ASTM F510-93(2008)

(Test Method)Standard Test Method for Resistance to Abrasion of Resilient Floor Coverings Using an Abrader with a Grit Feed Method

Standard Test Method for Resistance to Abrasion of Resilient Floor Coverings Using an Abrader with a Grit Feed Method

SIGNIFICANCE AND USE

When subjected to normal in-use traffic conditions, a flooring material is exposed to abrasion caused by the destructive action of fine hard particles. This situation occurs whenever a particle-polluted intermediate layer exists between traffic bodies (that is, shoes and a flooring surface). Under continuing exposure to an “abrasive action,” a flooring material may suffer a thickness loss sufficient to reduce its service life.

Abrasion resistance measurements of resilient floor coverings can be complicated since the resistance to abrasion is affected by many factors. One of these is the physical properties of the material in the floor covering surface, particularly its hardness and resilience. The type and degree of added substances, such as fillers and pigments, can also affect abrasion resistance. It can also be affected by conditions of the test (for example, the type and characteristics of the abradant and how it acts on the area of the specimen being abraded, including the development and dissipation of heat during the test cycle). The surface characteristics of the specimen, such as type, depth, and amount of embossing, can likewise affect the abrasion resistance of resilient floorings.

This test method is designed to simulate one kind of abrasive action and abradant that a flooring may encounter in the field. However, results should not be used as an absolute index of ultimate life because, as noted, there are too many factors and interactions to consider. Also involved are the many different types of service locations. Therefore, the data from this test method are of value chiefly in the development of materials and should not be used without qualifications as a basis for commercial comparisons.

SCOPE

1.1 This test method covers the laboratory procedure for determining the abrasion resistance of resilient flooring using an abrader with a grit feeder.

1.2 The equipment used in this test method is a modification of the Taber abraser. The regular ceramic wheels are replaced by leather clad brass rollers. A grit-feeding device feeds 240-mesh aluminum oxide grit onto the specimen before it passes under the leather clad rollers. Using the exhaust system incorporated in the apparatus, the used grit and abraded material are continuously removed after passing under both rollers.

1.3 This test method employs a rotary, rubbing action caused by the dual abrading wheels. One wheel rubs the specimen from the center outward and the other from the outside toward the center. The wheels traverse a complete circle and have an abrasive action on the rotating specimen at all angles. It is felt that this action approaches the twisting action between shoe and floor that occurs when a person turns. The use of loose grit serves the function of an abradant and also aids in the rolling action felt to be characteristic of normal walking.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F510 − 93(Reapproved 2008)

Standard Test Method for

Resistance to Abrasion of Resilient Floor Coverings Using

an Abrader with a Grit Feed Method

ThisstandardisissuedunderthefixeddesignationF510;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers the laboratory procedure for

D1860Test Method for Moisture and Creosote-Type Preser-

determining the abrasion resistance of resilient flooring using

vative in Wood (Withdrawn 2006)

an abrader with a grit feeder.

D792Test Methods for Density and Specific Gravity (Rela-

1.2 Theequipmentusedinthistestmethodisamodification

tive Density) of Plastics by Displacement

of the Taber abraser. The regular ceramic wheels are replaced

E122PracticeforCalculatingSampleSizetoEstimate,With

by leather clad brass rollers. A grit-feeding device feeds

Specified Precision, the Average for a Characteristic of a

240-mesh aluminum oxide grit onto the specimen before it

Lot or Process

passes under the leather clad rollers. Using the exhaust system

E171Practice for Conditioning and Testing Flexible Barrier

incorporated in the apparatus, the used grit and abraded

Packaging

material are continuously removed after passing under both 2.2 ANSI Standard:

rollers.

B74.12Checking the Size of Abrasive Grain for Grinding

Wheels, Polishing, and General Industrial Uses

1.3 This test method employs a rotary, rubbing action

caused by the dual abrading wheels. One wheel rubs the

3. Terminology

specimen from the center outward and the other from the

3.1 Definitions:

outside toward the center. The wheels traverse a complete

3.1.1 abrasion—of resilient floor coverings, a form of wear,

circle and have an abrasive action on the rotating specimen at

in which a gradual removing of a flooring surface is caused by

all angles. It is felt that this action approaches the twisting

the frictional action of relatively fine hard particles.

action between shoe and floor that occurs when a person turns.

3.1.2 resistance to abrasion— of resilient floor coverings,

Theuseofloosegritservesthefunctionofanabradantandalso

the ability of a material to withstand mechanical actions of

aids in the rolling action felt to be characteristic of normal

relatively fine hard particles, which by rubbing, scraping, and

walking.

eroding remove material from a floor covering surface.

1.4 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 When subjected to normal in-use traffic conditions, a

priate safety and health practices and determine the applica-

flooring material is exposed to abrasion caused by the destruc-

bility of regulatory limitations prior to use.

tive action of fine hard particles. This situation occurs when-

ever a particle-polluted intermediate layer exists between

traffic bodies (that is, shoes and a flooring surface). Under

continuingexposuretoan“abrasiveaction,”aflooringmaterial

ThistestmethodisunderthejurisdictionofASTMCommitteeF06onResilient

Floor Coveringsand is the direct responsibility of Subcommittee F06.30 on Test may suffer a thickness loss sufficient to reduce its service life.

Methods - Performance.

Current edition approved Nov. 1, 2008. Published December 2008. Originally

approved in 1978. Last previous edition approved in 2004 as F510–93(2004). DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/F0510-93R08. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This test method is described by W. E. Irwin in “Development of a Method to Standards volume information, refer to the standard’s Document Summary page on

MeasureWearonResilientFlooring,” Journal of Testing and Evaluation,Vol4,No. the ASTM website.

1, January 1976, pp. 15–20. The last approved version of this historical standard is referenced on

This grit feed method is frequently referred to as the “Frick Grit Feed Method” www.astm.org.

becauseitisbasedonworkdonebyOttoF.V.Frickasdescribedin“StudiesofWear Available from American National Standards Institute, 25 West 43rd St., 4th

on Flooring Materials,” Wear, Vol 14, 1969, pp. 119–131. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F510 − 93 (2008)

5.1.2 Feeder attachment, for the abraser.

5.1.3 Leather-covered brass wheels shall have a diameter

of1.75in.(4.44cm),andthewidthshallbe0.50in.(1.27cm);

weightofthebrasswheelshallbe5.11oz(145g).Widthofthe

leather covering shall be 0.50 in. (1.27 cm), and the weight of

the leather strip shall be 0.202 oz (5 g).

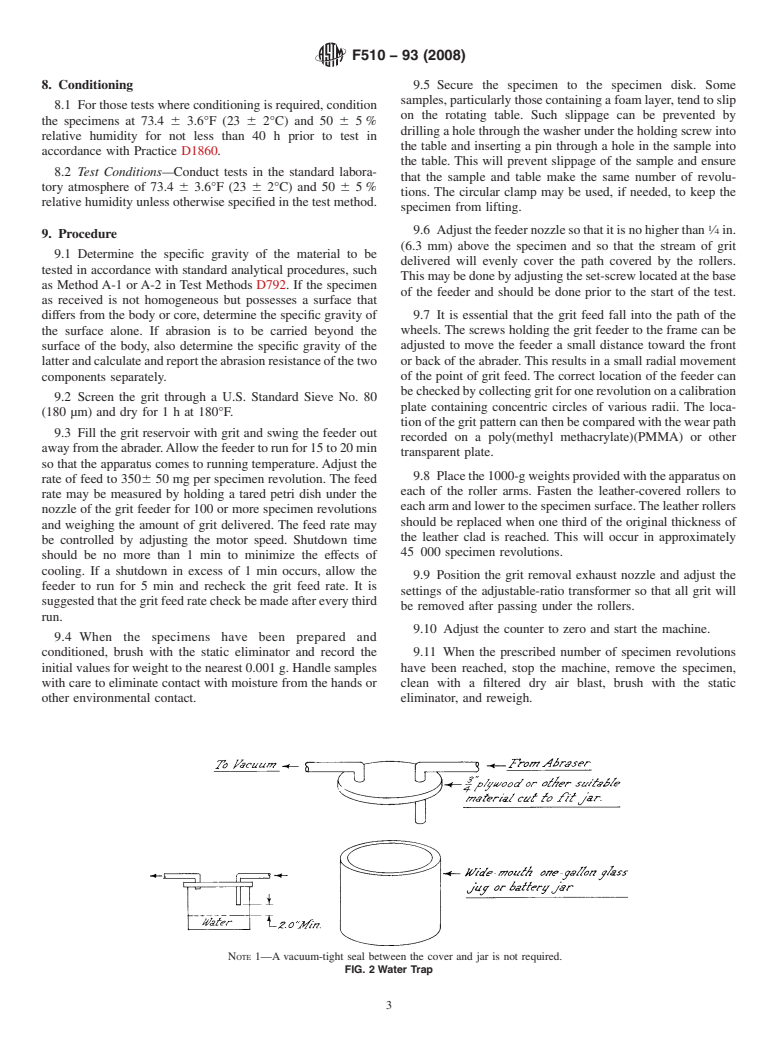

5.1.4 Vacuum unit, or equivalent, and a water trap as

shown in Fig. 2.The purpose of the water trap is to protect the

vacuum equipment motor, reduce the need to empty the

vacuum bag frequently, and minimize readjustment of speed.

Theinletpipetothewatertrapshouldbefarenoughawayfrom

thewatersurfacesothatundueturbulenceisavoidedandwater

does not enter the exhaust line.

5.1.5 Speed control, or equivalent, for adjusting grit feed

rate.

5.2 Aluminum Oxide Grit 240 grit, ANSI B74.12.

5.3 Conditioning Room, providing the standard laboratory

atmosphere of 50 6 5% relative humidity at a temperature of

73.4 6 3.6°F (23 6 2°C) in accordance with Specification

E171.

5.4 Equipment, for determining specific gravity.

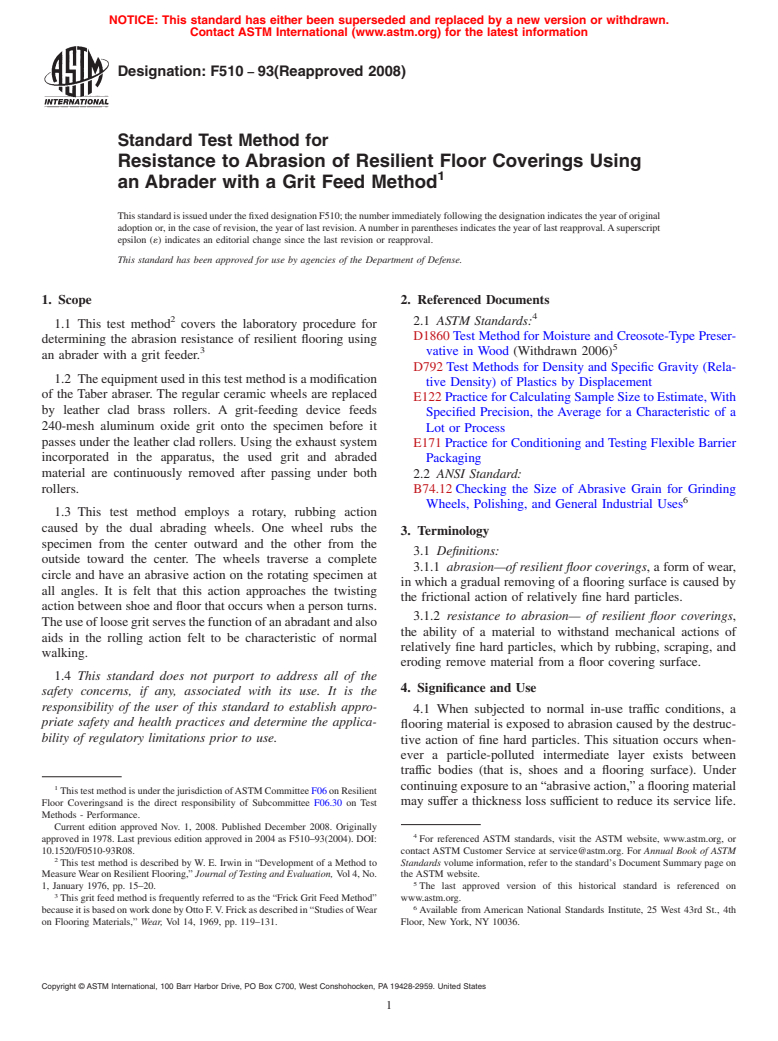

FIG. 1 Taber Abraser with Grit Feeder

5.5 Analytical Balance, for weighing specimens to a preci-

sion of 0.001 g.

4.2 Abrasion resistance measurements of resilient floor

coveringscanbecomplicatedsincetheresistancetoabrasionis

5.6 Die or Knife, for cutting specimens to designated size.

affected by many factors. One of these is the physical proper-

5.7 Sieve, No. 80 (180 µm).

tiesofthematerialinthefloorcoveringsurface,particularlyits

hardness and resilience. The type and degree of added 5.8 Oven, to dry grit by heating at 180°F (82°C).

substances, such as fillers and pigments, can also affect

5.9 Static Eliminator Brush.

abrasion resistance. It can also be affected by conditions of the

test (for example, the type and characteristics of the abradant

6. Test Specimens

and how it acts on the area of the specimen being abraded,

1 1

6.1 The test specimen shall measure 4 6 ⁄32 by 4 6 ⁄32 in.

including the development and dissipation of heat during the

1 1

testcycle).Thesurfacecharacteristicsofthespecimen,suchas (101.60 6 0.8 by 101.60 6 0.8 mm). A ⁄4 6 ⁄64-in. (6.25 6

0.4-mm) diameter hole is drilled through the precise center of

type, depth, and amount of embossing, can likewise affect the

abrasion resistance of resilient floorings. the specimen to allow fastening to the specimen holder.

4.3 This test method is designed to simulate one kind of 6.2 The required number of specimens for each test shall be

abrasive action and abradant that a flooring may encounter in

indicated in the material specification. If no number is given,

the field. However, results should not be used as an absolute four samples shall be taken from the material and one

index of ultimate life because, as noted, there are too many

determination made on each. The average of the four or

factorsandinteractionstoconsider.Alsoinvolvedarethemany otherwise specified measurements shall be taken as the abra-

different types of service locations. Therefore, the data from sion loss for the material.

this test method are of value chiefly in the development of

materials and should not be used without qualifications as a

7. Calibration and Standardization

basis for commercial comparisons.

7.1 Adjust the abrader with the grit feeder for proper

operationusingcastacrylicsheet asthestandardmaterial.The

5. Apparatus

equipment, when running properly, shall produce an average

5.1 Apparatus, as shown in Fig. 1, shall consist of the

weight loss of 127.5 6 10 mg for four specimens and 127.5 6

following:

18 mg for an individual test at 2000 revolutions (Note 1).

5.1.1 Abraser,

Operationoftheequipmentforcalibrationshallbeasdescribed

in Section 9, except that specific gravity will not need to be

determined.

The sole source of supply of the Part No. S-38, Taber model 530 or 5130

abraser, and Model 155 grit feeder attachment (Part No. 0503-00-0155), and

NOTE 1—If the desired weight loss is not obtained, check on the

top-grade belt leather (Part No. S-39) known to the committee at this time is

following: grit feed rate, path of the grit, removal of the grit, condition of

Teledyne Taber Corp., 455 Bryant St., North Tonawanda, NY 14120. If you are

the leather on the wheels, free rotation of wheel bearings, specimen

aware of alternative suppliers, please provide this information toASTM Headquar-

ters. Your comments will receive careful consideration at a meeting of the slippage, static charge effects, humidity control, faulty revolution counter,

responsible technical committee, which you may attend. and weighing errors.

F510 − 93 (2008)

8. Conditioning 9.5 Secure the specimen to the specimen disk. Some

samples,particularlythosecontainingafoamlayer,tendtoslip

8.1 Forthosetestswhereconditioningisrequired,condition

on the rotating table. Such slippage can be prevented by

the specimens at 73.4 6 3.6°F (23 6 2°C) and 50 6 5%

drillingaholethroughthewasherundertheholdingscrewinto

relative humidity for not less than 40 h prior to test in

the table and inserting a pin through a hole in the sample into

accordance with Practice D1860.

the table. This will prevent slippage of the sample and ensure

8.2 Test Conditions—Conduct tests in the standard labora-

that the sample and table make the same number of revolu-

tory atmosphere of 73.4 6 3.6°F (23 6 2°C) and 50 65%

tions. The circular clamp may be used, if needed, to keep the

relativehumidityunlessotherwisespecifiedinthetestmethod.

specimen from lifting.

9.6 Adjustthefeedernozzlesothatitisnohigherthan ⁄4in.

9. Procedure

(6.3 mm) above the specimen and so that the stream of grit

9.1 Determine the specific gravity of the material to be

delivered will evenly cover the path covered by the rollers.

tested in accordance with standard analytical procedures, such

Thismaybedonebyadjustingtheset-screwlocatedatthebase

as MethodA-1 orA-2 in Test Methods D792. If the specimen

of the feeder and should be done prior to the start of the test.

as received is not homogeneous but possesses a surface that

differs from the body or core, determine the specific gravity of 9.7 It is essential that the grit feed fall into the path of the

the surface alone. If abrasion is to be carried beyond the wheels. The screws holding the grit feeder to the frame can be

surface of the body, also determine the specific gravity of the adjusted to move the feeder a small distance toward the front

or back of the abrader.This results in a small radial movement

latterandcalculateandreporttheabrasionresistanceofthetwo

components separately. of the point of grit feed. The correct location of the feeder can

becheckedbycollectinggritforonerevolutiononacalibration

9.2 Screen the grit through a U.S. Standard Sieve No. 80

plate containing concentric circles of various radii. The loca-

(180 µm) and dry for1hat 180°F.

tionofthegritpatterncanthenbecomparedwiththewearpath

9.3 Fill the grit reservoir with grit and swing the feeder out

recorded on a poly(methyl methacrylate)(PMMA) or other

awayfromtheabrader.Allowthefeedertorunfor15to20min

transparent plate.

so that the apparatus comes to running temperature.Adjust the

9.8 Placethe1000-gweightsprovidedwiththeapparatuson

rate of feed to 3506 50 mg per specimen revolution. The feed

each of the roller arms. Fasten the leather-covered rollers to

rate may be measured by holding a tared petri dish under the

eacharmandlowertothespecimensurface.Theleatherrollers

nozzle of the grit feeder for 100 or more specimen revolutions

should be replaced when one third of the original thickness of

and weighing the amount of grit delivered. The feed rate may

the leather clad is reached. This will occur in approximately

be controlled by adjusting the motor speed. Shutdown time

45 000 specimen revolutions.

should be no more than 1 min to minimize the effects of

cooling. If a shutdown in excess of 1 min occurs, allow the

9.9 Position the grit removal exhaust nozzle and adjust the

feeder to run for 5 min and recheck the grit feed rate. It is

settings of the adjustable-ratio transformer so that all grit will

suggestedthatthegritfeedratecheckbemadeaftereverythird

be removed after passing under the rollers.

run.

9.10 Adjust the counter to zero and start the machine.

9.4 When the specimens have been prepared and

conditioned, brush with the static eliminator and record the 9.11 When the prescribed number of specimen revolutions

initialvaluesforweighttothenearest0.001g.Handlesamples have been reached, stop the machine, remove the specimen,

with care to eliminate contact with moisture from the hands or clean with a filtered dry air blast, brush with the static

other environmental contact. eliminator, and reweigh.

NOTE 1—A vacuum-tight seal between the cover and jar is not required.

FIG. 2 Water Trap

F510 − 93 (2008)

10. Calculation and Report 11. Precision and Bias

NOTE2—Forfurtherinformationontheuseofstatisticalmethods,refer

10.1 Report the resistance to abrasion for the number of

to the appendix.

revolutions employed using one or more of the following

11.1 Precision:

equations:

11.1.1 Therepeatabilityforsmoothsurfacesis10%forthis

W 2 W

1 2 test.

Volumeloss, cm 5 (1)

S

11.1.2 The reproducibility for smooth surfaces is 20% for

this test.

where:

11.1.3 The repeatability and reproducibility for embossed

W = initial weight, g,

surfaces has not been established.

W = weight after abrasion g, and

S = density of the material being abraded, g/cm . 11.2 Bias—Thisprocedureformeasuringresistancetoabra-

sionofresilientfloorcoveringusinganabraderwithagritfeed

or:

hasnobiasbecausethevalueofabrasionresistancecanonlybe

cm 31000

3 defined in terms of a test method.

Volumeloss, mm /100revolutions 5 3100 (2)

totalrevolutions

12. Keywords

10.2 The average loss in thickness can be calculated by

dividing the loss in volume by the abraded area of the

12.1 abrasion resistance; aluminum oxide; grit feed; resil-

specimen.

ient flooring; Taber abraser

The method of calculating the coefficient of variation may be found in

MNL 7,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.