ASTM D4855-97(2002)

(Practice)Standard Practice for Comparing Test Methods (Withdrawn 2008)

Standard Practice for Comparing Test Methods (Withdrawn 2008)

SIGNIFICANCE AND USE

Task groups developing a test method frequently find themselves with two or more alternative procedures that must be compared. Three common situations are:

4.1.1 Two or more new test methods may have been proposed to measure a property for which there is no existing method.

4.1.2 A new test method may have been suggested to replace an existing test method.

4.1.3 Two or more existing test methods may overlap in their scopes so that one should be chosen over the other.

The selection of one test method in preference to another is not simply a statistical choice. There are many other aspects of two test methods that should be considered, which may have an influence (on the engineering judgment of the task group) equal to or greater than the statistical evidence. Some of these characteristics are discussed in Section 6.

SCOPE

1.1 This practice provides a procedure for evaluating and comparing test methods under controlled conditions using the same materials tested during the same time span. The practice describes how to obtain and compare estimates on precision, sensitivity, and bias.

1.2 This practice covers the following topics:Topic TitleSection numberScope1Referenced Documents2Terminology3Significance and Use4Requirements for Materials5Evaluating Test Methods6Sensitivity Criterion7Basic Statistical Design8Experimental Procedure9Procedure for Comparing Precision10Evaluating the Bias Between Test Methods11Procedure for Comparing Sensitivities12Report13

WITHDRAWN RATIONALE

This practice provides a procedure for evaluating and comparing test methods under controlled conditions using the same materials tested during the same time span. The practice describes how to obtain and compare estimates on precision, sensitivity, and bias.

This practice is being withdrawn with no replacement because D13 no longer has the expertise to maintain and statistical standards are being maintained by committee E11.

Formerly under the jurisdiction of Committee D13 on Textiles, this practice was withdrawn in July 2008.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4855–97 (Reapproved 2002)

Standard Practice for

1

Comparing Test Methods

This standard is issued under the fixed designation D4855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

statements on the relative merits of the two test methods are part of the

1. Scope

output.

1.1 This practice provides a procedure for evaluating and

comparing test methods under controlled conditions using the

3. Terminology

same materials tested during the same time span. The practice

3.1 Definitions:

describes how to obtain and compare estimates on precision,

3.1.1 accuracy, n—of a test method, the degree of agree-

sensitivity, and bias.

ment between the true value of the property being tested (or an

1.2 This practice covers the following topics:

acceptedstandardvalue)andtheaverageofmanyobservations

Topic Title Section

made according to the test method, preferably by many

number

observers. (See also bias and precision.)

Scope 1

3.1.1.1 Discussion—Increased accuracy is associated with

Referenced Documents 2

decreased bias relative to the true value; two methods with

Terminology 3

equal bias relative to the true value have equal accuracy even

Significance and Use 4

Requirements for Materials 5

if one method is more precise than the other. The true value is

Evaluating Test Methods 6

the exact value of the property being tested for the statistical

Sensitivity Criterion 7

universe being sampled. When the true value is not known or

Basic Statistical Design 8

Experimental Procedure 9

cannot be determined, and an acceptable standard value is not

Procedure for Comparing Precision 10

available, accuracy cannot be established. No valid inferences

Evaluating the Bias Between Test Methods 11

on the accuracy of a method can be drawn from an individual

Procedure for Comparing Sensitivities 12

Report 13

observation.

3.1.2 bias, n—in statistics, a constant or systematic error in

2. Referenced Documents

test results.

2.1 ASTM Standards:

3.1.2.1 Discussion—Bias can exist between the accepted

2

D123 Terminology Relating to Textiles

reference value and a test result obtained from one method,

D2905 Practice for Statements on Number of Specimens

between test results obtained from two methods, or between

2

for Textiles

two test results obtained from a single method, for example,

D2906 Practice for Statements on Precision and Bias for

between operators or between laboratories.

2

Textiles

3.1.3 confidence interval, n—the interval estimate of a

3

E456 Terminology Relating to Quality and Statistics

population parameter computed so that the statement “the

2.2 ASTM Adjuncts:

population parameter lies in this interval” will be true, on the

4

TEX-PAC

average, in a stated proportion of the times such statements are

made.

NOTE 1—Tex-Pac is a group of PC programs on floppy disks, available

throughASTM Headquarters, 100 Barr Harbor Drive, Conshohocken, PA

3.1.4 confidence level, n—the stated proportion of times the

19428,USA.Thecalculationsforcomparingtheprecision,sensitivityand

confidence interval is expected to include the population

bias of two test methods can be done using one of these programs and

parameter.

3.1.4.1 Discussion—Statisticians generally accept that, in

the absence of special consideration, 0.95 or 95% is a realistic

1

ThispracticeisunderthejurisdictionofASTMCommitteeD13onTextilesand

confidence level. If the consequences of incorrectly estimating

is the direct responsibility of Subcommittee D13.93 on Statistics.

the confidence interval would be grave, then a higher confi-

Current edition approved September 10, 1997. Published August 1998. Origi-

nally published as D4855–88. Last previous edition D4855–91.

dence level might be considered. If the consequences of

2

Annual Book of ASTM Standards, Vol 07.01.

incorrectly estimating the confidence interval are of less than

3

Annual Book of ASTM Standards, Vol 14.02.

4

1 usual concern, then a lower confidence interval might be

PC programs on floppy disks are available throughASTM. For a 3 ⁄2 inch disk

1

request PCN:12-429040-18, for a 5 ⁄4 inch disk request PCN:12-429041-18. considered.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4855–97 (2002)

3.1.5 confidence limits, n—the two statistics that define the 3.1.17 statistic, n—a quantity that is calculated from obser-

ends of a confidence interval. vations on a sample and that estimates a parameter of a sample

and that estimates a parameter of a population.

3.1.6 degrees of freedom, n—for a set,thenumberofvalues

that ca

...

Questions, Comments and Discussion

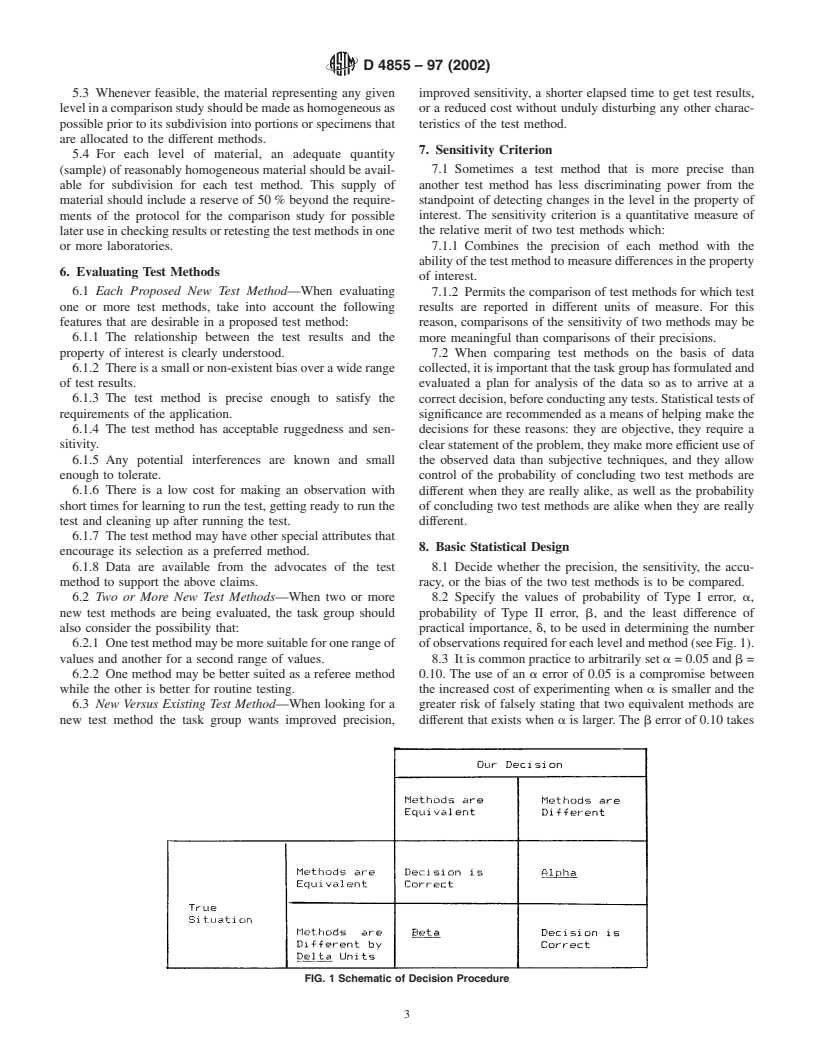

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.