ASTM A1054-16(2022)

(Specification)Standard Specification for Sintered Ferrite Permanent Magnets

Standard Specification for Sintered Ferrite Permanent Magnets

ABSTRACT

This specification covers technically important, commercially available, magnetically hard sintered ceramic ferrite permanent magnets. Both barium and strontium ferrite materials are covered by this specification. Both isotropic (1 type) and anisotropic (12 types) are covered. A cross reference to both IEC and MMPA designations is provided. The magnetic property requirements for each type are defined as is the method of test. Other defined requirements include the workmanship. Typical physical properties are listed in the appendices.

SCOPE

1.1 This specification covers technically important, commercially available, magnetically hard sintered ferrite permanent magnets.

1.2 Ferrite permanent magnets have residual induction Br from 0.2 T (2000 G) up to about 0.5 T (5000 G) and intrinsic coercive field strength HcJ from 160 kA/m (2000 Oe) up to about 400 kA/m (5000 Oe). Their specific magnetic hysteresis behavior (demagnetization curve) can be characterized using Test Method A977/A977M.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to customary (cgs-emu and inch-pound) units which are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A1054 −16 (Reapproved 2022)

Standard Specification for

Sintered Ferrite Permanent Magnets

This standard is issued under the fixed designation A1054; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Standards:

MMPA Standard No. 0100-00 Standard Specifications for

1.1 This specification covers technically important, com-

Permanent Magnet Materials

mercially available, magnetically hard sintered ferrite perma-

IEC 60404-8-1 Magnetic Materials Part 8: Specifications for

nent magnets.

individual materials Section 1 – Standard specifications

1.2 Ferrite permanent magnets have residual induction B

r

for magnetically hard materials

from 0.2 T (2000 G) up to about 0.5 T (5000 G) and intrinsic

coercive field strength H from 160 kA⁄m (2000 Oe) up to

cJ

3. Terminology

about 400 kA/m (5000 Oe). Their specific magnetic hysteresis

3.1 The terms and symbols used in this specification are

behavior (demagnetization curve) can be characterized using

defined in Terminology A340.

Test Method A977/A977M.

3.2 Terms that are not defined in Terminology A340 but are

1.3 The values stated in SI units are to be regarded as

in common usage and used herein are as follows.

standard. The values given in parentheses are mathematical

3.2.1 Recoil permeability, µ , is the permeability corre-

REC

conversions to customary (cgs-emu and inch-pound) units

sponding to the slope of the recoil line. For reference, see

whichareprovidedforinformationonlyandarenotconsidered

incremental, relative, and reversible permeabilities as defined

standard.

in Terminology A340. In practical use, this is the slope of the

1.4 This standard does not purport to address all of the

normal hysteresis loop in the second quadrant and in proximity

safety concerns, if any, associated with its use. It is the

to the B-axis. The value of recoil permeability is dimension-

responsibility of the user of this standard to establish appro-

less. Note that in producers’ product literature, recoil perme-

priate safety, health, and environmental practices and deter-

ability is sometimes represented by the symbol µ , which is

r

mine the applicability of regulatory limitations prior to use.

defined by Terminology A340 as relative permeability.

1.5 This international standard was developed in accor-

3.2.2 Magnetic characteristics change with temperature.

dance with internationally recognized principles on standard-

Two key metrics of permanent magnet performance are re-

ization established in the Decision on Principles for the

sidual induction, B , and intrinsic coercive field strength, H .

r cJ

Development of International Standards, Guides and Recom-

The change in these characteristics over a defined and limited

mendations issued by the World Trade Organization Technical

temperature range can be reversible, that is, non-destructive.

Barriers to Trade (TBT) Committee.

Thischangeisrepresentedbyvaluescalledreversibletempera-

ture coefficients. The symbol for reversible temperature coef-

2. Referenced Documents

ficient of induction is α(B ) and of (intrinsic) coercivity is

r

2.1 ASTM Standards:

α(H ). They are expressed in percent change per degree

cJ

A340 Terminology of Symbols and Definitions Relating to

Celsius, %/°C, or the numerically equivalent percent per

Magnetic Testing

Kelvin, %/K. The change in magnetic characteristics is non-

A977/A977M Test Method for Magnetic Properties of High-

linear so it is necessary to specify the temperature range over

Coercivity Permanent Magnet Materials Using Hyster-

which the coefficient applies.

esigraphs

3.2.3 The maximum recommended working temperature of

a permanent magnet, T , is a semi-arbitrary value sometimes

w

This specification is under the jurisdiction of ASTM Committee A06 on

assigned by magnet manufacturers to their products. T is not

w

Magnetic Properties and is the direct responsibility of Subcommittee A06.02 on

normative. See Appendix X3 for a more complete discussion.

Material Specifications.

Current edition approved Oct. 1, 2022. Published November 2022. Originally

approved in 2007. Last previous addition approved in 2016 as A1054 – 16. DOI:

10.1520/A1054-16R22.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from The International Magnetics Association (IMA), 8 South

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Michigan Avenue, Suite 1000, Chicago, IL 60603.

Standards volume information, refer to the standard’s Document Summary page on Available from IEC (International Electrotechnical Commission) Central Office

the ASTM website. 3, rue de Varembé, P.O. Box 131, CH - 1211, GENEVA 20 Switzerland.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1054−16 (2022)

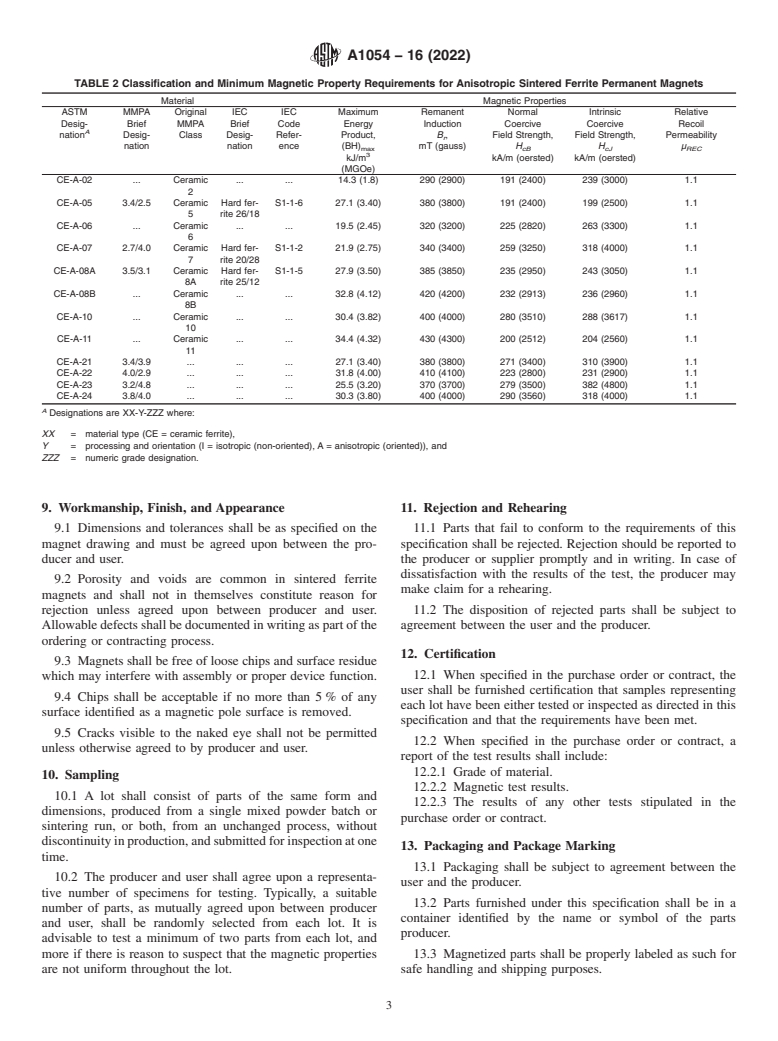

4. Classification 8. Magnetic Property Requirements

4.1 The classification of ferrite permanent magnets is given

8.1 Magnetic properties are listed in Tables 1 and 2.

in Tables 1 and 2, with cross-reference to MMPAStandard No.

8.2 The values of essential magnetic properties listed in the

0100-00 and IEC 60404-8-1 standards.

table are specified minimum values at +20 °C 6 2 °C (+68 °F

6 4 °F), determined after magnetizing to saturation.

5. Ordering Information

5.1 Orders for parts conforming to this specification shall

8.3 The specified values of magnetic properties are valid

include the following information: only for magnet test specimens with a uniform cross-section

5.1.1 Reference to this standard and year of issue/revision.

along the axis of magnetization. Properties for anisotropic

5.1.2 Reference to an applicable part drawing. (magneticallyoriented)magnetsaremeasuredalongtheaxisof

5.1.3 Magnetic property requirements if they are more

preferred orientation.

stringent than the minimum values listed in the tables.

8.4 Because of the nature of permanent magnet production,

5.1.4 Quantity required.

magnetic testing of each lot is strongly recommended, espe-

5.1.5 The required magnetization state of the provided

ciallyforapplicationswherethemagnetperformanceisclosely

material (unmagnetized, fully magnetized, magnetized and

specified. Such magnetic property evaluations shall be con-

thermally stabilized, magnetized and partially demagnetized or

ductedinthemannerdescribedbelow.Wherethemagnetshape

“calibrated”). This information should appear on the part

is not suitable for magnetic testing, a specimen shall be cut

drawing whenever possible.

from the magnet using appropriate slicing and grinding

5.1.6 Certification of magnetic property evaluation.

techniques, paying attention to any magnetic orientation within

5.1.7 Marking and packaging requirements.

the magnet.

5.1.8 Exceptions to this specification or special require-

8.4.1 The magnetic properties shall be determined in accor-

mentssuchasplating,coating,orfunctionaltestingasmutually

dance with Test Method A977/A977M, or by using a suitable,

agreed upon by the producer and user.

mutually agreed upon magnetometric method.

6. Chemical Composition

8.4.2 When magnets are being purchased in the fully

magnetized condition, the testing shall determine the magnetic

6.1 The general chemical composition of ferrite magnets is

properties from the as-received magnetization state, followed

MO · 6Fe O with M being barium, strontium (strontium

2 3

by magnetization to saturation and testing of the magnetic

preferredduetoenvironmentalissues),orsomecombinationof

properties from the fully magnetized condition.

the two. New ferrite grades may also include some rare earth

8.4.3 When magnets are being purchased in the unmagne-

elementsandcobalt.Chemicalcompositionslistedinthetables

tized condition or in an unknown state of magnetization, the

are typical and are not guaranteed.

test laboratory shall magnetize the test specimen(s) to satura-

7. Physical and Mechanical Properties

tion and measure the magnetic properties from the fully

magnetized condition.

7.1 Typical thermal properties are listed in Appendix X1.

8.4.4 When magnets are being purchased in a calibrated,

7.2 Typical physical properties are listed in Appendix X2.

stabilized, or “knocked-down” condition, magnets should be

7.3 Physical density values in Appendix X2 are given for

handled with care to prevent exposure to externally applied

information purposes only and are not guaranteed.

fields. Refer to Appendix X3 for an explanation of these terms.

7.4 Strength testing of brittle materials such as ferrite 8.4.5 Other test methods may be utilized as agreed to

permanent magnets is difficult, expensive, and time- between producer and user. Such tests may include the open

consuming. Results can be widely distributed. Producers typi- circuit magnetic field strength Helmholtz test, field strength

cally make these measurements at the onset of production and measurements in a defined magnetic circuit, or magnetic flux

they are seldom repeated. density measurements adjacent to the magnet surface.

TABLE 1 Classification and Minimum Magnetic Property Requirements for Isotropic Sintered Ferrite Permanent Magnets

Material Magnetic Properties

ASTM MMPA Original IEC IEC Maximum Remanent Normal Intrinsic Relative

Desig- Brief MMPA Brief Code Energy Induction Coercive Coercive Recoil

A

nation Desig- Class Desig- Refer- Product, B, Field Strength, Field Strength, Permeability,

r

nation nation ence (BH) mT (gauss) H H µ

max cB cJ REC

kJ/m kA/m (oersted) kA/m (oersted)

(MGOe)

CE-I-01 1.03/3 Ceramic . S1-0-1 8.4 (1.05) 230 (2300) 148 (1860) 259 (3250) 1.2

A

Designations are XX-Y-ZZZ where:

XX = material type (CE = ceramic ferrite),

Y = processing and orientation (I = isotropic (non-oriented), A = anisotropic (oriented)), and

ZZZ = numeric grade designation.

A1054−16 (2022)

TABLE 2 Classification and Minimum Magnetic Property Requirements for Anisotropic Sintered Ferrite Permanent Magnets

Material Magnetic Properties

ASTM MMPA Original IEC IEC Maximum Remanent Normal Intrinsic Relative

Desig- Brief MMPA Brief Code Energy Induction Coercive Coercive Recoil

A

nation Desig- Class Desig- Refer- Product, B, Field Strength, Field Strength, Permeability

r

nation nation ence (BH) mT (gauss) H H µ

max cB cJ REC

kJ/m kA/m (oersted) kA/m (oersted)

(MGOe)

CE-A-02 . Ceramic . . 14.3 (1.8) 290 (2900) 191 (2400) 239 (3000) 1.1

CE-A-05 3.4/2.5 Ceramic Hard fer- S1-1-6 27.1 (3.40) 380 (3800) 191 (2400) 199 (2500) 1.1

5 rite 26/18

CE-A-06 . Ceramic . . 19.5 (2.45) 320 (3200) 225 (2820) 263 (3300) 1.1

CE-A-07 2.7/4.0 Ceramic Hard fer- S1-1-2 21.9 (2.75) 340 (3400) 259 (3250) 318 (4000) 1.1

7 rite 20/28

CE-A-08A 3.5/3.1 Ceramic Hard fer- S1-1-5 27.9 (3.50) 385 (3850) 235 (2950) 243 (3050) 1.1

8A rite 25/12

CE-A-08B . Ceramic . . 32.8 (4.12) 420 (4200) 232 (2913) 236 (2960) 1.1

8B

CE-A-10 . Ceramic . . 30.4 (3.82) 400 (4000) 280 (3510) 288 (3617) 1.1

CE-A-11 . Ceramic . . 34.4 (4.32) 430 (4300) 200 (2512) 204 (2560) 1.1

CE-A-21 3.4/3.9 . . . 27.1 (3.40) 380 (3800) 271 (3400) 310 (3900) 1.1

CE-A-22 4.0/2.9 . . . 31.8 (4.00) 410 (4100) 223 (2800) 231 (2900) 1.1

CE-A-23 3.2/4.8 . . . 25.5 (3.20) 370 (3700) 279 (3500) 382 (4800) 1.1

CE-A-24 3.8/4.0 . . . 30.3 (3.80) 400 (4000) 290 (3560) 318 (4000) 1.1

A

Designations are XX-Y-ZZZ where:

XX = material type (CE = ceramic ferrite),

Y = processing and orientation (I = isotropic (non-oriented), A = anisotropic (oriented)), and

ZZZ = numeric grade designation.

9. Workmanship, Finish, and Appearance 11. Rejection and Rehearing

9.1 Dimensions and tolerances shall be as specified on the 11.1 Parts that fail to conform to the requirements of this

magnet drawing and must be agreed upon between the pro- specification shall be rejected. Rejection should be reported to

ducer and user. the producer or supplier promptly and in writing. In case of

dissatisfaction with the results of the test, the producer may

9.2 Porosity and voids are common in sintered ferrite

make claim for a rehearing.

magnets and shall not in themselves constitute reason for

rejection unless agreed upon between producer and user. 11.2 The disposition of rejected parts shall be subject to

Allowable defects shall be documented in writing as part of the agreement between the user and the producer.

ordering or contracting process.

12. Certification

9.3 Magnets shall be free of loose chips and surface residue

12.1 When specified in the purchase order or contract, the

which may interfere with assembly or proper device function.

user shall be furnished certification that samples representing

9.4 Chips shall be acceptable if no more than 5 % of any

each lot have been either tested or inspected as directed in this

surface identified as a magnetic pole surface is removed.

specification and that the requirements have been met.

9.5 Cracks visible to the naked eye shall not be permitted

12.2 When specified in the purchase order or contract, a

unless otherwise agreed to by producer and user.

report of the test results shall include:

12.2.1 Grade of material.

10. Sampling

12.2.2 Magnetic test results.

10.1 A lot shall consist of parts of the same form and

12.2.3 The results of any other tests stipulated in the

dimensions, produced from a single mixed powder batch or

purchase order or contract.

sintering run, or both, from an unchanged process, without

discontinuityinproduction,andsubmittedforinspectionatone

13. Packaging and Package Marking

time.

13.1 Packaging shall be subject to agreement between the

10.2 The producer and user shall agree upon a representa-

user and the producer.

tive number of specimens for testing. Typically, a suitable

13.2 Parts furnished under this specification shall be in a

number of parts, as mutually agreed upon between producer

container identified by the name or symbol of the parts

and user, shall be randomly selected from each lot. It is

producer.

advisable to test a minimum of two parts from each lot, and

more if there is reason to suspect that the magnetic properties 13.3 Magnetized parts shall be properly labeled as such for

are not uniform throughout the lot. safe handling and shipping purposes.

A1054−16 (2022)

13.3.1 Magnetized parts to be shipped via aircraft must be agreement between producer and user, to reduce the magnetic

packagedinanappropriatemannertomeetrequirementsfor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.