, or

compactor, and γ' , the maximum dry unit weight obtained

max

of the complete lead deformation apparatus assembly. To

with the mechanical compactor.

measure the complete assembly, a dial comparator with a

minimum opening of 2 in. (50 mm) is required (see Fig. 2). 5.4 Determine W, the percentage difference of maximum

dry unit weight values for a single set of data (see Section 7).

NOTE 2—The use of vernier calipers is not recommended since the

If the absolute value of W is equal to or less than 2.0, the

vernier calipers can produce erroneous readings if not zeroed correctly, or

mechanical compactor is satisfactory for immediate use. If the

if the vernier caliper is not of high quality.

absolute value of W is greater than 2.0, then obtain two

4.2.3 Guide Sleeve Pedestal—A guide sleeve pedestal for

additional sets of data. Use the same soil sample, prepared in

use with guide sleeves used to control the drop of the manual

accordance with 5.2, that was used previously. Determine W,

rammers in Test Methods D698 and D1557 (see Fig. 3).

the average percentage difference of maximum dry unit mass

4.2.4 Test Cylinders—A supply of commercially pure lead

values for three sets of data (see Section 7). If the absolute

test cylinders having individual weights such that the lightest

value of W is equal to or less than 2.0, the mechanical

cylinder is within 0.06 g of the heaviest, each having a length

compactor is satisfactory for immediate use. If the absolute

of 0.675 6 0.005 in. (17.1 6 0.1 mm) and a diameter of 0.310

¯

3 value of¯W is greater than 2.0, then adjust the rammer mass of

6 0.002 in. (7.87 6 0.05 mm). A minimum of ten test

the mechanical compactor in accordance with 5.5. Then secure

cylinders is required for the calibration of one mechanical

¯

three new values of γ' and compute a new value of W.

max

compactor. However, depending on circumstances, as many as

¯

Repeat this procedure until the absolute value of W is equal to

100 test cylinders may be required.

or less than 2.0.

5.5 Make changes in the weight of the mechanical hammer

The sole source of supply of the lead test cylinders known to the committee at

this time is Hornady Manufacturing Co., P.O. Box 1848, Grand Island, Nebr. 68801

with due consideration to good workmanship. Makeshift modi-

in lots of 500. If you are aware of alternative suppliers, please provide this

fications that could affect the operation of the mechanical

information to ASTM International Headquarters. Your comments will receive

compactor are not permitted. The maximum permissible varia-

careful consideration at a meeting of the responsible technical committee, which

you may attend. tion in the weight of the mechanical hammer as the result of

D2168 − 10 (2018)

in. mm

2.10 53.34

1 ⁄8 48

1 ⁄8 41

1 ⁄2 38

1.250 31.75

1.248 31.70

0.626 15.90

0.625 15.88

⁄2 13

0.317 8.05

⁄4 6.4

⁄8 3.2

⁄16 1.6

⁄32 0.79

0.005 0.13

0.004 0.10

0.002 0.05

0.001 0.02

NOTE 1—Inside dimension of guide collar should slip easily over raised section of anvil without excessive free play. Anvil should slip easily inside

guide sleeve pedestal without excessive free play.

FIG. 1 Lead Deformation Apparatus

calibration is as follows: The total mass added to the original (2.49 kg) or 10 lbf (4.54 kg) depending on the test method

mass of the hammer as received from the manufacturer must rammer standard, carefully recheck all equipment and calibra-

not exceed ten percent of its original mass. If it is necessary to

tions and report the procedure. If removal of mass is still

add more than ten percent, the mechanical compactor is to be

indicated, the height-of-drop should be adjusted.

rebuilt or repaired. If the calibration indicates that the mass of

NOTE 5—Graphical procedures are helpful in estimating the correct

the original rammer needs to be reduced to less than 5.5 lbf

D2168 − 10 (2018)

amount of mass to be added or subtracted.

5.6 If a larger change than that permitted in 5.5 is found to

be necessary, then improper operation of the mechanical

compactor is indicated. Evaluate and adjust the mechanical

compactor in order to determine and eliminate the cause of the

malfunction and repeat the calibration procedure.

5.7 Do not use the mechanical compactor if the indicated

weight change still exceeds that permitted in 5.5.

6. Procedure—Practice B

6.1 Evaluate and adjust the mechanical and manual com-

pactors as described in 5.1 of Practice A.

6.2 Deformation by the Manual Compactor—Obtain the

deformation value for the manual compactor as follows:

6.2.1 Select a set of lead cylinders from the same lot or

shipment. Remove any burrs from the ends of the lead

cylinders using a fine grade of emery cloth.

in. mm NOTE 6—Deformation of the lead cylinders is affected by changes in

temperature. Take precautions to maintain the cylinders within 65°F

8 203

(62.7°C) during the calibration of the mechanical compactor and the

securing of the manual compactor values.

6.2.2 Obtain c , the (initial) micrometer or dial comparator

⁄4 6.4

⁄8 3.2 reading before impact, following the procedures decribed in

0.001 0.02

6.2.5.

6.2.3 Place the base plate of the compaction mold on a rigid

FIG. 2 Dial Comparator

foundation. On the base plate, place the assembled lead

deformation apparatus with the lead cylinder (see Fig. 4) and

guide sleeve pedestal in place. Insert the guide sleeve of the

manual compactor into the recess in the guide sleeve pedestal.

Check that the distance from rammer release point to striking

pin contact meets the specified requirements. Apply one drop

of the manual rammer with the guide sleeve of the manual

compactor held vertically, so that the rammer does not strike

the guide sleeve pedestal.

6.2.4 Obtain c , the micrometer or dial comparator reading

after impact, following the procedures described in 6.2.5. The

difference between dial readings c and c is equal to D, the

1 2

deformation value.

in. mm

2.77 70.4

2.13 54.10

⁄8 10

⁄8 3.2

0.03 0.8

0.005 0.13

NOTE 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.