ASTM A348/A348M-05(2011)

(Test Method)Standard Test Method for Alternating Current Magnetic Properties of Materials Using the Wattmeter-Ammeter-Voltmeter Method, 100 to 10 000 Hz and 25-cm Epstein Frame

Standard Test Method for Alternating Current Magnetic Properties of Materials Using the Wattmeter-Ammeter-Voltmeter Method, 100 to 10 000 Hz and 25-cm Epstein Frame

SIGNIFICANCE AND USE

This test method evaluates the performance of flat-rolled magnetic materials over a wide frequency range of ac excitation with and without incremental dc bias, as used on transformers, motors, and other laminated core devices.

This test method is suitable for design, specification acceptance, service evaluation, and research.

The application of test results obtained with this test method to the design or evaluation of a particular magnetic device must recognize the influence of the magnetic circuitry upon its performance. Some specific items to consider are size, shape, holes, welding, staking, bolting, bracketing, shorting between laminations, ac waveform, adjacent magnetic fields, and stress.

SCOPE

1.1 This test method covers the determination of the magnetic properties of flat-rolled magnetic materials using Epstein test specimens with double-lap joints in the 25-cm Epstein frame. It covers determination of core loss, rms and peak exciting current, exciting power, magnetic field strength, and permeability. This test method is commonly used to test grain-oriented and nonoriented electrical steels but may also be used to test nickel-iron, cobalt-iron, and other flat-rolled magnetic materials.

1.2 This test method shall be used in conjunction with Practice A 34/A 34M and Test Method A 343/A 343M.

1.3 Tests under this test method may be conducted with either normal ac magnetization or with ac magnetization and superimposed dc bias (incremental magnetization).

1.4 In general, this test method has the following limitations:

1.4.1 FrequencyThe range of this test method normally covers frequencies from 100 to 10 000 Hz. With proper equipment, the test method may be extended above 10 000 Hz. When tests are limited to the use of power sources having frequencies below 100 Hz, they shall use the procedures of Test Method A 343/A 343M.

1.4.2 Magnetic Flux Density(may also be referred to as Flux Density)-The range of magnetic flux density for this test method is governed by the test specimen properties and by the available instruments and other equipment components. Normally, for many materials, the magnetic flux density range is from 1 to 15 kG [0.1 to 1.5 T].

1.4.3 Core Loss and Exciting PowerThese measurements are normally limited to test conditions that do not cause a test specimen temperature rise in excess of 50C or exceed 100 W/lb [220 W/kg].

1.4.4 ExcitationEither rms or peak values of exciting current may be measured at any test point that does not exceed the equipment limitations provided that the impedance of the ammeter shunt is low and its insertion into the test circuit does not cause appreciably increased voltage waveform distortion at the test magnetic flux density.

1.4.5 Incremental PropertiesMeasurement of incremental properties shall be limited to combinations of ac and dc excitations that do not cause secondary voltage waveform distortion, as determined by the form factor method, to exceed a shift of 10 % away from sine wave conditions.

1.5 The values and equations stated in customary (cgs-emu and inch-pound) or SI units are to be regarded separately as standard. Within this standard, SI units are shown in brackets except for the sections concerning calculations where there are separate sections for the respective unit systems. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with this standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A348/A348M − 05(Reapproved 2011)

Standard Test Method for

Alternating Current Magnetic Properties of Materials Using

the Wattmeter-Ammeter-Voltmeter Method, 100 to 10 000 Hz

and 25-cm Epstein Frame

This standard is issued under the fixed designationA348/A348M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4.4 Excitation—Either rms or peak values of exciting

current may be measured at any test point that does not exceed

1.1 This test method covers the determination of the mag-

the equipment limitations provided that the impedance of the

netic properties of flat-rolled magnetic materials using Epstein

ammeter shunt is low and its insertion into the test circuit does

test specimens with double-lap joints in the 25-cm Epstein

notcauseappreciablyincreasedvoltagewaveformdistortionat

frame. It covers determination of core loss, rms and peak

the test magnetic flux density.

exciting current, exciting power, magnetic field strength, and

1.4.5 Incremental Properties—Measurement of incremental

permeability. This test method is commonly used to test

properties shall be limited to combinations of ac and dc

grain-orientedandnonorientedelectricalsteelsbutmayalsobe

excitations that do not cause secondary voltage waveform

used to test nickel-iron, cobalt-iron, and other flat-rolled

distortion, as determined by the form factor method, to exceed

magnetic materials.

a shift of 10% away from sine wave conditions.

1.2 This test method shall be used in conjunction with

1.5 The values and equations stated in customary (cgs-emu

Practice A34/A34M and Test Method A343/A343M.

and inch-pound) or SI units are to be regarded separately as

1.3 Tests under this test method may be conducted with

standard. Within this standard, SI units are shown in brackets

either normal ac magnetization or with ac magnetization and

except for the sections concerning calculations where there are

superimposed dc bias (incremental magnetization).

separate sections for the respective unit systems. The values

1.4 In general, this test method has the following limita- stated in each system may not be exact equivalents; therefore,

each system shall be used independently of the other. Combin-

tions:

1.4.1 Frequency—The range of this test method normally ingvaluesfromthetwosystemsmayresultinnonconformance

covers frequencies from 100 to 10000 Hz. With proper with this standard.

equipment,thetestmethodmaybeextendedabove10000Hz.

1.6 This standard does not purport to address all of the

When tests are limited to the use of power sources having

safety concerns, if any, associated with its use. It is the

frequenciesbelow100Hz,theyshallusetheproceduresofTest

responsibility of the user of this standard to establish appro-

Method A343/A343M.

priate safety and health practices and determine the applica-

1.4.2 Magnetic Flux Density (may also be referred to as

bility of regulatory limitations prior to use.

Flux Density)—Therangeofmagneticfluxdensityforthistest

2. Referenced Documents

method is governed by the test specimen properties and by the

available instruments and other equipment components. 2

2.1 ASTM Standards:

Normally, for many materials, the magnetic flux density range

A34/A34MPractice for Sampling and Procurement Testing

is from 1 to 15 kG [0.1 to 1.5 T].

of Magnetic Materials

1.4.3 Core Loss and Exciting Power—These measurements

A340Terminology of Symbols and Definitions Relating to

are normally limited to test conditions that do not cause a test

Magnetic Testing

specimen temperature rise in excess of 50°C or exceed 100

A343/A343MTest Method for Alternating-Current Mag-

W/lb [220 W/kg].

netic Properties of Materials at Power Frequencies Using

Wattmeter-Ammeter-Voltmeter Method and 25-cm Ep-

stein Test Frame

This test method is under the jurisdiction of ASTM Committee A06 on

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2011. Published December 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1960. Last previous edition approved in 2005 as A348/A348M–05. Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/A0348_A0348M-05R11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A348/A348M − 05 (2011)

TABLE 1 Number of Strips for Various Nominal Specimen Weight

3. Summary of Test Method

Epstein Frames (Minimum Strip Length is 28 cm [280 mm])

3.1 A representative sample of the magnetic material is cut

Number of Strips for Test Specimens of

Nominal Strip Thickness

into Epstein strips and then annealed or otherwise treated in

Nominal Weight

accordance with the appropriate material specification or as

Thick (cm) Thick (in.) 125 g 250 g 500 g 1000 g

agreed between producer and user. The strips are weighed and

0.079 0.0310 . . 12 20

loaded into the Epstein frame becoming the transformer core. 0.071 0.0280 . . 12 24

0.064 0.0250 . . 12 24

The primary coil is then excited with ac voltage and current at

0.056 0.0220 . . 16 28

the frequencies and magnetic flux densities of interest and

0.047 0.0185 . 12 16 32

measurements taken. In some cases, a dc magnetic field 0.043 0.0170 . 12 20 36

0.039 0.0155 . 12 20 40

strength is superimposed (incremental dc bias). The magnetic

0.036 0.0140 . 12 24 44

parameters are then calculated from the data.

0.032 0.0125 . 12 24 48

0.028 0.0110 . 16 28 56

4. Significance and Use

0.025 0.0100 . 16 32 60

0.023 0.0090 . 16 36 68

4.1 Thistestmethodevaluatestheperformanceofflat-rolled

0.020 0.0080 12 20 40 76

magnetic materials over a wide frequency range of ac excita-

0.018 0.0070 12 24 44 88

A

0.015 0.0060 12 24 52

tion with and without incremental dc bias, as used on

A

0.013 0.0050 16 32 60

transformers, motors, and other laminated core devices.

A

0.010 0.0040 20 40 76

AA

0.0076 0.0030 24 52

4.2 This test method is suitable for design, specification

AA

0.0051 0.0020 40 76

acceptance, service evaluation, and research.

AAA

0.0025 0.0010 76

A

4.3 The application of test results obtained with this test Not recommended.

method to the design or evaluation of a particular magnetic

device must recognize the influence of the magnetic circuitry

uponitsperformance.Somespecificitemstoconsideraresize,

shape, holes, welding, staking, bolting, bracketing, shorting driving the test circuit with an ac sinusoidal waveform voltage

between laminations, ac waveform, adjacent magnetic fields, of desired amplitude and frequency. The series resistance

and stress. components, randwattmetercurrentshunt,inconjunctionwith

the ac source, shall be such as to provide a pure sine wave

5. Test Specimens

voltage either at the test frame transformer primary, or if

5.1 The test specimens shall consist of Epstein strips cut

overall negative feedback is implemented, then the pure sine

from sheets or coiled strips of magnetic materials in accor-

wave shall be at the test frame transformer secondary. The

dance with the test lot and sampling requirements of Practice

wiring and switches shall be selected to minimize current or

A34/A34M, Sections 5 and 7, and Test Method A343/A343M,

voltage reading errors, for example, the voltage connections

Annex A3 (see Note 1).

across rshallbemadepreciselyattheresistorterminalssothat

no wire resistance is effectively added to that of the resistor.

NOTE1—Excessiveburrandnonflatnessofstripscanappreciablyaffect

Also, all voltage reading or negative feedback components

test results.

across the secondary of the test frame transformer shall cause

5.1.1 If specimen is primarily isotropic, cut one half of the

negligible loading, that is, shall draw sufficiently low currents

stripswithgrainandone-halfcrossgrain.Ifanisotropic,cutall

to not appreciably affect power or current readings. When a

with grain. Other ratios of with and cross grain may be chosen

common ground connection is made between primary and

by agreement.

secondary of the test frame transformer, the ac source ground

5.2 The test specimen shall consist of multiples of four

connection must be isolated to eliminate ground loop current.

strips. The total number of strips shall be such as to:

5.2.1 Provide sufficient total losses to register within the

7. Apparatus

range of required accuracy of the wattmeter.

7.1 The test apparatus shall consist of as many of the

5.2.2 Fill the available vertical opening space in the test

following components as required to perform the desired

frame to at least ⁄4 of its maximum height and

measurement functions:

5.2.3 Contain a minimum of twelve strips.

7.2 Balance or Scale—The balance or scales used for

5.3 Check each strip to assure its length and width are

determining the mass of the test specimen shall weigh to an

accurate to 60.04 cm [0.4 mm]. If the length is not 30.5 cm

accuracy of 0.05%. The calculated test voltage E is directly

f

[305 mm], use the actual length as described in Sections 9 and

proportional to specimen mass and magnetic flux density (see

10.

Note 2).

5.4 Table 1 shows the number of Epstein strips that will

NOTE 2—Errors in the weight of a specimen will cause errors in

provide nominal weights of approximately 125, 250, 500, and

magnetic flux density, core loss, and exciting power.

1000 g for various strip thicknesses.

7.3 Epstein Test Frame:

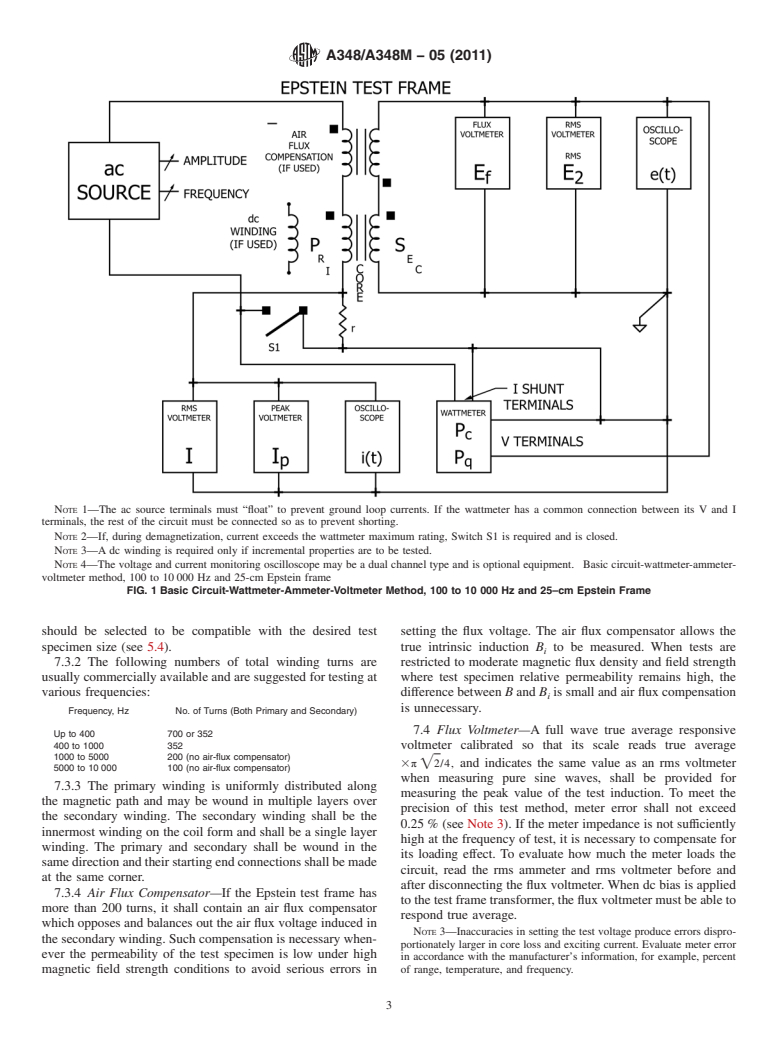

6. Basic Circuit (see Fig. 1)

7.3.1 Thedimensionsofthewindings,theirspacing,andthe

6.1 Fig. 1 shows the essential apparatus and basic circuit general precautions and construction details of Test Method

connections for this test. The ac source shall be capable of A343/A343M, Annex A1, shall apply. The Epstein test frame

A348/A348M − 05 (2011)

NOTE 1—The ac source terminals must “float” to prevent ground loop currents. If the wattmeter has a common connection between its V and I

terminals, the rest of the circuit must be connected so as to prevent shorting.

NOTE 2—If, during demagnetization, current exceeds the wattmeter maximum rating, Switch S1 is required and is closed.

NOTE 3—A dc winding is required only if incremental properties are to be tested.

NOTE 4—The voltage and current monitoring oscilloscope may be a dual channel type and is optional equipment. Basic circuit-wattmeter-ammeter-

voltmeter method, 100 to 10000 Hz and 25-cm Epstein frame

FIG. 1 Basic Circuit-Wattmeter-Ammeter-Voltmeter Method, 100 to 10 000 Hz and 25–cm Epstein Frame

should be selected to be compatible with the desired test setting the flux voltage. The air flux compensator allows the

specimen size (see 5.4). true intrinsic induction B to be measured. When tests are

i

7.3.2 The following numbers of total winding turns are restricted to moderate magnetic flux density and field strength

usuallycommerciallyavailableandaresuggestedfortestingat where test specimen relative permeability remains high, the

various frequencies: difference between B and B is small and air flux compensation

i

is unnecessary.

Frequency, Hz No. of Turns (Both Primary and Secondary)

7.4 Flux Voltmeter—A full wave true average responsive

Up to 400 700 or 352

400 to 1000 352 voltmeter calibrated so that its scale reads true average

1000 to 5000 200 (no air-flux compensator)

3π =2/4, and indicates the same value as an rms voltmeter

5000 to 10 000 100 (no air-flux compensator)

when measuring pure sine waves, shall be provided for

7.3.3 The primary winding is uniformly distributed along

measuring the peak value of the test induction. To meet the

the magnetic path and may be wound in multiple layers over

precision of this test method, meter error shall not exceed

the secondary winding. The secondary winding shall be the

0.25% (see Note 3). If the meter impedance is not sufficiently

innermost winding on the coil form and shall be a single layer

high at the frequency of test, it is necessary to compensate for

winding. The primary and secondary shall be wound in the

its loading effect. To evaluate how much the meter loads the

samedirectionandtheirstartingendconnectionsshallbemade

circuit, read the rms ammeter and rms voltmeter before and

at the same corner.

after disconnecting the flux voltmeter. When dc bias is applied

7.3.4 Air Flux Compensator—If the Epstein test frame has

tothetestframetransformer,thefluxvoltmetermustbeableto

more than 200 turns, it shall contain an air flux compensator

respond true average.

which opposes and balances out the air flux voltage induced in

NOTE 3—Inaccuracies in setting the test voltage produce errors dispro-

the secondary winding. Such compensation is necessary when-

portionately larger in core loss and exciting current. Evaluate meter error

ever the permeability of the test specimen is low under high

in accordance with the manufacturer’s information, for example, percent

magnetic field strength conditions to avoid serious errors in of range, temperature, and frequency.

A348/A348M − 05 (2011)

7.5 RMS Voltmeter—ARMSvoltmetershallbeprovidedfor 7.10 Oscilloscope Current Monitor (Optional)—Extreme

evaluating the exciting power and also the form factor of the current wave peaking occurs as the magnetic core material

voltage induced in the secondary winding of the test frame goes into saturation. This is readily observable on an oscillo-

transformer. The meter error shall not exceed 0.25% at the scope connected across the current sensing resistor. An oscil-

loscope also makes it possible to recognize current waveform

frequency of test. The meter burden shall have no more than

0.05% effect on the test frame transformer voltage or current. nonsymmetry with positive and negative polarity. Such non-

symmetry results when a dc component is present along with

To evaluate how much the meter loads the circuit, read the

RMS ammeter and flux voltmeter before and after disconnect- the ac in the primary winding of the test frame, causing

nonsymmetrical B versus H excitation. This condition causes

ing the RMS voltmeter. When dc bias is applied to the test

serious peak current reading errors. Temporarily inverting the

frametransformer,theRMSmetermustbeabletoindicatetrue

waveform by flipping the oscilloscope “invert” switch is an

RMS ac voltage.

effective way to observe waveform symmetry. Some oscillo-

7.6 Oscilloscope Voltage Monitor (Optional)—An oscillo-

scopeshaveaprovisionforautomaticallyanddigitallydisplay-

scope may be provided to mon

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.