ASTM A723/A723M-94(1999)

(Specification)Standard Specification for Alloy Steel Forgings for High-Strength Pressure Component Application

Standard Specification for Alloy Steel Forgings for High-Strength Pressure Component Application

SCOPE

1.1 This specification covers requirements for high-strength quenched and tempered alloy steel forgings for pressure vessels, isostatic presses, shock tubes, and similar components.

1.2 These materials are not intended for welded construction.

1.3 Three grades of nickel-chromium-molybdenum steels and six classes of increasing tensile strength are included. The strength class, section size, and configuration of the forging will largely dictate the applicable type(s) of steel.

1.4 The values stated in either inch-pound units or SI (metric) units are to be regarded separately as the standard. Within the text and tables, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.5 Unless the order specifies the applicable "M" specification designation, the material shall be furnished to the inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 723/A 723M – 94 (Reapproved 1999) An American National Standard

Standard Specification for

Alloy Steel Forgings for High-Strength Pressure Component

Application

This standard is issued under the fixed designation A 723/A 723M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope inquiry and order a detailed drawing, sketch, or written

description of the forging and the method of selecting test

1.1 This specification covers requirements for high-

location (see 6.2). When appropriate, the areas of significant

strength quenched and tempered alloy steel forgings for pres-

loading in the forging shall be designated.

sure vessels, isostatic presses, shock tubes, and similar com-

3.2 Material supplied to this specification shall conform to

ponents.

the requirements of Specification A 788, which outlines addi-

1.2 These materials are not intended for welded construc-

tional ordering information, manufacturing requirements, test-

tion.

ing and retesting methods and procedures, marking, certifica-

1.3 Three grades of nickel-chromium-molybdenum steels

tion, product analysis variations, and additional supplementary

and six classes of increasing tensile strength are included. The

requirements.

strength class, section size, and configuration of the forging

3.3 If the requirements of this specification are in conflict

will largely dictate the applicable type(s) of steel.

with the requirements of Specification A 788, the requirements

1.4 The values stated in either inch-pound units or SI

of this specification shall prevail.

(metric) units are to be regarded separately as the standard.

Within the text and tables, the SI units are shown in brackets.

4. Materials and Manufacture

The values stated in each system are not exact equivalents;

4.1 Melting Practice—The steel melting procedures of

therefore, each system must be used independently of the other.

Specification A 788 shall apply except that the open-hearth

Combining values from the two systems may result in noncon-

process shall not be used, and that the steel shall be vacuum

formance with the specification.

degassed prior to or during the pouring of the ingot, in order to

1.5 Unless the order specifies the applicable “M” specifica-

remove objectionable gases, particularly hydrogen.

tion designation, the material shall be furnished to the inch-

4.2 Discard—Sufficient discard shall be taken from each

pound units.

ingot to secure freedom from piping and excessive segregation.

2. Referenced Documents 4.3 Heat Treatment:

4.3.1 Forgings shall be rough-machined prior to final heat

2.1 ASTM Standards:

treatment if it is necessary to reduce the mass to ensure full

A 275/A 275M Test Method for Magnetic Particle Exami-

hardening or to meet the requirements of 6.2. The risk of

nation of Steel Forgings

cracking during heat treatment with high-hardenability steels

A 370 Test Methods and Definitions for Mechanical Testing

of the type covered by this specification should be borne in

of Steel Products

mind when deciding on the degree of surface preparation

A 388/A 388M Practice for Ultrasonic Examination of

3 before heat treatment.

Heavy Steel Forgings

4.3.2 Heat Treatment for Mechanical Properties—Heat

A 788 Specification for Steel Forgings, General Require-

3 treatment shall consist of normalizing (which may be part of

ments

the preliminary treatment), reaustenitization, liquid quenching,

3. Ordering Information and General Requirements and tempering. The forgings shall be quenched in a suitable

liquid medium by spraying or immersion. Quenching shall be

3.1 In addition to the ordering information required by

followed by tempering at a minimum temperature of 1000°F

Specification A 788, the purchaser shall include with the

[540°C]. The minimum time at tempering temperature shall be

1 1

⁄2 h/in. [ ⁄2 h/25 mm] of maximum section thickness, unless

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

otherwise agreed between supplier and purchaser.

Stainless Steel and Related Alloys, and is the direct responsibility of Subcommittee

A01.06 on Steel Forgings and Billets.

5. Chemical Composition

Current edition approved Jan. 15, 1994. Published March 1994. Originally

published as A 723 – 75. Last previous edition A 723 – 91.

2 5.1 Heat Analysis—The heat analysis obtained from sam-

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

pling in accordance with Specification A 788 shall comply with

cation SA–723/SA–723M in Section II of that Code.

Annual Book of ASTM Standards, Vol 01.05.

Table 1.

Annual Book of ASTM Standards, Vol 01.03.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

A 723/A 723M

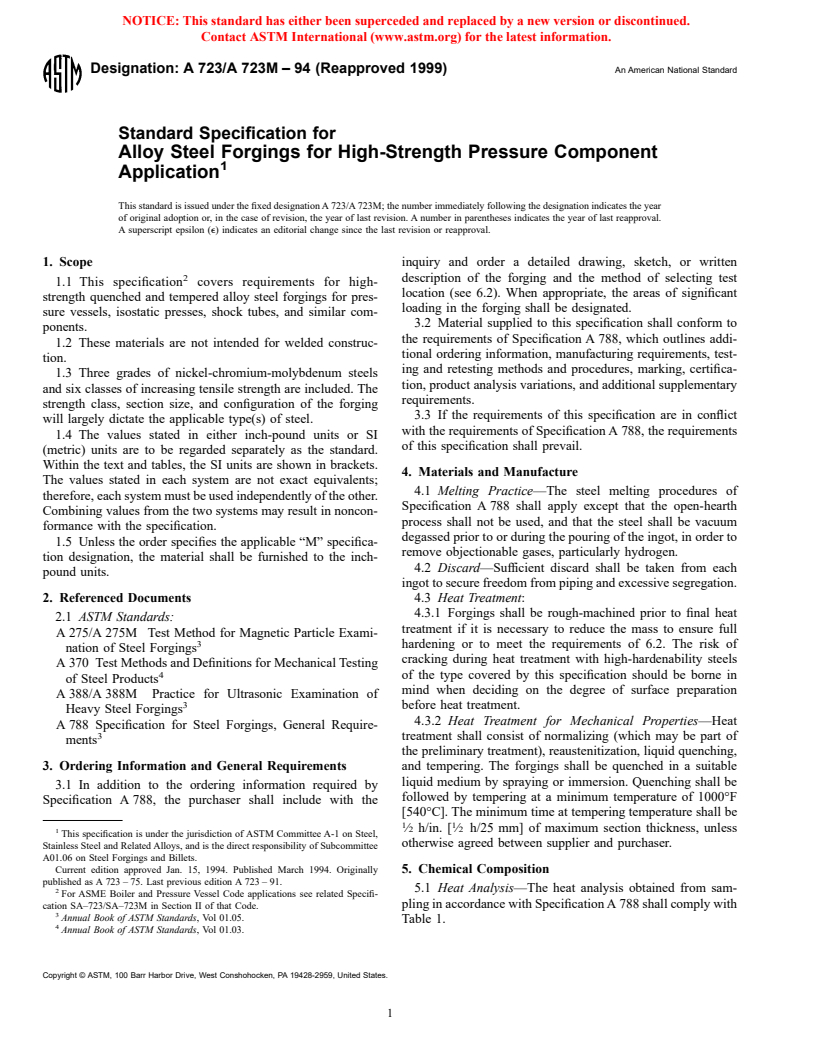

TABLE 1 Chemical Requirements

testing is employed, the datum points of the test specimen, as

Composition, % described in 6.2, shall be removed ⁄4 T from the nearest

quenched surface and ⁄3 T from the quenched end surface or

Grade 1 Grade 2 Grade 3

nearest adjacent surface.

Carbon, max 0.35 0.40 0.40

Manganese, max 0.90 0.90 0.90

6.2.4 Method 4—Test specimens shall be taken from a

Phosphorus, max 0.015 0.015 0.015

representative separate test forging made from the same heat of

Sulfur, max 0.015 0.015 0.015

steel, which shall receive substantially the same reduction and

Silicon, max 0.35 0.35 0.35

Nickel 1.5 to 2.25 2.3 to 3.3 3.3 to 4.5

type of hot working, and have a cross section not less than the

Chromium 0.80 to 2.00 0.80 to 2.00 0.80 to 2.00

production forgings which it represents. It shall be heat treated

Molybdenum 0.20 to 0.40 0.30 to 0.50 0.40 to 0.80

in the same furnace charge and under the same conditions as

Vanadium, max 0.20 0.20 0.20

the production forgings. The test specimen shall be removed

using the Method 3 procedure.

5.2 Product Analysis—The manufacturer shall use the prod-

6.3 Thermal Buffers:

uct analysis provision of Specification A 788 to obtain a

6.3.1 Thermal buffer rings, at least T by T in cross section or

product analysis from a forging representing each heat or

sections of such a ring at least 3 T in length, shall be welded to

multiple heat. The purchaser may also make this determination

the test end(s) of a forging prior to heat treatment for

in accordance with Specification A 788.

mechanical properties. The buffer material may be any weld-

able carbon or low-alloy steel and shall be joined to the forging

6. Mechanical Properties

with a partial penetration-type weld which completely seals the

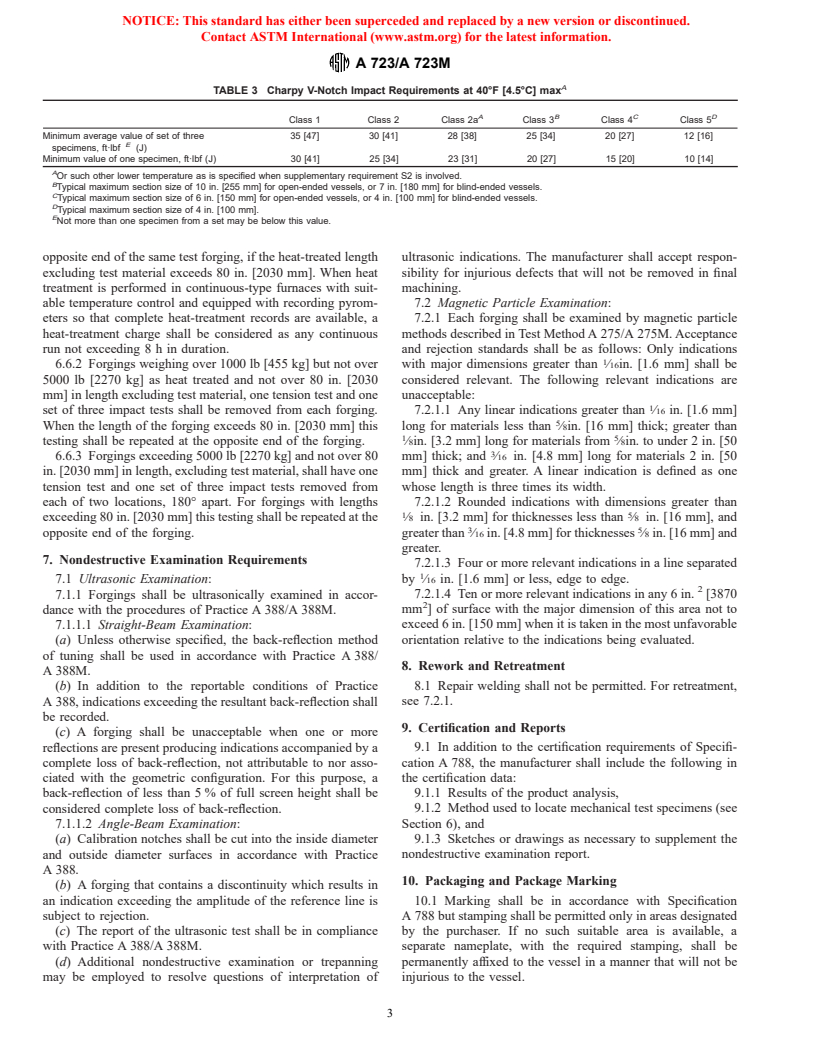

6.1 General Requirements—The forging shall conform to

buffered surface. The test coupons shall be removed from the

the requirements of Table 2 and Table 3. The largest obtainable

forging in the region buffered by the ring or ring segments. If

tension test specimen as specified in Test Methods and Defi-

the latter are used, the test coupons shall be removed from the

nitions A 370 (that is, standard round 0.500-in. [12.5-mm]

forging in the area under the center ⁄3 of the buffer ring

diameter specimen) shall be used. Charpy V-notch Type A

segment length. In either case, the test specimens shall be

impact specimens, as shown in Test Methods and Definitions

located at a minimum distance of ⁄2 in. [13 mm] from the

A 370, shall be used.

buffered surface of the forging and at least ⁄4 T from a

6.2 Sampling—The mid-point of the gage length of tension

quenched surface of the forging. Buffered weld areas must be

test specimens and the area under the notch of impact speci-

at least 1 in. [25 mm] from any finished machining surface of

mens shall be located in accordance with one of the following

the complete forging.

methods as specified by the purchaser, or suggested by the

6.3.2 Bearing in mind the characteristics of the base mate-

supplier and approved by the purchaser. Wherever practical, all

rials included in this specification, precautions should be taken,

testing shall be from integral prolongations of the forging.

such as the use of pre- and post-weld heating and austenitic

6.2.1 Method 1—This method shall always be used when

weld metal, to minimize the occurrence of crack-like defects.

the maximum quenched thickness does not exceed 4 in. [100

6.3.3 Approval of the purchaser should be obtained for the

mm]. Datum points of the specimens, as described in 6.2, shall

use of this method.

be located in the forging or test forging (6.2.4) at mid-thickness

6.4 Samples shall be removed from the forgings after

and at least ⁄3 T (T is the maximum heat-treated thickness)

quenching and tempering.

from the quenched end surface or nearest adjacent surfaces.

6.5 Orientation—For upset disk forgings, the longitudinal

6.2.2 Method 2—t by 2t, where t is the distance from the

axis of all test specimens shall be oriented in the tangential or

area of significant loading (3.1) to the nearest quenched

radial direction. For all other forgings, the longitudinal axis of

surface. However, the datum points of the specimens as

the specimens shall be oriented in the direction of maximum

described in 6.2 shall not be nearer to one quenched surface

3 working of the forging, or as agreed between manufacturer and

than ⁄4 in. [20 mm] and to the second quenched surface than 1

1 purchaser.

⁄2 in. [40 mm]. When this method of testing is employed,

6.6 Number of Tests:

forgings are usually manufactured in accordance with a

purchaser-approved drawing showing prequenched dimensions 6.6.1 For forgings weighing 1000 lb [455 kg] or less, as heat

and the location of mechanical test specimens. It is commonly treated but not exceeding 80 in. [2030 mm] in length, exclud-

used for disk-type forgings such as tube sheets and cove

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.