ASTM F892-95

(Specification)Specification for Polyethylene (PE) Corrugated Pipe With a Smooth Interior and Fittings (Withdrawn 2001)

Specification for Polyethylene (PE) Corrugated Pipe With a Smooth Interior and Fittings (Withdrawn 2001)

SCOPE

1.1 This specification includes requirements, test methods, and materials for a polyethylene (PE) corrugated pipe with a smooth interior. The pipe consists of an outer corrugated wall connected to a smooth inner wall. Joints and fittings are included in this specification.

1.2 The requirements of this specification are intended to provide pipe and fittings suitable for underground use in nonpressure applications such as sewers, conduit, and land drainage.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 The following safety hazards caveat pertains only to the test methods portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 892 – 95 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Polyethylene (PE) Corrugated Pipe With a Smooth Interior

1

and Fittings

This standard is issued under the fixed designation F 892; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 3212 Specification for Joints for Drain and Sewer Plastic

3

Pipes Using Flexible Elastomeric Seals

1.1 This specification includes requirements, test methods,

D 3350 Specification for Polyethylene Plastic Pipe and

and materials for a polyethylene (PE) corrugated pipe with a

3

Fittings Materials

smooth interior. The pipe consists of an outer corrugated wall

3

F 412 Terminology Relating to Plastic Piping Systems

connected to a smooth inner wall. Joints and fittings are

F 449 Practice for Subsurface Installation of Corrugated

included in this specification.

Thermoplastic Tubing for Agricultural Drainage or Water

1.2 The requirements of this specification are intended to

3

Table Control

provide pipe and fittings suitable for underground use in

F 477 Specification for Elastomeric Seals (Gaskets) for

nonpressure applications such as sewers, conduit, and land

3

Joining Plastic Pipe

drainage.

F 481 Practice for Installation of Thermoplastic Pipe and

1.3 The values stated in inch-pound units are to be regarded

3

Corrugated Tubing in Septic Tank Leach Fields

as the standard. The values given in parentheses are for

2.2 Federal Standard:

information only.

4

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

1.4 The following safety hazards caveat pertains only to the

2.3 Military Standard:

test methods portion, Section 11, of this specification: This

4

MIL-STD-129 Marking for Shipment and Storage

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

3. Terminology

of this standard to establish appropriate safety and health

3.1 Definitions— Definitions are in accordance with Termi-

practices and determine the applicability of regulatory limita-

nology F 412, and abbreviations are in accordance with Ter-

tions prior to use.

minology D 1600, unless otherwise specified. The abbreviation

2. Referenced Documents

for polyethylene is PE.

3.1.1 crease—a deformation that cannot be removed like a

2.1 ASTM Standards:

dent; generally associated with wall buckling.

D 618 Practice for Conditioning Plastics and Electrical

2

3.1.2 parting line—a slight mark or surface irregularity in

Insulating Materials for Testing

the pipe or fitting surface as a result of a mold separation at that

D 1600 Terminology for Abbreviated Terms Relating to

2

location.

Plastics

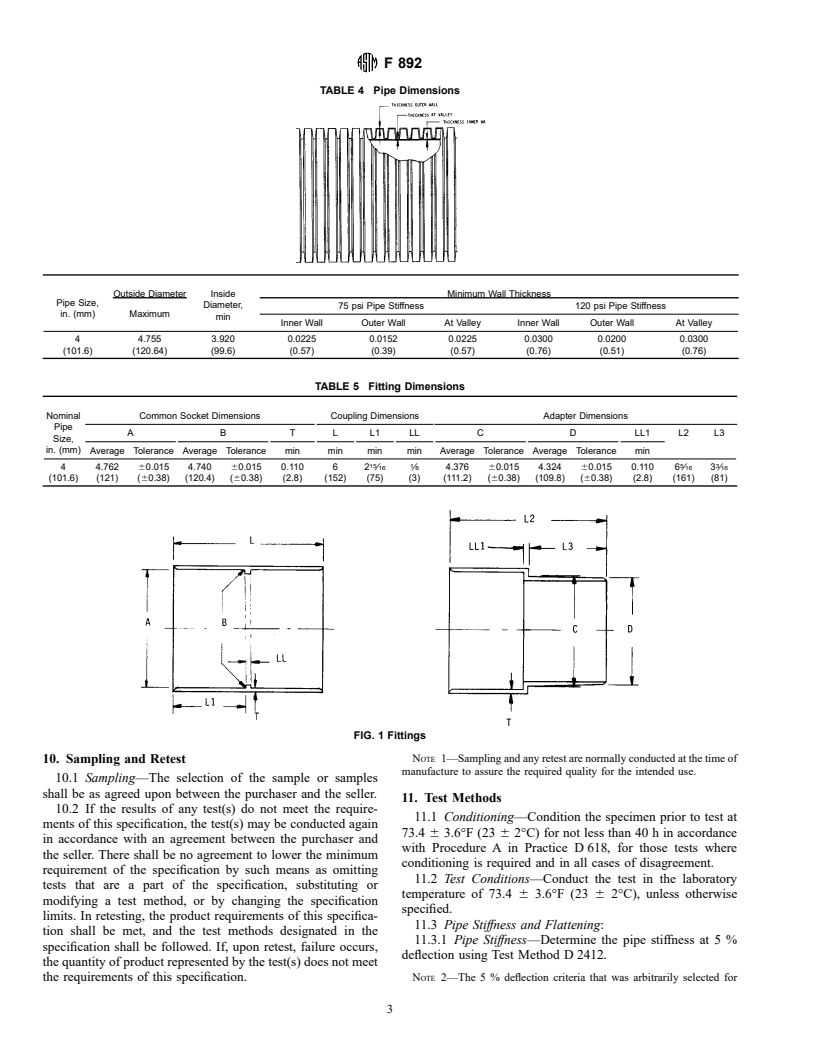

D 2122 Test Method for Determining Dimensions of Ther-

3 4. Classification

moplastic Pipe and Fittings

4.1 Pipe and fittings produced in accordance with this

D 2321 Practice for Underground Installation of Flexible

3

specification shall be classified as Type R or Type NR, based

Thermoplastic Sewer Pipe

upon the compounds used in the manufacture.

D 2412 Test Method for Determination of External Loading

3

4.1.1 Type R pipe or fittings shall be produced from

Characteristics of Plastic Pipe by Parallel-Plate Loading

compounds for which a hydrostatic design basis has been

D 2444 Test Method for Impact Resistance of Thermoplas-

3

established in accordance with Test Method D 2837.

tic Pipe and Fittings by Means of a Tup (Falling Weight)

4.1.2 Type NR pipe or fittings may be produced from

D 2837 Test Method for Obtaining Hydrostatic Design

3

compounds for which no hydrostatic design basis exists.

Basis for Thermoplastic Pipe Materials

4.2 Pipe and fittings classified as Type R or Type NR are

intended for nonpressure applications only. Users should con-

1

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

sult the manufacturer for information regarding the effects of

Piping Systems and is the direct responsibility of Subcommittee F17.26 on Olefin

other environments, such as exposure to sunlight, weathering,

Based Pipe.

Current edition approved Sept. 10, 1995. Published November 1995. Originally

published as F 892 – 84. Last previous edition F 892 – 94.

2 4

Annual Book of ASTM Standards, Vol 08.01. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

3

Annual Book of ASTM Standards, Vol 08.04. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

1

---------------------- Page: 1 ----------------------

F 892

TABLE 2 Minimum Pipe Stiffness at 5 % D

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.