ASTM D5823-19(2024)

(Test Method)Standard Test Method for Tuft Height of Pile Floor Coverings

Standard Test Method for Tuft Height of Pile Floor Coverings

SIGNIFICANCE AND USE

5.1 This test method is useful in quality and cost control during the manufacture of pile yarn floor covering. Both appearance and performance can be affected by changes in the tuft height.

5.1.1 In case of a dispute arising from differences in reported test results when using this test method for acceptance testing of commercial shipments, the purchaser and the supplier should conduct comparative tests to determine if there is a statistical bias between their laboratories. Competent statistical assistance is recommended for the investigation of bias. As a minimum, the two parties should take a group of test specimens that are as homogeneous as possible and are from a lot of material of the type in question. The test specimens should then be randomly assigned in equal numbers to each laboratory for testing. The average results from the two laboratories should be compared using Student's t-test for unpaired data and an acceptable probability level chosen by the two parties before testing is begun. If a bias is found, either its cause must be found and corrected or the purchaser and the supplier must agree to interpret future test results in view of the known bias.

SCOPE

1.1 This test method covers the determination of tuft height using a grooved specimen holder. It applies to cut-pile and loop-pile floor covering after adhesive backing has been applied to bond the pile yarn to the backing fabric.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D5823 − 19 (Reapproved 2024)

Standard Test Method for

Tuft Height of Pile Floor Coverings

This standard is issued under the fixed designation D5823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 For all terminology related to Pile Floor Coverings,

1.1 This test method covers the determination of tuft height

D13.21, refer to Terminology D5684.

using a grooved specimen holder. It applies to cut-pile and

3.1.1 The following terms are relevant to this standard:

loop-pile floor covering after adhesive backing has been

finished, finished pile yarn floor covering, floor covering, level

applied to bond the pile yarn to the backing fabric.

pile, loop pile yarn floor covering, pile, pile yarn floor

1.2 The values stated in inch-pound units are to be regarded

covering, textile floor covering, tuft height, tuft leg, tufted

as standard. The values given in parentheses are mathematical

fabric.

conversions to SI units that are provided for information only

3.2 For all other terminology related to textiles see Termi-

and are not considered standard.

nology D123.

1.3 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 For cut pile floor covering, individual tuft leg specimens

priate safety, health, and environmental practices and deter-

of like character (either cut or loop and of uniform height) are

mine the applicability of regulatory limitations prior to use.

cut as closely as possible to the surface of the backing of a pile

1.4 This international standard was developed in accor- floor covering sample and placed, one at a time, in a grooved

specimen holder that maintains the tuft yarn in a straight line

dance with internationally recognized principles on standard-

while the length of the tuft leg is measured using a graduated

ization established in the Decision on Principles for the

scale and a magnifying glass.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

4.2 For loop pile floor covering, the two tuft legs forming

Barriers to Trade (TBT) Committee.

the loop are each severed from the adjacent binding sites at the

backing surface to provide a specimen of twice the tuft height

2. Referenced Documents

and the length measured as in 4.1.

2.1 ASTM Standards:

5. Significance and Use

D123 Terminology Relating to Textiles

5.1 This test method is useful in quality and cost control

D1776/D1776M Practice for Conditioning and Testing Tex-

during the manufacture of pile yarn floor covering. Both

tiles

appearance and performance can be affected by changes in the

D1909 Standard Tables of Commercial Moisture Regains

tuft height.

and Commercial Allowances for Textile Fibers

5.1.1 In case of a dispute arising from differences in

D5684 Terminology Relating to Pile Floor Coverings

reported test results when using this test method for acceptance

E122 Practice for Calculating Sample Size to Estimate, With

testing of commercial shipments, the purchaser and the sup-

Specified Precision, the Average for a Characteristic of a

plier should conduct comparative tests to determine if there is

Lot or Process

a statistical bias between their laboratories. Competent statis-

tical assistance is recommended for the investigation of bias.

As a minimum, the two parties should take a group of test

This test method is under the jurisdiction of ASTM Committee D13 on Textiles

specimens that are as homogeneous as possible and are from a

and is the direct responsibility of Subcommittee D13.21 on Pile Floor Coverings.

lot of material of the type in question. The test specimens

Current edition approved Jan. 1, 2024. Published January 2024. Originally

should then be randomly assigned in equal numbers to each

approved in 1995. Last previous edition approved in 2019 as D5823–19. DOI:

10.1520/D5823-19R24.

laboratory for testing. The average results from the two

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

laboratories should be compared using Student’s t-test for

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

unpaired data and an acceptable probability level chosen by the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. two parties before testing is begun. If a bias is found, either its

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

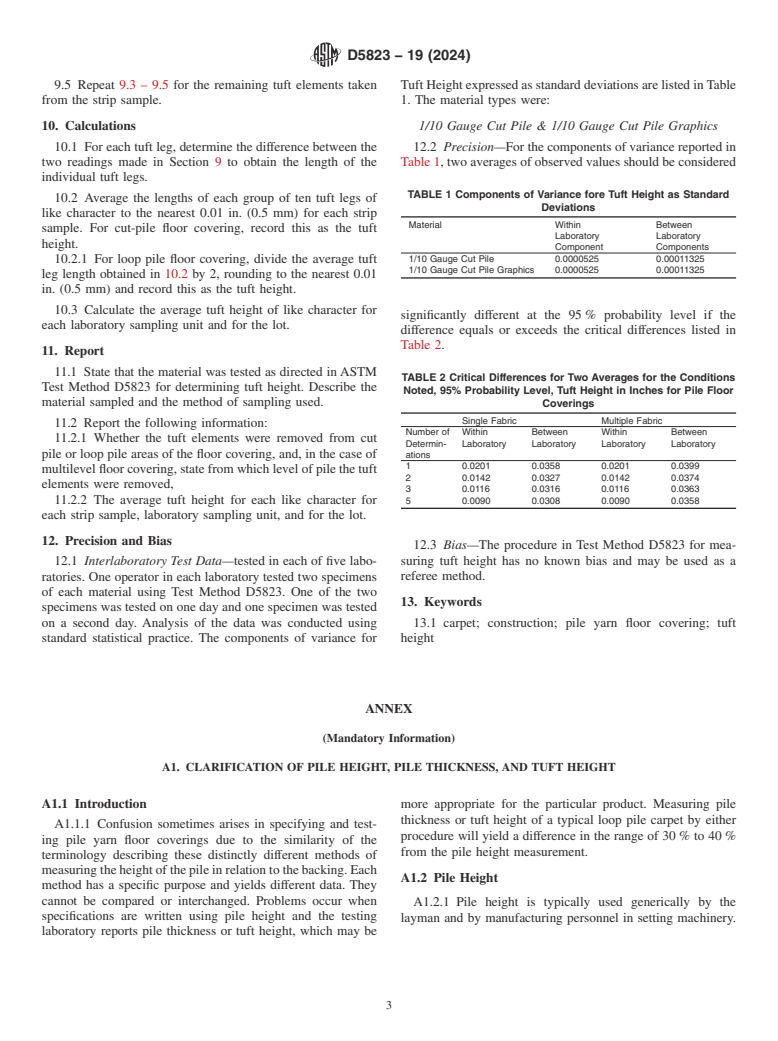

D5823 − 19 (2024)

cause must be found and corrected or the purchaser and the 7.3.1 Where it is known that systematic variations in a floor

supplier must agree to interpret future test results in view of the covering characteristic may occur in bands 18 in. (0.5 m) or

known bias. more in width, as with modular pattern devices having separate

controls or adjustments for each module, or individual needle

6. Apparatus

control, take test samples from the middle of each band and in

the same area of the pattern.

6.1 Grooved Specimen Holder, having a length at least 10 %

7.3.2 When a full width lab sample is not available, take a

longer than the longest tuft element to be measured.

6.1.1 Specimen Holder, 4 in. (100 mm) long, has been found test sample as directed in 7.3 and state in the report the width

available and the number of test specimens taken.

satisfactory for this purpose.

6.1.2 The grooves shall have a V-shaped cross-section with

7.4 Strip Sample— From each test sample, take a strip

a 1.05 rad (60°) angle at the bottom and widths across the top

sample approximately 2.5 in. by 10 in. (63 mm by 250 mm),

to accommodate several size yarns as follows:

with the longer dimension parallel to the manufacturing

Yarn Bulk Groove Widths

direction.

Coarse 0.18 in. (4.6 mm)

7.5 Test Specimens— Test 10 tufts from each strip sample.

Medium 0.13 in. (3.3 mm)

Fine 0.08 in. (2.0 mm)

6.1.3 Additional grooves of intermediate width may also be

8. Conditioning

used.

8.1 Condition and maintain the strip samples in the standard

6.2 Tuft Cutting Device, blade capable of cutting tuft per-

atmosphere for testing textiles, as specified in Practice D1776/

pendicular with the primary backing so as to permit cutting at D1776M. This method describes the process and measure-

the back surface.

ments acceptable for textile conditioning.

6.3 Graduated Scale, clear or opaque, measuring to the 8.2 If the fiber in any layer of the backing has a commercial

nearest 0.01 in. (0.5 mm).

regain of more than 5 %, the strip sample shall be conditioned

before measuring. Commercial moisture regains for textile

6.4 Magnifying Glass, 5× magnification.

fibers are listed in the Table in D1909.

6.5 Cover Plates, clear plastic or glass.

9. Procedure

7. Sampling

9.1 Cut ten tuft legs of each kind of tuft, cut or loop, to be

7.1 Lot Sample—The basic sampling unit of coated floor

measured from the strip samples. Choose the tuft legs to take

covering is a shipping roll. The number of shipping rolls

a nearly equal number of tuft legs of each kind from each strip

obtained from each production roll ranges from one to more

sample. Sever the leg of each selected tuft leg or loop as close

than ten.

to the backing surface as possible.

7.1.1 Take a lot sample as directed in Practice E122 when

statistical knowledge of the product variability and test method 9.2 Select the groove of the specimen holder appropriate to

precision is available, and decision has been made on the the tuft element yarn diameter.

maximum deviation that can be tolerated between the estimate 9.2.1 The groove is of appropriate size if the bend in the

to be made from the sample and the result that would be middle of the tuft element is substantially removed when the

obtained by measuring every sampling unit of the lot. graduated scale or cover plate is placed over the yarn in the

Otherwise, the number of sampling units in a lot sample and groove. The groove is too small if the fibers of the tuft element

the use of the test results obtained from the individual test spread beyond the edge of the groove and hold the cover plate

sample shall be in accordance with the manufacturer’s quality above the specimen holder surface. A deflection of the tuft

control program or with the specification agreed to by the element from straightness of as much as 0.04 in. (1 mm) will

purchaser and the supplier. not significantly a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.