ASTM F1924-01e1

(Specification)Standard Specification for Plastic Mechanical Fittings for Use on Outside Diameter Controlled Polyethylene Gas Distribution Pipe and Tubing

Standard Specification for Plastic Mechanical Fittings for Use on Outside Diameter Controlled Polyethylene Gas Distribution Pipe and Tubing

SCOPE

1.1 This specification describes requirements and test methods for the qualification of plastic bodied mechanical fittings for use with outside diameter controlled polyethylene (PE) gas distribution pipe, nominal 2 pipe size (IPS) and smaller complying with Specification D2513. In addition, it specifies general requirements of the material from which these fittings are made.

1.2 The test methods described in this specification are not intended to be used as routine quality control tests.

1.3 This specification covers the types of mechanical fittings described in 3.2.1.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 The text of this specification references notes and footnotes, which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: F 1924 – 01

Standard Specification for

Plastic Mechanical Fittings for Use on Outside Diameter

1

Controlled Polyethylene Gas Distribution Pipe and Tubing

This standard is issued under the fixed designation F1924; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Section 10 was editorially updated in December 2002.

1. Scope D2513 Specification forThermoplastic Gas Pressure Pipe,

3

Tubing, and Fittings

1.1 Thisspecification describes requirements andtestmeth-

D2837 Test Method for Obtaining Hydrostatic Design

ods for the qualification of plastic bodied mechanical fittings

3

Basis for Thermoplastic Pipe Materials

for use with outside diameter controlled polyethylene (PE) gas

3

F412 Terminology Relating to Plastic Piping Systems

distribution pipe, nominal 2 pipe size (IPS) and smaller

F1588 Test Method for Constant Tensile Load Joint Test

complying with Specification D2513. In addition, it specifies

3

(CTLJT)

general requirements of the material from which these fittings

2.2 ASME Standard:

are made.

ASME B31.8 Gas Transmission and Distribution Piping

1.2 The test methods described in this specification are not

4

Systems

intended to be used as routine quality control tests.

2.3 Federal Standard:

1.3 Thisspecificationcoversthetypesofmechanicalfittings

5

CFR, Title 49, Part 192 Pipeline Safety Regulations

described in 3.2.1.

2.4 Plastics Pipe Institute Standard:

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

PPI TR-4 Recommended Hydrostatic Strengths and Design

as the standard. The values given in parentheses are for

6

Stresses forThermoplastic Pipe and Fittings Compounds

information only.

1.5 The following safety hazards caveat pertains only to the

3. Terminology

test method portion, Section 7, of this specification. This

3.1 Definitions—Definitions of terms used in this specifica-

standard does not purport to address all of the safety concerns,

tion are in accordance with Terminology F412 unless other-

if any, associated with its use. It is the responsibility of the user

wisespecified.AbbreviationsareinaccordancewithTerminol-

of this standard to establish appropriate safety and health

ogy D1600 unless otherwise specified.

practices and determine the applicability of regulatory limita-

3.1.1 The Gas Industry terminology used in this specifica-

tions prior to use.

tion is in accordance withASME B31.8 or CFR, Title 49, Part

1.6 The text of this specification references notes and

192 unless otherwise indicated.

footnotes,whichprovideexplanatorymaterial.Thesenotesand

3.1.2 The term “pipe” used herein refers to both “pipe” and

footnotes (excluding those in tables and figures) shall not be

“tubing”unlessspecificallystatedotherwise.Theterm“fitting”

considered as requirements of this specification.

refers to a mechanical connecting device as described in 3.1.4

2. Referenced Documents and 3.1.6.

3.1.3 joint, n—the location at which two pieces of pipe, or

2.1 ASTM Standards:

2

a pipe and a fitting are connected together, for example, an

D638 Test Method for Tensile Properties of Plastics

installed coupling has two joints.

D1598 Test Method for Time-to-Failure of Plastic Pipe

3

3.1.4 joint, mechanical, n— a connection between piping

Under Constant Internal Pressure

components employing physical force to develop a seal or

D1600 Terminology for Abbreviated Terms Relating to

2

produce alignment.

Plastics

1 4

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Available from American Society of Mechanical Engineers, Three Park

Piping Systems and is the direct responsibility of Subcommittee F17.60 on Gas. Avenue, New York, NY 10016–5990.

5

Available from Superintendent of Documents, U.S. Government Printing

Current edition approved Oct. 10, 2001. Published January 2002.Orginally

published as F 1924–98. Last previous edition F 1924–98. Office, Washington, DC 20402.

2 6

Annual Book of ASTM Standards, Vol 08.01. Available from Plastics Pipe Institute, 1801 K Street NW, Suite 600K,

3

Annual Book of ASTM Standards, Vol 08.04. Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

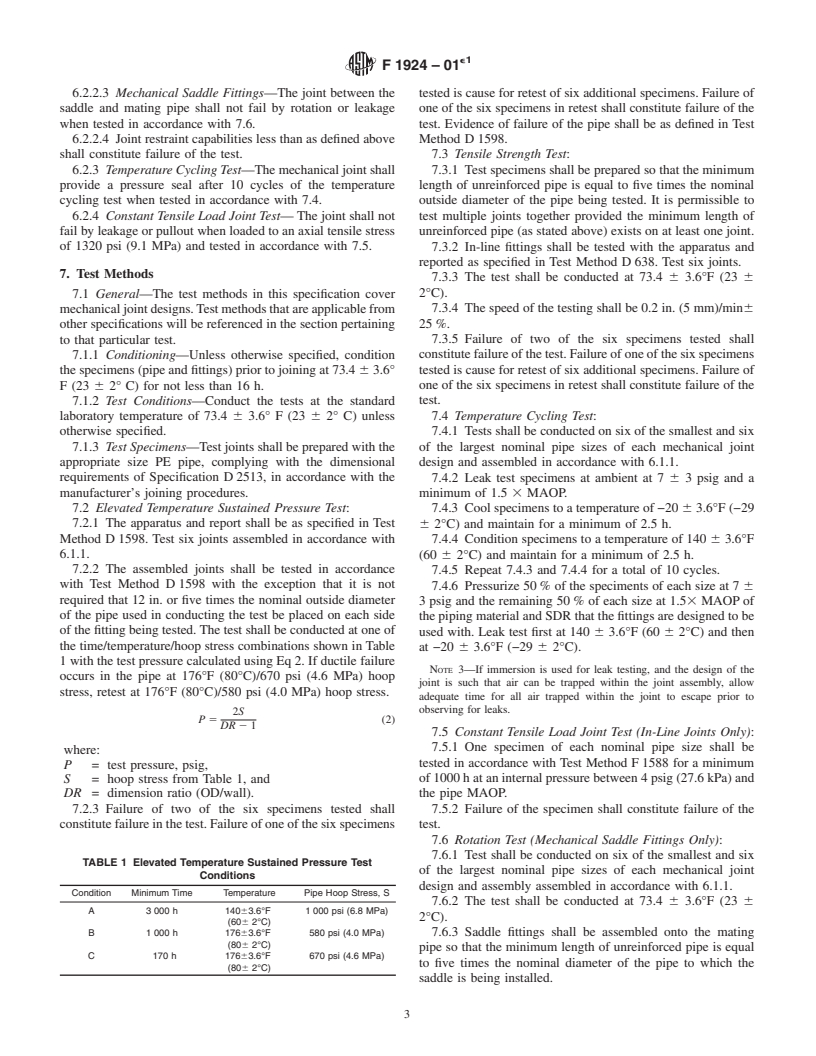

e1

F1924–01

3.1.5 long-term strength (LTS), n—the estimated tensile 4.3 Specifications outlining all the physical properties and

stress that when applied continuously will cause failure at effects of environmental conditions for materials of manufac-

100000 h. This is the intercept of the stress regression line ture shall be available from the fitting manu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.