ASTM D4660-00(2006)e1

(Test Method)Standard Test Methods for Polyurethane Raw Materials: Determination of the Isomer Content of Toluenediisocyanate

Standard Test Methods for Polyurethane Raw Materials: Determination of the Isomer Content of Toluenediisocyanate

SCOPE

1.1 These test methods measure the amount of toluene-2,6-diisocyanate (TDI) or toluene-2,4-diisocyanate in mixtures of the 2,4- and 2,6-isomers. Two test methods are required to give accurate results over a broad range of isomer concentrations.

1.1.1 Test Method AApplicable to TDI samples containing 5 to 95 % 2,6-isomer (95 to 5 % 2,4-isomer).

1.1.2 Test Method BApplicable to TDI samples containing 0 to 5 % 2,6-isomer (95 to 100 % 2,4-isomer). There are no equivalent ISO standards.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning and precautionary statements see Note 3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D4660–00 (Reapproved 2006)

Standard Test Methods for

Polyurethane Raw Materials: Determination of the Isomer

Content of Toluenediisocyanate

This standard is issued under the fixed designation D4660; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Removed non-mandatory language throughout the standard in March 2006.

1. Scope* 3.2.1 isomer—a compound having the same percentage

composition and molecular weight as another compound but

1.1 These test methods measure the amount of toluene-2,6-

differs in chemical or physical properties.

diisocyanate (TDI) or toluene–2,4–diisocyanate in mixtures of

3.2.2 isomer content—theamountofanisomerexpressedas

the 2,4– and 2,6–isomers. Two test methods are required to

a percentage of total isomer amount.

give accurate results over a broad range of isomer concentra-

tions.

4. Summary of Test Methods

1.1.1 Test Method A—Applicable to TDI samples contain-

4.1 Both test methods are based on the quantitative mea-

ing 5 to 95% 2,6–isomer (95 to 5% 2,4–isomer).

surement of absorption bands arising from out-of-plane C–H

1.1.2 Test Method B—Applicable to TDI samples contain-

deformation vibrations of the aromatic ring at 810 and 782

ing 0 to 5% 2,6–isomer (95 to 100% 2,4–isomer).

−1

cm (12.3 and 13.8 µm).

NOTE 1—There are no equivalent ISO standards.

4.2 In Test MethodA, the infrared spectrum of a cyclohex-

ane solution of the sample is recorded in the 770 to 840-

1.2 This standard does not purport to address all of the

−1

safety concerns, if any, associated with its use. It is the cm (12to13-µm)region.Theabsorbanceratioofthe810and

−1

782-cm bands is measured and converted to percent toluene-

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- 2,6-diisocyanate from a previously established calibration

curve.

bility of regulatory limitations prior to use. For specific

−1

warning and precautionary statements see Note 3. 4.3 InTestMethodB,theabsorbanceofthe782-cm band

is measured from an infrared spectrum of an undiluted sample

2. Referenced Documents

and then converted to percent 2,6-isomer from a previously

2.1 ASTM Standards: established calibration curve.

D883 Terminology Relating to Plastics

5. Significance and Use

E180 Practice for Determining the Precision of ASTM

Methods for Analysis and Testing of Industrial and Spe- 5.1 These test methods can be used for research or for

quality control to determine the isomer ratios of toluene

cialty Chemicals

diisocyanates.

3. Terminology

5.2 The isomer ratio of a toluene diisocyanate relates to its

3.1 Terminologyinthesetestmethodsisinaccordancewith reactivity.

Terminology D883.

6. Apparatus

3.2 Definitions of Terms Specific to This Standard:

6.1 Spectrophotometer—Any single- or double-beam re-

cordinginfraredspectrophotometeraccurateto0.2%transmis-

These test methods are under the jurisdiction of ASTM Committee D20 on

sion and capable of resolving the two peaks of the 2,4-isomer

Plastics and are the direct responsibility of Subcommittee D20.22 on Cellular

−1

doublet at 810 cm .

Materials—Plastics and Elastomers.

6.2 Cells, sealed sodium chloride (NaCl) liquid absorption

Current edition approved March 15, 2006. Published June 2006. Originally

approved in 1959. Last previous edition approved in 2000 as D4660-00.

cells with 0.2-mm (Test MethodA) and 0.1-mm (Test Method

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

B) path lengths. The actual thicknesses of the cells are to be

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

known to 60.002 mm.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D4660–00 (2006)

NOTE 3—Dry carefully all glassware since the diisocyanates react

6.3 Glassware, 25-mL, glass-stoppered, volumetric flasks,

readily with moisture.

0.80-mL pipet, and an all-glass syringe.

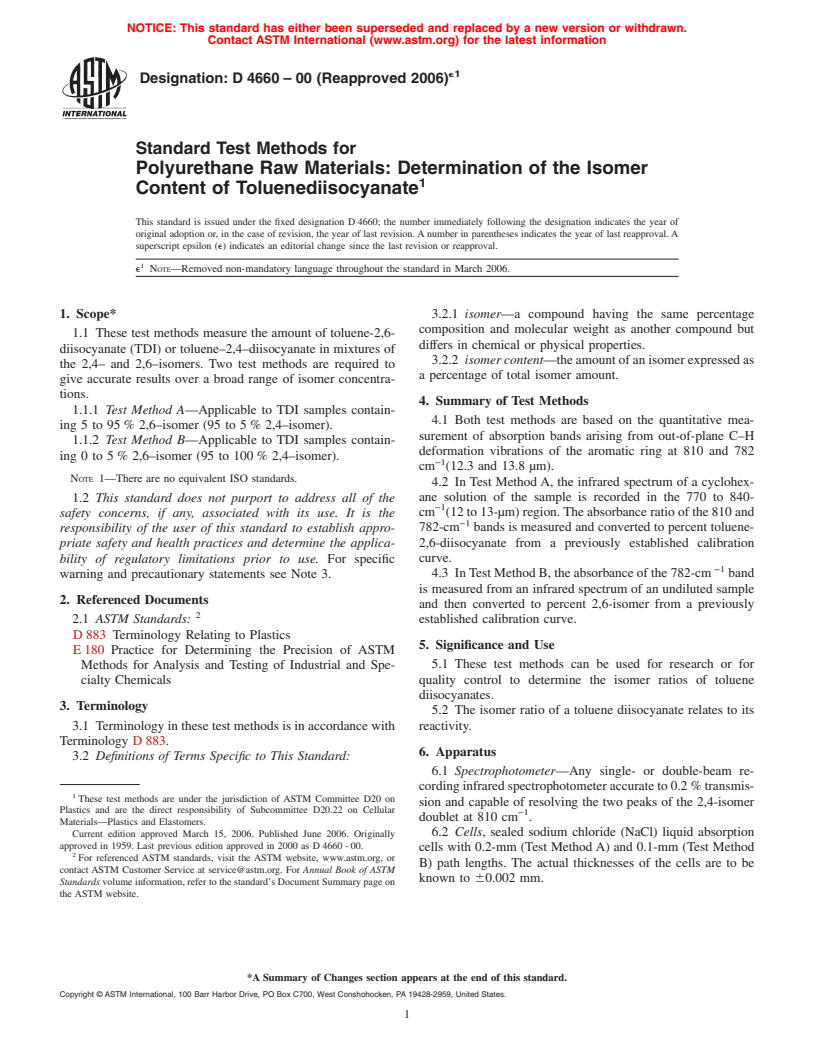

10.1.1 Approximate standard mixtures for wide-range cali-

7. Reagents and Materials

bration are given in Table 1.

7.1 Purity of Reagents—Use reagent grade chemicals in all

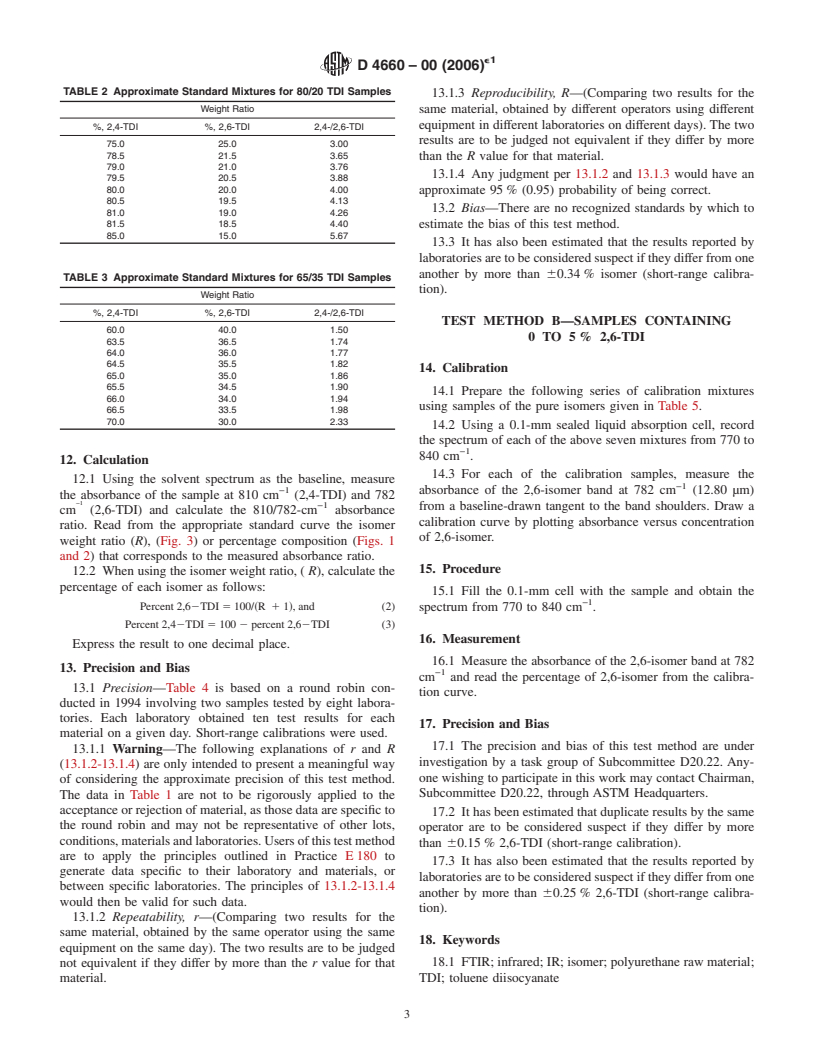

10.1.2 Approximate standard mixtures for short-range cali-

tests. Unless otherwise noted, all reagents conform to the

brations (see Note 4) are given in Tables 2 and 3 (see Figs. 1

specifications of the Committee onAnalytical Reagents of the

and 2).

American Chemical Society where such specifications are

3 NOTE 4—Calibrationoveranarrowrangecoveringtheexpectedisomer

available. Othergradesmaybeused,provideditisascertained

ratio gives more accurate results than a wide-range calibration.

that the reagent is of sufficiently high purity to permit its use

without lessening the accuracy of the determination. 10.2 Preparation of Standard Solutions— Using a pipet,

7.2 Cyclohexane, distilled and stored over silica gel to transfer0.80mL(0.98g)ofstandardmixtureintoadry,25-mL

remove traces of moisture. glass-stoppered, volumetric flask. Dilute to volume with cy-

7.3 Diisocyanate Standards—Pure samples of 2,4-TDI and clohexane and mix thoroughly.

2,6-TDI are required for calibration (Note 2). The following 10.3 Filltwo0.2-mmsealed,liquidabsorptioncells(onefor

criteria can be used to judge purity: a single-beam instrument) with cyclohexane and record its

−1

spectrumfrom770to840cm (12to13µm).Refillthesample

2,4–TDI—freezingpoint 522.0°C,n 51.56781, (1)

D

cell with a solution from 10.2 and record the spectrum

d 51.2186,and2,6–TDI—freezingpoint

4 superimposing it over the previously recorded solvent spec-

20 20

trum.Theinstrumentcontrolsmustremainunchangedbetween

518.2°C,n 51.57111,d 51.2270.

D 4

samples of a given series. Repeat the process for each solution

NOTE 2—The diisocyanates can be prepared by phosgenating the

from 10.2.

corresponding pure amines and vacuum-distilling the products. Since

10.4 Using the solvent spectrum as the baseline, measure

these diisocyanates will react with moisture and may discolor in the

the absorbance of each standard solution sample at 810

presence of air, store them under dry nitrogen.

−1 −1

cm (2,4-TDI) and 782 cm (2,6-TDI) and calculate the

−1

8. Sampling

810/782-cm absorbance ratio. Construct a calibration curve

(see Fig. 3) by plotting absorbance ratio (ordinate) versus

8.1 Since organic isocyanates react with atmospheric mois-

weight ratio of 2,4- to 2,6-TDI (abscissa).

ture, take special precautions in sampling. See 8.1.1. Usual

10.5 For convenience in short-range calibrations, the absor-

sampling methods (for example, sampling an open drum with

banceratiomaybeplottedagainsttheconcentration,expressed

a thief), even when carried out rapidly, can cause contamina-

in weight percent, of each isomer (see Figs. 1 and 2). This

tion of the sample with insoluble urea. Therefore, blanket the

allows direct determination of composition without equations,

sample with dry air or nitrogen at all times.

however, the relationship is not linear and the shape of the

8.1.1 Warning: Organic isocyanates are toxic when they

calibration curve must be carefully determined.

areabsorbedthroughtheskin,orwhenthevaporsarebreathed.

Provide adequate ventilation and wear protective gloves and

11. Procedure

eyeglasses.

11.1 Using a pipet, transfer 0.8 mL (0.98 g) of sample into

9. Test Conditions

a dry, 25-mL, glass-stoppered, volumetric flask. Dilute to

9.1 Since isocyanates react with moisture, keep laboratory

volume with cyclohexane and mix thoroughly. Fill the 0.2-mm

humidity low, preferably around 50% relative humidity.

cell with the solution and record the spectrum from 770 to 840

−1

cm (12 to 13 µm), and without changing instrument settings,

TEST METHOD A—SAMPLES CONTAINING 5 TO

refill the sample cell with pure solvent and record its spectrum

95% 2,6-TD

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.