ASTM B1017-21

(Specification)Standard Specification for Seamless Copper-Iron Tube for Air Conditioning and Refrigeration

Standard Specification for Seamless Copper-Iron Tube for Air Conditioning and Refrigeration

SCOPE

1.1 This specification establishes the requirements for seamless copper iron tube intended for use in heat exchangers and connection lines of high-pressure air conditioning or refrigeration units.

1.2 The tube shall be produced from the following copper alloy:

Copper UNS No.

C19400

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 The following safety caveat pertains only to the test method(s) described in this specification:

1.4.1 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B1017 −21

Standard Specification for

Seamless Copper-Iron Tube for Air Conditioning and

1

Refrigeration

This standard is issued under the fixed designation B1017; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B251/B251MSpecification for General Requirements for

Wrought Seamless Copper and Copper-Alloy Tube

1.1 Thisspecificationestablishestherequirementsforseam-

B846Terminology for Copper and Copper Alloys

less copper iron tube intended for use in heat exchangers and

B900Practice for Packaging of Copper and Copper Alloy

connection lines of high-pressure air conditioning or refrigera-

Mill Products for U.S. Government Agencies

tion units.

E8/E8MTest Methods for Tension Testing of Metallic Ma-

1.2 The tube shall be produced from the following copper

terials

alloy:

E54Test Methods for ChemicalAnalysis of Special Brasses

3

Copper UNS No.

and Bronzes (Withdrawn 2002)

E62Test Methods for Chemical Analysis of Copper and

C19400

3

CopperAlloys(PhotometricMethods)(Withdrawn2010)

1.3 The values stated in inch-pound units are to be regarded

E243PracticeforElectromagnetic(EddyCurrent)Examina-

as standard. The values given in parentheses are mathematical

tion of Copper and Copper-Alloy Tubes

conversions to SI units that are provided for information only

E478Test Methods for ChemicalAnalysis of CopperAlloys

and are not considered standard. 4

2.2 ASME Standard:

1.4 The following safety caveat pertains only to the test

ASMEBoiler and Pressure Vessel Code Application

5

method(s) described in this specification:

2.3 CEN Standard:

1.4.1 This standard does not purport to address all of the

EN 14276-1Pressure equipment for refrigerating systems

safety concerns, if any, associated with its use. It is the

and heat pumps - Part 1: Vessels - General requirements

responsibility of the user of this standard to establish appro-

3. General Requirements

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use. 3.1 The following sections of Specification B251/B251M

constitute a part of this specification:

1.5 This international standard was developed in accor-

3.1.1 Sampling,

dance with internationally recognized principles on standard-

3.1.2 Number of tests and retests,

ization established in the Decision on Principles for the

3.1.3 Dimensions and permissible variations,

Development of International Standards, Guides and Recom-

3.1.4 Test specimens, and

mendations issued by the World Trade Organization Technical

3.1.5 Significance of numerical limits.

Barriers to Trade (TBT) Committee.

3.2 Whenasectionwithanidenticaltitletothosereferenced

2. Referenced Documents

in 3.1 appears in this specification and is in conflict with the

2

section appearing in Specification B251/B251M, the section in

2.1 ASTM Standards:

this specification shall prevail.

B153Test Method for Expansion (Pin Test) of Copper and

Copper-Alloy Pipe and Tubing

4. Terminology

4.1 Definitions—For definitions of terms related to copper

and copper alloys, refer to Terminology B846.

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

3

and Tube. The last approved version of this historical standard is referenced on

Current edition approved Feb. 15, 2021. Published March 2021. DOI: 10.1520/ www.astm.org.

4

B1017-21. Available from American Society of Mechanical Engineers (ASME), ASME

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or International Headquarters, Two Park Ave., New York, NY 10016-5990, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.asme.org.

5

Standards volume information, refer to the standard’s Document Summary page on Available from European Committee for Standardization (CEN), Rue de la

the ASTM website. Science 23, B - 1040 Brussels, Belgium, http://www.cen.eu.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B1017−21

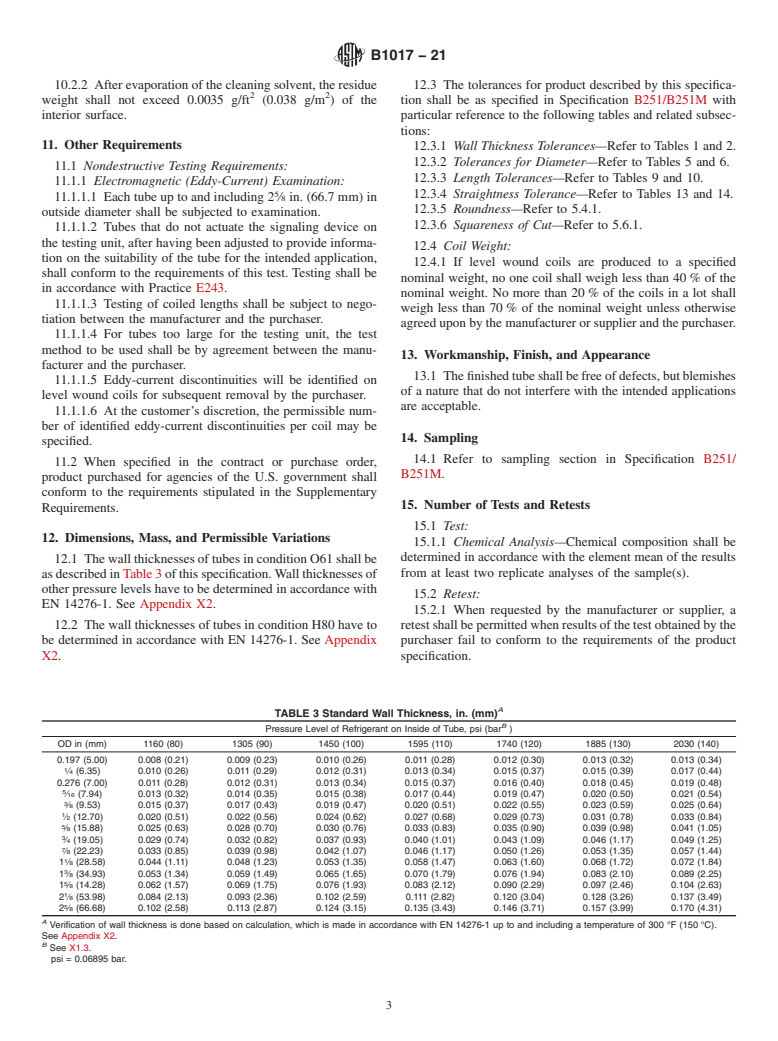

TABLE 1 Chemical Composition—Weight %

Composition %

Copper Alloy UNS No.

Copper Iron Zinc Lead, max Phosphorus

C19400 97.0 min 2.1–2.6 0.05–0.20 0.03 0.015–0.15

5. Ordering Information 6.2.3 Straight lengths specified as O61 annealed temper or

H80 hard-drawn temper shall be cleaned and capped, plugged,

5.1 Include the following spec

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.