ASTM E2562-12

(Test Method)Standard Test Method for Quantification of Pseudomonas aeruginosa Biofilm Grown with High Shear and Continuous Flow using CDC Biofilm Reactor

Standard Test Method for Quantification of <i>Pseudomonas aeruginosa</i> Biofilm Grown with High Shear and Continuous Flow using CDC Biofilm Reactor

SIGNIFICANCE AND USE

Bacteria that exist in biofilms are phenotypically different from suspended cells of the same genotype. Research has shown that biofilm bacteria are more difficult to kill than suspended bacteria (5, 7). Laboratory biofilms are engineered in growth reactors designed to produce a specific biofilm type. Altering system parameters will correspondingly result in a change in the biofilm. For example, research has shown that biofilm grown under high shear is more difficult to kill than biofilm grown under low shear (5, 8). The purpose of this test method is to direct a user in the laboratory study of a Pseudomonas aeruginosa biofilm by clearly defining each system parameter. This test method will enable an investigator to grow, sample, and analyze a Pseudomonas aeruginosa biofilm grown under high shear. The biofilm generated in the CDC Biofilm Reactor is also suitable for efficacy testing. After the 48 h growth phase is complete, the user may add the treatment in situ or harvest the coupons and treat them individually.

SCOPE

1.1 This test method specifies the operational parameters required to grow a reproducible (1) Pseudomonas aeruginosa biofilm under high shear. The resulting biofilm is representative of generalized situations where biofilm exists under high shear rather than being representative of one particular environment.

1.2 This test method uses the Centers for Disease Control and Prevention (CDC) Biofilm Reactor. The CDC Biofilm Reactor is a continuously stirred tank reactor (CSTR) with high wall shear. Although it was originally designed to model a potable water system for the evaluation of Legionella pneumophila (2), the reactor is versatile and may also be used for growing and/or characterizing biofilm of varying species (3-5).

1.3 This test method describes how to sample and analyze biofilm for viable cells. Biofilm population density is recorded as log10 colony forming units per surface area.

1.4 Basic microbiology training is required to perform this test method.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E2562 −12

Standard Test Method for

Quantification of Pseudomonas aeruginosa Biofilm Grown

with High Shear and Continuous Flow using CDC Biofilm

1

Reactor

This standard is issued under the fixed designation E2562; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

3

1.1 This test method specifies the operational parameters 2.1 ASTM Standards:

2

required to grow a reproducible (1) Pseudomonas aeruginosa D5465Practice for Determining Microbial Colony Counts

biofilm under high shear. The resulting biofilm is representa- from Waters Analyzed by Plating Methods

tive of generalized situations where biofilm exists under high 2.2 Other Standards:

shear rather than being representative of one particular envi- Method 9050 C.1.a Buffered Dilution Water Preparation

ronment. according to Eaton et al (6)

1.2 This test method uses the Centers for Disease Control

3. Terminology

and Prevention (CDC) Biofilm Reactor. The CDC Biofilm

3.1 Definitions:

Reactorisacontinuouslystirredtankreactor(CSTR)withhigh

3.1.1 biofilm, n—microorganisms living in a self-organized

wall shear. Although it was originally designed to model a

community attached to surfaces, interfaces, or each other,

potablewatersystemfortheevaluationof Legionella pneumo-

embedded in a matrix of extracellular polymeric substances of

phila (2), the reactor is versatile and may also be used for

microbial origin, while exhibiting altered phenotypes with

growingand/orcharacterizingbiofilmofvaryingspecies (3-5).

respect to growth rate and gene transcription.

1.3 This test method describes how to sample and analyze

3.1.1.1 Discussion—Biofilmsmaybecomprisedofbacteria,

biofilm for viable cells. Biofilm population density is recorded

fungi, algae, protozoa, viruses, or infinite combinations of

as log colony forming units per surface area.

these microorganisms. The qualitative characteristics of a

10

biofilm, including, but not limited to, population density,

1.4 Basic microbiology training is required to perform this

taxonomic diversity, thickness, chemical gradients, chemical

test method.

composition,consistency,andothermaterialsinthematrixthat

1.5 The values stated in SI units are to be regarded as

arenotproducedbythebiofilmmicroorganisms,arecontrolled

standard. No other units of measurement are included in this

by the physicochemical environment in which it exists.

standard.

3.1.2 coupon, n—biofilm sample surface.

1.6 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 This test method is used for growing a reproducible

priate safety and health practices and determine the applica-

Pseudomonas aeruginosa biofilm in a CDC Biofilm Reactor.

bility of regulatory limitations prior to use.

The biofilm is established by operating the reactor in batch

mode (no flow of the nutrients) for 24 h. A steady state

population is reached while the reactor operates for an addi-

1

This test method is under the jurisdiction of ASTM Committee E35 on

tional24hwithcontinuousflowofthenutrients.Theresidence

Pesticides, Antimicrobials, and Alternative Control Agents and is the direct

time of the nutrients in the reactor is set to select for biofilm

responsibility of Subcommittee E35.15 on Antimicrobial Agents.

Current edition approved April 1, 2012. Published June 2012. Originally

3

approved in 2007. Last previous edition approved in 2007 as E2562–07. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/E2562-12. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

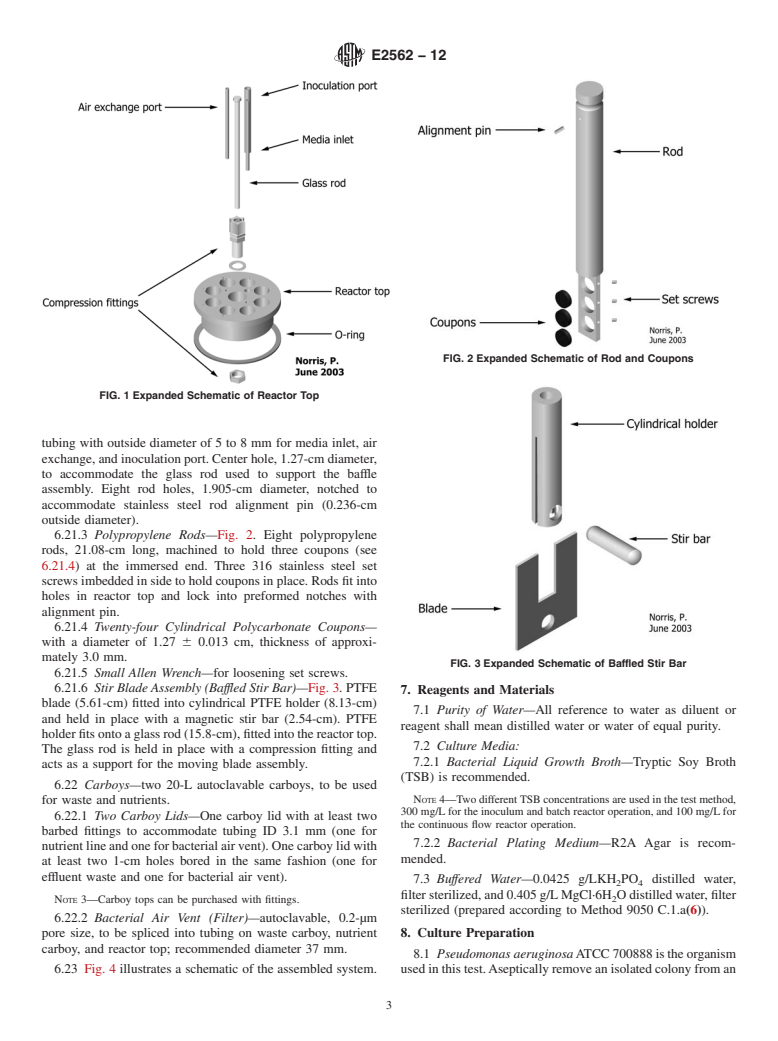

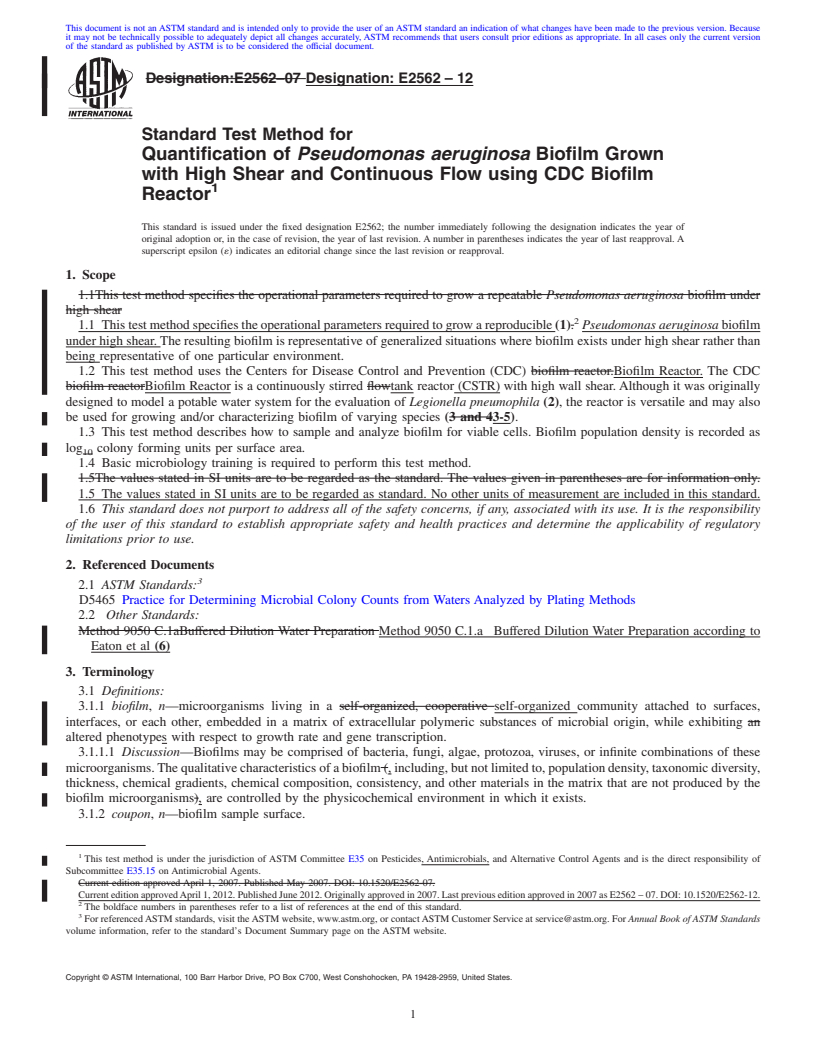

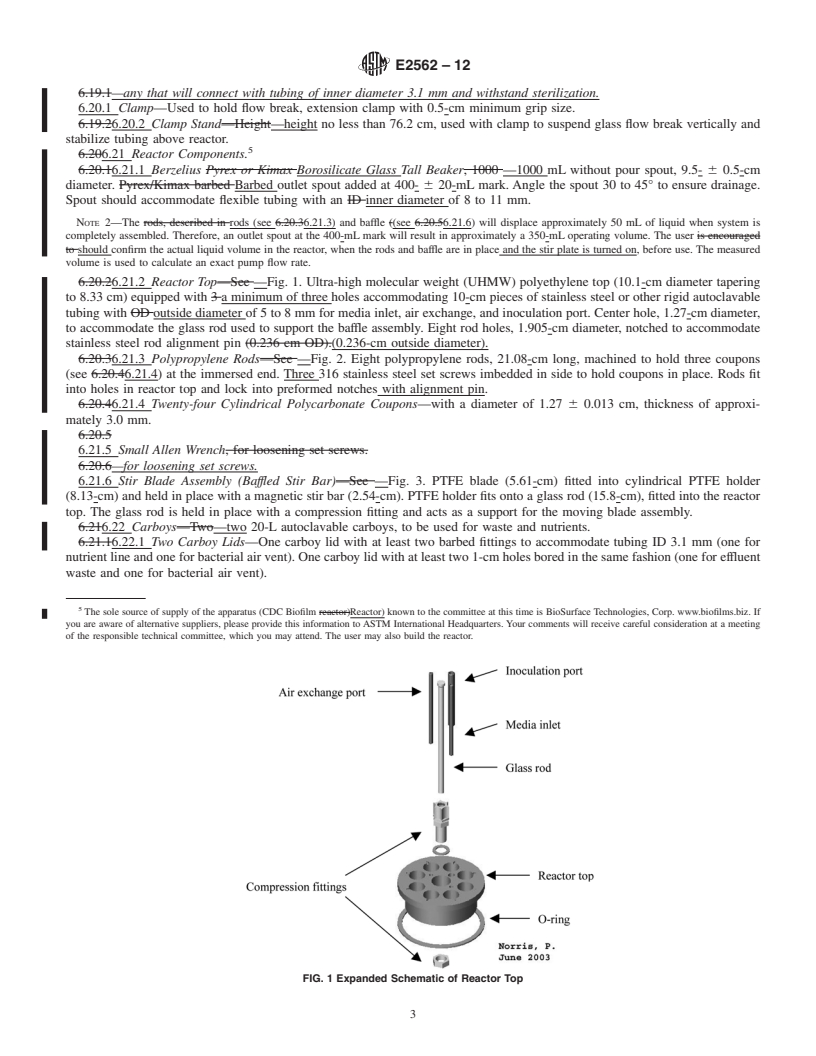

---------------------- Page: 1 ----------------------

E2562−12

4

NOTE 1—Alternatively, a coupon holder may be used.

growth, and is species and reactor parameter specific. During

theentire48h,thebiofilmisexposedtocontinuousfluidshear

6.12 Environmental Shaker—that can maintain a tempera-

from the rotation of a baffled stir bar. Controlling the rate at

ture of 36 6 2°C.

which the baffle turns determines the intensity of the shear

6.13 Analytical Balance—sensitive to 0.01 g.

stress to which the coupons are exposed.At the end of the 48

6.14 Sterilizer—any steam sterilizer that can produce the

h, biofilm accu

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2562–07 Designation: E2562 – 12

Standard Test Method for

Quantification of Pseudomonas aeruginosa Biofilm Grown

with High Shear and Continuous Flow using CDC Biofilm

1

Reactor

This standard is issued under the fixed designation E2562; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This test method specifies the operational parameters required to grow a repeatable Pseudomonas aeruginosa biofilm under

high shear

2

1.1 Thistestmethodspecifiestheoperationalparametersrequiredtogrowareproducible(1). Pseudomonasaeruginosabiofilm

under high shear.The resulting biofilm is representative of generalized situations where biofilm exists under high shear rather than

being representative of one particular environment.

1.2 This test method uses the Centers for Disease Control and Prevention (CDC) biofilm reactor.Biofilm Reactor. The CDC

biofilm reactorBiofilm Reactor is a continuously stirred flowtank reactor (CSTR) with high wall shear.Although it was originally

designed to model a potable water system for the evaluation of Legionella pneumophila (2), the reactor is versatile and may also

be used for growing and/or characterizing biofilm of varying species (3 and 43-5).

1.3 This test method describes how to sample and analyze biofilm for viable cells. Biofilm population density is recorded as

log colony forming units per surface area.

10

1.4 Basic microbiology training is required to perform this test method.

1.5The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

D5465 Practice for Determining Microbial Colony Counts from Waters Analyzed by Plating Methods

2.2 Other Standards:

Method 9050 C.1aBuffered Dilution Water Preparation Method 9050 C.1.a Buffered Dilution Water Preparation according to

Eaton et al (6)

3. Terminology

3.1 Definitions:

3.1.1 biofilm, n—microorganisms living in a self-organized, cooperative self-organized community attached to surfaces,

interfaces, or each other, embedded in a matrix of extracellular polymeric substances of microbial origin, while exhibiting an

altered phenotypes with respect to growth rate and gene transcription.

3.1.1.1 Discussion—Biofilms may be comprised of bacteria, fungi, algae, protozoa, viruses, or infinite combinations of these

microorganisms.Thequalitativecharacteristicsofabiofilm(,including,butnotlimitedto,populationdensity,taxonomicdiversity,

thickness, chemical gradients, chemical composition, consistency, and other materials in the matrix that are not produced by the

biofilm microorganisms), are controlled by the physicochemical environment in which it exists.

3.1.2 coupon, n—biofilm sample surface.

1

This test method is under the jurisdiction of ASTM Committee E35 on Pesticides, Antimicrobials, and Alternative Control Agents and is the direct responsibility of

Subcommittee E35.15 on Antimicrobial Agents.

Current edition approved April 1, 2007. Published May 2007. DOI: 10.1520/E2562-07.

CurrenteditionapprovedApril1,2012.PublishedJune2012.Originallyapprovedin2007.Lastpreviouseditionapprovedin2007asE2562 – 07.DOI:10.1520/E2562-12.

2

The boldface numbers in parentheses refer to a list of references at the end of this standard.

3

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2562 – 12

4. Summary of Test Method

4.1 This test method is used for growing a repeatablereproducible Pseudomonas aeruginosa biofilm in a CDC biofilm

reactor.Biofilm Reactor. The biofilm is established by operating the reactor in batch mode

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.