ASTM C1063-06

(Specification)Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster

Standard Specification for Installation of Lathing and Furring to Receive Interior and Exterior Portland Cement-Based Plaster

SCOPE

1.1 This specification covers the minimum requirements for lathing and furring for the application of exterior and interior portland cement-based plaster as in Specification C 926 or Specification C 841.

1.2 Where a fire resistance rating is required for plastered assemblies and constructions, details of construction shall be in accordance with reports of fire tests of assemblies that have met the requirements of the fire rating imposed.

1.3 Where a specific degree of sound control is required for plastered assemblies and constructions, details of construction shall be in accordance with official reports of tests conducted in recognized testing laboratories in accordance with the applicable requirements of Test Method E 90.

1.4 The values stated in inch-pound units are to be regarded as the standard. The SI (metric) values given in parentheses are approximate and are provided for information purposes only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 1063 – 06

Standard Specification for

Installation of Lathing and Furring to Receive Interior and

1

Exterior Portland Cement-Based Plaster

This standard is issued under the fixed designation C 1063; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B221 Specification for Aluminum and Aluminum-Alloy

Extruded Bars, Rods, Wire, Profiles, and Tubes

1.1 This specification covers the minimum requirements for

C11 Terminology Relating to Gypsum and Related Build-

lathing and furring for the application of exterior and interior

ing Materials and Systems

portland cement-based plaster as in Specification C926 or

C841 Specification for Installation of Interior Lathing and

Specification C841.

Furring

1.2 Where a fire resistance rating is required for plastered

C847 Specification for Metal Lath

assembliesandconstructions,detailsofconstructionshallbein

C926 Specification for Application of Portland Cement-

accordance with reports of fire tests of assemblies that have

Based Plaster

met the requirements of the fire rating imposed.

C933 Specification for Welded Wire Lath

1.3 Where a specific degree of sound control is required for

C954 Specification for Steel Drill Screws for the Applica-

plastered assemblies and constructions, details of construction

tion of Gypsum Panel Products or Metal Plaster Bases to

shallbeinaccordancewithofficialreportsoftestsconductedin

Steel Studs from 0.033 in. (0.84 mm) to 0.112 in. (2.84

recognized testing laboratories in accordance with the appli-

mm) in Thickness

cable requirements of Test MethodE90.

C 1002 Specification for Steel Self-Piercing Tapping

1.4 The values stated in inch-pound units are to be regarded

Screws for the Application of Gypsum Panel Products or

asthestandard.TheSI(metric)valuesgiveninparenthesesare

Metal Plaster Bases to Wood Studs or Steel Studs

approximate and are provided for information purposes only.

C1032 Specification for Woven Wire Plaster Base

2. Referenced Documents D1784 SpecificationforRigidPoly(VinylChloride)(PVC)

2

Compounds and Chlorinated Poly(Vinyl Chloride)

2.1 ASTM Standards:

(CPVC) Compounds

A526/A526M Specification for Steel Sheet, Zinc-Coated

D4216 SpecificationforRigidPoly(VinylChloride)(PVC)

(Galvanized) by the Hot-Dip Process, Commercial Qual-

3

and Related PVC and Chlorinated Poly(Vinyl Chloride)

ity

(CPVC) Building Products Compounds

A641/A641M SpecificationforZinc−Coated(Galvanized)

E90 Test Method for Laboratory Measurement ofAirborne

Carbon Steel Wire

Sound Transmission Loss of Building Partitions and Ele-

A653/A653M Specification for Steel Sheet, Zinc-Coated

ments

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

by the Hot-Dip Process

3. Terminology

B69 Specification for Rolled Zinc

3.1 Definitions—For definitions relating to Ceilings and

Walls, see TerminologyC11.

1

This specification is under the jurisdiction of ASTM Committee C11 on 3.2 Definitions of Terms Specific to This Standard:

GypsumandRelatedBuildingMaterialsandSystemsandisthedirectresponsibility

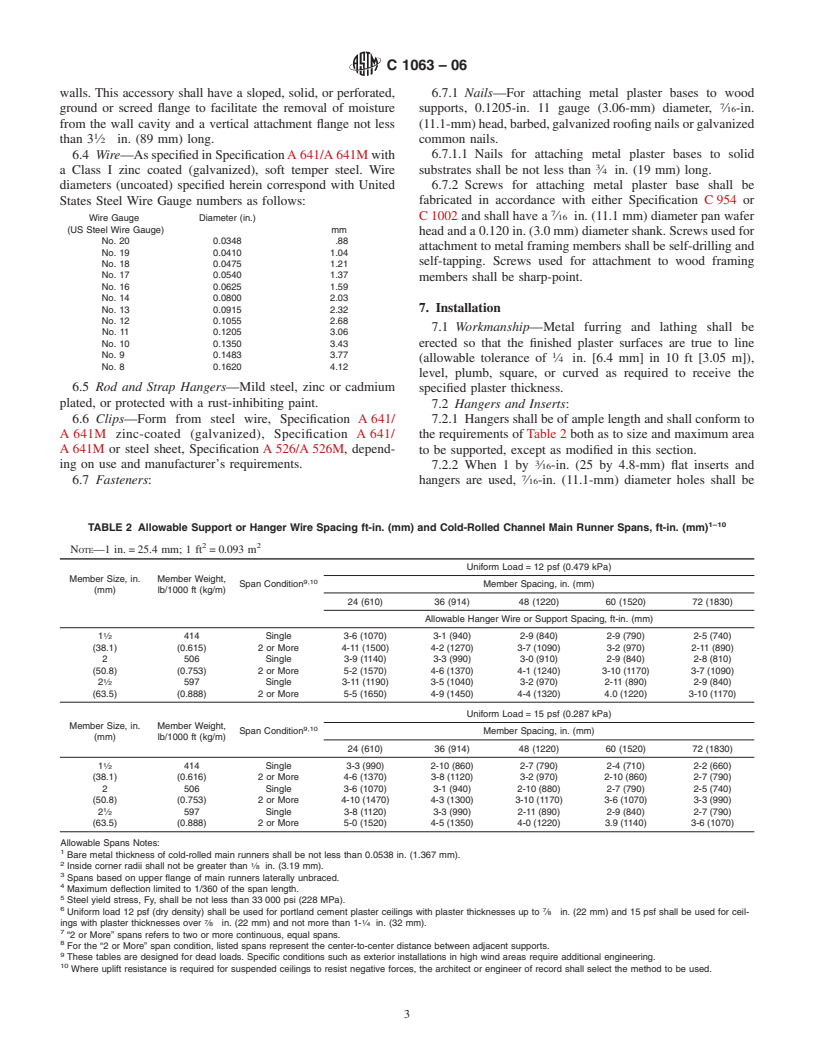

3.2.1 hangers—wires or steel rods or straps used to support

ofSubcommitteeC11.03onSpecificationsfortheApplicationofGypsumandOther

main runners for suspended ceilings beneath floor or roof

Products in Assemblies.

constructions.

Current edition approved Dec. 1, 2006. Published December 2006. Originally

approved in 1986. Last previous edition approved in 2003 as C1063–03.

3.2.2 inserts—devices embedded in concrete structural

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

members to provide a loop or opening for attachment of

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

hangers.

Standards volume information, refer to the standard’s Document Summary page on

3.2.3 saddle tie—see Figs. 1 and 2.

the ASTM website.

3

Withdrawn; see 1994 Annual Book of ASTM Standards , Vol 01.06.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C 1063 – 06

6.1.2.1 Welded Wire Lath—Specification C933.

6.1.2.2 Woven Wire Lath—Specification C1032.

6.1.2.3 Paper Backed Plaster Bases—Specification C847.

6.2 Accessories:

6.2.1 General—All accessories shall have perforated or

expanded flanges or clips shaped to permit complete embed-

ment in the plaster, to provide means for accurate alignment,

and to secure attachment of the accessory to the underlying

surface.Accessoriesshallbedesignedtoreceivea

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.