ASTM C740/C740M-97(2009)

(Practice)Standard Practice for Evacuated Reflective Insulation In Cryogenic Service

Standard Practice for Evacuated Reflective Insulation In Cryogenic Service

ABSTRACT

This practice covers the use of thermal insulations formed by a number of thermal radiation shields positioned perpendicular to the direction of heat flow. These radiation shields consist of alternate layers of a low-emittance metal and an insulating layer combined such that metal-to-metal contact in the heat flow direction is avoided and direct heat conduction is minimized. These are commonly referred to as multilayer insulations (MLI) or super insulations (SI) by the industry. The performance considerations, typical applications, manufacturing methods, material specification, and safety considerations in the use of these insulations in cryogenic service are also discussed. MLI can be manufactured by any of the following: spiral-wrap method, blanket method, single layer method, and filament-wound method.

SCOPE

1.1 This practice covers the use of thermal insulations formed by a number of thermal radiation shields positioned perpendicular to the direction of heat flow. These radiation shields consist of alternate layers of a low-emittance metal and an insulating layer combined such that metal-to-metal contact in the heat flow direction is avoided and direct heat conduction is minimized. These are commonly referred to as multilayer insulations (MLI) or super insulations (SI) by the industry.

1.2 The practice covers the use of these insulation constructions where the warm boundary temperatures are below approximately 450 K.

1.3 Insulations of this construction are used when apparent thermal conductivity less than 0.007 W/m·K [0.049 Btu·in./h·ft2·°F] at 300k are required.

1.4 Insulations of this construction are used in a vacuum environment.

1.5 This practice covers the performance considerations, typical applications, manufacturing methods, material specification, and safety considerations in the use of these insulations in cryogenic service.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety hazards, see Section 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C740/C740M −97(Reapproved 2009)

Standard Practice for

Evacuated Reflective Insulation In Cryogenic Service

This standard is issued under the fixed designation C740/C740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.1 evacuated reflective insulation—Multilayer composite

thermal insulation consisting of radiation shield materials

1.1 This practice covers the use of thermal insulations

separated by low thermal conductivity insulating spacer mate-

formed by a number of thermal radiation shields positioned

rialofcellular,powdered,orfibrousnaturedesignedtooperate

perpendicular to the direction of heat flow. These radiation

at low ambient pressures.

shields consist of alternate layers of a low-emittance metal and

an insulating layer combined such that metal-to-metal contact

2.1.2 ohms per square—The electrical resistance of a

intheheatflowdirectionisavoidedanddirectheatconduction vacuum metallized coating measured on a sample in which the

is minimized. These are commonly referred to as multilayer dimensions of the coating width and length are equal. The

insulations (MLI) or super insulations (SI) by the industry. ohm-per-squaremeasurementisindependentofsampledimen-

sions.

1.2 The practice covers the use of these insulation construc-

tions where the warm boundary temperatures are below ap- 2.2 Symbols:

proximately 450K.

a = accommodation coefficient, dimensionless

1.3 Insulations of this construction are used when apparent

b = exponent, dimensionless

thermal conductivity less than 0.007 W/m·K [0.049 Btu·in./

d = distance between confining surfaces, m

h·ft ·°F] at 300k are required.

q = heat flow per unit time, W

A = unit area, m

1.4 Insulations of this construction are used in a vacuum

n = number of radiation shields

environment.

−8 2 4

σ = Stefan-Boltzmann constant, 5.67×10 W/m ·K

1.5 This practice covers the performance considerations,

T = temperature, K; T at hot boundary, T at cold boundary

h c

typical applications, manufacturing methods, material

E = emittance factor, dimensionless; E , system effective

eff

specification, and safety considerations in the use of these

emittance

insulations in cryogenic service.

e = total hemispherical emittance of a surface, dimension-

less; e at hot boundary, e at cold boundary

h c

1.6 The values stated in either SI units or inch-pound units

t = distance between the hot boundary and the cold

are to be regarded separately as standard. The values stated in

boundary, m

each system may not be exact equivalents; therefore, each

k = thermal conductivity, W/m·K

system shall be used independently of the other. Combining

R = shielding factor, dimensionless; equivalent to 1/E

values from the two systems may result in non-conformance

D = degradation factor, dimensionless

with the standard.

P = mechanical loading pressure, Pa

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Insulation Performance

responsibility of the user of this standard to establish appro-

3.1 Theoretical Performance:

priate safety and health practices and determine the applica-

3.1.1 The lowest possible heat flow is obtained in an MLI

bility of regulatory limitations prior to use. For specific safety

when the sole heat transfer mode is by radiation between free

hazards, see Section 8.

floating shields of low emittance and of infinite extent. The

2. Terminology

heatflowbetweenanytwosuchshieldsisgivenbytherelation:

4 4

2.1 Definitions of Terms Specific to This Standard:

q/A 5 E σT 2 σT (1)

~ !

h c

3.1.1.1 (RefertoSection2forsymbolsanddefinitions.)The

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

emittance factor, E, is a property of the shield surfaces facing

Insulation and is the direct responsibility of Subcommittee C16.21 on Reflective

Insulation. one another. For parallel shields, the emittance factor is

Current edition approved Nov. 1, 2009. Published December 2009. Originally

determined from the equation:

approvedin1973.Lastpreviouseditionapprovedin2004asC740–97(2004).DOI:

10.1520/C0740-97R09. E 51/ 1/e 11/e 2 1 5 e e /e 1 1 2 e e (2)

~ ! ~ !

h c h c h h c

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C740/C740M−97 (2009)

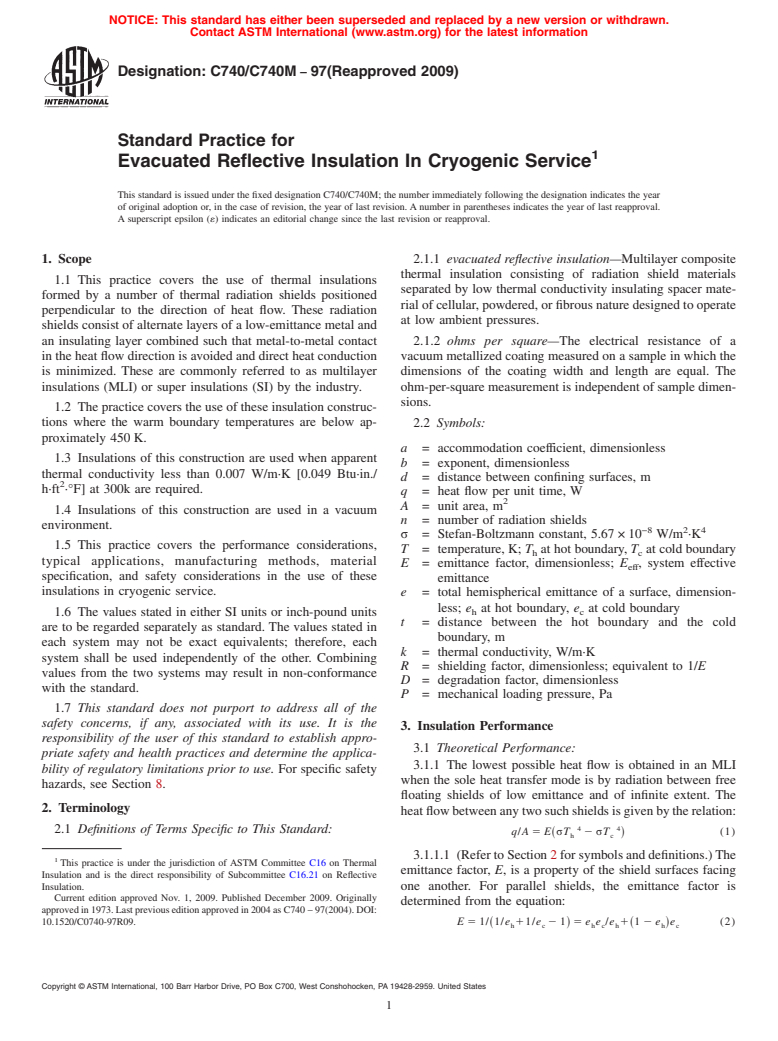

FIG. 1 MLI Theoretical Heat Flow for Various Shield Emittances and 1.0 Boundary Emittance

3.1.1.2 When these opposing surfaces have the same total cantly the actual performance compared to the theoretical

hemispherical emittance, Eq 2 reduces to: performance. The principal sources of this degradation are:

3.1.5.1 Themechanicalloadingpressureimposedacrossthe

E 5 e/ 2 2 e (3)

~ !

insulation boundaries,

3.1.2 An MLI of n shields is normally isolated in a vacuum

3.1.5.2 Thecompositionandpressureleveloftheinterstitial

environment by inner and outer container walls. When the

gas; and

surface emittance of the shields and of the container walls

3.1.5.3 Penetration such as mechanical supports, piping and

facing the shields have the same value, then the emittance

wiring.

factor is given by:

3.2 Mechanical Loading Pressure:

E 5 e/ n11 2 2 e (4)

~ !~ !

3.2.1 Inpractice,theshieldsofanMLIarenotfree-floating.

where (n+1) is the number of successive spaces formed by Compression between the layers due to the weight of the

both the container walls and the shields. insulation or to pressures induced at the boundaries, or both,

3.1.3 When the surface emittance of the shields has a value can cause physical contact between the shields producing a

e < 1.0 and the boundaries have an emittance of 1.0, then the direct conduction heat transfer path between the shields,

emittance factor is given by: thereby increasing the total heat flux of the system.

3.2.2 Theeffectsofcompressionontheheatfluxareusually

E 5 e/ n 2 2 e 1e (5)

~ ~ ! !

obtained experimentally using a flat plate calorimeter. Experi-

For values of e ≤ 0.1, Eq 4 and Eq 5 can be simplified to

mental correlations have been obtained for a variety of

E= e/(2 (n+1)) and E= e/2 n, respectively, and the loss in

shield-spacer combinations which indicate that the heat flux is

b

accuracy will be less than 10%.

proportional to P where b varies between 0.5 and 0.66.

3.1.4 Computed values of the theoretical MLI heat flow

obtained by using Eq 1 and Eq 5 are presented in Fig. 1.

3.1.5 Well-designed and carefully fabricated MLI systems

Black, I. A., Glaser, P. E., and Perkins, P. “A Double-Guarded Cold-Plate

have produced measured heat flows within approximately

Thermal ConductivityApparatus,” Thermal Conductivity Measurements of Insulat-

50% of their theoretical performance. In practice, however,

ing Materials at Cryogenic Temperatures, ASTM STP 411, ASTM International,

several important factors usually combine to reduce signifi- 1967.

C740/C740M−97 (2009)

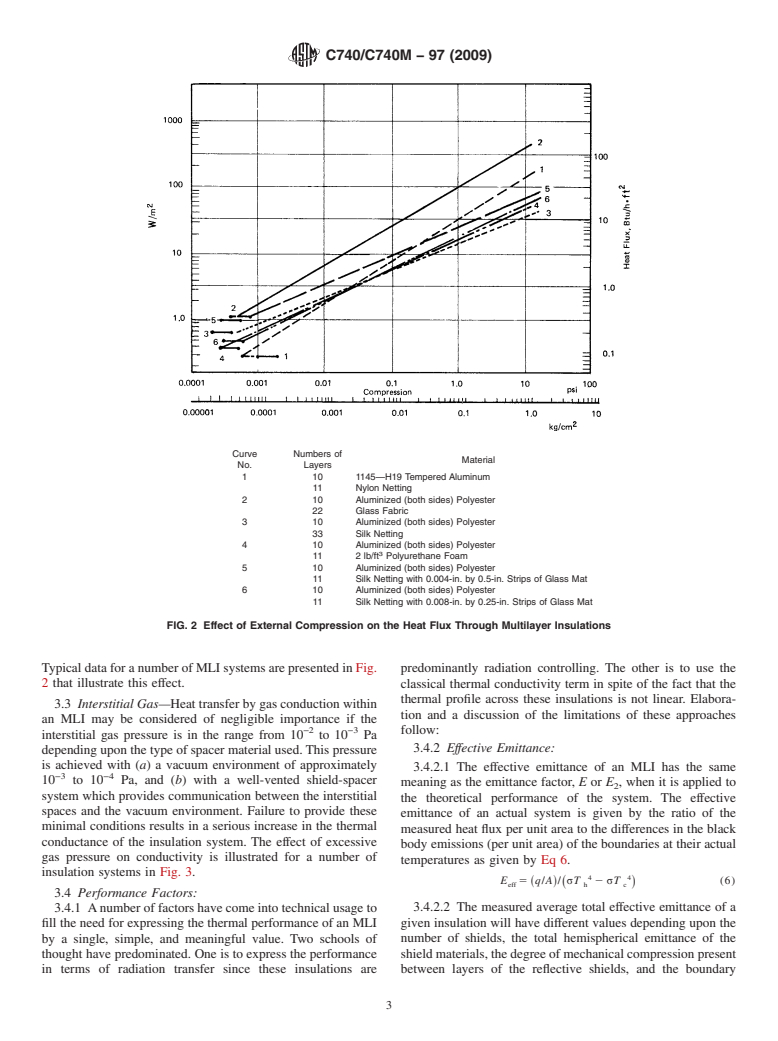

Curve Numbers of

Material

No. Layers

110 1145—H19 Tempered Aluminum

11 Nylon Netting

210 Aluminized (both sides) Polyester

22 Glass Fabric

310 Aluminized (both sides) Polyester

33 Silk Netting

410 Aluminized (both sides) Polyester

11 2 lb/ft Polyurethane Foam

510 Aluminized (both sides) Polyester

11 Silk Netting with 0.004-in. by 0.5-in. Strips of Glass Mat

610 Aluminized (both sides) Polyester

11 Silk Netting with 0.008-in. by 0.25-in. Strips of Glass Mat

FIG. 2 Effect of External Compression on the Heat Flux Through Multilayer Insulations

TypicaldataforanumberofMLIsystemsarepresentedinFig. predominantly radiation controlling. The other is to use the

2 that illustrate this effect. classical thermal conductivity term in spite of the fact that the

thermal profile across these insulations is not linear. Elabora-

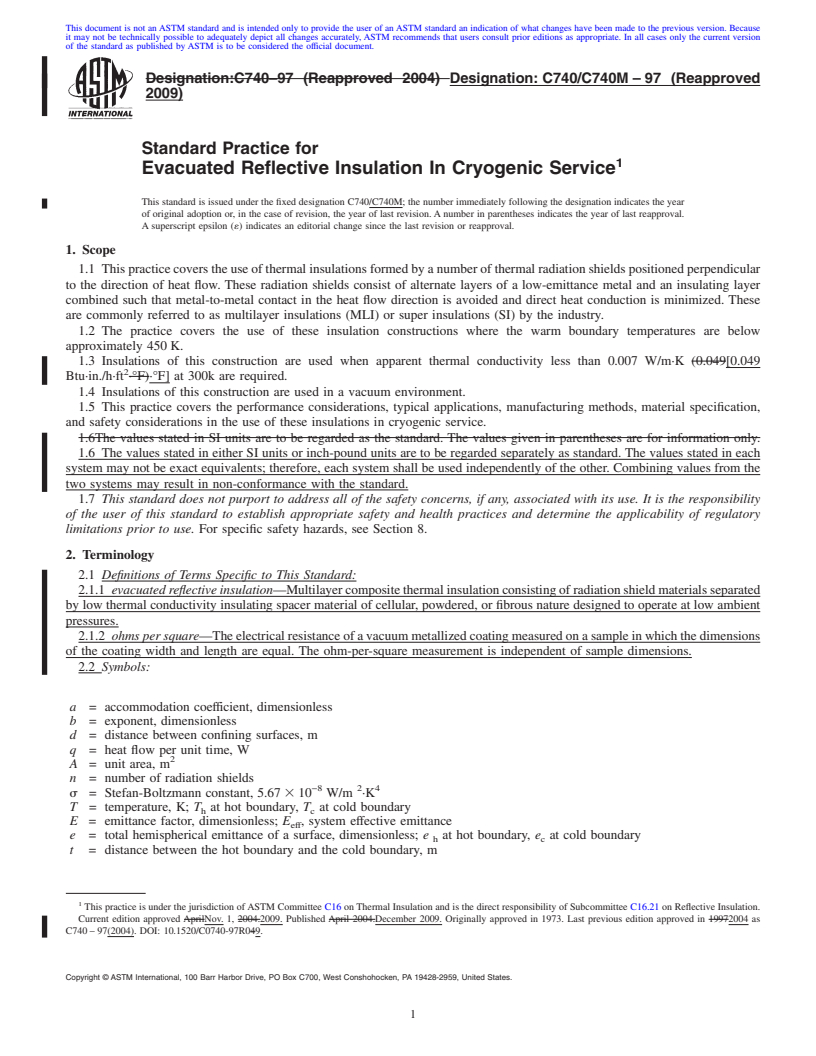

3.3 Interstitial Gas—Heattransferbygasconductionwithin

tion and a discussion of the limitations of these approaches

an MLI may be considered of negligible importance if the

−2 −3

follow:

interstitial gas pressure is in the range from 10 to 10 Pa

3.4.2 Effective Emittance:

dependinguponthetypeofspacermaterialused.Thispressure

is achieved with (a) a vacuum environment of approximately

3.4.2.1 The effective emittance of an MLI has the same

−3 −4

10 to 10 Pa, and (b) with a well-vented shield-spacer

meaning as the emittance factor, E or E , when it is applied to

system which provides communication between the interstitial

the theoretical performance of the system. The effective

spaces and the vacuum environment. Failure to provide these

emittance of an actual system is given by the ratio of the

minimal conditions results in a serious increase in the thermal

measured heat flux per unit area to the differences in the black

conductance of the insulation system. The effect of excessive

body emissions (per unit area) of the boundaries at their actual

gas pressure on conductivity is illustrated for a number of

temperatures as given by Eq 6.

insulation systems in Fig. 3.

4 4

E 5 ~q/A!/ σT 2 σT (6)

~ !

eff h c

3.4 Performance Factors:

3.4.1 Anumberoffactorshavecomeintotechnicalusageto 3.4.2.2 The measured average total effective emittance of a

given insulation will have different values depending upon the

fill the need for expressing the thermal performance of an MLI

by a single, simple, and meaningful value. Two schools of number of shields, the total hemispherical emittance of the

shieldmaterials,thedegreeofmechanicalcompressionpresent

thought have predominated. One is to express the performance

in terms of radiation transfer since these insulations are between layers of the reflective shields, and the boundary

C740/C740M−97 (2009)

NOTE 1—d=distance between confining surfaces

a=accommodation coefficient (dimensionless)

FIG. 3Effect of Gas Pressure on Thermal Conductivity

temperatures of the system.This effective emittance factor can 3.4.3.2 The actual system shielding factor is the reciprocal

be used to compare the thermal performance of different MLI of the effective emittance of the system, that is, R = 1/E.

systems under similar boundary temperature conditions.

3.4.4 Degradation Factor—Thedegradationfactor, D,isthe

3.4.3 Shielding Factor:

ratio of the actual system heat flux to the theoretical system

3.4.3.1 The theoretical shielding factor, R, is the reciprocal

heat flux, that is,

of the emittance factor. This factor can also be obtained by

D 5 q/A actual/ q/A theoretical (7)

~ ! ~ !

summing the reciprocal emittances of each shield surface as

one proceeds from one of the system boundaries to the other thisfactorcanonlyhavevalueslargerthan1.0.Atavalueof

and then subtracting 1.0 from the result for each space 1.0 the amount of degradation is zero and the actual perfor-

traversed. mance corresponds to the theoretical performance.

C740/C740M−97 (2009)

3.4.5 Thermal Conductivity: metal-coatedplasticsoftencrinkledordimpled,withaseparate

3.4.5.1 TheapparentthermalconductivityofanMLIsystem material, usually a glass, polymer, or natural fiber formed into

can be defined by the ratio of the heat flow per unit area to the a fabric, netting, foam, paper, mat, or web to ensure that no

averagetemperaturegradientofthesystemincomparableunits direct metal contact is made. In some cases when a metal-

as follows: coated plastic is used, the low thermal conductivity plastic

forms the separator (see 7.3.2).

k 5 q/A / T 2 T /t (8)

~ !

~~ ! !

a h c

5.1.2 It is the objective of the MLI manufacturing tech-

3.4.5.2 Since radiative heat transfer present within an MLI

niques to:

system produces a nonlinear temperature gradient, k will vary

5.1.2.1 Reduce the solid conduction heat flow by minimiz-

approximately as the third power of the mean temperature.

ing the compression between the layers.

Thus, k can be used only for comparison of performance of

5.1.2.2 Reduce gas conduction heat flow by providing flow

different MLI systems when the boundary temperatures are the

paths within the insulation so that the interstitial gas can be

same.

removed by the vacuum environment, and

3.4.5.3 Asecond difficulty associated with the use of a k for

5.1.2.3 Reduce the radiation heat flow by utilizing low-

MLI systems is the necessity of defining the insulation thick-

emittance shield materials and by the elimination of gaps,

ness. This is possible only in certain types of measurement

spaces, or openings in each shield layer.

apparatus and in mechanized MLI systems. Thus, whenever k

is used to describe the thermal performance of an MLI, it

5.2 Application:

should be accompanied by a statement indicating the method

5.2.1 The user has a wide variety of application techniques

used in making the thickness measurement or the accuracy

available to him. They include, but are not limited to, the

with which such a measurement was made.

spiral-wrap, blanket, single-layer, and filament-wound tech-

niques.

3.5 Typical Thermal Performance of MLI—The thermal

performance of MLIs can vary over a wide range from system 5.2.2 Spiral-Wrap Method:

to system depending largely upon the fabrication techniques,

5.2.2.1 The spiral-wrap technique is applicable mainly to

but also upon the materials used for the shields and spacers.

the cylindrical segments of tanks. The shields and spacers are

Typical performance values of installed systems are shown in

applied together from rolls onto the rotating cylinder in a

Table 1 as well as the pertinent information concerning the

continuous manner until the desired thickness or number of

system characteristics and installation data. Thermal perfor-

layers is achieved. This method is compatible with automatic

mance for some systems was shown in both the effective

manufacturing techniques as well as with manual techniques.

emittance and thermal conductivity terms where this informa-

Theshieldandspacermaterialmayhavethesamewidthasthe

tion was available.

cylinder or segments of the cylinder. In some cases the shield

segments are butt-joined. It is the recommended and general

4. Typical Applications

practice, however, to eliminate the possibility of gaps devel-

oping between segments by providing a generous overlap of

4.1 Insulations of the type described above are generally

the shield segments. Overlaps of 51 mm [2 in.] are typically

used when lower conductivities are required than can be

used.

obtained with other evacuated insulations or with gas-filled

insulations.This may be dictated by the value of the cryogenic 5.2.2.2 To obtain the best thermal performance, the shields

fluid being isolated or by weight or thickness limitations and spacers of the

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C740–97 (Reapproved 2004) Designation: C740/C740M – 97 (Reapproved

2009)

Standard Practice for

Evacuated Reflective Insulation In Cryogenic Service

This standard is issued under the fixed designation C740/C740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thispracticecoverstheuseofthermalinsulationsformedbyanumberofthermalradiationshieldspositionedperpendicular

to the direction of heat flow. These radiation shields consist of alternate layers of a low-emittance metal and an insulating layer

combined such that metal-to-metal contact in the heat flow direction is avoided and direct heat conduction is minimized. These

are commonly referred to as multilayer insulations (MLI) or super insulations (SI) by the industry.

1.2 The practice covers the use of these insulation constructions where the warm boundary temperatures are below

approximately 450K.

1.3 Insulations of this construction are used when apparent thermal conductivity less than 0.007 W/m·K (0.049[0.049

Btu·in./h·ft ·°F)·°F] at 300k are required.

1.4 Insulations of this construction are used in a vacuum environment.

1.5 This practice covers the performance considerations, typical applications, manufacturing methods, material specification,

and safety considerations in the use of these insulations in cryogenic service.

1.6The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific safety hazards, see Section 8.

2. Terminology

2.1 Definitions of Terms Specific to This Standard:

2.1.1 evacuated reflective insulation—Multilayercompositethermalinsulationconsistingofradiationshieldmaterialsseparated

by low thermal conductivity insulating spacer material of cellular, powdered, or fibrous nature designed to operate at low ambient

pressures.

2.1.2 ohms per square—Theelectricalresistanceofavacuummetallizedcoatingmeasuredonasampleinwhichthedimensions

of the coating width and length are equal. The ohm-per-square measurement is independent of sample dimensions.

2.2 Symbols:

a = accommodation coefficient, dimensionless

b = exponent, dimensionless

d = distance between confining surfaces, m

q = heat flow per unit time, W

A = unit area, m

n = number of radiation shields

−8 2 4

s = Stefan-Boltzmann constant, 5.67 310 W/m ·K

T = temperature, K; T at hot boundary, T at cold boundary

h c

E = emittance factor, dimensionless; E , system effective emittance

eff

e = total hemispherical emittance of a surface, dimensionless; e at hot boundary, e at cold boundary

h c

t = distance between the hot boundary and the cold boundary, m

This practice is under the jurisdiction ofASTM Committee C16 onThermal Insulation and is the direct responsibility of Subcommittee C16.21 on Reflective Insulation.

Current edition approved AprilNov. 1, 2004.2009. Published April 2004.December 2009. Originally approved in 1973. Last previous edition approved in 19972004 as

C740–97(2004). DOI: 10.1520/C0740-97R049.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C740/C740M – 97 (2009)

k = thermal conductivity, W/m·K

R = shielding factor, dimensionless; equivalent to 1/E

D = degradation factor, dimensionless

P = mechanical loading pressure, Pa

2.2Definitions:

2.2.1evacuated reflective insulation—Multilayer composite thermal insulation consisting of radiation shield materials separated

by low thermal conductivity insulating spacer material of cellular, powdered, or fibrous nature designed to operate at low ambient

pressures.

2.2.2ohms per square—Theelectricalresistanceofavacuummetallizedcoatingmeasuredonasampleinwhichthedimensions

of the coating width and length are equal. The ohm-per-square measurement is independent of sample dimensions.

3. Insulation Performance

3.1 Theoretical Performance:

3.1.1 ThelowestpossibleheatflowisobtainedinanMLIwhenthesoleheattransfermodeisbyradiationbetweenfreefloating

shields of low emittance and of infinite extent. The heat flow between any two such shields is given by the relation:

(1) q/A 5 E~sTh42sTc4!

3.1.1.1 (Refer to Section 2 for symbols and definitions.)The emittance factor, E, is a property of the shield surfaces facing one

another. For parallel shields, the emittance factor is determined from the equation:

3.1.1.2 When these opposing surfaces have the same total hemispherical emittance, Eq 2 reduces to:

3.1.2 An MLI of n shields is normally isolated in a vacuum environment by inner and outer container walls. When the surface

emittance of the shields and of the container walls facing the shields have the same value, then the emittance factor is given by:

where (n+1) is the number of successive spaces formed by both the container walls and the shields.

3.1.3 When the surface emittance of the shields has a value e < 1.0 and the boundaries have an emittance of 1.0, then the

emittance factor is given by:

For values of e# 0.1, Eq 4 and Eq 5 can be simplified to E= e/(2 (n+1)) and E= e/2 n, respectively, and the loss in accuracy

will be less than 10%.

3.1.4 Computed values of the theoretical MLI heat flow obtained by using Eq 1 and Eq 5 are presented in Fig. 1.

3.1.5 Well-designed and carefully fabricated MLI systems have produced measured heat flows within approximately 50% of

their theoretical performance. In practice, however, several important factors usually combine to reduce significantly the actual

performance compared to the theoretical performance. The principal sources of this degradation are:

3.1.5.1 The mechanical loading pressure imposed across the insulation boundaries,

3.1.5.2 The composition and pressure level of the interstitial gas; and

3.1.5.3 Penetration such as mechanical supports, piping and wiring.

3.2 Mechanical Loading Pressure:

3.2.1 Inpractice,theshieldsofanMLIarenotfree-floating.Compressionbetweenthelayersduetotheweightoftheinsulation

or to pressures induced at the boundaries, or both, can cause physical contact between the shields producing a direct conduction

heat transfer path between the shields, thereby increasing the total heat flux of the system.

3.2.2 The effects of compression on the heat flux are usually obtained experimentally using a flat plate calorimeter.

Experimental correlations have been obtained for a variety of shield-spacer combinations which indicate that the heat flux is

b

proportional to P where b varies between 0.5 and 0.66. Typical data for a number of MLI systems are presented in Fig. 2 that

illustrate this effect.

3.3 Interstitial Gas—Heat transfer by gas conduction within an MLI may be considered of negligible importance if the

−2 −3

interstitial gas pressure is in the range from 10 to 10 Pa depending upon the type of spacer material used. This pressure is

−3 −4

achievedwith(a)avacuumenvironmentofapproximately10 to10 Pa,and( b)withawell-ventedshield-spacersystemwhich

provides communication between the interstitial spaces and the vacuum environment. Failure to provide these minimal conditions

results in a serious increase in the thermal conductance of the insulation system. The effect of excessive gas pressure on

conductivity is illustrated for a number of insulation systems in Fig. 3.

3.4 Performance Factors:

3.4.1 A number of factors have come into technical usage to fill the need for expressing the thermal performance of an MLI

by a single, simple, and meaningful value.Two schools of thought have predominated. One is to express the performance in terms

of radiation transfer since these insulations are predominantly radiation controlling. The other is to use the classical thermal

conductivity term in spite of the fact that the thermal profile across these insulations is not linear. Elaboration and a discussion of

the limitations of these approaches follow:

Black,I.A.,Glaser,P.E.,andPerkins,P.“ADouble-GuardedCold-PlateThermalConductivityApparatus,” Thermal Conductivity Measurements of Insulating Materials

at Cryogenic Temperatures, ASTM STP 411, ASTM International, 1967.

C740/C740M – 97 (2009)

FIG. 1 MLI Theoretical Heat Flow for Various Shield Emittances and 1.0 Boundary Emittance

3.4.2 Effective Emittance:

3.4.2.1 The effective emittance of an MLI has the same meaning as the emittance factor, E or E , when it is applied to the

theoretical performance of the system. The effective emittance of an actual system is given by the ratio of the measured heat flux

per unit area to the differences in the black body emissions (per unit area) of the boundaries at their actual temperatures as given

by Eq 6.

3.4.2.2 The measured average total effective emittance of a given insulation will have different values depending upon the

numberofshields,thetotalhemisphericalemittanceoftheshieldmaterials,thedegreeofmechanicalcompressionpresentbetween

layersofthereflectiveshields,andtheboundarytemperaturesofthesystem.Thiseffectiveemittancefactorcanbeusedtocompare

the thermal performance of different MLI systems under similar boundary temperature conditions.

3.4.3 Shielding Factor:

3.4.3.1 Thetheoreticalshieldingfactor, R,isthereciprocaloftheemittancefactor.Thisfactorcanalsobeobtainedbysumming

thereciprocalemittancesofeachshieldsurfaceasoneproceedsfromoneofthesystemboundariestotheotherandthensubtracting

1.0 from the result for each space traversed.

3.4.3.2 The actual system shielding factor is the reciprocal of the effective emittance of the system, that is, R = 1/E.

3.4.4 Degradation Factor—The degradation factor, D, is the ratio of the actual system heat flux to the theoretical system heat

flux, that is,

(7) D 5 q/A!actual/ q/A!theoretical

~ ~

this factor can only have values larger than 1.0.At a value of 1.0 the amount of degradation is zero and the actual performance

corresponds to the theoretical performance.

3.4.5 Thermal Conductivity:

3.4.5.1 The apparent thermal conductivity of an MLI system can be defined by the ratio of the heat flow per unit area to the

average temperature gradient of the system in comparable units as follows:

3.4.5.2 Since radiative heat transfer present within an MLI system produces a nonlinear temperature gradient, k will vary

approximately as the third power of the mean temperature. Thus, k can be used only for comparison of performance of different

MLI systems when the boundary temperatures are the same.

3.4.5.3 Asecond difficulty associated with the use of a k for MLI systems is the necessity of defining the insulation thickness.

C740/C740M – 97 (2009)

Curve Numbers of

Material

No. Layers

110 1145—H19 Tempered Aluminum

11 Nylon Netting

210 Aluminized (both sides) Polyester

22 Glass Fabric

310 Aluminized (both sides) Polyester

33 Silk Netting

410 Aluminized (both sides) Polyester

11 2 lb/ft Polyurethane Foam

510 Aluminized (both sides) Polyester

11 Silk Netting with 0.004-in. by 0.5-in. Strips of Glass Mat

610 Aluminized (both sides) Polyester

11 Silk Netting with 0.008-in. by 0.25-in. Strips of Glass Mat

FIG. 2 Effect of External Compression on the Heat Flux Through Multilayer Insulations

This is possible only in certain types of measurement apparatus and in mechanized MLI systems. Thus, whenever k is used to

describe the thermal performance of an MLI, it should be accompanied by a statement indicating the method used in making the

thickness measurement or the accuracy with which such a measurement was made.

3.5 Typical Thermal Performance of MLI—The thermal performance of MLIs can vary over a wide range from system to

system depending largely upon the fabrication techniques, but also upon the materials used for the shields and spacers. Typical

performance values of installed systems are shown in Table 1 as well as the pertinent information concerning the system

characteristicsandinstallationdata.Thermalperformanceforsomesystemswasshowninboththeeffectiveemittanceandthermal

conductivity terms where this information was available.

4. Typical Applications

4.1 Insulationsofthetypedescribedabovearegenerallyusedwhenlowerconductivitiesarerequiredthancanbeobtainedwith

other evacuated insulations or with gas-filled insulations. This may be dictated by the value of the cryogenic fluid being isolated

or by weight or thickness limitations imposed by the particular application. Generally these fall into either a storage or a

distribution equipment category. Typical storage applications include the preservation of biologicals, onboard aviation breathing

gas, piped-in hospital oxygen systems, welding and heat-treating requirements, distribution storage reservoirs, and industrial users

whose requirement cannot be economically met with gas storage. Distribution applications include railroad tank cars, highway

trucks and trailers, pipe lines, portable tankage of various sizes, all serving the metal industry, medicine, and space exploration

programs. Specialized applications such as surgical operating tools and space vehicle oxidizer and fuel tanks have also seen

significant development.

5. Techniques of Manufacture

5.1 General:

C740/C740M – 97 (2009)

NOTE 1—d=distance between confining surfaces

a=accommodation coefficient (dimensionless)

FIG. 3 Effect of Gas Pressure on Thermal Conductivity

5.1.1 An MLI requires that each metal layer is separated from the next with a minimum number and size of low conductance

contacts and with a minimum contact pressure. Thus each radiation shield is made from metal foils or from metal-coated plastics

often crinkled or dimpled, with a separate material, usually a glass, polymer, or natural fiber formed into a fabric, netting, foam,

paper, mat, o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.