ASTM D6180-98(2004)

(Test Method)Standard Test Method for Stability of Insulating Oils of Petroleum Origin Under Electrical Discharge

Standard Test Method for Stability of Insulating Oils of Petroleum Origin Under Electrical Discharge

SCOPE

1.1 This test method covers a laboratory technique that measures the stability of new, used, or reclaimed insulating oils, similar to those described in Specification D 3487 in the presence of a controlled electric discharge. When subjected to this type of discharge, insulating oils absorb energy and produce gases as well as ionized molecules (charge carriers). The quantity of these decay products can be measured and can provide an indication of the stability of oils under the conditions of this test.

1.2 The gases are retained in the discharge cell and their pressure measured. The charge carriers remain in the test specimen. The change in the dissipation factor before and after the discharge is determined.

1.3 The values stated in SI units are to be regarded as the standard. The values stated in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific cautionary statements are given in and .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6180–98 (Reapproved2004)

Standard Test Method for

Stability of Insulating Oils of Petroleum Origin Under

Electrical Discharge

This standard is issued under the fixed designation D 6180; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 IEEE Standard:

4–1995 IEEE Standard Techniques for High-Voltage Test-

1.1 This test method covers a laboratory technique that

ing

measures the stability of new, used, or reclaimed insulating

oils, similar to those described in Specification D 3487 in the

3. Summary of Test Method

presence of a controlled electric discharge. When subjected to

3.1 A test specimen is introduced into a discharge cell and

this type of discharge, insulating oils absorb energy and

degassed under vacuum at room temperature. An ac potential

produce gases as well as ionized molecules (charge carriers).

of 10 kV is applied between a high voltage electrode and a

The quantity of these decay products can be measured and can

grounded salt water electrode for 300 min. The gradual rise of

provide an indication of the stability of oils under the condi-

the pressure inside the discharge cell is measured on an

tions of this test.

electronic vacuum meter as a function of time. The dissipation

1.2 The gases are retained in the discharge cell and their

factor of the oil at 100°C is determined before and after the

pressure measured. The charge carriers remain in the test

stability test.

specimen.The change in the dissipation factor before and after

the discharge is determined.

4. Significance and Use

1.3 The values stated in SI units are to be regarded as the

4.1 During this test, insulating oil in an evacuated cell is

standard. The values stated in parentheses are for information

subjected to a high voltage discharge between two electrodes.

only.

The discharge generates free electrons. These electrons collide

1.4 This standard does not purport to address all of the

with the oil molecules causing many of them to become

safety concerns, if any, associated with its use. It is the

electronically excited. Some of these molecules lose this

responsibility of the user of this standard to establish appro-

energyasaquantaoflightemittingfluorescentradiation.Some

priate safety and health practices and determine the applica-

of the other excited molecules decompose into gases, ionized

bility of regulatory limitations prior to use. Specific cautionary

molecules and free radicals. These changes can provide an

statements are given in 5.3 and 7.1.

indication of the stability of oils under the conditions of this

test method. The measures of these changes are the increase of

2. Referenced Documents

2 the pressure in the test cell and the increase in the dissipation

2.1 ASTM Standards:

factor of the test specimen.

D 923 Practice for Sampling Electrical Insulating Liquids

4.2 During the test, the gas content increases in the cell and

D 924 TestMethodforDissipationFactor(orPowerFactor)

the concentration of charge carriers increases in the oil.

and Relative Permittivity (Dielectric Constant) of Electri-

cal Insulating Liquids

5. Apparatus

D 3487 Specification for Mineral Insulating Oil Used in

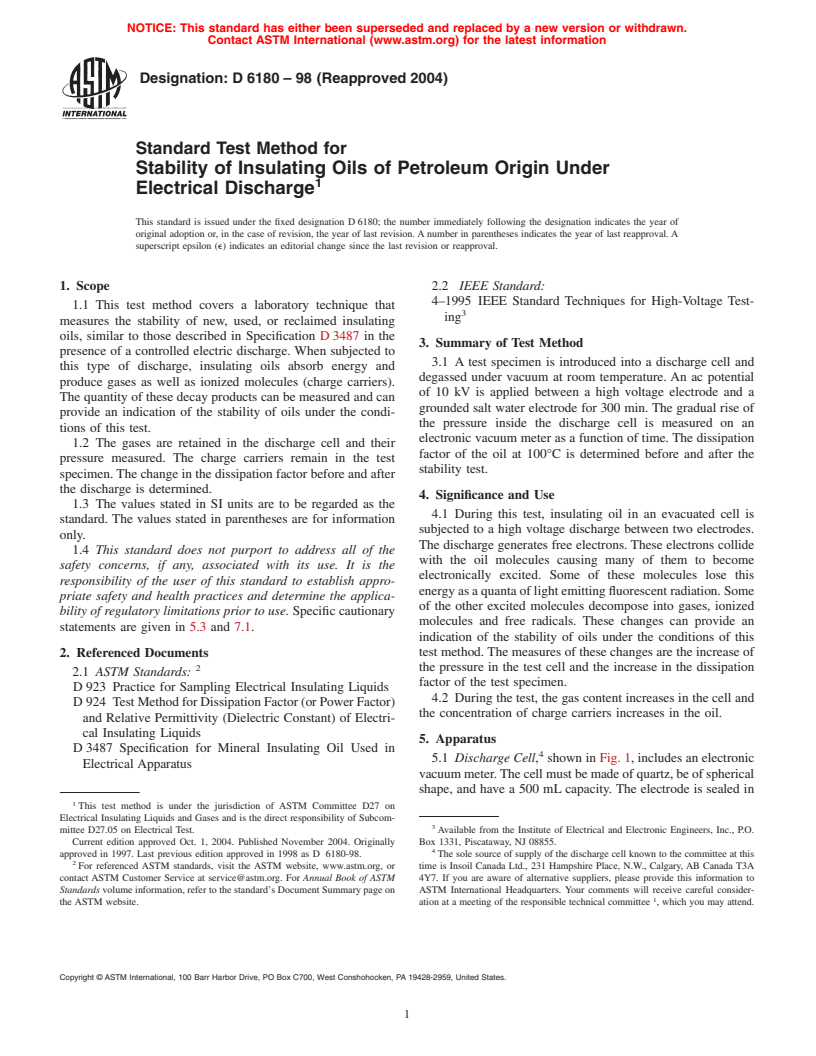

5.1 Discharge Cell, shown in Fig. 1, includes an electronic

Electrical Apparatus

vacuummeter.Thecellmustbemadeofquartz,beofspherical

shape, and have a 500 mL capacity. The electrode is sealed in

This test method is under the jurisdiction of ASTM Committee D27 on

Electrical Insulating Liquids and Gases and is the direct responsibility of Subcom-

mittee D27.05 on Electrical Test. Available from the Institute of Electrical and Electronic Engineers, Inc., P.O.

Current edition approved Oct. 1, 2004. Published November 2004. Originally Box 1331, Piscataway, NJ 08855.

approved in 1997. Last previous edition approved in 1998 as D 6180-98. The sole source of supply of the discharge cell known to the committee at this

For referenced ASTM standards, visit the ASTM website, www.astm.org, or time is Insoil Canada Ltd., 231 Hampshire Place, N.W., Calgary, AB Canada T3A

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4Y7. If you are aware of alternative suppliers, please provide this information to

Standards volume information, refer to the standard’s Document Summary page on ASTM International Headquarters. Your comments will receive careful consider-

the ASTM website. ation at a meeting of the responsible technical committee , which you may attend.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D6180–98 (2004)

FIG. 1 Discharge Cell

the cell as shown in Fig. 1. The free electrons are generated by 5.7 Switch, double-pole, 115 or 230 V, on-off switch for

a cylindrical copper electrode 15 mm (0.6 in.) in diameter and applying voltage to circuit.

10 mm (0.4–in.) long, which is placed in the center of the

5.8 Voltmeter—Measure the voltage by a method that ful-

discharge cell.

fills the requirements of IEEE Standard No. 4 , giving rms

5.2 Glass Dish, approximately 150 mm (6 in.) in diameter

values, preferably by means of:

and 100 mm (4 in.) deep for holding a salt-water ground

5.8.1 A voltmeter connected to the secondary of a separate

electrode.

potential transformer, or

5.3 Test Chamber, with safety interlocked door, which

5.8.2 Avoltmeter connected to a well-designed tertiary coil

deenergizesthetesttransformerwhenopenedandlargeenough

in the test transformer, or

to contain the desired number of cells with at least 100 mm (4

5.8.3 A voltmeter connected to the low voltage side of the

in.) clearance between cells, sides, and top.

testing transformer if the measurement error can be maintained

5.4 Power Source Step-Up Transformer, 60 Hz, 200 VA,

within the limit specified in 5.9.

115 or 230 V to at least 10 kV. Design the transformer of such

5.9 Accuracy—Thecombinedaccuracyofthevoltmeterand

a size that, with the test specimen in the circuit, the voltage

voltage measuring circuit should be such that the measurement

waveshape is approximately a sinusoid with both half cycles

error does not exceed 5 %, calibrated by means of a recom-

alike, and it should have a ratio of peak-to-rms value equal to

mended method in IEEE Standard No. 4.

the 2 65%.

=

5.10 Vacuum Pump, laboratory-type capable of attaining a

5.5 Variable-Tap Autotransformer or Equivalent, 200 VA

vacuum of less than 100 Pa.

min, 115 or 230 V for applying voltage to transformer.

5.11 Clamp Stand, for supporting cell in chamber.

5.6 Relay, 115 or 230 V, double-pole, for energizing trans-

former. 5.12 Vacuum Gage, Electronic vacuum meter.

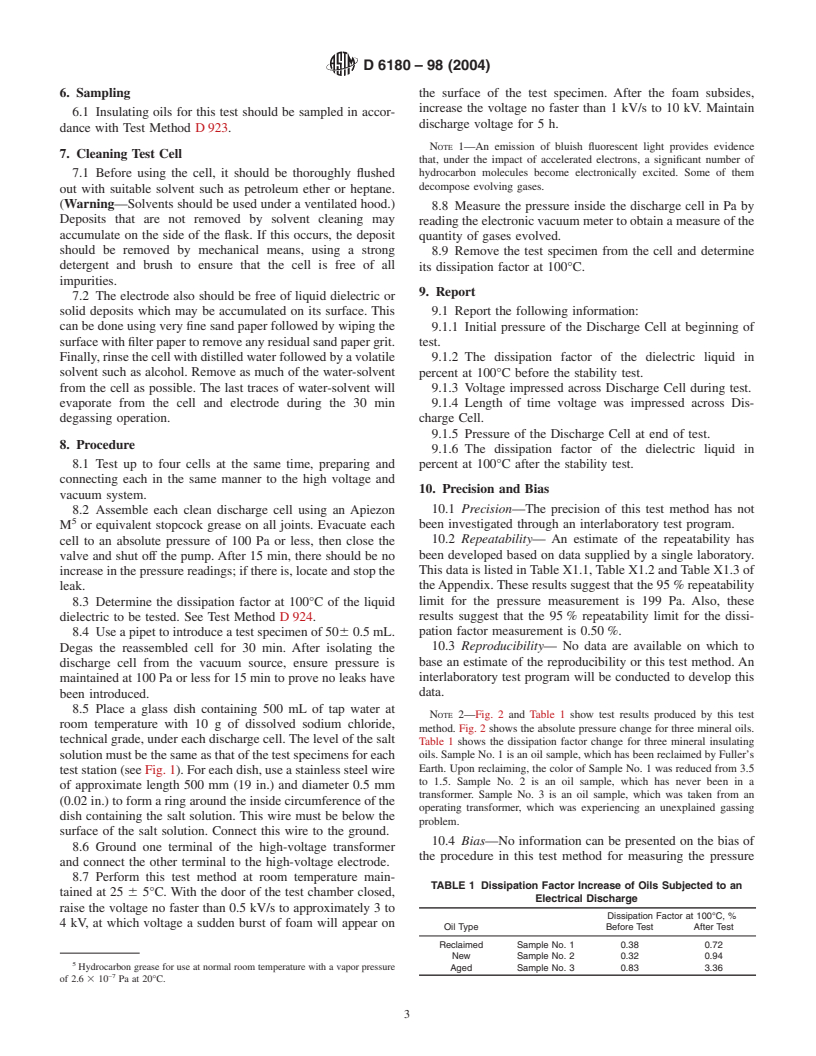

D6180–98 (2004)

6. Sampling the surface of the test specimen. After the foam subsides,

increase the voltage no faster than 1 kV/s to 10 kV. Maintain

6.1 Insulating oils for this test should be sampled in accor-

discharge voltage for 5 h.

dance with Test Method D 923.

NOTE 1—An emission of bluish fluorescent light provides evidence

7. Cleaning Test Cell

that, under the impact of accelerated electrons, a significant number of

hydrocarbon molecules become electronically excited. Some of them

7.1 Before using the cell, it should be thoroughly flushed

decompose evolving gases.

out with suitable solvent such as petroleum ether or heptane.

(Warning—Solvents should be used under a ventilated hood.)

8.8 Measure the pressure inside the discharge cell in Pa by

Deposits that are not removed by solvent cleaning may

reading the electronic vacuum meter to obtain a measure of the

accumulate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.