ASTM C1919-22

(Practice)Standard Practice for Measurement of the Steady-State Thermal Transmission Properties of Small Specimens Using the Heat Flow Meter Apparatus

Standard Practice for Measurement of the Steady-State Thermal Transmission Properties of Small Specimens Using the Heat Flow Meter Apparatus

SIGNIFICANCE AND USE

5.1 Thermal conductivity measurements on small insulation specimens are important during new product development processes or when larger specimens cannot be collected during forensic investigation (that is, failure analysis) (1, 2).

5.2 Numerous research projects have recently been initiated to develop insulation materials that have very high thermal resistivities (greater than 83 (m K)/W). Projects ranging from coatings to improve the thermal performance of single pane/layer glazing systems to the development of novel insulation products for building envelopes are being undertaken (1-4). All these projects have struggled in the development of new material technologies due to the difficulty associated with the measurement of thermal conductivity of small sections (approximately 0.025 m by 0.025 m) of high thermal resistance materials. As new materials are being developed, the size of each test specimen impacts the cost of development. Most of the existing test equipment and the methods do not align with the researcher’s need; the equipment requires a large specimen size is time consuming, and expensive to produce.

5.3 This practice provides a standardized procedure to enable the thermal characterization of small specimens of insulation materials. Accurate, and reliable thermal metrology to assess thermal properties of new insulation materials, such as novel very low thermal conductivity (

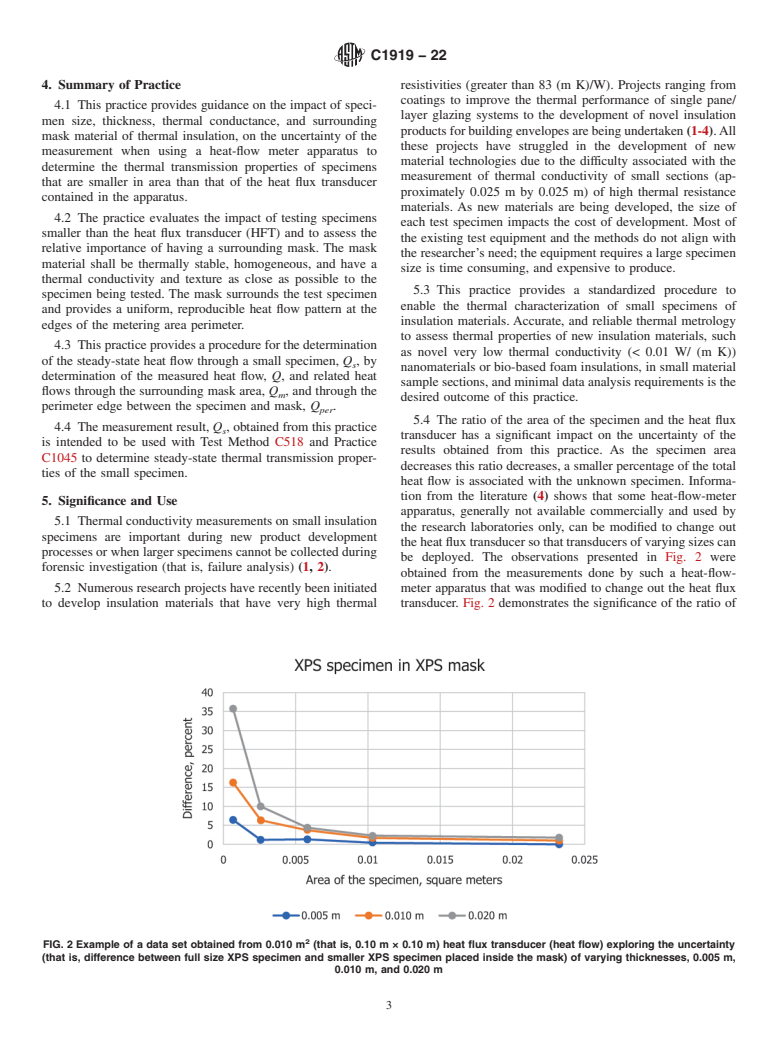

5.4 The ratio of the area of the specimen and the heat flux transducer has a significant impact on the uncertainty of the results obtained from this practice. As the specimen area decreases this ratio decreases, a smaller percentage of the total heat flow is associated with the unknown specimen. Information from the literature (4) shows that some heat-flow-meter apparatus, generally not available commercially and used by the research laboratories only, can be modified to change out the heat flux transducer so that transducers of varying sizes can be deployed. The observat...

SCOPE

1.1 This practice covers the measurement of steady state thermal transmission properties of the small flat slab thermal insulation specimen using a heat-flow-meter apparatus.

1.2 This practice provides a supplemental procedure for use in conjunction with Test Method C518 for testing a small specimen. This practice is limited to only small specimens and, in all other particulars, the requirements of Test Method C518 apply.

1.3 This practice characterizes small specimens having lateral dimensions less than the lateral dimensions of the heat flux transducer used to measure the heat flow. The procedure in Test Method C518 shall be used for specimens having lateral dimensions equal to or larger than the lateral dimensions of the heat flux transducer.

Note 1: The lower limit for specimen size is typically determined by the user for their particular material. As an example, Ref. (1)2 established a lower limit for specimen dimensions of 0.1 m by 0.1 m for several different thermal insulation materials for a 0.3 m by 0.3 m heat-flow-meter apparatus having a heat flux transducer 0.15 m by 0.15 m.

1.4 This practice is intended only for research purposes, in particular, when larger specimens are unavailable. This practice shall not be used in conjunction with Test Method C518 for certification testing of products; compliance with ASTM Specifications; or compliance with regulatory or building code requirements.

1.5 The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this practice.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationall...

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C1919 −22

Standard Practice for

Measurement of the Steady-State Thermal Transmission

Properties of Small Specimens Using the Heat Flow Meter

1

Apparatus

This standard is issued under the fixed designation C1919; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 This practice covers the measurement of steady state

1.7 This international standard was developed in accor-

thermal transmission properties of the small flat slab thermal

dance with internationally recognized principles on standard-

insulation specimen using a heat-flow-meter apparatus.

ization established in the Decision on Principles for the

1.2 This practice provides a supplemental procedure for use

Development of International Standards, Guides and Recom-

in conjunction with Test Method C518 for testing a small

mendations issued by the World Trade Organization Technical

specimen.Thispracticeislimitedtoonlysmallspecimensand,

Barriers to Trade (TBT) Committee.

in all other particulars, the requirements of Test Method C518

2. Referenced Documents

apply.

3

2.1 ASTM Standards:

1.3 This practice characterizes small specimens having

C168Terminology Relating to Thermal Insulation

lateral dimensions less than the lateral dimensions of the heat

C518Test Method for Steady-State Thermal Transmission

fluxtransducerusedtomeasuretheheatflow.Theprocedurein

Properties by Means of the Heat Flow Meter Apparatus

Test Method C518 shall be used for specimens having lateral

C1045Practice for Calculating Thermal Transmission Prop-

dimensionsequaltoorlargerthanthelateraldimensionsofthe

erties Under Steady-State Conditions

heat flux transducer.

NOTE 1—The lower limit for specimen size is typically determined by

2

3. Terminology

the user for their particular material.As an example, Ref. (1) established

a lower limit for specimen dimensions of 0.1 m by 0.1 m for several

3.1 Definitions—For definitions of terms and symbols used

differentthermalinsulationmaterialsfora0.3mby0.3mheat-flow-meter

in this test method, refer to Terminology C168 and to the

apparatus having a heat flux transducer 0.15 m by 0.15 m.

following subsections.

1.4 This practice is intended only for research purposes, in

3.2 Definitions of Terms Specific to This Standard:

particular, when larger specimens are unavailable. This prac-

3.2.1 mask, n—themaskisauniformthermalinsulation(for

ticeshallnotbeusedinconjunctionwithTestMethodC518for

3

example,mediumdensityfoam(≈25610kg/m ),aerogeletc.)

certificationtestingofproducts;compliancewithASTMSpeci-

having stable structural and thermal properties that covers the

fications; or compliance with regulatory or building code

entire heat-flow-meter plate area with a central section cut out

requirements.

representing the area covered by the specimen (see Fig. 1).

1.5 The values stated in SI units are to be regarded as the

3.3 Symbols and Units—The symbols used in this test

standard. No other units of measurement are included in this

method have the following significance:

practice.

3.3.1 λ —apparent thermal conductivity, W/(m·K).

a

1.6 This standard does not purport to address all of the 2

3.3.2 C—thermal conductance, W/(m ·K).

safety concerns, if any, associated with its use. It is the 2

3.3.3 R—thermal resistance, (m ·K)/W.

responsibility of the user of this standard to establish appro- 2

3.3.4 R —mask thermal resistance, (m ·K)/W.

m

3.3.5 Q—heat flow determined from Test Method C518,W.

3.3.6 Q —heat flow through the specimen area A,W.

s s

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal 3.3.7 Q —heat flow through the mask area A ,W.

m m

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal

Measurement.

3

Current edition approved Dec. 1, 2022. Published January 2023. DOI: 10.1520/ For referenced ASTM standards, visit the ASTM website, www.astm.org, or

C1919-22. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1919−22

FIG. 1 (a) Typical set up for thermal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.