ASTM F480-00

(Specification)Standard Specification for Thermoplastic Well Casing Pipe and Couplings Made in Standard Dimension Ratios (SDR), SCH 40 and SCH 80

Standard Specification for Thermoplastic Well Casing Pipe and Couplings Made in Standard Dimension Ratios (SDR), SCH 40 and SCH 80

SCOPE

1.1 This specification covers water well casing pipe and couplings made from thermoplastic materials in standard dimension ratios (SDR), SCH 40 and SCH 80.

1.2 Specifications are provided for the application of these materials to water well and ground water monitoring applications. Flush threaded joint systems are included for screen and casing used primarily in the construction of ground water monitoring wells (see Practice D5092).

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only (see Practice E380). Note 1-Certain field conditions may require alternative materials to ensure safe long-term use. The user should consult federal, state, and local codes governing the use of thermoplastic materials for well casing or monitor pipe.

1.4 Although the pipe sizes and SDR values listed in this specification are generally available, numerous other plastic pipes in Schedule 40 and 80 wall, other SDR values and various outside diameters have been used for well casing. Such products are often selected because they fulfill certain needs and Annex A1 includes a list of these Plastic Pipe Well Casing Specials.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: F 480 – 00

Standard Specification for

Thermoplastic Well Casing Pipe and Couplings Made in

Standard Dimension Ratios (SDR), SCH 40 and SCH 80

This standard is issued under the fixed designation F480; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D618 Practice for Conditioning Plastics and Electrical

Insulating Materials for Testing

1.1 This specification covers water well casing pipe and

D638 Test Method for Tensile Properties of Plastics

couplings made from thermoplastic materials in standard

D648 Test Method for Deflection Temperature of Plastics

dimension ratios (SDR), SCH 40 and SCH 80.

Under Flexural Load

1.2 Specifications are provided for the application of these

D653 Terminology Relating to Soil, Rock, and Contained

materials to water well and ground water monitoring applica-

Fluids

tions. Flush threaded joint systems are included for screen and

D1527 Specification for Acrylonitrile-Butadiene-Styrene

casing used primarily in the construction of ground water

(ABS) Plastic Pipe, Schedules 40 and 80

monitoring wells (see Practice D5092).

D1600 Terminology for Abbreviated Terms Relating to

1.3 The values stated in inch-pound units are to be regarded

Plastics

as the standard. The values given in parentheses are provided

D1784 SpecificationforRigidPoly(VinylChloride)(PVC)

for information only (see Practice E380).

Compounds and Chlorinated Poly(Vinyl Chloride)

NOTE 1—Certain field conditions may require alternative materials to

(CPVC) Compounds

ensuresafelong-termuse.Theusershouldconsultfederal,state,andlocal

D1785 Specification for Poly(Vinyl Chloride) (PVC) Plas-

codes governing the use of thermoplastic materials for well casing or

tic Pipe, Schedules 40, 80, and 120

monitor pipe.

D1892 Specification for Styrene-Butadiene Molding and

1.4 Although the pipe sizes and SDR values listed in this 6

Extrusion Materials

specification are generally available, numerous other plastic

D1898 Practice for Sampling of Plastics

pipes in Schedule 40 and 80 wall, other SDR values and

D2122 Test Method for Determining Dimensions of Ther-

variousoutsidediametershavebeenusedforwellcasing.Such

moplastic Pipe and Fittings

products are often selected because they fulfill certain needs

D2235 Specification for Solvent Cement forAcrylonitrile-

andAnnexA1 includes a list of these Plastic PipeWell Casing

Butadiene-Styrene (ABS) Plastic Pipe and Fittings

Specials.

D 2241 Specification for Poly(Vinyl Chloride) (PVC)

1.5 The following safety hazards caveat pertains only to the

Pressure-Rated Pipe (SDR Series)

test method portion, Section 6, of this specification: This

D2282 Specification for Acrylonitrile-Butadiene-Styrene

standard does not purport to address all of the safety concerns,

(ABS) Plastic Pipe (SDR-PR)

if any, associated with its use. It is the responsibility of the user

D2412 TestMethodforDeterminationofExternalLoading

of this standard to establish appropriate safety and health

Characteristics of Plastic Pipe by Parallel-Pipe Loading

practices and determine the applicability of regulatory limita-

D2444 Test Method for Impact Resistance of Thermoplas-

tions prior to use.

tic Pipe and Fittings by Means of a Tup (Falling Weight)

D2564 Specification for Solvent Cements for Poly(Vinyl

2. Referenced Documents

Chloride) (PVC) Plastic Piping Systems

2.1 ASTM Standards:

D2672 Specification for Joints for IPS PVC Pipe Using

D256 Test Methods for Impact Resistance of Plastics and

Solvent Cement

Electrical Insulating Materials

D2855 Practice for Making Solvent-Cemented Joints with

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

ThisspecificationisunderthejurisdictionofASTMCommitteeF-17onPlastic

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water

Systems. Annual Book of ASTM Standards, Vol 04.08.

Current edition approved April 10, 2000. Published July 2000. Originally Annual Book of ASTM Standards, Vol 08.04.

published as F480–76. Last previous edition F480–99a. Annual Book of ASTM Standards, Vol 08.02.

2 6

Annual Book of ASTM Standards, Vol 08.01. Discontinued—Replaced by Specification D4549.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 480

NOTE 2—Caution should be exercised to control heat of hydration

D3122 Specification for Solvent Cements for Styrene-

during grouting as thermoplastic materials are heat sensitive.Accelerators

Rubber (SR) Plastic Pipe and Fittings

tend to increase the heat of hydration and are not recommended.

D3965 Specification for Rigid Acrylonitrile-Butadiene-

5.2 Acrylonitrile-butadiene-styrene (ABS) well casing pipe

Styrene (ABS) Compounds for Pipe and Fittings

D5092 Practice for Design and Installation of Ground and couplings plastic shall be virgin plastic produced by the

original compounder (see Specification D1527). The mini-

Water Monitoring Wells in Aquifers

E380 Practice for Use of the International System of Units mum butadiene content is 6%; the minimum acrylonitrile

content is 15%; the minimum styrene or substituted styrene

(SI) (The Modernized Metric System)

F402 Practice for Safe Handling of Solvent Cements, content, or both, is 15%; and the maximum content of other

monomers is 5% and lubricants, stabilizers, and colorants.

Primers,andCleanersUsedforJoiningThermoplasticPipe

and Fittings 5.3 Poly(vinyl chloride) (PVC) well casing pipe and cou-

plings plastic shall be made of virgin plastic produced by the

F412 Terminology Relating to Plastic Piping Systems

2.2 ANSI Standards: original compounder. It shall contain poly(vinyl chloride)

homopolymer, and such additives—stabilizers, lubricants, pro-

B1.5 ACME Screw Threads

cessing aids, impact improvers, and colorants—as needed to

B1.8 Stub ACME Screw Threads

B1.9 Buttress Inch Screw Threads provide the required processing and toughness characteristics

(see Test Method D638).

2.3 Federal Standard:

FED-STD-123 Marking for Shipment (Civil Agencies) 5.4 The SR plastics compound shall contain at least 50%

styrene plastics, combined with rubbers to a minimum rubber

2.4 Military Standard:

MIL-STD-129 Marking for Shipment and Storage content of 5%, and compounding materials such as antioxi-

dants and lubricants, and may contain up to 15% acrylonitrile

2.5 Other Standards:

Screw-Threads Standards for Federal Services 1957, Hand- combined in the styrene plastics or rubbers, or both. The

rubbers shall be of the poly-butadiene or butadiene-styrene

book H28, Part III

NSF 14 Plastic Piping System Components and Related type, or both, with a maximum styrene content of 25% or

nitrile type, or both. The combined styrene plastics and rubber

Materials

NSF 61 Drinking Water System Components content shall be not less than 90%.

5.5 Rework Material—Clean rework material generated

3. Terminology

from the manufacturer’s own well casing pipe and couplings

3.1 Definitions are in accordance with Terminology F412 production may be used by the same manufacturer, provided

andabbreviationsareinaccordancewithTerminologyD1600,

the well casing pipe and couplings produced meet all the

unless otherwise specified. The abbreviation for acrylonitrile- requirements of this specification.

butadiene-styrene plastic is ABS. The abbreviation for poly-

5.6 Solvent Cement:

(vinyl chloride) is PVC.The abbreviation for styrene-rubber is 5.6.1 Specification—The solvent cement shall meet the

SR.

requirements of Specification D2235 for ABS, Specification

3.2 Groundwaterinvestigationtermsareinaccordancewith D2564 for PVC, or Specification D3122 for SR (see Supple-

Terminology D653. mentary Requirements S3).

4. Classification 6. Requirements

4.1 Well casing is produced in either plain end, belled end, 6.1 Workmanship—The pipe shall be homogeneous

or threaded, and is used for water wells, ground water throughout and essentially uniform in color, opacity, density,

monitoring, leak detection, recovery systems, dewatering sys- and other properties. The inside and outside surfaces shall be

tems, and waste disposal. semi-matte or glossy in appearance (depending on the type of

plastic) and free of chalking, sticky, or tacky material. The

5. Materials and Manufacture

surfaces shall be free of excessive bloom, that is, slight bloom

5.1 Specification—The material described shall meet or

is acceptable. The pipe walls shall be free of cracks, holes,

exceed the requirements of (1) Specification D3965 for ABS

blisters, voids, foreign inclusion, or other defects that are

with a cell classification of 44322 or 33333, (2) Specification

visible to the naked eye and that may affect the wall integrity.

D1784forPVCwithacellclassificationof12454Cor14333C

Machined slots or holes deliberately placed in pipe are accept-

or D, or (3) Specification D1892 for SR with a cell classifi-

able.Bloomorchalkingmaydevelopinpipeexposedtodirect

cation of 4434A. The material so described shall be approved

rays of the sun (ultraviolet radiant energy) for extended

for potable water.

periods, and consequently these requirements do not apply to

pipe after extended exposure to direct rays of the sun.

6.1.1 GroundWaterInvestigations—Pipemanufacturedinto

Annual Book of ASTM Standards, Vol 14.02.

8 products used in ground water investigations should have

Available fromAmerican National Standards Institute, 11 West 42nd St., 13th

surfaces that are visually free of oils, grease, dust, and marks

Floor, New York, NY 10036. Sponsored by the American Society of Mechanical

Engineering, United Engineering Center, 345 East 47th St., New York, NY 10017.

imparted as a result of the manufacturing process.

AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

6.2 Well Casing Pipe:

Robbins Ave., Philadelphia, PA 19111-5094.

6.2.1 Dimensions—Theoutsidediameterandwallthickness

Available from the Superintendent of Documents, Washington, DC.

NSF International, PO Box 130140, Ann Arbor, MI 48113–0140. of the well casing pipe shall meet the requirements given in

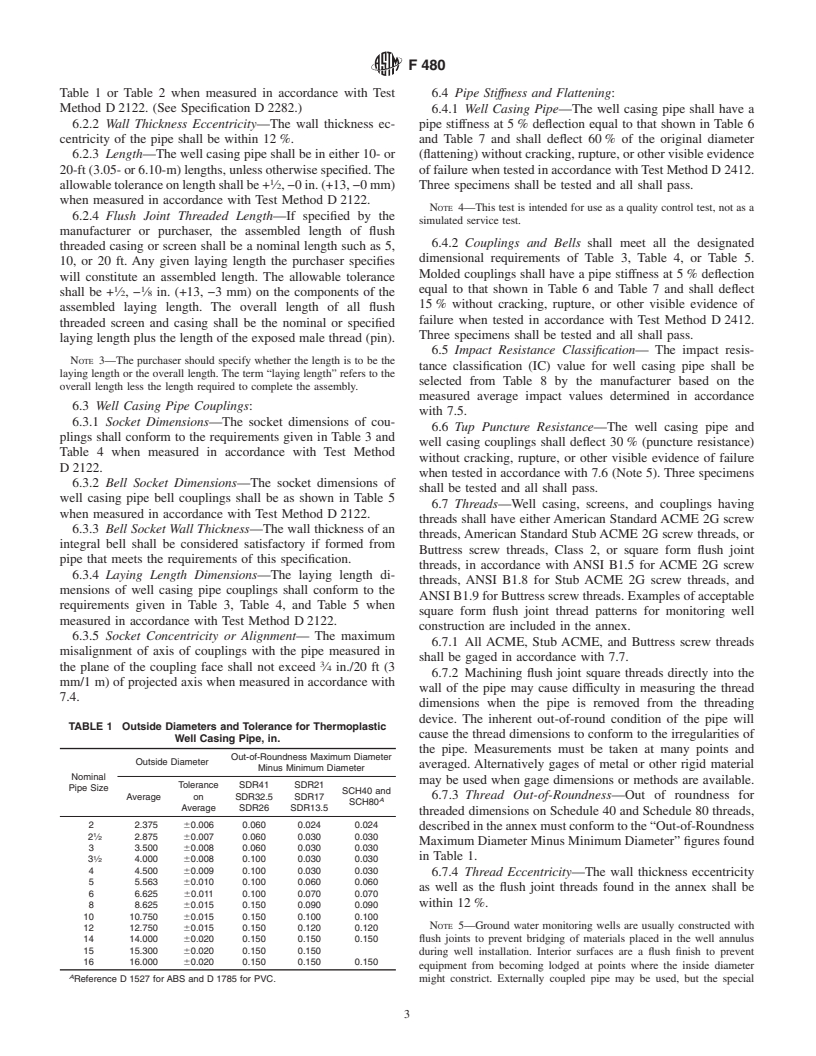

F 480

Table 1 or Table 2 when measured in accordance with Test 6.4 Pipe Stiffness and Flattening:

Method D2122. (See Specification D2282.) 6.4.1 Well Casing Pipe—The well casing pipe shall have a

6.2.2 Wall Thickness Eccentricity—The wall thickness ec- pipe stiffness at 5% deflection equal to that shown in Table 6

centricity of the pipe shall be within 12%. and Table 7 and shall deflect 60% of the original diameter

6.2.3 Length—The well casing pipe shall be in either 10- or (flattening)withoutcracking,rupture,orothervisibleevidence

20-ft(3.05-or6.10-m)lengths,unlessotherwisespecified.The offailurewhentestedinaccordancewithTestMethodD2412.

allowabletoleranceonlengthshallbe+ ⁄2,−0in.(+13,−0mm) Three specimens shall be tested and all shall pass.

when measured in accordance with Test Method D2122.

NOTE 4—This test is intended for use as a quality control test, not as a

6.2.4 Flush Joint Threaded Length—If specified by the

simulated service test.

manufacturer or purchaser, the assembled length of flush

6.4.2 Couplings and Bells shall meet all the designated

threaded casing or screen shall be a nominal length such as 5,

dimensional requirements of Table 3, Table 4, or Table 5.

10, or 20 ft. Any given laying length the purchaser specifies

Molded couplings shall have a pipe stiffness at 5% deflection

will constitute an assembled length. The allowable tolerance

1 1 equal to that shown in Table 6 and Table 7 and shall deflect

shall be + ⁄2,− ⁄8 in. (+13, −3 mm) on the components of the

15% without cracking, rupture, or other visible evidence of

assembled laying length. The overall length of all flush

failure when tested in accordance with Test Method D2412.

threaded screen and casing shall be the nominal or specified

Three specimens shall be tested and all shall pass.

laying length plus the length of the exposed male thread (pin).

6.5 Impact Resistance Classification— The impact resis-

NOTE 3—The purchaser should specify whether the length is to be the

tance classification (IC) value for well casing pipe shall be

laying length or the overall length. The term “laying length” refers to the

selected from Table 8 by the manufacturer based on the

overall length less the length required to complete the assembly.

measured average impact values determined in accordance

6.3 Well Casing Pipe Couplings:

with 7.5.

6.3.1 Socket Dimensions—The socket dimensions of cou-

6.6 Tup Puncture Resistance—The well casing pipe and

plings shall conform to the requirements given in Table 3 and

well casing couplings shall deflect 30% (puncture resistance)

Table 4 when measured in accordance with Test Method

without cracking, rupture, or other visible evidence of failure

D2122.

when tested in accordance with 7.6 (Note 5). Three specimens

6.3.2 Bell Socket Dimensions—The socket dimensions of

shall be tested and all shall pass.

well casing pipe bell couplings shall be as shown in Table 5

6.7 Threads—Well casing, screens, and couplings having

when measured in accordance with Test Method D2122.

threads shall have eitherAmerican StandardACME 2G screw

6.3.3 Bell Socket Wall Thickness—The wall thickness of an

threads,American Standard StubACME 2G screw threads, or

integral bell shall be considered satisfactory if formed from

Buttress screw threads, Class 2, or square form flush joint

pipe that meets the requirements of this specification.

threads, in accordance with ANSI B1.5 for ACME 2G screw

6.3.4 Laying Length Dimensions—The laying length di-

threads, ANSI B1.8 for Stub ACME 2G screw threads, and

mensions of well casing pipe couplings shall conform to the

ANSIB1.9forButtressscrewthreads.Examplesofacceptable

requirements given in Table 3, Table 4, and Table 5 when

square form flush joint thread patterns for monitoring well

measured in accordance with Test Method D2122.

construction are included in the annex.

6.3.5 Socket Concentricity or Alignment— The maximum

6.7.1 All ACME, Stub ACME, and Buttress screw threads

misalignment of axis of couplings with the pipe measured in

shall be gaged in accordance with 7.7.

the plane of the coupling face shall not exceed ⁄4 in./20 ft (3

6.7.2 Machining flush joint square threads directly into the

mm/1 m) of projected axis when measured in accordance with

wall of the pipe may cause difficulty in measuring the thread

7.4.

dimensions when the pipe is removed from the threading

device. The inherent out-of-round condition of the pipe will

TABLE 1 Outside Diameters and Tolerance for Thermoplastic

cause the thread dimensions to conform to the irregularities of

Well Casing Pipe, in.

the pi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.