ASTM D7002-15

(Practice)Standard Practice for Electrical Leak Location on Exposed Geomembranes Using the Water Puddle Method

Standard Practice for Electrical Leak Location on Exposed Geomembranes Using the Water Puddle Method

SCOPE

1.1 This practice is a performance-based standard for an electrical method for locating leaks in exposed geomembranes. For clarity, this practice uses the term “leak” to mean holes, punctures, tears, knife cuts, seam defects, cracks, and similar breaches in an installed geomembrane (as defined in 3.2.5).

1.2 This practice can be used for geomembranes installed in basins, ponds, tanks, ore and waste pads, landfill cells, landfill caps, canals, and other containment facilities. It is applicable for geomembranes made of materials such as polyethylene, polypropylene, polyvinyl chloride, chlorosulfonated polyethylene, bituminous geomembrane, and any other electrically insulating materials. This practice is best applicable for locating geomembrane leaks where the proper preparations have been made during the construction of the facility.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7002 − 15

StandardPractice for

Electrical Leak Location on Exposed Geomembranes Using

the Water Puddle Method

This standard is issued under the fixed designation D7002; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D7953 Practice for Electrical Leak Location on Exposed

Geomembranes Using the Arc Testing Method

1.1 This practice is a performance-based standard for an

electrical method for locating leaks in exposed geomembranes.

3. Terminology

For clarity, this practice uses the term “leak” to mean holes,

3.1 Definitions:

punctures, tears, knife cuts, seam defects, cracks, and similar

3.1.1 For general definitions used in this practice, refer to

breaches in an installed geomembrane (as defined in 3.2.5).

Terminology D4439.

1.2 This practice can be used for geomembranes installed in

3.2 Definitions of Terms Specific to This Standard:

basins, ponds, tanks, ore and waste pads, landfill cells, landfill

3.2.1 artificial leak, n—an electrical simulation of a leak in

caps, canals, and other containment facilities. It is applicable

a geomembrane.

for geomembranes made of materials such as polyethylene,

3.2.2 conductive-backed geomembrane, n—a specialty

polypropylene, polyvinyl chloride, chlorosulfonated

geomembrane manufactured using coextrusion technology fea-

polyethylene, bituminous geomembrane, and any other electri-

turing an insulating layer in intimate contact with a conductive

cally insulating materials. This practice is best applicable for

layer.

locating geomembrane leaks where the proper preparations

3.2.3 current, n—the flow of electricity or the flow of

have been made during the construction of the facility.

electric charge.

1.3 The values stated in SI units are to be regarded as

3.2.4 electrical leak location, n—a method which uses

standard. No other units of measurement are included in this

electrical current or electrical potential to locate leaks.

standard.

3.2.5 leak, n—for the purposes of this document, a leak is

1.4 This standard does not purport to address all of the

any unintended opening, perforation, breach, slit, tear,

safety concerns, if any, associated with its use. It is the

puncture, crack, or seam breach. Significant amounts of liquids

responsibility of the user of this standard to establish appro-

or solids may or may not flow through a leak. Scratches,

priate safety and health practices and determine the applica-

gouges, dents, or other aberrations that do not completely

bility of regulatory limitations prior to use.

penetrate the geomembrane are not considered to be leaks.

2. Referenced Documents

Types of leaks detected during surveys include, but are not

limitedto:burns,circularholes,linearcuts,seamdefects,tears,

2.1 ASTM Standards:

punctures, and material defects.

D4439 Terminology for Geosynthetics

D6747 GuideforSelectionofTechniquesforElectricalLeak

3.2.6 leak detection sensitivity, n—the smallest leak that the

Location of Leaks in Geomembranes leak location equipment and survey methodology are capable

D7703 Practice for Electrical Leak Location on Exposed

of detecting under a given set of conditions. The leak detection

Geomembranes Using the Water Lance Method sensitivity specification is usually stated as a diameter of the

smallest leak that can likely be detected.

3.2.7 poor contact condition, n—for the purposes of this

practice, a poor contact condition means that a leak is not in

This practice is under the jurisdiction of ASTM Committee D35 on Geosyn- intimate contact with the conductive layer above or underneath

thetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

the geomembrane to be tested. This occurs on a wrinkle or

Current edition approved Jan. 1, 2015. Published January 2015. Originally

wave, under the overlap flap of a fusion weld, in an area of

approved in 2003. Last previous edition approved in 2010 as D7002–10. DOI:

liner bridging and in an area where there is a subgrade

10.1520/D7002-15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

depression or rut.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.8 probe, n—for the purposes of this practice, any con-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. ductive structure that is attached to a power source.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7002 − 15

3.2.9 squeegee, n—for the purposes of this document, a 5.1.2 Currently available methods include the water lance

squeegee is a device used to contain and push water on top of method (Practice D7703), the arc testing method (Practice

an exposed geomembrane. It may consist of a handle and a D7953), and the water puddle method.

transverse piece at one end set with a strip of leather or rubber,

5.1.3 All of the methods listed in 5.1.2 are effective at

or a roller apparatus.

locating leaks in exposed geomembranes. Each method has

specific site and labor requirements, survey speeds, advantages

3.2.10 water puddle, n—a small pool of water placed on the

and limitations. A professional specializing in the electrical

geomembrane to create a conduit for current to flow through

leak location methods can provide advice on the advantages

any leaks.

and disadvantages of each method for a specific project.

4. Significance and Use

5.1.4 Alternative ASTM Standard Practices for electrical

leaklocationsurveymethodsshouldbeallowedwhenmutually

4.1 Geomembranes are used as barriers to prevent liquids

agreeable and warranted by adverse site conditions, clearly

fromleakingfromlandfills,ponds,andothercontainments.For

technical superiority, logistics, or schedule.

this purpose, it is desirable that the geomembrane have as little

leakage as practical.

6. Water Puddle Method

4.2 The liquids may contain contaminants that, if released,

6.1 Asummary of the method capabilities and limitations is

can cause damage to the environment. Leaking liquids can

presented in Table 1.

erodethesubgrade,causingfurtherdamage.Leakagecanresult

in product loss or otherwise prevent the installation from

NOTE 1—If used, conductive-backed geomembrane must be installed

performing its intended containment purpose.

per the manufacturer’s recommendations in order to allow it to be tested

using all of the available electrical leak location methods. In particular,

4.3 Geomembranes are often assembled in the field, either

there must be some means to break the conductive path through the fusion

by unrolling and welding panels of the geomembrane material

welds along the entire lengths of the welds, the undersides of adjacent

together in the field, unfolding flexible geomembranes in the

panels (and patches) should be electrically connected together, and a

field, or a combination of both.

means of preventing unwanted grounding at the anchor trenches or other

unwanted earth grounds should be provided.

4.4 Geomembrane leaks can be caused by poor quality of

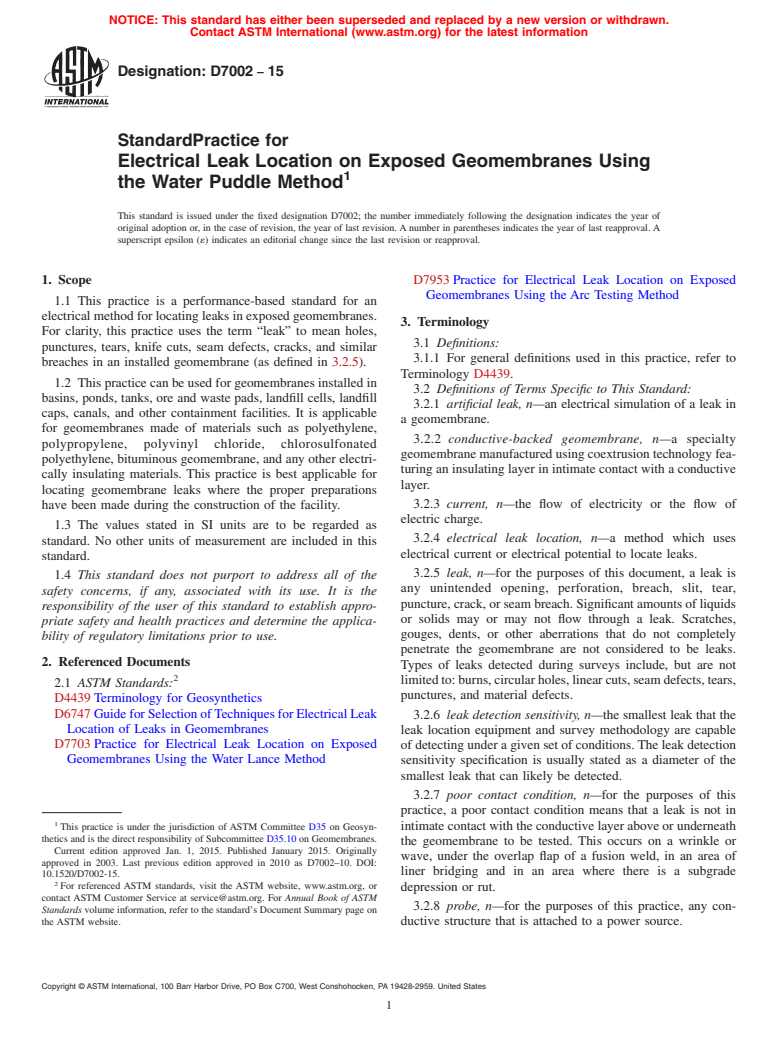

6.2 Principle of the Water Puddle Method:

the subgrade, poor quality of the material placed on the

geomembrane, accidents, poor workmanship, manufacturing 6.2.1 Fig. 1 shows a diagram of electrical leak location

defects, and carelessness.

using the water puddle method for exposed geomembranes.

One output of an electrical excitation power supply is con-

4.5 Electrical leak location methods are an effective and

nected to an electrode placed in a water puddle created on top

proven quality assurance measure to detect and locate leaks.

of the geomembrane. The other output of the power supply is

connected to an electrode placed in the electrically conductive

5. Summary of Exposed Geomembrane Electrical Leak

material under the geomembrane.

Location Methods

6.2.2 Measurements are made using an electrical current

5.1 Principles of the Electrical Leak Location Methods for

measurement system. An electronic assembly is used to pro-

Exposed Geomembranes:

duce an audio tone whose frequency is proportional to the

5.1.1 The principle of the electrical leak location methods is

current flow.

to place a voltage across a geomembrane and then locate areas

where electrical current flows through leaks in the geomem- 6.3 Leak Location Surveys of Exposed Geomembrane Using

brane. the Water Puddle Method:

TABLE 1 Summary of Water Puddle Method

Geomembranes Bituminous, CSPE, CPE, EIA, fPP, HDPE, LLDPE, LDPE, PVC, VLDPE U applicable

A

Conductive-backed Geomembrane U applicable

Seams All types: welded, tape, adhesive, glued and other U applicable: project specific

Junctions At synthetic pipes and accessories U applicable: project specific

At grounded conducting structures X not applicable

Survey During construction phase (installation of GM) U applicable

After installation (exposed) U applicable

Slopes U applicable: project specific

Insufficiently conductive subgrade X not applicable

During the service life (if exposed) U project specific

Climate Sunny, temperate, warm U applicable

Rainy weather X not applicable

Frozen conditions X not applicable

Leaks detected Discrimination between multiple leaks U applicable

A

If used, condu

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7002 − 10 D7002 − 15

Standard Practice for

Electrical Leak Location on Exposed Geomembranes Using

the Water Puddle SystemMethod

This standard is issued under the fixed designation D7002; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice, practice is a performance-based standard for electrical methods, covers detectingan electrical method for

locating leaks in exposed geomembranes. For clarity, this practice uses the term “leak” to mean holes, punctures, tears, knife cuts,

seam defects, cracks, and similar breaches in an installed geomembrane (as defined in 3.2.5).

1.2 This practice can be used for geomembranes installed in basins, ponds, tanks, ore and waste pads, landfill cells, landfill caps,

canals, and other containment facilities. It is applicable for geomembranes made of materials such as polyethylene, polypropylene,

polyvinyl chloride, chlorosulfonated polyethylene, bituminous geomembrane, and any other electrically insulating materials. This

practice may not be is best applicable for locating geomembrane leaks where the proper preparations have not been made during

the construction of the facility.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D4439 Terminology for Geosynthetics

D6747 Guide for Selection of Techniques for Electrical Leak Location of Leaks in Geomembranes

D7703 Practice for Electrical Leak Location on Exposed Geomembranes Using the Water Lance Method

This practice is under the jurisdiction of ASTM Committee D35 on Geosynthetics and is the direct responsibility of Subcommittee D35.10 on Geomembranes.

Current edition approved July 1, 2010Jan. 1, 2015. Published September 2010January 2015. Originally approved in 2003. Last previous edition approved in 20032010

as D7002–03.D7002–10. DOI: 10.1520/D7002-10.10.1520/D7002-15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7002 − 15

D7953 Practice for Electrical Leak Location on Exposed Geomembranes Using the Arc Testing Method

3. Terminology

3.1 Definitions:

3.1.1 For general definitions used in this practice, refer to Terminology D4439.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 artificial leak, n—an electrical simulation of a leak in a geomembrane.

3.2.2 conductive-backed geomembrane, n—a specialty geomembrane manufactured using coextrusion technology featuring an

insulating layer in intimate contact with a conductive layer.

3.2.3 current, n—the flow of electricity or the flow of electric charge.

3.2.4 electrical leak location, n—a method which uses electrical current or electrical potential to detect and locate leaks.

3.2.4 electrodes, n—the conductive plate that is placed in earth ground or in the material under the geomembrane or a

conductive structure, such as a copper manifold, that is placed in the water puddle on the geomembrane.

3.2.5 leak, n—for the purposes of this document, a leak is any unintended opening, perforation, breach, slit, tear, puncture,

crack, or seam breach. Significant amounts of liquids or solids may or may not flow through a leak. Scratches, gouges, dents, or

other aberrations that do not completely penetrate the geomembrane are not considered to be leaks. Leaks Types of leaks detected

during surveys have been grouped into five categories:include, but are not limited to: burns, circular holes, linear cuts, seam

defects, tears, punctures, and material defects.

3.2.5.1 burned through zones—voids created by melting polymer during welding.

3.2.5.2 holes—round shaped voids with downward or upward protruding rims.

3.2.5.3 linear cuts—linear voids with neat close edges.

3.2.5.4 seam defects—area of partial or total separation between sheets.

3.2.5.5 tears—linear or areal voids with irregular edge borders.

3.2.6 leak detection sensitivity, n—the smallest leak that the leak location equipment and survey methodology are capable of

detecting under a given set of conditions. The leak detection sensitivity specification is usually stated as a diameter of the smallest

leak that can likely be reliably detected.

3.2.7 poor contact condition, n—for the purposes of this practice, a poor contact condition means that a leak is not in intimate

contact with the conductive layer above or underneath the geomembrane to be tested. This occurs on a wrinkle or wave, under the

overlap flap of a fusion weld, in an area of liner bridging and in an area where there is a subgrade depression or rut.

3.2.8 probe, n—for the purposes of this practice, any conductive structure that is attached to a power source.

3.2.9 squeegee, n—for the purposes of this document, a squeegee is a device used to contain and push water on top of an

exposed geomembrane. It may consist of a handle and a transverse piece at one end set with a strip of leather or rubber.rubber,

or a roller apparatus.

3.2.10 water puddle, n—a small pool of water placed on the geomembrane to create a conduit for current to flow through any

leaks.

4. Summary of Practice

4.1 Principle of Electrical Leak Location Method Using the Water Puddle System:

4.1.1 The principle of the electrical leak location method is to place a voltage across a geomembrane and then locate areas where

electrical current flows through discontinuities in the geomembrane and at seams.

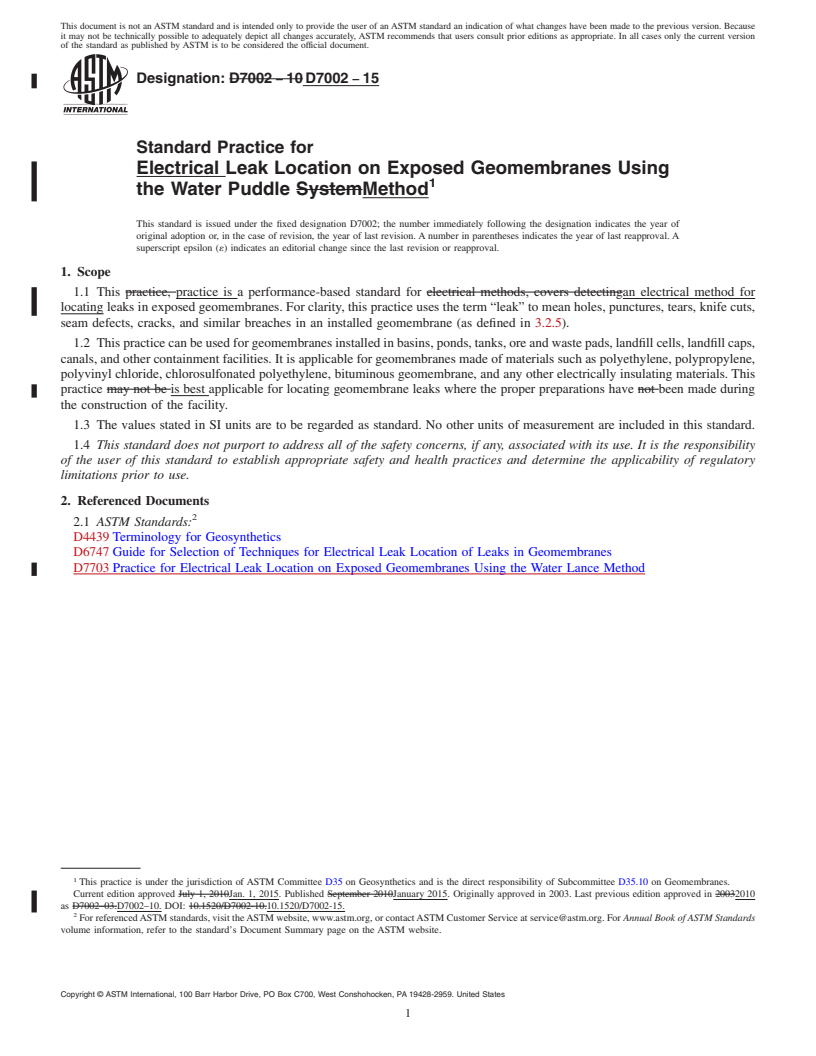

4.1.2 Fig. 1 shows a diagram of the electrical leak location method of the water puddle system for exposed geomembranes. One

output of an electrical excitation power supply is connected to an electrode placed in a water puddle created on top of the

geomembrane. The other output of the power supply is connected to an electrode placed in electrically conductive material under

the geomembrane.

4.1.3 Measurements are made using an electrical current measurement system, the magnitude of the current being related to the

size of the leak. An electronic assembly is usually used to produce an audio tone whose frequency is proportional to the current

flow.

4.2 Leak Location Surveys of Exposed Geomembrane Using the Water Puddle System:

4.2.1 The water puddle detection system usually consists of a horizontal water spray manifold with multiple nozzles that spray

water onto a geomembrane, a squeegee device to push the resultant puddle of water, and a handle assembly as shown in Fig. 2.

A pressurized water source, usually from a tank truck parked at higher elevation, is connected to the spray manifold using a plastic

or rubber hose. Figs. 3 and 4 show one example of such an apparatus.

4.2.2 Direct current power supplies (usually a 12 or 24 volt battery) have been used for leak location surveys. An alternating

current (output requirement of 12 to 30 volt ac) could be used.

D7002 − 15

FIG. 1 Diagram of the Electrical Leak Location Method for Surveys with Water Puddle on Exposed GeomembraneWater Puddle Method

4.2.3 For leak location surveys of exposed geomembrane, the water puddle created is pushed systematically over the

geomembrane area to locate the points where the electrical current flow increases.

4.2.4 The signal from the probe is typically connected to an electronic detector assembly that converts the electrical signal to

a detector and an audible signal that increases in pitch and amplitude as the leak signal increases.

4.2.5 When a leak signal is detected, the location of the leak is then marked or measured relative to fixed points.

4.2.6 The leak detection sensitivity can be very good for this technique. Leaks smaller than 1 mm in diameter are routinely

found, including leaks through seams in the geomembrane.

4.2.7 The survey rate depends primarily on the manifold and squeegee width and the presence of wrinkles and waves in the

geomembrane.

4.3 Preparations and Measurement Considerations:

4.3.1 Proper field preparations and other measures shall be implemented to ensure an electrical connection to the conductive

material directly below the geomembrane is in place to successfully complete the leak location survey.

4.3.2 There shall be a conductive material below the geomembrane being tested. Leak location survey of geomembrane have

been conducted with a conductivity of a subgrade equivalent to sand with moisture greater than 0.7 % (by weight). A

properly-prepared subgrade typically will have sufficiently conductivity. Under proper conditions and preparations, geosynthetic

clay liners (GCLs) can be adequate as conductive material. There are some conductive geotextiles with successful field experience

which can be installed beneath the geomembrane to facilitate electrical leak survey (that is, on dry subgrades, or as part of a planar

drainage geocomposite).

4.3.3 Measures should be taken to perform the leak location survey when geomembrane wrinkles are minimized.

NOTE 1—The leak location survey should be conducted at night or early morning when wrinkles are minimized. Sometimes wrinkles can be flattened

by personnel walking or standing on them as the survey progresses.

4.3.4 For lining systems comprised of two geomembranes with only a geonet or geonet geocomposite between them, to make

the method feasible a conductive layer such as a conductive geotextile shall be installed under the geomembrane or integrated into

the geonet geocomposite.

4.3.5 For best results, conductive paths such as metal pipe penetrations, pump grounds, and batten strips on concrete should be

isolated or insulated from the water puddle on the geomembrane. These conductive paths conduct electricity and mask nearby leaks

from detection. See also Guide D6747.

4.3.6 Depending on specific construction practices and site conditions, other preparations and support may still be needed to

successfully perform the leak location survey.

4.3.7 The system specifications are presented in Table 1.

4. Significance and Use

4.1 Geomembranes are used as barriers to prevent liquids from leaking from landfills, ponds, and other containments. For this

purpose, it is desirable that the geomembrane have as little leakage as practical.

4.2 The liquids may contain contaminants that, if released, can cause damage to the environment. Leaking liquids can erode the

subgrade, causing further damage. Leakage can result in product loss or otherwise prevent the installation from performing its

intended containment purpose.

4.3 Geomembranes are often assembled in the field, either by unrolling and welding panels of the geomembrane material

together in the field, unfolding flexible geomembranes in the field, or a combination of both.

D7002 − 15

TABLE 1 Specifications—Water Puddle Leak Detection TechniquesSummary of Water Puddle Method

Geomembranes Bituminous, CSPE, CPE, EIA, fPP, HDPE, LLDPE, LDPE, PVC, VLDPE U applicable

EPDM, GCL X not applicable

Exposed U applicable

Covered X not applicable

A

Conductive-backed Geomembrane U applicable

Characteristics Training time 1 day

Set up time and calibration time 1 to 3 h

Measurement time instantaneous

Leak location time 10 min max

Subgrade moisture (by weight) equivalent to sand with > 0.7 %

Average survey speed (horizontal surface) 500 m per hour per operator

Power supply 12 or 24 volts dc or ac

Seams All types: welded, tape, adhesive, glued and other U applicable: project specific

Seams All types: welded, tape, adhesive, glued and other U applicable: project specific

Junctions At synthetic pipes and accessories U applicable: project specific

Junctions At synthetic pipes and accessories U applicable: project specific

At permanent structure U applicable: project specific

At grounded conducting structures X not applicable

Survey During construction phase (installation of GM) U applicable

After installation (exposed) U applicable

After soil covering X not applicable

Presence of large wrinkles and waves X not applicable

Slopes U applicable: project specific

Desiccated subgrade (conductivity equivalent to sand with < 0.7 % moisture) X not applicable

Insufficiently conductive subgrade X not applicable

During the service life (if exposed) U applicable

During the service life (if exposed) U project specific

Electrical isolated conductive structures U applicable

Climate Sunny, temperate, warm U applicable

Rainy weather, freezing weather X not applicable

Rainy weather X not applicable

Leak detected Size of 1 mm and larger U applicable

Frozen conditions X not applicable

Leaks detected Discrimination between multiple leaks U applicable

A

If used, conductive-backed geomembrane must be installed per the manufacturer’s recommendations in order to allow it to be tested using all of the available electrical

leak location methods. In particular, there must be some means to break the conductive path through the fusion welds along the entire lengths of the welds, the undersides

of adjacent panels (and patches) should be electrically connected together, and a means of preventing unwanted grounding at the anchor or other unwanted earth grounds

should be provided.

4.4 Geomembrane leaks can be caused by poor quality of the subgrade, poor quality of the material placed on the geomembrane,

accidents, poor workmanship, manufacturing defects, and carelessness.

4.5 Electrical leak location methods are an effective and proven quality assurance measure to detect and locate leaks.

5. Significance and Use

5.1 Geomembranes are used as barriers to prevent liquids from leaking from landfills, ponds, and other containments. For this

purpose, it is desirable that the geomembrane have as little leakage as practical.

5.2 The liquids may contain contaminants that if released can cause damage to the environment. Leaking li

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.