ASTM B339-00(2005)

(Specification)Standard Specification for Pig Tin

Standard Specification for Pig Tin

ABSTRACT

This specification covers refined tin in pig form recovered and cast from primary and secondary tin bearing materials. One grade of tin metal is specified and is designated as Grade A. The refined tin shall be produced from primary, secondary, or a combination of tin-bearing materials to obtain the requirements of this specification, and may be manufactured by fire refining, vacuum refining, electrolytic or electrowinning refining methods, or a combination of these methods. The metal shall conform to the chemical composition requirements prescribed for tin, antimony, arsenic, bismuth, cadmium, copper, iron, lead, nickel, sulfur, zinc, silver, and other impurities. All tin of Grade A produced and cast at one time shall constitute a lot for chemical analysis. Sampling for chemical analysis shall be one of the following methods: (1) sampling from the lot during casting, and (2) sampling from the solidified cast pig product by sawing, drilling, or melting. The methods of sampling cast pig product are illustrated. If product analysis is desired, it may be made by methods including, but not limited to, wet chemical or spectrographic techniques.

SCOPE

1.1 This specification covers refined tin in pig form recovered and cast from primary and secondary tin-bearing materials. One grade of tin metal is specified and is designated by the grade letter shown in .

1.2 The percent values of tin contained are to be regarded as the standard.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B339 – 00 (Reapproved 2005)

Standard Specification for

Pig Tin

This standard is issued under the fixed designation B339; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

TABLE 1 Chemical Composition and Impurity Contents

1. Scope

Composition, - wt%

1.1 This specification covers refined tin in pig form recov-

Grade “A” for

ered and cast from primary and secondary tin-bearing materi-

Element

Ultra Pure

Grade “A” the Manufacture

als. One grade of tin metal is specified and is designated by the Grade

of Tinplate

grade letter shown in Table 1.

Tin, min 99.85 99.85 99.95

1.2 The percent values of tin contained are to be regarded as

Antimony, max 0.04 0.04 0.005

the standard. Arsenic, max 0.05 0.05 0.005

Bismuth, max 0.030 0.030 0.015

1.3 The values stated in inch-pound units are to be regarded

Cadmium, max 0.001 0.001 0.001

as standard. The values given in parentheses are mathematical

Copper, max 0.04 0.04 0.005

conversions to SI units that are provided for information only Iron, max 0.010 0.010 0.010

Lead, max 0.05 0.010 0.001

and are not considered standard.

Ni+ Co, max 0.01 0.01 0.010

1.4 This standard does not purport to address all of the

Sulfur, max 0.01 0.01 0.010

Zinc, max 0.005 0.005 0.005

safety concerns, if any, associated with its use. It is the

Silver, max 0.01 0.01 0.010

responsibility of the user of this standard to become familiar

A

Other impurities 0.010 0.010

with all hazards including those identified in the appropriate

A

Maximum per impurity not listed above.

Material Safety Data Sheet (MSDS) for this product/material

as provided by the manufacturer, to establish appropriate

safety and health practices, and determine the applicability of

3. Terminology

regulatory limitations prior to use.

3.1 Definitions of Terms Specific to This Standard:

2. Referenced Documents

3.1.1 pig, n—an oblong or square mass of metal that has

2.1 ASTM Standards:

been cast while still molten into a mold that gives the metal its

E29 Practice for Using Significant Digits in Test Data to

particular shape.

Determine Conformance with Specifications

4. Ordering Information

E46 Test Methods for Chemical Analysis of Lead- and

Tin-Base Solder 4.1 Orders for material under this specification shall include

E51 Method for Spectrographic Analysis of Tin Alloys by the following information:

the Powder Technique 4.1.1 ASTM designation and year of issue,

E57 Method for Chemical Analysis of White Metal Bear- 4.1.2 Quantity in weight, metric tons or kilograms,

ings Alloy 4.1.3 Shape and size,

E88 Practice for Sampling Nonferrous Metals andAlloys in 4.1.4 Method of manufacturing (Section 5),

Cast Form for Determination of Chemical Composition 4.1.5 Chemistry (Section 6),

4.1.6 Product marking (Section 16), and

4.1.7 Packaging (Section 17).

This specification is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

5. Materials and Manufacture

B02.02 on Refined Lead, Tin, Antimony, and Their Alloys.

Current edition approved Nov. 1, 2005. Published February 2006. Originally

5.1 The refined tin shall be produced from primary, second-

approved in 1967. Last previous edition approved in 2000 as B339 - 00. DOI:

ary, or a combination of tin-bearing materials to obtain the

10.1520/B0339-00R05.

2 requirements of this specification.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 5.2 The refined metal for GradeAtin may be manufactured

Standards volume information, refer to the standard’s Document Summary page on

by fire refining, vacuum refining, electrolytic or electrowinning

the ASTM website.

refining methods, or a combination of these methods.

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

B339 – 00 (2005)

6. Chemical Composition

6.1 The tin shall conform to the requirements as to chemical

composition prescribed in Table 1.

7. Methods of Chemical Analysis

7.1 An analysis of each lot shall be made by the supplier.

The analysis shall be made from representative test samples

obtained from the lot during pouring or from the final pig

product. The chemical composition determined shall conform

to the requirements of Table 1.

7.2 If a product analysis is desired by the purchaser, it shall

be made in the purchaser’s laboratory or elsewhere. Such

analysis may be made by various methods including, but not

limited to, wet chemical or spectrographic techniques.

8. Lot

8.1 All tin of Grade A produced and cast at one time shall

constitute a lot for chemical analysis. Each pig of the lot shall

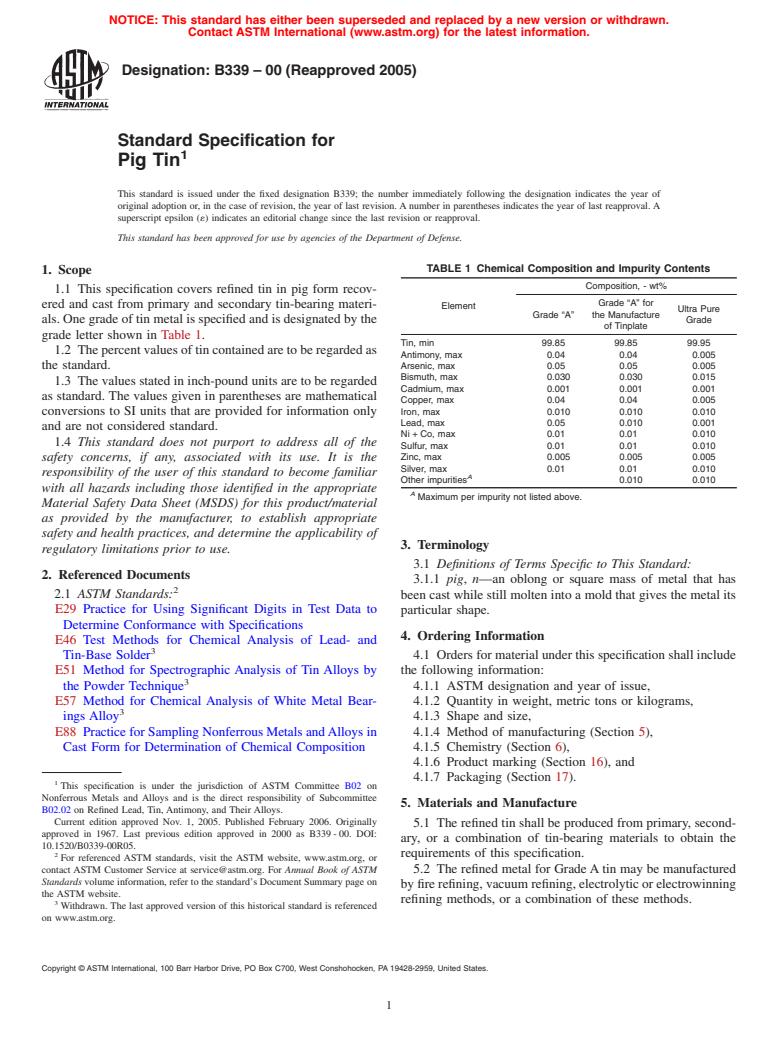

FIG. 1 Pig Tin Sampling Methods

bear a single identifying number that can be related to the

manufacturing lot. This lot number can be cast, metal die

10.3.2 Sampling—Aportion representative of the total ship-

stamped, or marked legibly upon each pig.

ment shall be selected at random for the final sample. For lots

containing at least 55 115 lb (25 000 kg) of pig tin, one pig

9. Workmanship, Finish and Appearance

shallbetakenforevery10 000lb(4530kg)orpartthereof.For

9.1 The manufacturer shall use care to have each lot of tin

smaller lots, five pigs shall be taken at random. In case of

material as uniform in quality as possible.

shipment lots less than five pigs, each pig shall be sampled at

9.2 The pigs shall be clean and reasonably free of adhering

least once or as many times as may be necessary to provide a

foreign material.

sufficient sample for analysis. A minimum of five pigs is

preferred for sampling. If a shipment is comprised of batches

10. Sampling for Chemical Analysis

identified by heat numbers, each heat should be sampled as a

10.1 Care must be taken to ensure that the sample selected

separate lot.

for testing is representative of the material. The method of

10.3.3 Sample Preparation—Each pig should be cleaned

sampling for chemical analysis shall be agreed upon mutually

thoroughly to rid the surface of dirt or adhering foreign

between the supplier and the purchaser and shall consist of one

material prior to sampling by one of the following methods:

of the following methods:

sawing, drilling, or melting.

10.1.1 Test samples taken from the lot during casting or

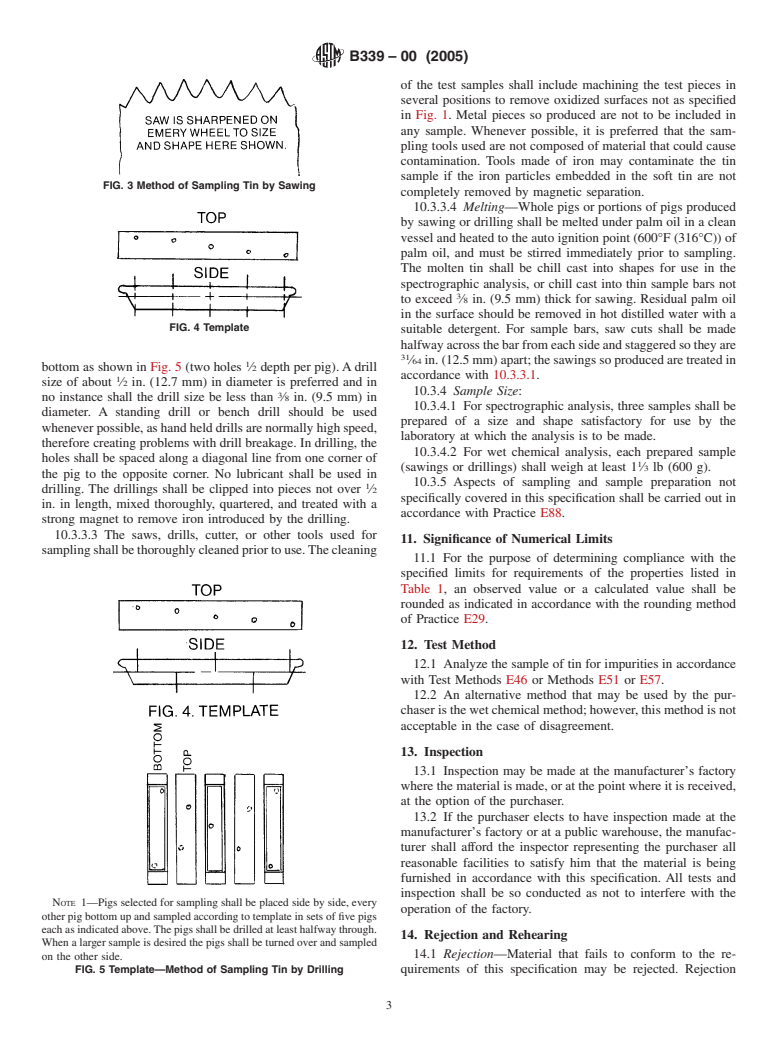

10.3.3.1 Sawing—The pigs selected shall be sawed com-

10.1.2 Test samples taken from the final solidified cast pig

pletely through as illustrated in Fig. 1 (one cut per pig) or shall

product.

be sawed half way across from both sides as illustrated in Fig.

10.2 Sampling From the Lot During Casting—The supplier

2 and Fig. 3 (two cuts on each pig). The sawings from all the

may obtain representative chill cast samples from the lot of

pigs shall be mixed thoroughly and quartered, and the samples

molten metal during casting.The shape of the cast sample shall

for analysis taken from the mixed material. The sawings must

be agreed upon by all parties concerned. The molten metal

be free of extraneous material introduced from the saw blade.

shall be mechanically stirred and dip samples taken. If the

All sawings should be screened to remove any coagulated saw

material is produced in a pot or kettle, the material shall be

chips and treated with a strong magnet to remove iron

drossed, stirred, and dip samples taken. If the facility does not

introduced by sawing. No lubricant shall be used when sawing.

allow for dip sampling, the samples shall be taken at the

10.3.3.2 Drilling—The pigs shall be drilled all the way

beginning, at the middle, and at the end of the pour. The

through the depth of pig as shown in Fig. 4 (one hole per pig)

sampling ladle must be clean and heated and the molten metal

or drilled half way through the depth of pig from top and

cast into chilled molds which produce forms suitable for

instrument use, drilling of cast sample, or sawing of cast

sample. Samples drawn at the producers plant shall be from a

clean bath of metal with all dross having been removed.

10.3 Sampling of Cast Pig Product:

10.3.1 If the pigs are of standard form (see Fig. 1), the

sample for chemical analysis shall be taken in accordance with

10.3.3.1, 10.3.3.2,or 10.3.3.4. If the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.