ASTM D2639-08

(Test Method)Standard Test Method for Plastic Properties of Coal by the Constant-Torque Gieseler Plastometer

Standard Test Method for Plastic Properties of Coal by the Constant-Torque Gieseler Plastometer

SIGNIFICANCE AND USE

p>Reliable values of the plastic properties of coals are used to predict or explain the behavior of a coal or blends during carbonization or in other processes such as gasification, liquefaction, and combustion.

SCOPE

1.1 This test method covers a relative measure of the plastic behavior of coal when heated under prescribed conditions. This test method may be used to obtain semiquantitative values of the plastic properties of coals and blends used in carbonization and in other situations where determination of plastic behavior of coals is of practical importance.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D2639 − 08

StandardTest Method for

Plastic Properties of Coal by the Constant-Torque Gieseler

1

Plastometer

This standard is issued under the fixed designation D2639; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2 initial softening temperature, n—as used in this test

method, the temperature at which the stirrer rotation rate first

1.1 This test method covers a relative measure of the plastic

reaches 1.0 dial divisions per minute.

behaviorofcoalwhenheatedunderprescribedconditions.This

3.1.3 maximum fluidity, n—as used in this test method, the

test method may be used to obtain semiquantitative values of

measured maximum stirrer rotation rate, in dial divisions per

the plastic properties of coals and blends used in carbonization

minute.

and in other situations where determination of plastic behavior

of coals is of practical importance.

3.1.4 maximum fluidity temperature, n—as used in this test

method, the temperature at which stirrer rotation rate reaches a

1.2 The values stated in SI units are to be regarded as the

maximum value.

standard. The values given in parentheses are for information

3.1.5 plastic range, n—difference between the solidification

only.

temperature and the initial softening temperatures.

1.3 This standard does not purport to address all of the

3.1.6 solidification temperature, n—as used in this test

safety concerns, if any, associated with its use. It is the

method, the temperature at which the the first zero ddpm is

responsibility of the user of this standard to establish appro-

reached after the last stirrer rotation.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

4. Summary of Test Method

4.1 The plastometer measures the plastic properties of coals

2. Referenced Documents

by the use of a constantly applied torque on a stirrer placed in

2

2.1 ASTM Standards:

a crucible into which the coal is charged. The crucible is

D2013 Practice for Preparing Coal Samples for Analysis

immersed in a bath and the temperature increased uniformly.

D2234/D2234M Practice for Collection of a Gross Sample

The rates of movement of the stirrer are recorded in relation to

of Coal

increase in temperature.

3. Terminology

5. Significance and Use

3.1 Definitions:

5.1 Reliablevaluesoftheplasticpropertiesofcoalsareused

3.1.1 dial division per minute, n—as used in this test

to predict or explain the behavior of a coal or blends during

method, a measure of stirrer rotation rate. There are 100 dial

carbonization or in other processes such as gasification,

divisions for each full 360° rotation of the stirrer. Stirrer

liquefaction, and combustion.

rotation rate is total dial divisions turned by the stirrer in a one

minute time period.

6. Apparatus

6.1 Gieseler Plastometer—The apparatus shall consist of

the following:

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal

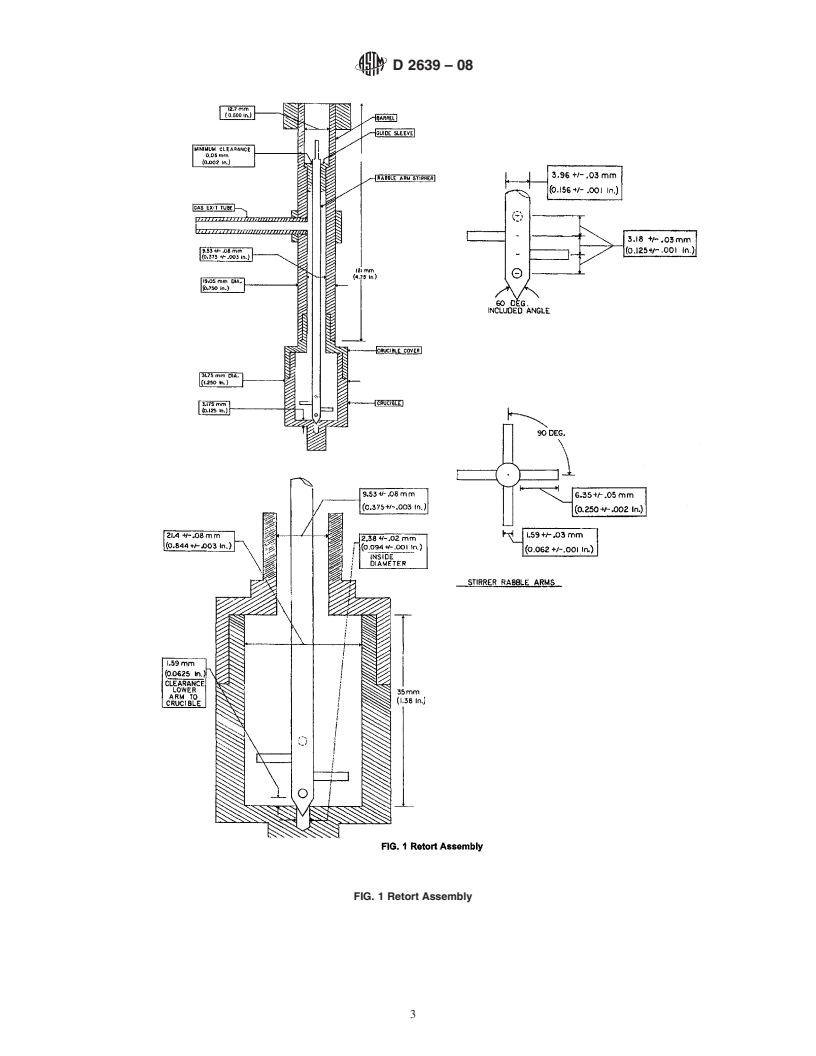

6.1.1 Retort—A steel retort consisting of four parts as

and Coke and is the direct responsibility of Subcommittee D05.15 on Metallurgical

shown in Fig. 1.

Properties of Coal and Coke.

6.1.2 Retort Crucible, cylindrical, 21.4 6 0.08 mm

Current edition approved May 15, 2008. Published June 2008. Originally

ε1

(0.844 6 0.003 in.) in inside diameter and 35.0 mm (1.38 in.)

approved in 1967. Last previous edition approved in 2004 as D2639–04 . DOI:

10.1520/D2639-08.

in depth, with exterior threads for joining the crucible to the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

crucible cover. The crucible shall have a 2.38- 6 0.02-mm

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

(0.094- 6 0.001-in.) diameter notch in the center of its inside

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. base to serve as a seat for the stirrer.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D2639 − 08

FIG. 1 Retort Assembly

2

---------------------- Page: 2 ----------------------

D2639 − 08

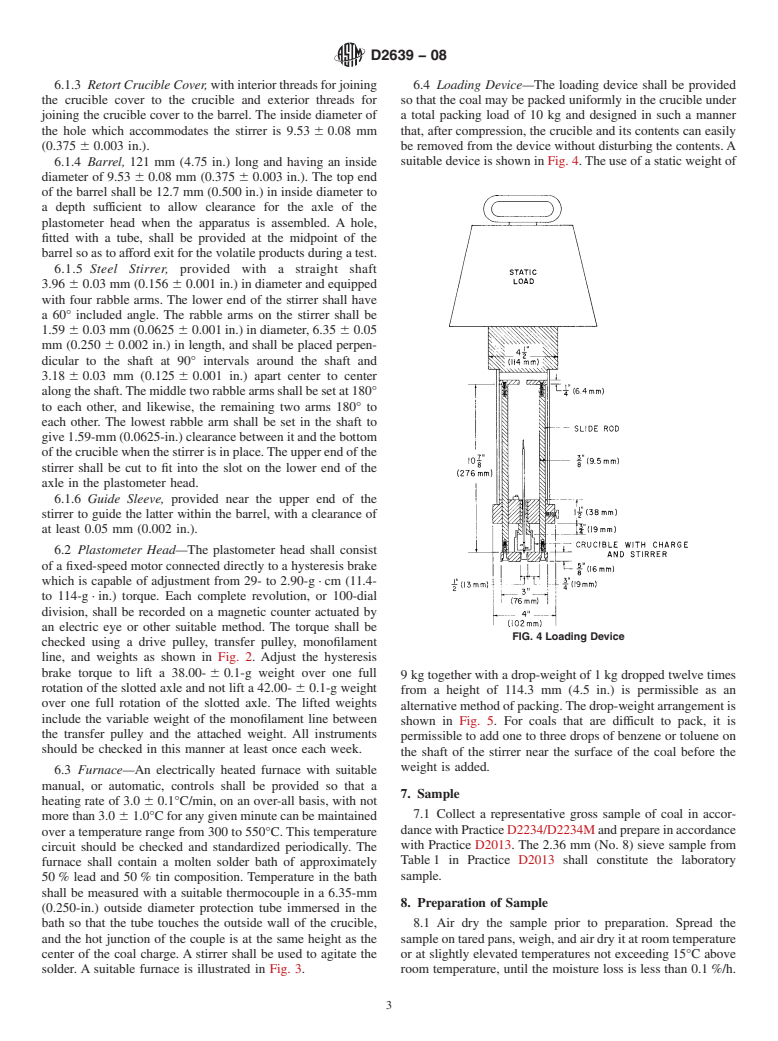

6.1.3 Retort Crucible Cover,withinteriorthreadsforjoining 6.4 Loading Device—The loading device shall be provided

the crucible cover to the crucible and exterior threads for so that the coal may be packed uniformly in the crucible under

joining the crucible cover to the barrel. The inside diameter of a total packing load of 10 kg and designed in such a manner

the hole which accommodates the stirrer is 9.53 6 0.08 mm that, after compression, the crucible

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:D 2639–04 Designation:D 2639–08

Standard Test Method for

Plastic Properties of Coal by the Constant-Torque Gieseler

1

Plastometer

This standard is issued under the fixed designation D 2639; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Editorial changes were made throughout in January 2005.

1. Scope

1.1 This test method covers a relative measure of the plastic behavior of coal when heated under prescribed conditions. This

test method may be used to obtain semiquantitative values of the plastic properties of coals and blends used in carbonization and

in other situations where determination of plastic behavior of coals is of practical importance.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D 2013 Practice offor Preparing Coal Samples for Analysis

D2234 2234/D 2234M Practice for Collection of a Gross Sample of Coal

3. Terminology

3.1 Definitions:

3.1.1 dial division per minute, n—as used in this test method, a measure of stirrer rotation rate. There are 100 dial divisions for

each full 360° rotation of the stirrer. Stirrer rotation rate is total dial divisions turned by the stirrer in a one minute time period.

3.1.2 initial softening temperature, n—as used in this test method, the temperature at which the stirrer rotation rate first reaches

1.0 dial divisions per minute.

3.1.3 maximum fluidity, n—as used in this test method, the measured maximum stirrer rotation rate, in dial divisions per minute.

3.1.4 maximum fluidity temperature, n—as used in this test method, the temperature at which stirrer rotation rate reaches a

maximum value.

3.1.5 plastic range, n—difference between the solidification temperature and the initial softening temperatures.

3.1.6 solidification temperature, n—as used in this test method, the temperature at which the the first zero ddpm is reached after

the last stirrer rotation.

4. Summary of Test Method

4.1 The plastometer measures the plastic properties of coals by the use of a constantly applied torque on a stirrer placed in a

crucible into which the coal is charged. The crucible is immersed in a bath and the temperature increased uniformly. The rates of

movement of the stirrer are recorded in relation to increase in temperature.

5. Significance and Use

5.1 Reliable values of the plastic properties of coals are used to predict or explain the behavior of a coal or blends during

carbonization or in other processes such as gasification, liquefaction, and combustion.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD05onCoalandCokeandisthedirectresponsibilityofSubcommitteeD05.15onMetallurgicalProperties

of Coal and Coke.

Current edition approved Nov. 1, 2004. Published November 2004. Originally approved in 1967. Last previous edition approved in 1998 as D2639–98

´1

Current edition approved May 15, 2008. Published June 2008. Originally approved in 1967. Last previous edition approved in 2004 as D 2639–04 .

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 2639–08

6. Apparatus

6.1 Gieseler Plastometer—The apparatus shall consist of the following:

6.1.1 Retort—A steel retort consisting of four parts as shown in Fig. 1.

6.1.2 Retort Crucible, cylindrical, 21.4 6 0.08 mm (0.844 6 0.003 in.) in inside diameter and 35.0 mm (1.38 in.) in depth, with

exterior threads for joining the crucible to the crucible cover. The crucible shall have a 2.38- 6 0.02-mm (0.094- 6 0.001-in.)

diameter notch in the center of its inside base to serve as a seat for the stirrer.

6.1.3 Retort Crucible Cover, with interior threads for joining the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.