ASTM D6719-01

(Guide)Standard Guide for Standard Test Methods and Practices for Evaluating Pile Yarn Floor Covering

Standard Guide for Standard Test Methods and Practices for Evaluating Pile Yarn Floor Covering

SCOPE

1.1 This guide provides users with an index of procedures in the form of test methods, practices, and related documents that are currently used in industry for determination of properties of pile yarn floor covering. This guide is not considered as all-inclusive for testing procedures related to pile yarn floor covering.

1.1.1 It is the responsibility of the user to choose from this guide those procedures that provide test information on properties of interest for pile yarn floor covering that relate to its physical and esthetic properties and performance.

1.1.2 Procedures for particular properties appear in the following sections:PropertySectionAppearance Change8.1-8.4Antimicrobial8.5Binding Sites8.6Backing Characteristics8.7Colorfastness8.8-8.12Carpets, Cleaning8.13-8.14Conditioning7Delamination Resistance8.15Fiber Analysis8.16Flammability8.17-8.20Pile Thickness8.21Mass per Unit Area8.22Soiling8.23-8.26Stain Resistance8.27Static8.28Tuft Bind8.29Tuft Height8.30Tuft Element Length8.31

1.2 In general, values stated in SI units are to be regarded as the standard. Values given in parentheses are for information only and may be approximate.

1.2.1 Some of the listed procedures may cite other units as standard. In this event, language of the procedure is controlling.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

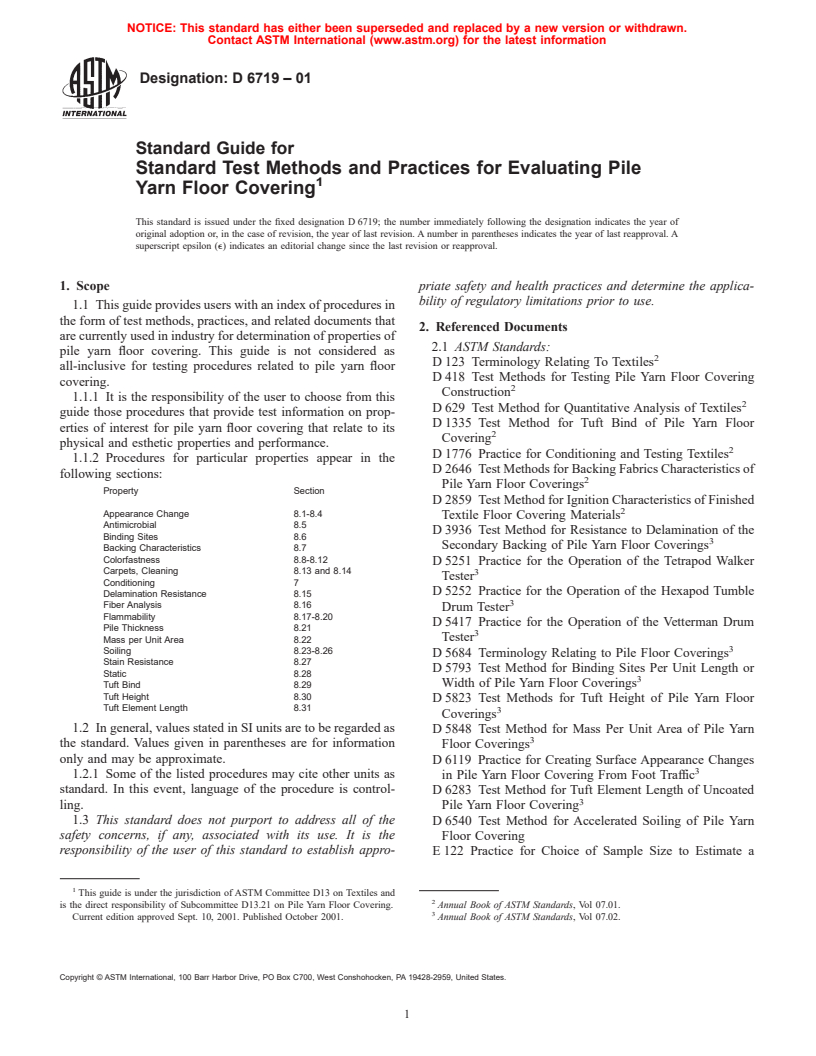

Designation: D 6719 – 01

Standard Guide for

Standard Test Methods and Practices for Evaluating Pile

Yarn Floor Covering

This standard is issued under the fixed designation D 6719; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 This guide provides users with an index of procedures in

the form of test methods, practices, and related documents that

2. Referenced Documents

are currently used in industry for determination of properties of

2.1 ASTM Standards:

pile yarn floor covering. This guide is not considered as

D 123 Terminology Relating To Textiles

all-inclusive for testing procedures related to pile yarn floor

D 418 Test Methods for Testing Pile Yarn Floor Covering

covering.

Construction

1.1.1 It is the responsibility of the user to choose from this

D 629 Test Method for Quantitative Analysis of Textiles

guide those procedures that provide test information on prop-

D 1335 Test Method for Tuft Bind of Pile Yarn Floor

erties of interest for pile yarn floor covering that relate to its

Covering

physical and esthetic properties and performance.

D 1776 Practice for Conditioning and Testing Textiles

1.1.2 Procedures for particular properties appear in the

D 2646 Test Methods for Backing Fabrics Characteristics of

following sections:

Pile Yarn Floor Coverings

Property Section

D 2859 Test Method for Ignition Characteristics of Finished

Appearance Change 8.1-8.4

Textile Floor Covering Materials

Antimicrobial 8.5

D 3936 Test Method for Resistance to Delamination of the

Binding Sites 8.6

Secondary Backing of Pile Yarn Floor Coverings

Backing Characteristics 8.7

Colorfastness 8.8-8.12

D 5251 Practice for the Operation of the Tetrapod Walker

Carpets, Cleaning 8.13 and 8.14

Tester

Conditioning 7

D 5252 Practice for the Operation of the Hexapod Tumble

Delamination Resistance 8.15

Fiber Analysis 8.16

Drum Tester

Flammability 8.17-8.20

D 5417 Practice for the Operation of the Vetterman Drum

Pile Thickness 8.21

Tester

Mass per Unit Area 8.22

Soiling 8.23-8.26

D 5684 Terminology Relating to Pile Floor Coverings

Stain Resistance 8.27

D 5793 Test Method for Binding Sites Per Unit Length or

Static 8.28

Width of Pile Yarn Floor Coverings

Tuft Bind 8.29

Tuft Height 8.30

D 5823 Test Methods for Tuft Height of Pile Yarn Floor

Tuft Element Length 8.31

Coverings

1.2 In general, values stated in SI units are to be regarded as D 5848 Test Method for Mass Per Unit Area of Pile Yarn

the standard. Values given in parentheses are for information

Floor Coverings

only and may be approximate.

D 6119 Practice for Creating Surface Appearance Changes

1.2.1 Some of the listed procedures may cite other units as

in Pile Yarn Floor Covering From Foot Traffic

standard. In this event, language of the procedure is control-

D 6283 Test Method for Tuft Element Length of Uncoated

ling.

Pile Yarn Floor Covering

1.3 This standard does not purport to address all of the

D 6540 Test Method for Accelerated Soiling of Pile Yarn

safety concerns, if any, associated with its use. It is the

Floor Covering

responsibility of the user of this standard to establish appro-

E 122 Practice for Choice of Sample Size to Estimate a

This guide is under the jurisdiction of ASTM Committee D13 on Textiles and

is the direct responsibility of Subcommittee D13.21 on Pile Yarn Floor Covering. Annual Book of ASTM Standards, Vol 07.01.

Current edition approved Sept. 10, 2001. Published October 2001. Annual Book of ASTM Standards, Vol 07.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6719

Measure of Quality for a Lot Process statistical knowledge of the product variability and test method

E 648 Test Method for Critical Radiant Flux of Floor precision is available and a decision has been made on the

Covering Systems using a Radiant Heat Energy Source maximum deviation that can be tolerated between the estimate

E 662 Test Method for Specific Optical Density of Smoke to be made from the lot sample and the result that would be

Generated by Solid Materials obtained by measuring every sampling unit of the lot. Other-

2.2 AATCC Test Methods: wise the number of sampling units is a lot sample and the use

16 Colorfastness to Light of the test results obtained from the individual test samples

20 Fiber Analysis: Quantitative shall be in accordance with the manufacturer’s Quality Control

20A Fiber Analysis: Quantitative program or with the specification agreed upon between pur-

107 Colorfastness to Water chaser and the supplier.

121 Carpet Soiling: Visual Rating Method 5.3 Laboratory Sampling Unit—A laboratory sampling unit

122 Carpet Soiling: Service Soiling Method shall consist of full width section of floor covering cut from

123 Carpet Soiling: Accelerated Soiling Method one end of each roll in the lot sample and shall be at least 100

129 Colorfastness to Ozone in the Atmosphere Under High mm (4 in.) longer than the specimens required for the test being

Humidities conducted. For coated pile yarn floor covering exclude the

134 Electrostatic Propensity of Carpets seam end of a production roll.

138 Cleaning: Washing of Textile Floor Coverings 5.4 Test Specimens—From each laboratory sampling unit,

164 Colorfastness to Oxides of Nitrogen in the Atmosphere take as many test specimens as directed by the procedure being

Under High Humidities used that will yield a standard test result.

165 Colorfastness to Crocking: Carpets-AATCC Crockme-

6 6. Calibration

ter Method

171 Carpets: Cleaning of; Hot Water Extraction Method 6.1 Many of the test methods cited herein require the use of

properly calibrated testing equipment. All testing systems

174 Antimicrobial Activity Assessment of Carpets

175 Stain Resistance: Pile Floor Coverings should be verified before use. Refer to the individual test

methods for specific information on the preparation, calibra-

2.3 Federal Regulations:

Title 16, Chapter II, Part 1630 Standard for the Surface tion, and verification of apparatus.

Flammability of

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.