ASTM A608/A608M-14(2018)

(Specification)Standard Specification for Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing for Pressure Application at High Temperatures

Standard Specification for Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing for Pressure Application at High Temperatures

ABSTRACT

This specification covers the standard for iron-chromium-nickel, high-alloy tubes made by the centrifugal casting process intended for use under pressure at high temperatures. The tubing shall be supplied in the as cast condition or as cast with machining on the outside or inside surfaces. The material shall conform to the required chemical composition in carbon, manganese, silicon, chromium, nickel, phosphorus, sulfur, and molybdenum. Tension test shall be performed in the tubing at elevated temperature and shall conform to the required values in tensile strength and elongation. Tubing shall meet several tests such as; pressure test, flattening test, and mechanical test.

SCOPE

1.1 This specification covers iron-chromium-nickel, high-alloy tubes made by the centrifugal casting process intended for use under pressure at high temperatures.

1.2 The grades of high alloys detailed in Table 1 are intended for applications requiring strength and resistance to corrosion and scaling at high temperatures. (A) Where ellipses (...) appear in this table there is no requirement, and the element need not be analyzed or reported.(B) Manufacturing control should ensure that this composition contains a minimal amount of ferrite. See Supplementary Requirement S5.

1.3 Optional Supplementary Requirements S1 to S11 are provided; these call for additional tests to be made if desired.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.4.1 Within the text, the SI units are shown in brackets.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A608/A608M −14 (Reapproved 2018)

Standard Specification for

Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing

for Pressure Application at High Temperatures

This standard is issued under the fixed designationA608/A608M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E8/E8M Test Methods for Tension Testing of Metallic Ma-

terials

1.1 This specification covers iron-chromium-nickel, high-

E21 TestMethodsforElevatedTemperatureTensionTestsof

alloy tubes made by the centrifugal casting process intended

Metallic Materials

for use under pressure at high temperatures.

E94/E94M Guide for Radiographic Examination Using In-

1.2 The grades of high alloys detailed in Table 1 are

dustrial Radiographic Film

intended for applications requiring strength and resistance to

E139 Test Methods for Conducting Creep, Creep-Rupture,

corrosion and scaling at high temperatures.

and Stress-Rupture Tests of Metallic Materials

1.3 Optional Supplementary Requirements S1 to S11 are E142 Method for Controlling Quality of Radiographic Test-

ing (Withdrawn 2000)

provided; these call for additional tests to be made if desired.

E151 Recommended Practice for Tension Tests of Metallic

1.4 The values stated in either SI units or inch-pound units

Materials at Elevated Temperatures with Rapid Heating

are to be regarded separately as standard. The values stated in

and Conventional or Rapid Strain Rates (Withdrawn

each system may not be exact equivalents; therefore, each

1984)

system shall be used independently of the other. Combining

E165/E165M Practice for Liquid Penetrant Examination for

values from the two systems may result in nonconformance

General Industry

with the standard.

E340 Practice for Macroetching Metals and Alloys

1.4.1 Within the text, the SI units are shown in brackets.

1.5 This international standard was developed in accor-

3. Ordering Information

dance with internationally recognized principles on standard-

3.1 Orders for material to this specification should include

ization established in the Decision on Principles for the

the following, as required, to describe the desired material

Development of International Standards, Guides and Recom-

adequately:

mendations issued by the World Trade Organization Technical

3.1.1 Quantity (feet, centimeters, or number of lengths),

Barriers to Trade (TBT) Committee.

3.1.2 Name of material (centrifugally cast tubing),

3.1.3 Specification number and grade (Table 1),

2. Referenced Documents

3.1.4 Size (outside or inside diameter and minimum wall

2.1 ASTM Standards:

thickness, see Section 8).

A342/A342M Test Methods for Permeability of Weakly

3.1.5 Condition (see Section 9, as-cast or as-cast with

Magnetic Materials

machining on outside or inside surfaces, or machined; see 5.1

A488/A488M Practice for Steel Castings, Welding, Qualifi-

and Sections 8 and 9),

cations of Procedures and Personnel

3.1.6 Length (specific or random), (Permissible Variations

A999/A999M Specification for General Requirements for

in Length Section of Specification A999/A999M),

Alloy and Stainless Steel Pipe

3.1.7 End finish (Ends Section of Specification A999/

A999M),

3.1.8 Optional requirements (see 8.2.3 regarding the manu-

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

facturer’s wall thickness allowance for as-cast tubing and

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

Supplementary Requirements S1 to S11),

A01.18 on Castings.

Current edition approved March 1, 2018. Published March 2018. Originally 3.1.9 Test report required (see Section 13), and

approved in 1970. Last previous edition approved in 2014 as A608/A608M – 14.

3.1.10 Special requirements to be added to the specification.

DOI: 10.1520/A0608_A0608M-14R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A608/A608M−14 (2018)

A

TABLE 1 Chemical Requirements

Grade

Composition, % (Values are maximums unless otherwise indicated.)

(UNS

Carbon Manganese Silicon Chromium Nickel Phosphorus Sulfur Molybdenum Niobium

Number)

HC30 0.25 – 0.35 0.5 – 1.0 0.50 – 2.00 26 – 30 4.0 0.04 0.04 0.50 . . .

(J92613)

HD50 0.45 – 0.55 1.50 0.50 – 2.00 26 – 30 4 – 7 0.04 0.04 0.50 . . .

(J93015)

HE35 0.30 – 0.40 1.50 0.50 – 2.00 26 – 30 8 – 11 0.04 0.04 0.50 . . .

(J93413)

HF30 0.25 – 0.35 1.50 0.50 – 2.00 19 – 23 9 – 12 0.04 0.04 0.50 . . .

(J92803)

HH30 0.25 – 0.35 1.50 0.50 – 2.00 24 – 28 11 – 14 0.04 0.04 0.50 . . .

(J93513)

B

HH33 0.28 – 0.38 1.50 0.50 – 2.00 24 – 26 12 – 14 0.04 0.04 0.50 . . .

(J93633)

HI35 0.30 – 0.40 1.50 0.50 – 2.00 26 – 30 14 – 18 0.04 0.04 0.50 . . .

(J94013)

HK30 0.25 – 0.35 1.50 0.50 – 2.00 23 – 27 19 – 22 0.04 0.04 0.50 . . .

(J94203)

HK40 0.35 – 0.45 1.50 0.50 – 2.00 23 – 27 19 – 22 0.04 0.04 0.50 . . .

(J94204)

HL30 0.25 – 0.35 1.50 0.50 – 2.00 28 – 32 18 – 22 0.04 0.04 0.50 . . .

(N08613)

HL40 0.35 – 0.45 1.50 0.50 – 2.00 28 – 32 18 – 22 0.04 0.04 0.50 . . .

(N08614)

HN40 0.35 – 0.45 1.50 0.50 – 2.00 19 – 23 23 – 27 0.04 0.04 0.50 . . .

HPNb 0.38 – 0.45 0.50 – 1.50 0.50 – 1.50 24 – 27 34 – 37 0.03 0.03 0.50 0.5 – 1.5

(N28701)

HPNbS 0.38 – 0.45 0.50 – 1.50 1.50 – 2.50 24 – 27 34 – 37 0.03 0.03 0.50 0.5 – 1.5

(N28702)

HT50 0.40 – 0.60 1.50 0.50 – 2.00 15 – 19 33 – 37 0.04 0.04 0.50 . . .

(N08050)

HU50 0.40 – 0.60 1.50 0.50 – 2.00 17 – 21 37 – 41 0.04 0.04 0.50 . . .

(N08005)

HW50 0.40 – 0.60 1.50 0.50 – 2.00 10 – 14 58 – 62 0.04 0.04 0.50 . . .

(N08006)

HX50 0.40 – 0.60 1.50 0.50 – 2.00 15 – 19 64 – 68 0.04 0.04 0.50 . . .

(N06050)

A

Where ellipses (.) appear in this table there is no requirement, and the element need not be analyzed or reported.

B

Manufacturing control should ensure that this composition contains a minimal amount of ferrite. See Supplementary Requirement S5.

4. General Requirements rupture properties, one of the supplementary requirements of

thisspecificationmaybestipulatedontheordertoascertainthe

4.1 Material furnished under this specification shall con-

ability of the material to meet the design properties.)

form to the applicable requirements of the current edition of

Specification A999/A999M, unless otherwise provided herein.

8. Permissible Variation in Dimensions

5. Materials and Manufacture

8.1 Machined Tubing (Tubing Machined on Inside and

Outside):

5.1 The tubing may be supplied in the as-cast condition or

as-cast with machining on the outside or inside surfaces, or 8.1.1 The tolerances given in Specification A999/A999M

machined, as agreed upon between the manufacturer and the shall govern, except that the wall thickness shall not vary over

purchaser. the specified minimum wall thickness by more than 10 % or

⁄16 in. [1.6 mm], whichever is greater. There shall be no

5.2 Heat treatment of the tubing shall not be required under

variation under the specified minimum wall thickness.

this specification.

8.2 As-Cast Tubing (No Machining or Machined on Inside

6. Chemical Requirements

or Outside):

6.1 The material shall conform to the requirements as to 8.2.1 Outside Diameter (For Tubes Ordered to Outside

Diameter):

chemical composition as prescribed in Table 1.

8.2.1.1 Tubes machined on the outside shall meet the

7. Tensile Properties

requirements of Specification A999/A999M.

8.2.1.2 Tubes not machined on the outside shall meet the

7.1 Tension tests at room temperature are not recommended

permissible variations of Table 2.

as acceptance criteria under this specification since the alloys

8.2.2 Inside Diameter (For Tubes Ordered to Inside Diam-

are intended for elevated temperature service, and room

temperature tests do not have a dependable relationship to eter):

elevated temperature properties. (Where the design of the 8.2.2.1 Tubesmachinedontheinsideshallmeettherequire-

tubing is based on an assumption of certain minimum creep- ments of Specification A999/A999M.

A608/A608M−14 (2018)

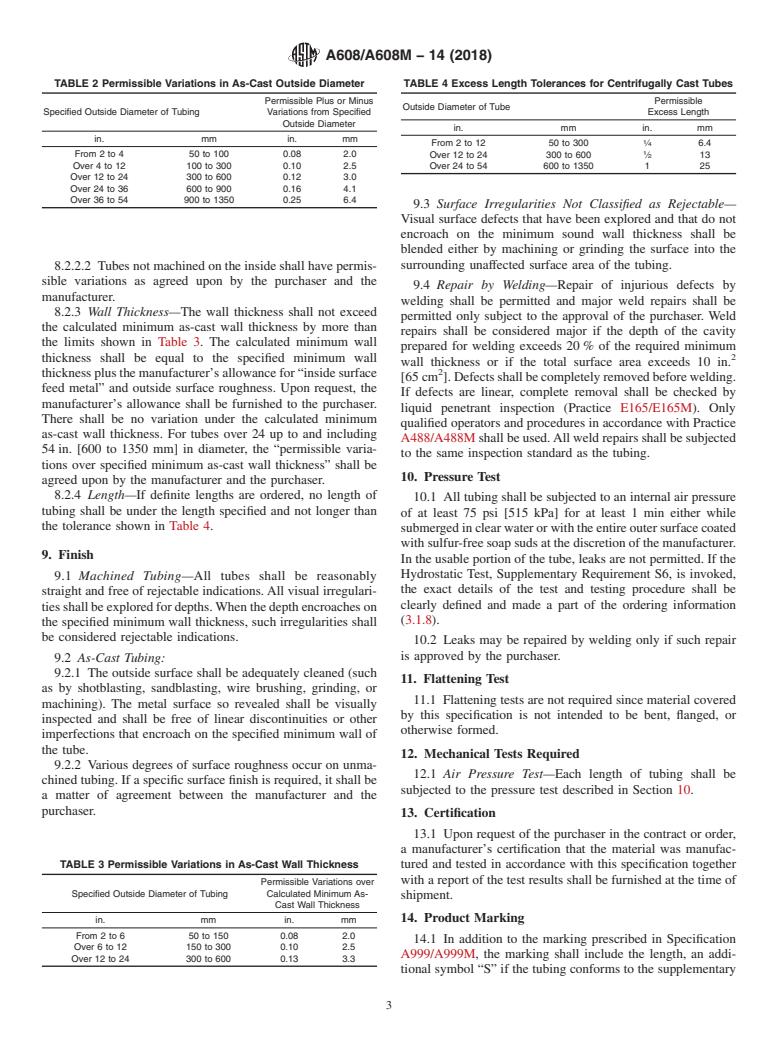

TABLE 2 Permissible Variations in As-Cast Outside Diameter TABLE 4 Excess Length Tolerances for Centrifugally Cast Tubes

Permissible Plus or Minus Permissible

Outside Diameter of Tube

Specified Outside Diameter of Tubing Variations from Specified Excess Length

Outside Diameter

in. mm in. mm

in. mm in. mm

From2to12 50to300 ⁄4 6.4

From 2 to 4 50 to 100 0.08 2.0 Over 12 to 24 300 to 600 ⁄2 13

Over 4 to 12 100 to 300 0.10 2.5

Over 24 to 54 600 to 1350 1 25

Over 12 to 24 300 to 600 0.12 3.0

Over 24 to 36 600 to 900 0.16 4.1

Over 36 to 54 900 to 1350 0.25 6.4

9.3 Surface Irregularities Not Classified as Rejectable—

Visual surface defects that have been explored and that do not

encroach on the minimum sound wall thickness shall be

blended either by machining or grinding the surface into the

surrounding unaffected surface area of the tubing.

8.2.2.2 Tubes not machined on the inside shall have permis-

sible variations as agreed upon by the purchaser and the

9.4 Repair by Welding—Repair of injurious defects by

manufacturer.

welding shall be permitted and major weld repairs shall be

8.2.3 Wall Thickness—The wall thickness shall not exceed

permitted only subject to the approval of the purchaser. Weld

the calculated minimum as-cast wall thickness by more than

repairs shall be considered major if the depth of the cavity

the limits shown in Table 3. The calculated minimum wall

prepared for welding exceeds 20 % of the required minimum

thickness shall be equal to the specified minimum wall

wall thickness or if the total surface area exceeds 10 in.

thicknessplusthemanufacturer’sallowancefor“insidesurface

[65 cm ].Defectsshallbecompletelyremovedbeforewelding.

feed metal” and outside surface roughness. Upon request, the

If defects are linear, complete removal shall be checked by

manufacturer’s allowance shall be furnished to the purchaser.

liquid penetrant inspection (Practice E165/E165M). Only

There shall be no variation under the calculated minimum

qualified operators and procedures in accordance with Practice

as-cast wall thickness. For tubes over 24 up to and including

A488/A488M shall be used.All weld repairs shall be subjected

54 in. [600 to 1350 mm] in diameter, the “permissible varia-

to the same inspection standard as the tubing.

tions over specified minimum as-cast wall thickness” shall be

10. Pressure Test

agreed upon by the manufacturer and the purchaser.

8.2.4 Length—If definite lengths are ordered, no length of

10.1 All tubing shall be subjected to an internal air pressure

tubing shall be under the length specified and not longer than

of at least 75 psi [515 kPa] for at least 1 min either while

the tolerance shown in Table 4.

submergedinclearwaterorwiththeentireoutersurfacecoated

with sulfur-free soap suds at the discretion of the manufacturer.

9. Finish

In the usable portion of the tube, leaks are not permitted. If the

Hydrostatic Test, Supplementary Requirement S6, is invoked,

9.1 Machined Tubing—All tubes shall be reasonably

the exact details of the test and testing procedure shall be

straight and free of rejectable indications.All visual irregulari-

clearly defined and made a part of the ordering information

tiesshallbeexploredfordepths.Whenthedepthencroacheson

(3.1.8).

the specified minimum wall thickness, such irregularities shall

be considered rejectable indications.

10.2 Leaks may be repaired by welding only if such repair

is approved by the purchaser.

9.2 As-Cast Tubing:

9.2.1 The outside surface shall be adequately cleaned (such

11. Flattening Test

as by shotblasting, sandblasting, wire brushing, grinding, or

11.1 Flattening tests are not required since material covered

machining). The metal surface so revealed shall be visually

by this specification is not intended to be bent, flanged, or

inspected and shall be free of linear discontinuities or other

otherwise formed.

imperfections that encroach on the specified minimum wall of

the tube.

12. Mechanical Tests Required

9.2.2 Various degrees of surface roughness occur on unma-

12.1 Air Pressure Test—Each length of tubing shall be

chined tubing. If a specific surface finish is required, it shall be

subjected to the pressure test described in Section 10.

a matter of agreement between the manufacturer and the

purchaser.

13. Certification

13.1 Upon request of the purchaser in the contract or order,

a manufacturer’s certification that the material was manufac-

TABLE 3 Permissible Variations in As-Cast Wall Thickness tured and tested in accordance with this specification together

with a report of the test results shall be furnished at the time of

Permissible Variations over

Specified Outside Diameter of Tubing Calculated Minimum As-

shipment.

Cast Wall Thickness

14. Product Marking

in. mm in. mm

From 2 to 6 50 to 150 0.08 2.0

14.1 In addition to the marking prescribed in Specification

Over 6 to 12 150 to 300 0.10 2.5

A999/A999M, the marking shall include the length, an addi-

Over 12 to 24 300 to 600 0.13 3.3

tional symbol “S” if the tubing conforms to the supplementary

A608/A608M−14 (2018)

requirements specified in Supplementary Requirements S1 to 15. Keywords

S11, the heat number or manufacturer’s number by which the

15.1 alloy; centrifugal casting; high temperatures; pressure

tube can be identified, and, when as cast (see 8.2), the notation

containing parts; steel tube; temperature service applications

“AS CAST.”

SUPPLEMENTARY REQUIREMENTS

One or more of the following supplementary requirements may become a part of the specification

when specified on the inquiry or invitation to bid and purchase order or contract.

S1. Product Analysis treatment to improve the hot tensile strength of the material or

specimen shall not be permitted. However, the specimens may

S1.1 Product analysis may be made on any length of tubing.

be aged for 24 h at test temperature before testing.

Individual lengths failing to conform to the chemical require-

S2.4 The test shall be made in accordance with Test

ments shall be rejected. For product analysis, the outside

Methods E21, except that the speed of the head of the testing

surface of the tube shall be ground clean before sampling and

machine shall be so adjusted that the c

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A608/A608M − 14 A608/A608M − 14 (Reapproved 2018)

Standard Specification for

Centrifugally Cast Iron-Chromium-Nickel High-Alloy Tubing

for Pressure Application at High Temperatures

This standard is issued under the fixed designation A608/A608M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers iron-chromium-nickel, high-alloy tubes made by the centrifugal casting process intended for use

under pressure at high temperatures.

1.2 The grades of high alloys detailed in Table 1 are intended for applications requiring strength and resistance to corrosion and

scaling at high temperatures.

1.3 Optional Supplementary Requirements S1 to S11 are provided; these call for additional tests to be made if desired.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformancenonconformance with the standard.

1.4.1 Within the text, the SI units are shown in brackets.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A342/A342M Test Methods for Permeability of Weakly Magnetic Materials

A488/A488M Practice for Steel Castings, Welding, Qualifications of Procedures and Personnel

A999/A999M Specification for General Requirements for Alloy and Stainless Steel Pipe

E8E8/E8M Test Methods for Tension Testing of Metallic Materials

E21 Test Methods for Elevated Temperature Tension Tests of Metallic Materials

E94E94/E94M Guide for Radiographic Examination Using Industrial Radiographic Film

E139 Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

E142 Method for Controlling Quality of Radiographic Testing (Withdrawn 2000)

E151 Recommended Practice for Tension Tests of Metallic Materials at Elevated Temperatures with Rapid Heating and

Conventional or Rapid Strain Rates (Withdrawn 1984)

E165E165/E165M Practice for Liquid Penetrant Examination for General Industry

E340 Practice for Macroetching Metals and Alloys

3. Ordering Information

3.1 Orders for material to this specification should include the following, as required, to describe the desired material

adequately:

3.1.1 Quantity (feet, centimeters, or number of lengths),

3.1.2 Name of material (centrifugally cast tubing),

3.1.3 Specification number and grade (Table 1),

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

Current edition approved Oct. 1, 2014March 1, 2018. Published November 2014March 2018. Originally approved in 1970. Last previous edition approved in 20122014

as A608/A608M – 12.A608/A608M – 14. DOI: 10.1520/A0608_A0608M-12. 10.1520/A0608_A0608M-14R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A608/A608M − 14 (2018)

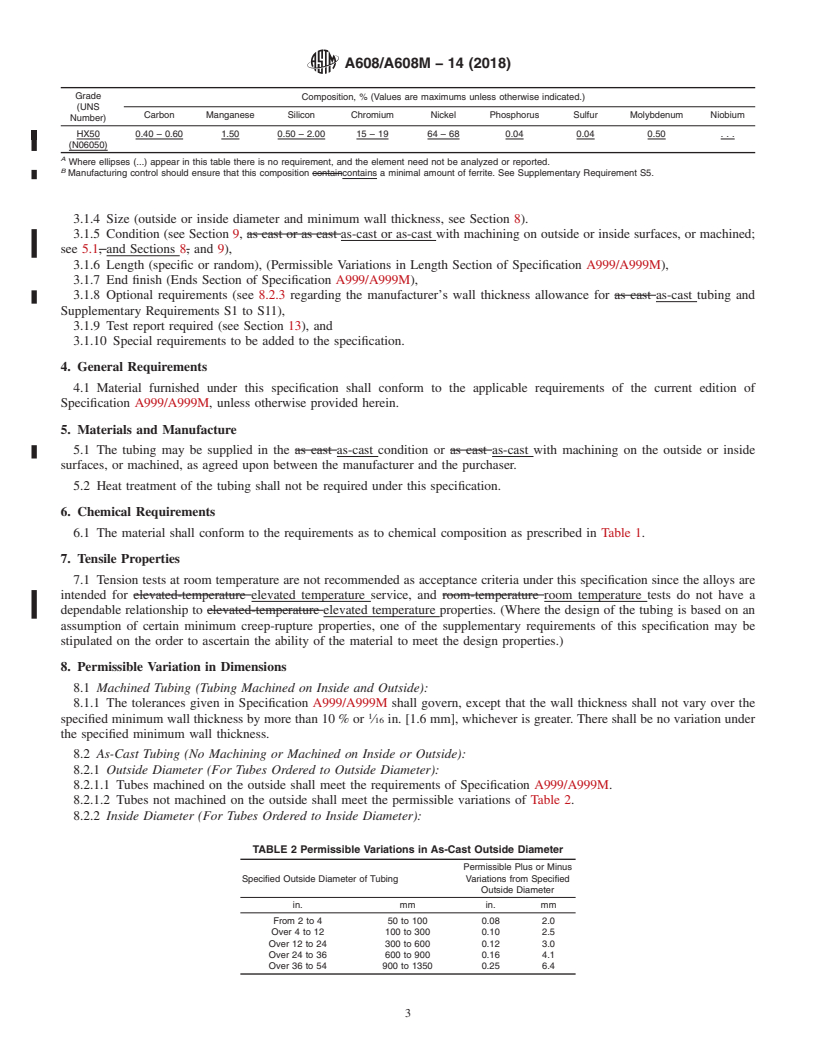

A

TABLE 1 Chemical Requirements

Grade

Composition, % (Values are maximums unless otherwise indicated.)

(UNS

Carbon Manganese Silicon Chromium Nickel Phosphorus Sulfur Molybdenum Niobium

Number)

HC30 0.25–0.35 0.5–1.0 0.50–2.00 26–30 4.0 0.04 0.04 0.50 {

(J92613)

HD50 0.45–0.55 1.50 0.50–2.00 26–30 4–7 0.04 0.04 0.50 {

(J93015)

HE35 0.30–0.40 1.50 0.50–2.00 26–30 8–11 0.04 0.04 0.50 {

(J93413)

HF30 0.25–0.35 1.50 0.50–2.00 19–23 9–12 0.04 0.04 0.50 {

(J92803)

HH30 0.25–0.35 1.50 0.50–2.00 24–28 11–14 0.04 0.04 0.50 {

(J93513)

B

HH33 0.28–0.38 1.50 0.50–2.00 24–26 12–14 0.04 0.04 0.50 {

(J93633)

HI35 0.30–0.40 1.50 0.50–2.00 26–30 14–18 0.04 0.04 0.50 {

(J94013)

HK30 0.25–0.35 1.50 0.50–2.00 23–27 19–22 0.04 0.04 0.50 {

(J94203)

HK40 0.35–0.45 1.50 0.50–2.00 23–27 19–22 0.04 0.04 0.50 {

(J94204)

HL30 0.25–0.35 1.50 0.50–2.00 28–32 18–22 0.04 0.04 0.50 {

(N08613)

HL40 0.35–0.45 1.50 0.50–2.00 28–32 18–22 0.04 0.04 0.50 {

(N08614)

HN40 0.35–0.45 1.50 0.50–2.00 19–23 23–27 0.04 0.04 0.50 {

HPNb 0.38–0.45 0.50–1.50 0.50–1.50 24–27 34–37 0.03 0.03 0.50 0.5–1.5

(N28701)

HPNbS 0.38–0.45 0.50–1.50 1.50-2.50 24–27 34–37 0.03 0.03 0.50 0.5–1.5

(N28702)

HT50 0.40–0.60 1.50 0.50–2.00 15–19 33–37 0.04 0.04 0.50 {

(N08050)

HU50 0.40–0.60 1.50 0.50–2.00 17–21 37–41 0.04 0.04 0.50 {

(N08005)

HW50 0.40–0.60 1.50 0.50–2.00 10–14 58–62 0.04 0.04 0.50 {

(N08006)

HX50 0.40–0.60 1.50 0.50–2.00 15–19 64–68 0.04 0.04 0.50 {

(N06050)

A

TABLE 1 Chemical Requirements

Grade

Composition, % (Values are maximums unless otherwise indicated.)

(UNS

Carbon Manganese Silicon Chromium Nickel Phosphorus Sulfur Molybdenum Niobium

Number)

HC30 0.25 – 0.35 0.5 – 1.0 0.50 – 2.00 26 – 30 4.0 0.04 0.04 0.50 . . .

(J92613)

HD50 0.45 – 0.55 1.50 0.50 – 2.00 26 – 30 4 – 7 0.04 0.04 0.50 . . .

(J93015)

HE35 0.30 – 0.40 1.50 0.50 – 2.00 26 – 30 8 – 11 0.04 0.04 0.50 . . .

(J93413)

HF30 0.25 – 0.35 1.50 0.50 – 2.00 19 – 23 9 – 12 0.04 0.04 0.50 . . .

(J92803)

HH30 0.25 – 0.35 1.50 0.50 – 2.00 24 – 28 11 – 14 0.04 0.04 0.50 . . .

(J93513)

B

HH33 0.28 – 0.38 1.50 0.50 – 2.00 24 – 26 12 – 14 0.04 0.04 0.50 . . .

(J93633)

HI35 0.30 – 0.40 1.50 0.50 – 2.00 26 – 30 14 – 18 0.04 0.04 0.50 . . .

(J94013)

HK30 0.25 – 0.35 1.50 0.50 – 2.00 23 – 27 19 – 22 0.04 0.04 0.50 . . .

(J94203)

HK40 0.35 – 0.45 1.50 0.50 – 2.00 23 – 27 19 – 22 0.04 0.04 0.50 . . .

(J94204)

HL30 0.25 – 0.35 1.50 0.50 – 2.00 28 – 32 18 – 22 0.04 0.04 0.50 . . .

(N08613)

HL40 0.35 – 0.45 1.50 0.50 – 2.00 28 – 32 18 – 22 0.04 0.04 0.50 . . .

(N08614)

HN40 0.35 – 0.45 1.50 0.50 – 2.00 19 – 23 23 – 27 0.04 0.04 0.50 . . .

HPNb 0.38 – 0.45 0.50 – 1.50 0.50 – 1.50 24 – 27 34 – 37 0.03 0.03 0.50 0.5 – 1.5

(N28701)

HPNbS 0.38 – 0.45 0.50 – 1.50 1.50 – 2.50 24 – 27 34 – 37 0.03 0.03 0.50 0.5 – 1.5

(N28702)

HT50 0.40 – 0.60 1.50 0.50 – 2.00 15 – 19 33 – 37 0.04 0.04 0.50 . . .

(N08050)

HU50 0.40 – 0.60 1.50 0.50 – 2.00 17 – 21 37 – 41 0.04 0.04 0.50 . . .

(N08005)

HW50 0.40 – 0.60 1.50 0.50 – 2.00 10 – 14 58 – 62 0.04 0.04 0.50 . . .

(N08006)

A608/A608M − 14 (2018)

Grade

Composition, % (Values are maximums unless otherwise indicated.)

(UNS

Carbon Manganese Silicon Chromium Nickel Phosphorus Sulfur Molybdenum Niobium

Number)

HX50 0.40 – 0.60 1.50 0.50 – 2.00 15 – 19 64 – 68 0.04 0.04 0.50 . . .

(N06050)

A

Where ellipses (.) appear in this table there is no requirement, and the element need not be analyzed or reported.

B

Manufacturing control should ensure that this composition containcontains a minimal amount of ferrite. See Supplementary Requirement S5.

3.1.4 Size (outside or inside diameter and minimum wall thickness, see Section 8).

3.1.5 Condition (see Section 9, as cast or as cast as-cast or as-cast with machining on outside or inside surfaces, or machined;

see 5.1, and Sections 8, and 9),

3.1.6 Length (specific or random), (Permissible Variations in Length Section of Specification A999/A999M),

3.1.7 End finish (Ends Section of Specification A999/A999M),

3.1.8 Optional requirements (see 8.2.3 regarding the manufacturer’s wall thickness allowance for as cast as-cast tubing and

Supplementary Requirements S1 to S11),

3.1.9 Test report required (see Section 13), and

3.1.10 Special requirements to be added to the specification.

4. General Requirements

4.1 Material furnished under this specification shall conform to the applicable requirements of the current edition of

Specification A999/A999M, unless otherwise provided herein.

5. Materials and Manufacture

5.1 The tubing may be supplied in the as cast as-cast condition or as cast as-cast with machining on the outside or inside

surfaces, or machined, as agreed upon between the manufacturer and the purchaser.

5.2 Heat treatment of the tubing shall not be required under this specification.

6. Chemical Requirements

6.1 The material shall conform to the requirements as to chemical composition as prescribed in Table 1.

7. Tensile Properties

7.1 Tension tests at room temperature are not recommended as acceptance criteria under this specification since the alloys are

intended for elevated-temperature elevated temperature service, and room-temperature room temperature tests do not have a

dependable relationship to elevated-temperature elevated temperature properties. (Where the design of the tubing is based on an

assumption of certain minimum creep-rupture properties, one of the supplementary requirements of this specification may be

stipulated on the order to ascertain the ability of the material to meet the design properties.)

8. Permissible Variation in Dimensions

8.1 Machined Tubing (Tubing Machined on Inside and Outside):

8.1.1 The tolerances given in Specification A999/A999M shall govern, except that the wall thickness shall not vary over the

specified minimum wall thickness by more than 10 % or ⁄16 in. [1.6 mm], whichever is greater. There shall be no variation under

the specified minimum wall thickness.

8.2 As-Cast Tubing (No Machining or Machined on Inside or Outside):

8.2.1 Outside Diameter (For Tubes Ordered to Outside Diameter):

8.2.1.1 Tubes machined on the outside shall meet the requirements of Specification A999/A999M.

8.2.1.2 Tubes not machined on the outside shall meet the permissible variations of Table 2.

8.2.2 Inside Diameter (For Tubes Ordered to Inside Diameter):

TABLE 2 Permissible Variations in As-Cast Outside Diameter

Permissible Plus or Minus

Specified Outside Diameter of Tubing Variations from Specified

Outside Diameter

in. mm in. mm

From 2 to 4 50 to 100 0.08 2.0

Over 4 to 12 100 to 300 0.10 2.5

Over 12 to 24 300 to 600 0.12 3.0

Over 24 to 36 600 to 900 0.16 4.1

Over 36 to 54 900 to 1350 0.25 6.4

A608/A608M − 14 (2018)

8.2.2.1 Tubes machined on the inside shall meet the requirements of Specification A999/A999M.

8.2.2.2 Tubes not machined on the inside shall have permissible variations as agreed upon by the purchaser and the

manufacturer.

8.2.3 Wall Thickness—The wall thickness shall not exceed the calculated minimum as cast as-cast wall thickness by more than

the limits shown in Table 3. The calculated minimum wall thickness shall be equal to the specified minimum wall thickness plus

the manufacturer’s allowance for “inside surface feed metal” and outside surface roughness. Upon request, the manufacturer’s

allowance shall be furnished to the purchaser. There shall be no variation under the calculated minimum as cast as-cast wall

thickness. For tubes over 24 up to and including 54 in. 54 in. [600 to 1350 mm] in diameter, the “permissible variations over

specified minimum as cast as-cast wall thickness” shall be agreed upon by the manufacturer and the purchaser.

8.2.4 Length—If definite lengths are ordered, no length of tubing shall be under the length specified and not longer than the

tolerance shown in Table 4.

9. Finish

9.1 Machined Tubing—All tubes shall be reasonably straight and free of rejectable indications. All visual irregularities shall be

explored for depths. When the depth encroaches on the specified minimum wall thickness, such irregularities shall be considered

rejectable indications.

9.2 As-Cast Tubing:

9.2.1 The outside surface shall be adequately cleaned (such as by shotblasting, sandblasting, wire brushing, grinding, or

machining). The metal surface so revealed shall be visually inspected and shall be free of linear discontinuities or other

imperfections that encroach on the specified minimum wall of the tube.

9.2.2 Various degrees of surface roughness occur on unmachined tubing. If a specific surface finish is required, it shall be a

matter of agreement between the manufacturer and the purchaser.

9.3 Surface Irregularities Not Classified as Rejectable—Visual surface defects that have been explored and that do not encroach

on the minimum sound wall thickness shall be blended either by machining or grinding the surface into the surrounding unaffected

surface area of the tubing.

9.4 Repair by Welding—Repair of injurious defects by welding shall be permitted and major weld repairs shall be permitted only

subject to the approval of the purchaser. Weld repairs shall be considered major if the depth of the cavity prepared for welding

2 2

exceeds 20 % of the required minimum wall thickness or if the total surface area exceeds 10 in. [65 cm[65 cm ]. Defects shall

be completely removed before welding. If defects are linear, complete removal shall be checked by liquid penetrant inspection

(Practice E165E165/E165M). Only qualified operators and procedures in accordance with Practice A488/A488M shall be used. All

weld repairs shall be subjected to the same inspection standard as the tubing.

10. Pressure Test

10.1 All tubing shall be subjected to an internal air pressure of at least 75 psi [515 kPa] for at least 1 min either while submerged

in clear water or with the entire outer surface coated with sulfur-free soap suds at the discretion of the manufacturer. In the usable

portion of the tube, leaks are not permitted. If the Hydrostatic Test, Supplementary Requirement S6, is invoked, the exact details

of the test and testing procedure shall be clearly defined and made a part of the Ordering Informationordering information (3.1.8).

10.2 Leaks may be repaired by welding only if such repair is approved by the purchaser.

11. Flattening Test

11.1 Flattening tests are not required since material covered by this specification is not intended to be bent, flanged, or otherwise

formed.

12. Mechanical Tests Required

12.1 Air Pressure Test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.