ASTM D3520-88(1998)

(Test Method)Standard Test Method for Quenching Time of Heat-Treating Fluids (Magnetic Quenchometer Method) (Withdrawn 2008)

Standard Test Method for Quenching Time of Heat-Treating Fluids (Magnetic Quenchometer Method) (Withdrawn 2008)

SCOPE

1.1 This test method describes a procedure for making an evaluation of the quenching speed characteristics of petroleum fluids used in the quenching of metals by means of the Magnetic Quenchometer. Note 1-A comparison method for testing the hardenability of steel is Method A255.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Notes 5, 6, 17, 18, and 19.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D3520–04

Standard Test Method for

Quenching Time of Heat-Treating Fluids (Magnetic

Quenchometer Method)

This standard is issued under the fixed designation D3520; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Petroleum Products (Hydrometer Method)

D445 Test Method for Kinematic Viscosity of Transparent

1.1 This test method covers a procedure for making a

and Opaque Liquids (the Calculation of Dynamic Viscos-

comparative evaluation of the quenching speed characteristics

ity)

of petroleum fluids used in the quenching of metals by means

D484 Specification for Hydrocarbon Drycleaning Sol-

of the Magnetic Quenchometer.

vents

NOTE 1—Acomparison method for testing the hardenability of steel is

D1218 Test Method for Refractive Index and Refractive

Test Method A255.

Dispersion of Hydrocarbon Liquids

NOTE 2—An additional comparison method for evaluation of the

D1744 Test Method for Water in Liquid Petroleum Prod-

quenching speed characteristics of petroleum fluids used in the quenching

ucts by Karl Fischer Reagent

of metals is Test Method D6200.

D6200 Test Method for Determining Cooling Characteris-

1.2 This test method provides a measure of changes in oil

tics of Quench Oils by Cooling Curve Analysis

chemistry due to contamination, base oil degradation, and

additivedrag-outduringuse.Thistestmeasureschangesinthe

3. Summary of Test Method

quenching speed characteristics of petroleum fluids at the high

3.1 This test method determines the time for cooling a

temperature (>354°C). This test method does not reliably

chromized nickel ball from approximately 885°C (1625°F) to

predict metallurgical performance.

approximately 354°C (670°F) when quenched in 200 mL of

1.3 This standard does not purport to address all of the

test fluid in a metal beaker at 21 to 27°C (70 to 81°F). The

safety concerns, if any, associated with its use. It is the

quenching time is recorded by a digital timer which is

responsibility of the user of this standard to establish appro-

energized by a photoelectric cell from light produced by the

priate safety and health practices and determine the applica-

ball at 885°C (1625°F) and which is stopped when the ball

bility of regulatory requirements prior to use.

becomes magnetic (Curie Point, approximately 354°C) and is

attracted by a magnet to the side of the beaker, tripping a relay

2. Referenced Documents

to stop the timer.

2.1 ASTM Standards:

A255 Test Method for End-Quench Test for Hardenability

4. Significance and Use

of Steel

4.1 The results obtained by the test method described are

D91 Test Method for Precipitation Number of Lubricating

useful as guides in selecting fluids with respect to quenching

Oils

speed characteristics desired for metal quenching applications.

D92 Test Method for Flash and Fire Points by Cleveland

NOTE 3—Although this test method has been found useful for some

Open Cup Tester

water-based fluids, the statistical significance of the test has been

D97 Test Method for Pour Point of Petroleum Products

established only by round-robin testing of petroleum-based fluids.

D287 TestMethodforAPIGravityofCrudePetroleumand

4.2 Theseresultswillprovideameasureofquenchingspeed

(cooling rate) from approximately 885°C (1625°F) to 354°C

This test method is under the jurisdiction of ASTM Committee D02 on

(670°F) and are not directly proportional to hardness obtain-

PetroleumProductsandLubricantsandisthedirectresponsibilityofSubcommittee

able on metals quenched therein as many other factors are

D02.L0 on Industrial Lubricants.

involved in the quenching process in actual plant operation

Current edition approved May 1, 2004. Published June 2004. Originally

with production parts.

approved in 1976. Withdrawn November 2003 and reinstated as D3520–04.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3520–04

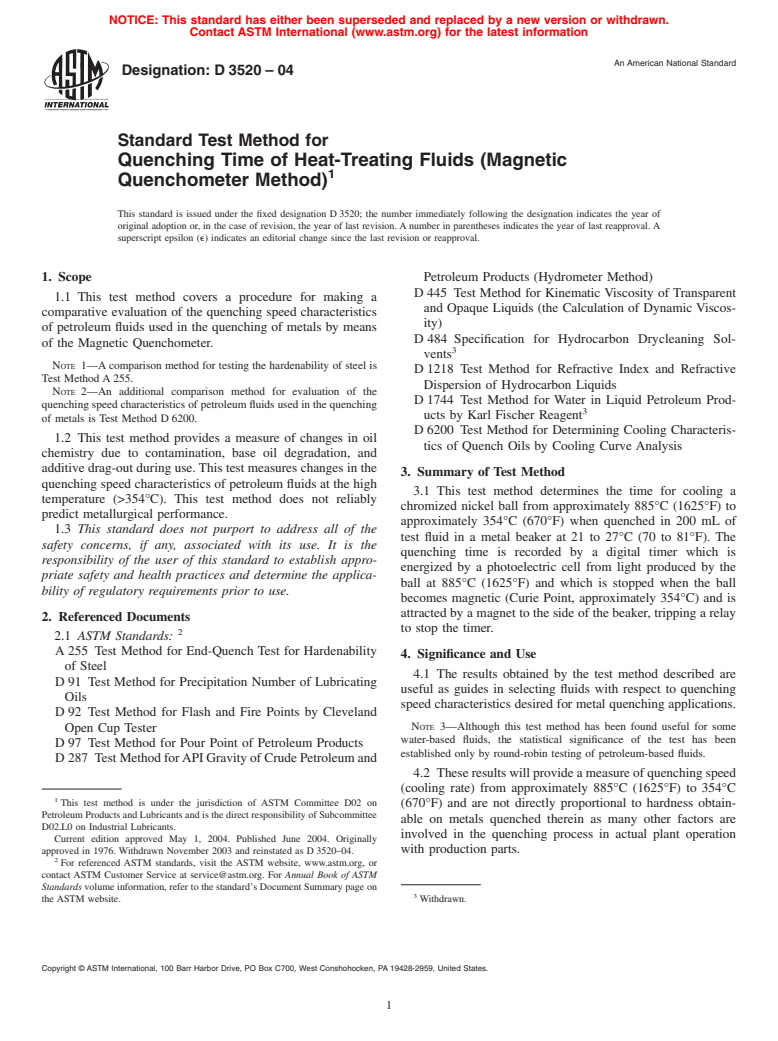

FIG. 1 Magnetic Quenchometer

connected controller near the heating elements can be used to minimize

temperature overrides, or both may be used. Further, 1 by 2 by 3-in. heat

sinks can be placed next to the area where the ball is to be placed to act

as heat shields and provide a more uniform temperature in this particular

area.

6. Materials

6.1 Ball, Chromized Nickel, having a diameter of 22.22 6

0.13mm(0.875 60.005in.),aweightof50 62g,andsurface

finish from 0.38 to 0.76 µm (15 to 30 µin.).

6.2 Reference Fluid.

NOTE 6—Fluids used in cooperative testing covered in Annex A2 are

suitable. Reference fluids TDL-VI-1 (35) the primary reference fluid and

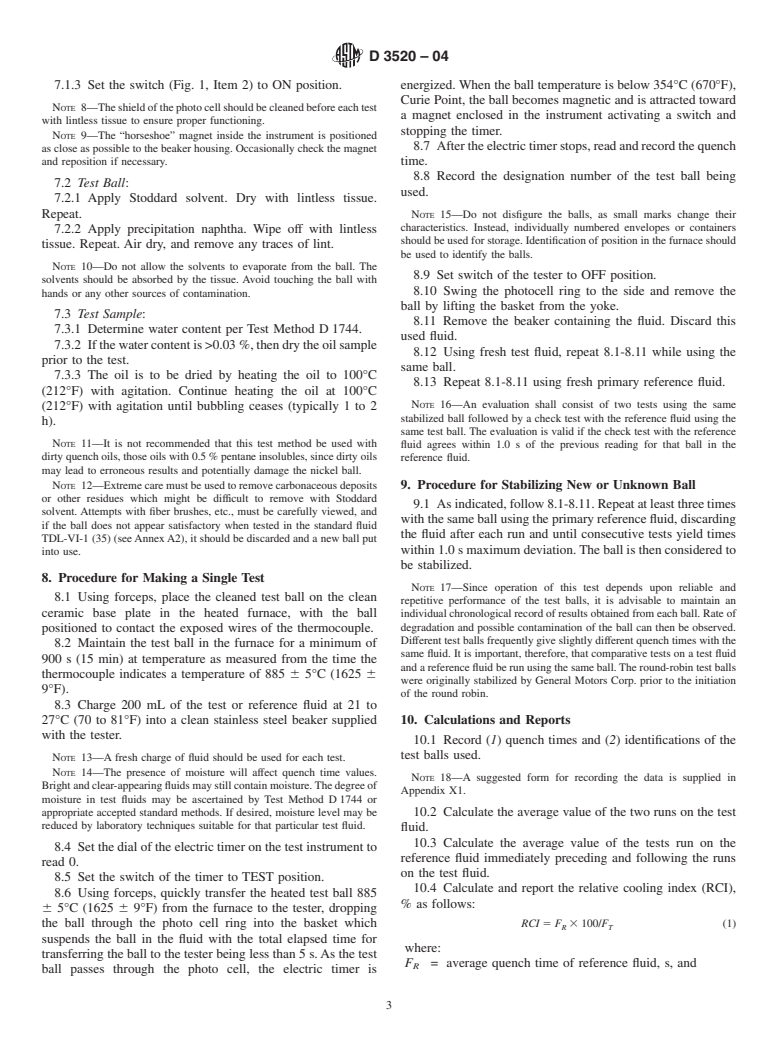

FIG. 2 Test Sequence in Beaker 4

TDL-VI-1 (100X) the secondary standard are suitable.

NOTE 7—The use of non-chromized nickel balls is not included in this

test method and is not recommended since the results obtained are

NOTE 4—Test Method D6200 describes the equipment and procedure

commonly more scattered and may be inconsistent with data properly

for characterizing the time-temperature performance of a quenching oil

obtained with chromized nickel balls. It is also recommended that

through the entire cooling process.

chromized nickel balls be used with a final initialization value of 29.0 to

5. Apparatus 32.0 seconds to obtain optimal repeatability.

5.1 Magnetic Quenchometer, as shown in Figs. 1 and 2. 6.3 Stoddard Solvent, conforming to Specification D484.

5.2 Furnace, Electric Muffle, with air atmosphere, capable (Warning—Combustible, skin irritant on repeated contact,

of maintaining a temperature of 885 6 5°C (1625 6 9°F), as aspiration hazard.)

measured at the ball by the thermocouple prior to quenching, 6.4 Precipitation Naphtha, conforming to the requirement

and fitted with (1) a clean ceramic base plate, for supporting for precipitation naphtha in Test Method D91. (Warning—

the test ball, and (2) a No. 14 B&S gage Chromel-Alumel Extremely flammable, skin irritant on repeated contact, aspi-

thermocouple probe (without a protection tube) inserted ration hazard.)

through a hole in a wall of the furnace, and positioned to 6.5 Forceps,approximately450mm(18in.)long.Weldtwo

contact the test ball. 20 mm ( ⁄4 in.) stainless steel washers to the tips of the forceps

for greater safety in transporting the hot nickel balls.

NOTE 5—A rheostat on the power supply may be used to provide a

6.6 Tissue, lintless.

closer control of furnace temperature, or a separate thermocouple-

7. Preparation of Apparatus

Thesolesourceofsupplyoftheapparatusknowntothecommitteeatthistime

7.1 Tester:

is Testron Corp., 34153 Industrial Rd., Livonia, MI 48150. If you are aware of

7.1.1 Place the instrument near the furnace and where

alternative suppliers, please provide this information to ASTM International

lighting does not activate the photo cell.

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee , which you may attend. 7.1.2 Connect to 110 V ac.

D3520–04

7.1.3 Set the switch (Fig. 1, Item 2) to ON position. energized.When the ball temperature is below 354°C (670°F),

Curie Point, the ball becomes magnetic and is attracted toward

NOTE 8—Theshieldofthephotocellshouldbecleanedbeforeeachtest

a magnet enclosed in the instrument activating a switch and

with lintless tissue to ensure proper functioning.

stopping the timer.

NOTE 9—The “horseshoe” magnet inside the instrument is positioned

8.7 Aftertheelectrictimerstops,readandrecordthequench

ascloseaspossibletothebeakerhousing.Occasionallycheckthemagnet

and reposition if necessary. time.

8.8 Record the designation number of the test ball being

7.2 Test Ball:

used.

7.2.1 Apply Stoddard solvent. Dry with lintless tissue.

Repeat. NOTE 15—Do not disfigure the balls, as small marks change their

characteristics. Instead, individually numbered envelopes or containers

7.2.2 Apply precipitation naphtha. Wipe off with lintless

shouldbeusedforstorage.Identificationofpositioninthefurnaceshould

tissue. Repeat. Air dry, and remove any traces of lint.

be used to identify the balls.

NOTE 10—Do not allow the solvents to evaporate from the ball. The

8.9 Set switch of the tester to OFF position.

solvents should be absorbed by the tissue. Avoid touching the ball with

8.10 Swing the photocell ring to the side and remove the

hands or any other sources of contamination.

ball by lifting the basket from the yoke.

7.3 Test Sample:

8.11 Remove the beaker containing the fluid. Discard this

7.3.1 Determine water content per Test Method D1744.

used fluid.

7.3.2 Ifthewatercontentis>0.03%,thendrytheoilsample

8.12 Using fresh test fluid, repeat 8.1-8.11 while using the

prior to the test.

same ball.

7.3.3 The oil is to be dried by heating the oil to 100°C

8.13 Repeat 8.1-8.11 using fresh primary reference fluid.

(212°F) with agitation. Continue heating the oil at 100°C

NOTE 16—An evaluation shall consist of two tests using the same

(212°F) with agitation until bubbling ceases (typically 1 to 2

stabilized ball followed by a check test with the reference fluid using the

h).

same test ball. The evaluation is valid if the check test with the reference

NOTE 11—It is not recommended that this test method be used with

fluid agrees within 1.0 s of the previous reading for that ball in the

dirtyquenchoils,thoseoilswith0.5%pentaneinsolubles,sincedirtyoils

reference fluid.

may lead to erroneous results and potentially damage the nickel ball.

9. Procedure for Stabilizing New or Unknown Ball

NOTE 12—Extremecaremustbeusedtoremovecarbonaceousdeposits

or other residues which might be difficult to remove with Stoddard

9.1 Asindicated,follow8.1-8.11.Repeatatleastthreetimes

solvent. Attempts with fiber brushes, etc., must be carefully viewed, and

withthesameballusingtheprimaryreferencefluid,discarding

if the ball does not appear satisfactory when tested in the standard fluid

the fluid after each run and until consecutive tests yield times

TDL-VI-1 (35) (seeAnnexA2), it should be discarded and a new ball put

within1.0smaximumdeviation.Theballis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.