ASTM A626/A626M-22

(Specification)Standard Specification for Tin Mill Products, Electrolytic Tin Plate, Double Reduced

Standard Specification for Tin Mill Products, Electrolytic Tin Plate, Double Reduced

ABSTRACT

This specification covers double-reduced electrolytic tin plate produced from low-carbon cold-reduced steel furnished in coils and cut sizes for use predominately in the manufacture of cans. Double-reduced plate is relatively brittle and has very distinct directional properties. The rolling direction shall be specified on cut sizes and will be indicated by underlining the slit (rolling width) dimension. In sampling for tin coating weights [masses], the following procedure shall be used: a test strip shall be taken at random from a representative section of each coil across its width; from one or two coil lots, each coil shall be sampled; and a sheet shall be taken at random from each packages, each taken from different bundles from any one item of a specific shipment. X-ray fluorescence method shall be performed to determine the tin coating weight. Surface appearance shall be bright or matte depending on coating processes and the base metal finish shall have a smooth finish with grit lines. Chemical treatments for tin plate shall be cathodic sodium dichromate (CDC) treatment or sodium dichromate dip (SDCD/SDD) treatment. Electrolytic tin plate is furnished with an oil film applied to both surfaces.

SCOPE

1.1 This specification covers double-reduced electrolytic tin plate produced from low-carbon cold-reduced steel furnished in coils and cut sizes for use predominately in the manufacture of cans. It is furnished in commercially available tin coating weights [masses] and is normally supplied with a trimmed edge.

1.2 This specification is applicable to orders in either inch-pound units (as A626) which is supplied in thicknesses from 0.0050 to 0.0118 in. or SI units [as A626M] which is supplied in thicknesses from 0.127 to 0.300 mm.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A626/A626M −22

Standard Specification for

1

Tin Mill Products, Electrolytic Tin Plate, Double Reduced

This standard is issued under the fixed designationA626/A626M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* A623 Specification for Tin Mill Products, General Require-

ments

1.1 This specification covers double-reduced electrolytic tin

A623M Specification for Tin Mill Products, General Re-

plate produced from low-carbon cold-reduced steel furnished

quirements [Metric]

in coils and cut sizes for use predominately in the manufacture

A630 Test Methods for Determination of Tin Coating

of cans. It is furnished in commercially available tin coating

Weights for Electrolytic Tin Plate

weights [masses] and is normally supplied with a trimmed

A754/A754M Test Method for Coating Weight [Mass] of

edge.

Metallic Coatings on Steel by X-Ray Fluorescence

1.2 This specification is applicable to orders in either

B339 Specification for Pig Tin

inch-pound units (as A626) which is supplied in thicknesses

from 0.0050 to 0.0118 in. or SI units [as A626M] which is 3. Ordering Information

supplied in thicknesses from 0.127 to 0.300 mm.

3.1 Orders for product under this specification shall include

1.3 Units—The values stated in either SI units or inch- the following information, as required and applicable, to

describe adequately the desired product:

pound units are to be regarded separately as standard. The

values stated in each system are not necessarily exact equiva- 3.1.1 Name of product (double-reduced electrolytic tin

plate) (Section 1),

lents; therefore, to ensure conformance with the standard, each

system shall be used independently of the other, and values 3.1.2 Tincoatingweight[mass]designation,andmarking,if

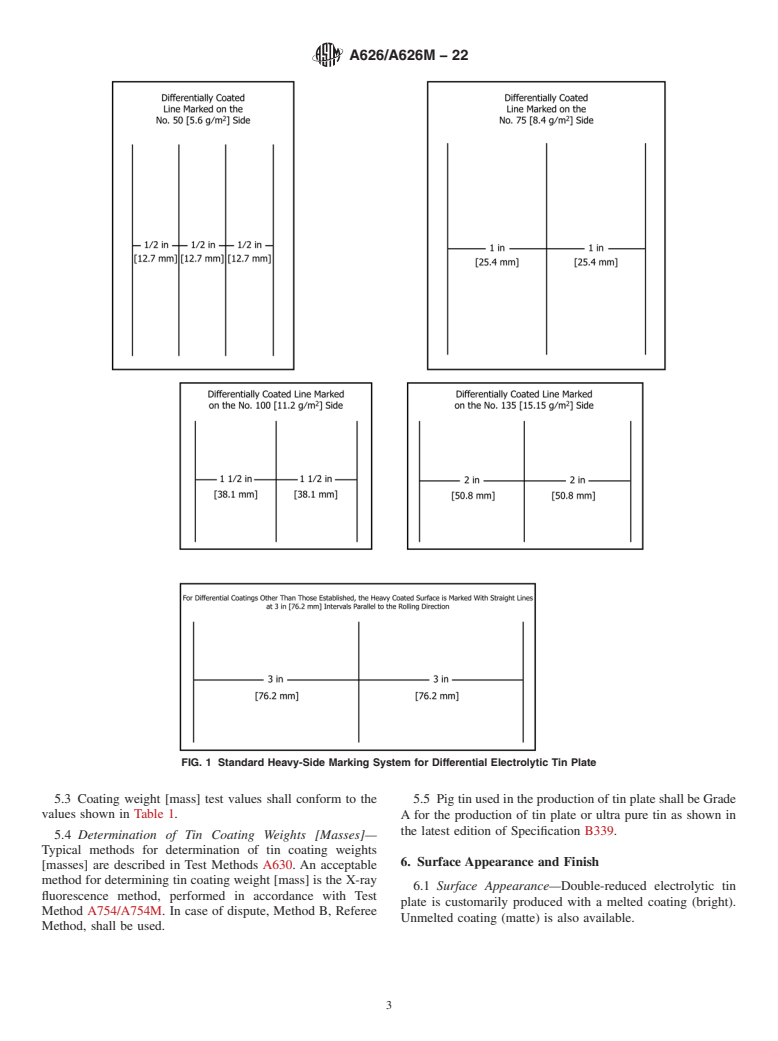

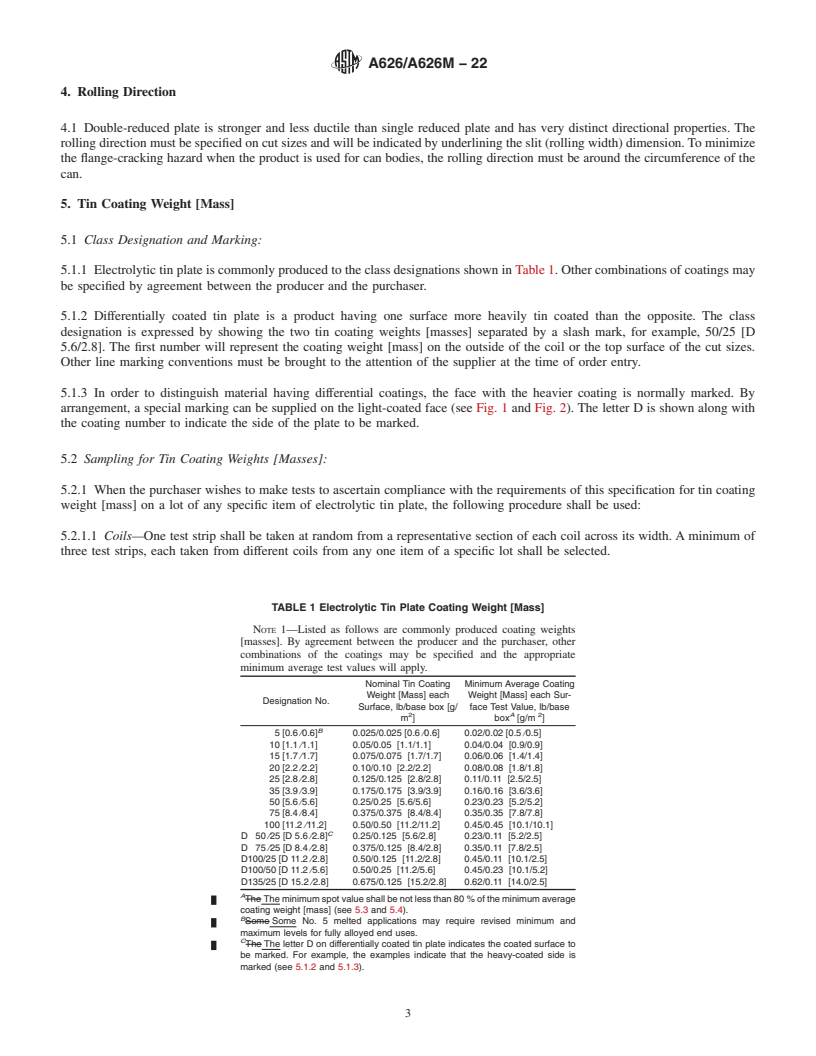

any (Section 5, Table 1, and Figs. 1 and 2),

from the two systems shall not be combined.

3.1.3 Surface appearance and finish (Section 6),

1.4 This standard does not purport to address all of the

3.1.4 Chemical treatment (Section 7),

safety concerns, if any, associated with its use. It is the

3.1.5 Oiling (Section 8),

responsibility of the user of this standard to establish appro-

3.1.6 Thickness (Specification A623 [A623M]) (consistent

priate safety, health, and environmental practices and deter-

with the intended application),

mine the applicability of regulatory limitations prior to use.

1

3.1.7 Coilwidthorcutsizeinincrementsof ⁄16 in.or1 mm,

1.5 This international standard was developed in accor-

3.1.8 Due to the very distinct directional properties, rolling

dance with internationally recognized principles on standard-

direction must be specified on cut sizes by underlining the slit

ization established in the Decision on Principles for the

(rolling width) dimension (Section 4) (consistent with the

Development of International Standards, Guides and Recom-

intended application),

mendations issued by the World Trade Organization Technical

3.1.9 Steel type (Specification A623 [A623M]),

Barriers to Trade (TBT) Committee.

3.1.10 Mechanical requirement designation (Specification

A623 [A623M]) (consistent with the intended application),

2. Referenced Documents

3.1.11 Intended application,

2

2.1 ASTM Standards:

3.1.12 Quantity in base boxes SITAs (see Note 4),

3.1.13 On coils, specify minimum or range of acceptable

inside diameters. The standard inside diameter is approxi-

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

mately 16 in. if ordered to Specification A626 [410 mm if

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

ordered to Specification A626M]. Coils should be specified to

A01.20 on Tin Mill Products.

a maximum coil weight if ordered to SpecificationA626 [mass

Current edition approved March 1, 2022. Published March 2022. Originally

if ordered to Specification A626M] or maximum outside

approved in 1968. Last previous edition approved in 2016 as A626/A626M – 16.

DOI: 10.1520/A0626_A0626M-22.

diameter, or both,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.14 Packaging,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.1.15 Special requirements, where applicable (J = plate or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. K = plate), and

*A Summary of Changes section appears at the end of t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A626/A626M − 16 A626/A626M − 22

Standard Specification for

1

Tin Mill Products, Electrolytic Tin Plate, Double Reduced

This standard is issued under the fixed designation A626/A626M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers double-reduced electrolytic tin plate produced from low-carbon cold-reduced steel furnished in coils

and cut sizes for use predominately in the manufacture of cans. It is furnished in commercially available tin coating weights

[masses] and is normally supplied with a trimmed edge.

1.2 This specification is applicable to orders in either inch-pound units (as A626) which is supplied in thicknesses from 0.0050

to 0.0118 in. 0.0118 in. or SI units [as A626M] which is supplied in thicknesses from 0.127 to 0.300 mm.0.300 mm.

1.3 Units—The values stated in either inch-pound or SI units or inch-pound units are to be regarded as standard. Within the text,

the SI units are shown in brackets. separately as standard. The values stated in each system are not exact equivalents. Therefore,

each system mustnecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other. Combiningother, and values from the two systems may result in nonconformance with this

specification.shall not be combined.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A623 Specification for Tin Mill Products, General Requirements

A623M Specification for Tin Mill Products, General Requirements [Metric]

A630 Test Methods for Determination of Tin Coating Weights for Electrolytic Tin Plate

A754/A754M Test Method for Coating Weight [Mass] of Metallic Coatings on Steel by X-Ray Fluorescence

B339 Specification for Pig Tin

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.20

on Tin Mill Products.

Current edition approved Dec. 1, 2016March 1, 2022. Published December 2016March 2022. Originally approved in 1968. Last previous edition approved in 20132016

as A626/A626M -13. – 16. DOI: 10.1520/A0626_A0626M-16.10.1520/A0626_A0626M-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A626/A626M − 22

3. Ordering Information

3.1 Orders for product under this specification shall include the following information, as required and applicable, to describe

adequately the desired product:

3.1.1 Name of product (double-reduced electrolytic tin plate) (Section 1),

3.1.2 Tin coating weight [mass] designation, and marking, if any (Section 5, Table 1, and FigFigs. 1 and 2),

3.1.3 Surface appearance and finish (Section 6),

3.1.4 Chemical treatment (Section 7),

3.1.5 Oiling (Section 8),

3.1.6 Thickness (Specification A623 [A623M]) (consistent with the intended application),

1

3.1.7 Coil width or cut size in increments of ⁄16 in. or 1 mm, in. or 1 mm,

3.1.8 Due to the very distinct directional properties, rolling direction must be specified on cut sizes by underlining the slit (rolling

width) dimension (Section 4) (consistent with the intended application),

3.1.9 Steel type (Specification A623 [A623M]),

3.1.1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.