ASTM C740/C740M-97(2009)

(Practice)Standard Practice for Evacuated Reflective Insulation In Cryogenic Service

Standard Practice for Evacuated Reflective Insulation In Cryogenic Service

ABSTRACT

This practice covers the use of thermal insulations formed by a number of thermal radiation shields positioned perpendicular to the direction of heat flow. These radiation shields consist of alternate layers of a low-emittance metal and an insulating layer combined such that metal-to-metal contact in the heat flow direction is avoided and direct heat conduction is minimized. These are commonly referred to as multilayer insulations (MLI) or super insulations (SI) by the industry. The performance considerations, typical applications, manufacturing methods, material specification, and safety considerations in the use of these insulations in cryogenic service are also discussed. MLI can be manufactured by any of the following: spiral-wrap method, blanket method, single layer method, and filament-wound method.

SCOPE

1.1 This practice covers the use of thermal insulations formed by a number of thermal radiation shields positioned perpendicular to the direction of heat flow. These radiation shields consist of alternate layers of a low-emittance metal and an insulating layer combined such that metal-to-metal contact in the heat flow direction is avoided and direct heat conduction is minimized. These are commonly referred to as multilayer insulations (MLI) or super insulations (SI) by the industry.

1.2 The practice covers the use of these insulation constructions where the warm boundary temperatures are below approximately 450 K.

1.3 Insulations of this construction are used when apparent thermal conductivity less than 0.007 W/m·K [0.049 Btu·in./h·ft2·°F] at 300k are required.

1.4 Insulations of this construction are used in a vacuum environment.

1.5 This practice covers the performance considerations, typical applications, manufacturing methods, material specification, and safety considerations in the use of these insulations in cryogenic service.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety hazards, see Section 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C740/C740M −97(Reapproved 2009)

Standard Practice for

1

Evacuated Reflective Insulation In Cryogenic Service

This standard is issued under the fixed designation C740/C740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.1.1 evacuated reflective insulation—Multilayer composite

thermal insulation consisting of radiation shield materials

1.1 This practice covers the use of thermal insulations

separated by low thermal conductivity insulating spacer mate-

formed by a number of thermal radiation shields positioned

rialofcellular,powdered,orfibrousnaturedesignedtooperate

perpendicular to the direction of heat flow. These radiation

at low ambient pressures.

shields consist of alternate layers of a low-emittance metal and

an insulating layer combined such that metal-to-metal contact

2.1.2 ohms per square—The electrical resistance of a

intheheatflowdirectionisavoidedanddirectheatconduction vacuum metallized coating measured on a sample in which the

is minimized. These are commonly referred to as multilayer dimensions of the coating width and length are equal. The

insulations (MLI) or super insulations (SI) by the industry. ohm-per-squaremeasurementisindependentofsampledimen-

sions.

1.2 The practice covers the use of these insulation construc-

tions where the warm boundary temperatures are below ap- 2.2 Symbols:

proximately 450K.

a = accommodation coefficient, dimensionless

1.3 Insulations of this construction are used when apparent

b = exponent, dimensionless

thermal conductivity less than 0.007 W/m·K [0.049 Btu·in./

d = distance between confining surfaces, m

2

h·ft ·°F] at 300k are required.

q = heat flow per unit time, W

2

A = unit area, m

1.4 Insulations of this construction are used in a vacuum

n = number of radiation shields

environment.

−8 2 4

σ = Stefan-Boltzmann constant, 5.67×10 W/m ·K

1.5 This practice covers the performance considerations,

T = temperature, K; T at hot boundary, T at cold boundary

h c

typical applications, manufacturing methods, material

E = emittance factor, dimensionless; E , system effective

eff

specification, and safety considerations in the use of these

emittance

insulations in cryogenic service.

e = total hemispherical emittance of a surface, dimension-

less; e at hot boundary, e at cold boundary

h c

1.6 The values stated in either SI units or inch-pound units

t = distance between the hot boundary and the cold

are to be regarded separately as standard. The values stated in

boundary, m

each system may not be exact equivalents; therefore, each

k = thermal conductivity, W/m·K

system shall be used independently of the other. Combining

R = shielding factor, dimensionless; equivalent to 1/E

values from the two systems may result in non-conformance

D = degradation factor, dimensionless

with the standard.

P = mechanical loading pressure, Pa

1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

3. Insulation Performance

responsibility of the user of this standard to establish appro-

3.1 Theoretical Performance:

priate safety and health practices and determine the applica-

3.1.1 The lowest possible heat flow is obtained in an MLI

bility of regulatory limitations prior to use. For specific safety

when the sole heat transfer mode is by radiation between free

hazards, see Section 8.

floating shields of low emittance and of infinite extent. The

2. Terminology

heatflowbetweenanytwosuchshieldsisgivenbytherelation:

4 4

2.1 Definitions of Terms Specific to This Standard:

q/A 5 E σT 2 σT (1)

~ !

h c

3.1.1.1 (RefertoSection2forsymbolsanddefinitions.)The

1

This practice is under the jurisdiction of ASTM Committee C16 on Thermal

emittance factor, E, is a property of the shield surfaces facing

Insulation and is the direct responsibility of Subcommittee C16.21 on Reflective

Insulation. one another. For parallel shields, the emittance factor is

Current edition approved Nov. 1, 2009. Published December 2009. Originally

determined from the equation:

approvedin1973.Lastpreviouseditionapprovedin2004asC740–97(2004).DOI:

10.1520/C0740-97R09. E 51/ 1/e 11/e 2 1 5 e e /e 1 1 2 e e (2)

~ ! ~ !

h c h c h h c

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C740/C740M−97 (2009)

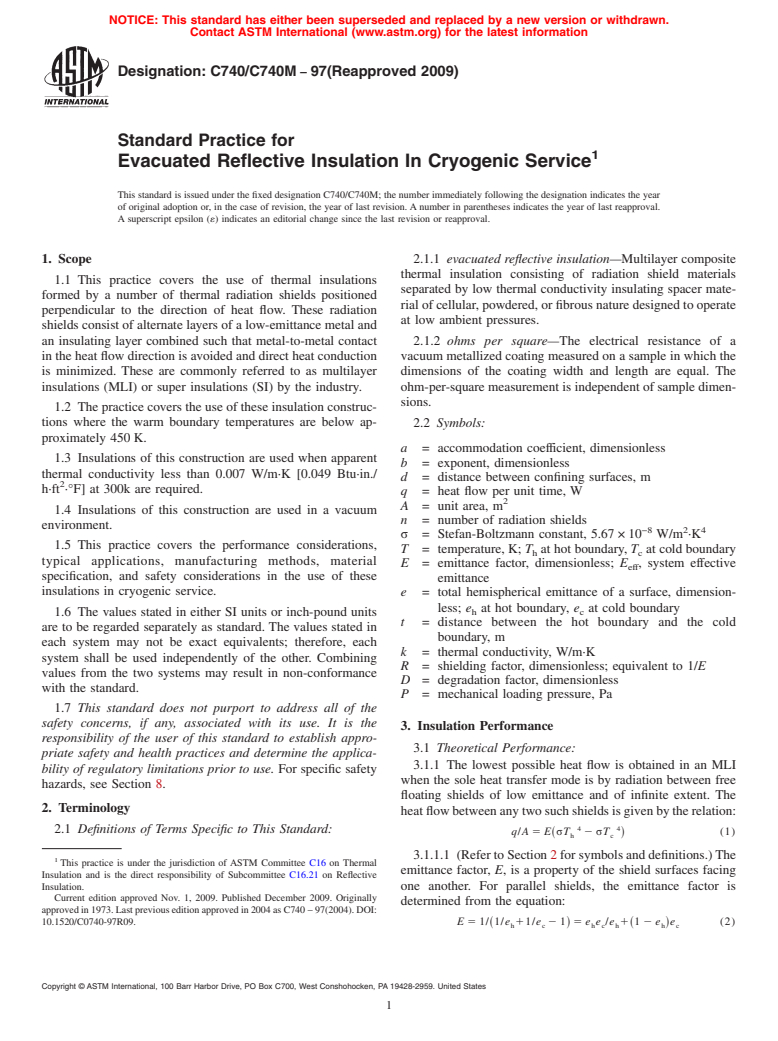

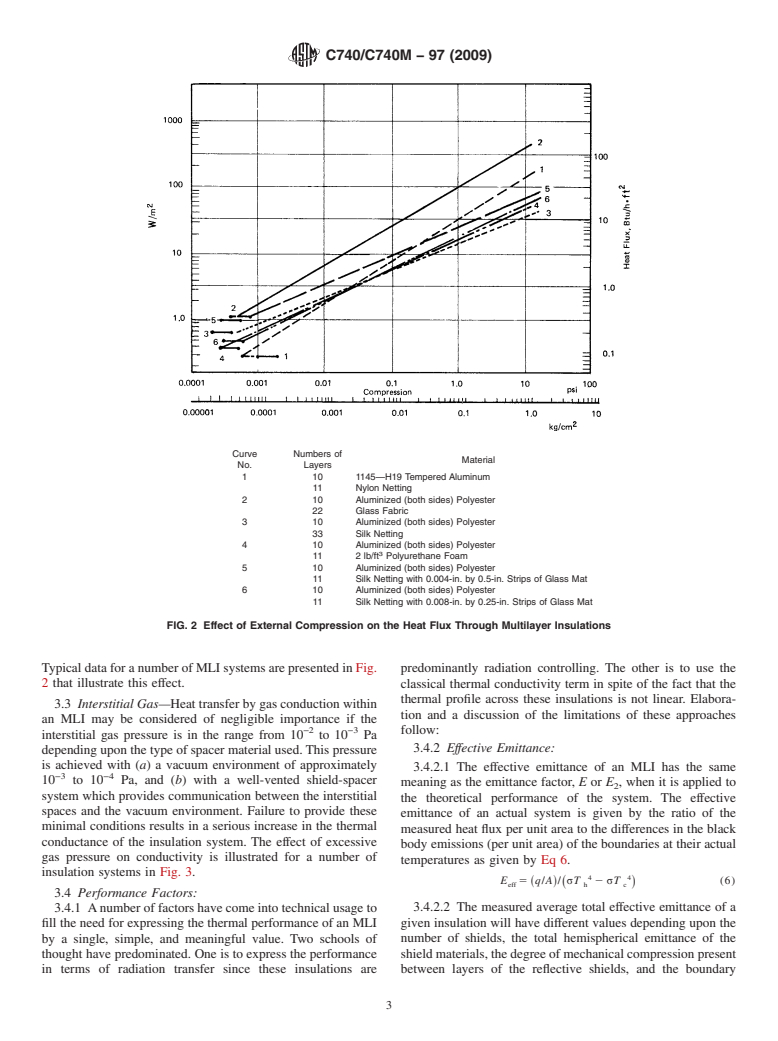

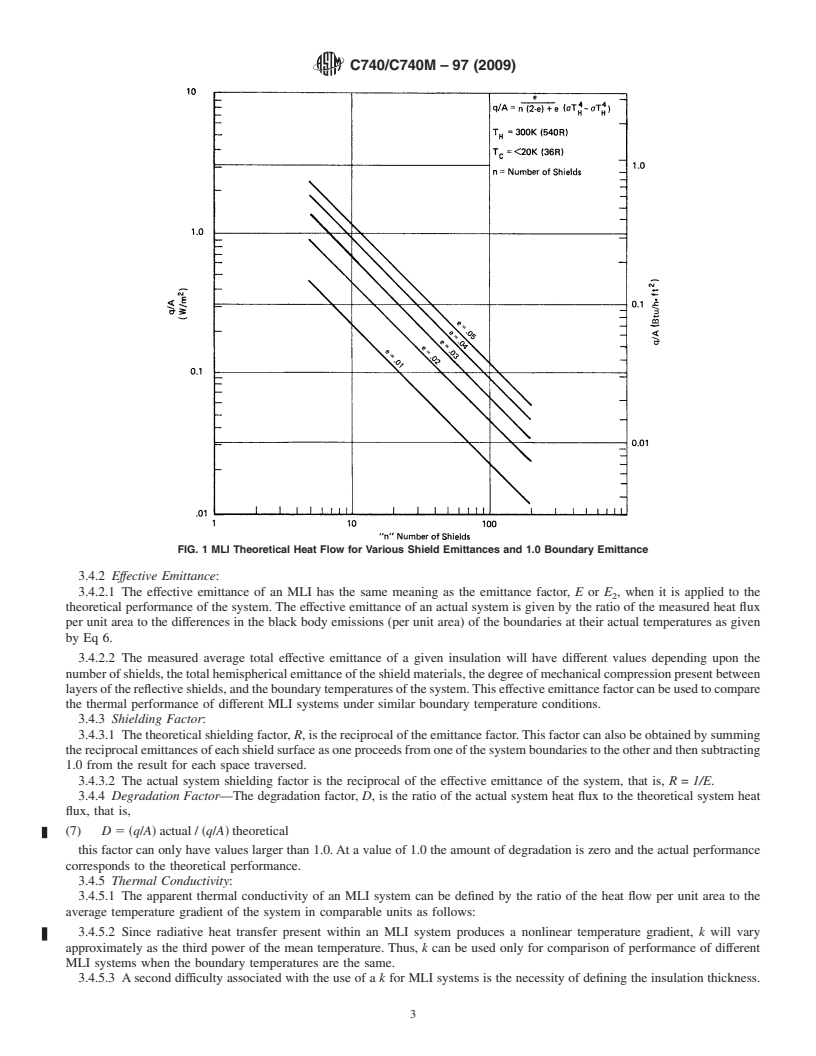

FIG. 1 MLI Theoretical Heat Flow for Various Shield Emittances and 1.0 Boundary Emittance

3.1.1.2 When these opposing surfaces have the same total cantly the actual performance compared to the theoretical

hemispherical emittance, Eq 2 reduces to:

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C740–97 (Reapproved 2004) Designation: C740/C740M – 97 (Reapproved

2009)

Standard Practice for

1

Evacuated Reflective Insulation In Cryogenic Service

This standard is issued under the fixed designation C740/C740M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Thispracticecoverstheuseofthermalinsulationsformedbyanumberofthermalradiationshieldspositionedperpendicular

to the direction of heat flow. These radiation shields consist of alternate layers of a low-emittance metal and an insulating layer

combined such that metal-to-metal contact in the heat flow direction is avoided and direct heat conduction is minimized. These

are commonly referred to as multilayer insulations (MLI) or super insulations (SI) by the industry.

1.2 The practice covers the use of these insulation constructions where the warm boundary temperatures are below

approximately 450K.

1.3 Insulations of this construction are used when apparent thermal conductivity less than 0.007 W/m·K (0.049[0.049

2

Btu·in./h·ft ·°F)·°F] at 300k are required.

1.4 Insulations of this construction are used in a vacuum environment.

1.5 This practice covers the performance considerations, typical applications, manufacturing methods, material specification,

and safety considerations in the use of these insulations in cryogenic service.

1.6The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. For specific safety hazards, see Section 8.

2. Terminology

2.1 Definitions of Terms Specific to This Standard:

2.1.1 evacuated reflective insulation—Multilayercompositethermalinsulationconsistingofradiationshieldmaterialsseparated

by low thermal conductivity insulating spacer material of cellular, powdered, or fibrous nature designed to operate at low ambient

pressures.

2.1.2 ohms per square—Theelectricalresistanceofavacuummetallizedcoatingmeasuredonasampleinwhichthedimensions

of the coating width and length are equal. The ohm-per-square measurement is independent of sample dimensions.

2.2 Symbols:

a = accommodation coefficient, dimensionless

b = exponent, dimensionless

d = distance between confining surfaces, m

q = heat flow per unit time, W

2

A = unit area, m

n = number of radiation shields

−8 2 4

s = Stefan-Boltzmann constant, 5.67 310 W/m ·K

T = temperature, K; T at hot boundary, T at cold boundary

h c

E = emittance factor, dimensionless; E , system effective emittance

eff

e = total hemispherical emittance of a surface, dimensionless; e at hot boundary, e at cold boundary

h c

t = distance between the hot boundary and the cold boundary, m

1

This practice is under the jurisdiction ofASTM Committee C16 onThermal Insulation and is the direct responsibility of Subcommittee C16.21 on Reflective Insulation.

Current edition approved AprilNov. 1, 2004.2009. Published April 2004.December 2009. Originally approved in 1973. Last previous edition approved in 19972004 as

C740–97(2004). DOI: 10.1520/C0740-97R049.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C740/C740M – 97 (2009)

k = thermal conductivity, W/m·K

R = shielding factor, dimensionless; equivalent to 1/E

D = degradation factor, dimensionless

P = mechanical loading pressure, Pa

2.2Definitions:

2.2.1evacuated reflective insulation—Multilayer composite thermal insulation consisting of radiation shield materials separated

by low thermal conductivity insulating spacer material of cellular, powdered, or fibrous nature designed to operate at low ambient

pressures.

2.2.2ohms per square—Theelectricalresistanceofavacuummetallizedcoatingmeasuredonasampleinw

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.