ASTM A685-84

(Specification)Specification for Machined Flat and Square Tool Steel Bars (Withdrawn 1985)

Specification for Machined Flat and Square Tool Steel Bars (Withdrawn 1985)

General Information

Standards Content (Sample)

~

= 9009276 0004029 741 m

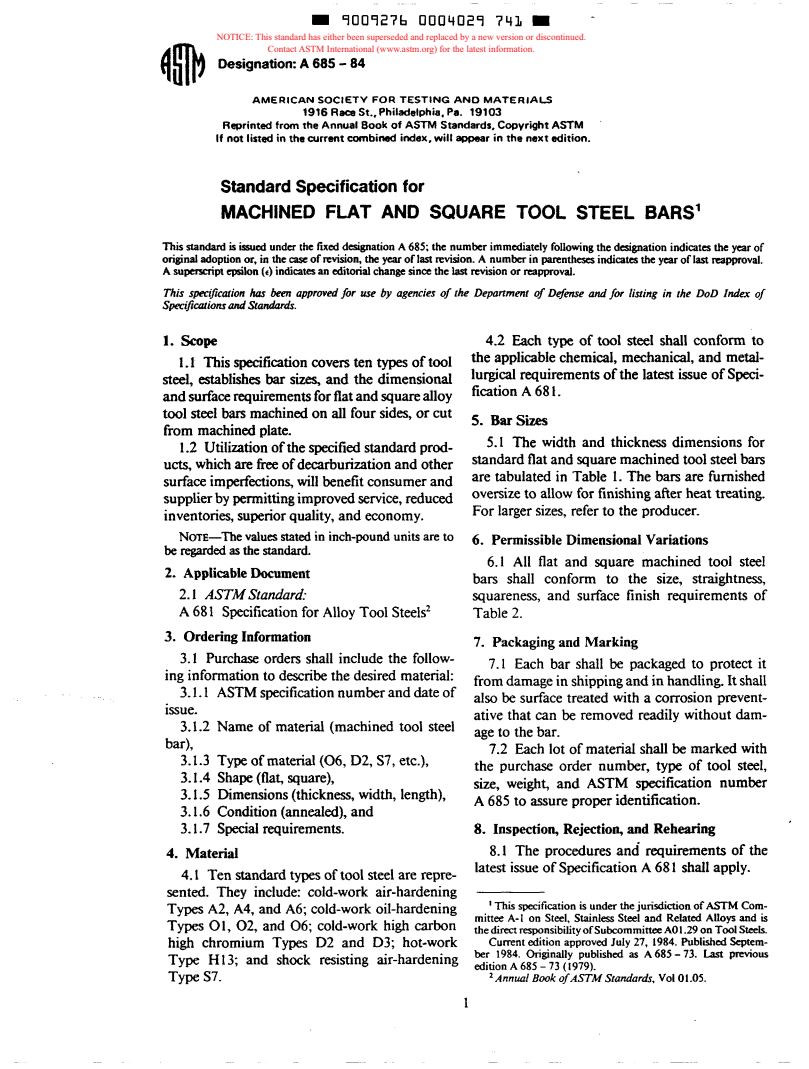

Designation: A 685 - 84

CisTii

AMERICAN SOCIETY FOR TESTING ANO MATERIALS

1916 Race St., Philadelphia. Pa. 19103

Reprinted from the Annual Book of ASN Standards. Copyright ASTM

If not listed in the current combined index, will appear in the next edition.

Standard Specification for

MACHINED FLAT AND SQUARE TOOL STEEL BARS’

This standard is ¡.sued under the fixed designation A 685; the number immediately following the designation indicates the year of

original adoption or, in the casc of revision, the year of last revision. A number in parentheses indicates the year of last rrapprovai.

A superscript epsilon (6) indicates an editorial change since the last revision or rmpproval.

This sperijiccllion has been approved for use by agencies of the Department of Ddme and for listing in the DoD index of

specl$auìomandst~.

1. scope 4.2 Each type of tool steel shall conform to

the applicable chemical, mechanical, and metai-

1.1 This specification covers ten types of tool

lurgical requirements of the latest issue of Speci-

steel, establishes bar sizes, and the dimensional

fication A 68 1.

and surface requirements for flat and square alloy

tool steel bars machined on all four sides, or cut

S. BarSi

from machined plate.

5.1 The width and thickness dimensions for

1.2 Utilization of the specified standard prod-

standard flat and square machined tool steel bars

ucts, which are free of decarburization and other

are tabulated in Table 1. The bars are furnished

surface imperfections, will benefit consumer and

oversize to allow for finishing after heat treating.

supplier by permitting improved service, reduced

For larger sizes, refer to the producer.

inventories, superior quality, and economy.

NOTE-The values stated in inch-pound units are to

6. Permissible Dimensional Variations

be regarded as the standard.

6.1 All flat and square machined tool steel

2. Applicable Document

bars shall conform to the size, straightness,

2.1 ASTM Standard:

squareness, and surface finish requirements of

A 68 1 Specification for Alloy Tool Steels2

Table 2.

3. Ordering Information

7. Packaging and Marking

3.1 Purchase orders shall include the follow-

7.1 Each bar shall be packaged to protect it

ing information to describe the desired material:

from damage in shipping and in handling. It shall

3.1.1 ASTM specification number and date of

also be surface treated with a corrosion prevent-

issue.

ative that can be removed readily without dam-

3.1.2 Name of material (machined tool steel

age to the bar.

bar),

7.2 Each lot of material shall be marked with

3.1.3 Type of material (06, D2, S7, etc.),

the purchase order number, type of tool steel,

3.1.4 Shape (flat, square),

size, weight, and ASTM specification number

3.1.5 Dimensions (thickness, width, length),

A 685 to assure proper identification.

3.1.6 Condition (annealed), and

3.1.7 Special requirements. 8. Inspection, Rejection, and Rehearing

8.1 The procedures and requirements of the

4. Material

latest issue of Specification A 68 1 shall apply.

4.1 Ten standard types of tool steel are repre-

sented. They include: cold-work air-hardening

-

I This specification is under the jurisdiction of ASTM Com-

A2, A4* and A6;

oil-hardening

mittee A-1 on Steel, Stainless Steel and Related Alloys and is

Types 0 1, 0

...

This May Also Interest You

ABSTRACT

This specification covers the chemical, mechanical, and physical requirements for available wrought alloy tool steel products. The material shall be made by an electric melting process. It shall be made from ingots that have been reduced in cross section in such a manner and to such a degree as to ensure proper refinement of the ingot structure. Chemical composition, hardness, macrostructure and decarburization of the material shall conform to the requirements in accordance to the referenced ASTM documents itemized herein.

SCOPE

1.1 This specification covers the chemical, mechanical, and physical requirements for available wrought alloy tool steel products.

1.2 These products, which include hot or cold finished bar, plate, sheet, strip, rod, wire, or forgings, are normally fabricated into tools, dies, or fixtures. The selection of a material for a particular application will depend upon design, service conditions, and desired properties.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification14 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers standards for carburizing steels to be used in anti-friction bearings. Materials shall conform to carbon, manganese, phosphorus, sulfur, chromium, nickel, molybdenum, copper, oxygen, and aluminum contents. Materials shall adhere to inclusion ratings set for thin and heavy series. Grain size and hardenability requirements shall be followed. Decarburization and surface imperfections of hot-rolled, cold-finished, or annealed bars and tubes shall not exceed specified limits as measured through microscopical methods.

SCOPE

1.1 This specification covers the requirements for carburizing bearing-quality steel to be used in the manufacture of anti-friction bearings.

1.2 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers carbon and high-strength low alloy steel structural shapes, plates and bars, and quenched and tempered alloy steel for structural plates intended for use in bridges. Heat analysis shall be used to determine the percentage of carbon, manganese, phosphorus, sulfur, silicon, and copper for the required chemical composition. A tension test shall be used to determine the required tensile properties such as tensile strength, yield strength, and elongation. Materials shall undergo: (1) an impact test for non-fracture critical and fracture critical members; and (2) a Brinell hardness test for Grades 100 and 100W. Atmospheric corrosion resistance shall also be determined.

SCOPE

1.1 This specification covers carbon and high-strength low-alloy steel structural shapes, plates, and bars, quenched and tempered alloy steel, and stainless steel for structural plates intended for use in bridges. Twelve grades are available in five yield strength levels as follows:

Grade U.S. [SI]

Yield Strength, ksi [MPa]

36 [250]

36 [250]

50 [345]

50 [345]

50S [345S]

50 [345]

QST 50 [QST 345]

50 [345]

QST 50S [QST 345S]

50 [345]

50W [345W]

50 [345]

HPS 50W [HPS 345W]

50 [345]

50CR [345CR]

50 [345]

QST 65 [QST450]

65 [450]

QST 70 [QST485]

70 [485]

HPS 70W [HPS 485W]

70 [485]

HPS 100W [HPS 690W]

100 [690]

1.1.1 Grades 36 [250], 50 [345], 50S [345S], 50W [345W], 50CR [345CR], QST 50 [QST 345], QST 50S [QST 345S], QST 65 [QST 450], and QST 70 [QST 485] are also included in Specifications A36/A36M, A572/A572M, A992/A992M, A588/A588M, A1010/A1010M (UNS S41003), and A913/A913M respectively. When the requirements of Table 11 or Table 12 or the supplementary requirements of this specification are specified, they exceed the requirements of Specifications A36/A36M, A572/A572M, A992/A992M, A588/A588M, A1010/A1010M (UNS S41003), and A913/A913M. Product availability is shown in Table 1.

1.1.2 Grades 50W [345W], 50CR [345CR], HPS 50W [HPS 345W], HPS 70W [HPS 485W], and HPS 100W [HPS 690W] have enhanced atmospheric corrosion resistance (see 13.1.2). Product availability is shown in Table 1.

1.2 Grade HPS 70W [HPS 485W] or HPS 100W [HPS 690W] shall not be substituted for Grades 36 [250], 50 [345], 50S [345S], 50W [345W], or HPS 50W [HPS 345W]. Grade 50W [345W], or HPS 50W [HPS 345W] shall not be substituted for Grades 36 [250], 50 [345] or 50S [345S] without agreement between the purchaser and the supplier.

1.3 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.4 For structural products to be used as tension components requiring notch toughness testing, standardized requirements are provided in this standard, and they are based upon American Association of State Highway and Transportation Officials (AASHTO) requirements for both fracture critical and non-fracture critical members.

1.5 Supplementary requirements are available but shall apply only if specified in the purchase order.

1.6 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.7 For structural products produced from coil and furnished without heat treatment or with stress relieving only, the additional requirements, including additional testing requirements and the reporting of additional test results, of Specification A6/A6M apply.

1.8 This international standard was developed in accordance with internationally recognized principles on standardizati...

- Technical specification9 pagesEnglish languagesale 15% off

- Technical specification9 pagesEnglish languagesale 15% off

ABSTRACT

This specifiation covers the standard requirements for Grades 42 [290], 50 [345], 55 [380], 60 [415], and 65 [450] of high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars for applications in bolted, welded, and riveted structures in bridges and buildings. The alloy shall conform to the required contents of columbium, vanadium, titanium, and nitrogen. Permissible values for the product thickness and size is given. Tensile requirements (including yield point, tensile strength, and minimum elongation) and alloy content are also specified. General delivery and test report requirements are also cited.

SCOPE

1.1 This specification covers five grades of high-strength low-alloy structural steel shapes, plates, sheet piling, and bars. Grades 42 [290], 50 [345], and 55 [380] are intended for riveted, bolted, or welded structures. Grades 60 [415] and 65 [450] are intended for riveted or bolted construction of bridges, or for riveted, bolted, or welded construction in other applications.

1.2 For applications, such as welded bridge construction, where notch toughness is important, notch toughness requirements are to be negotiated between the purchaser and the producer.

1.3 Specification A588/A588M shall not be substituted for Specification A572/A572M without agreement between the purchaser and the supplier.

1.4 The use of columbium (niobium), vanadium, titanium, nitrogen, or combinations thereof, within the limitations noted in Section 5, is required; the selection of type (1, 2, 3, or 5) is at the option of the producer, unless otherwise specified by the purchaser. (See Supplementary Requirement S90.)

1.5 The maximum thicknesses available in the grades and products covered by this specification are shown in Table 1.

1.6 When the steel is to be welded, a welding procedure suitable for the grade of steel and intended use or service is to be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.7 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other, without combining values in any way.

1.8 The text of this specification contains notes or footnotes, or both, that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.9 For structural products produced from coil and furnished without heat treatment or with stress relieving only, the additional requirements, including additional testing requirements and the reporting of additional tests, of Specification A6/A6M apply.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification4 pagesEnglish languagesale 15% off

- Technical specification4 pagesEnglish languagesale 15% off

ABSTRACT

This specifiation covers the standard requirements for Grades 42 [290], 50 [345], 55 [380], 60 [415], and 65 [450] of high-strength low-alloy columbium-vanadium structural steel shapes, plates, sheet piling, and bars for applications in bolted, welded, and riveted structures in bridges and buildings. The alloy shall conform to the required contents of columbium, vanadium, titanium, and nitrogen. Permissible values for the product thickness and size is given. Tensile requirements (including yield point, tensile strength, and minimum elongation) and alloy content are also specified. General delivery and test report requirements are also cited.

SCOPE

1.1 This specification covers five grades of high-strength low-alloy structural steel shapes, plates, sheet piling, and bars. Grades 42 [290], 50 [345], and 55 [380] are intended for riveted, bolted, or welded structures. Grades 60 [415] and 65 [450] are intended for riveted or bolted construction of bridges, or for riveted, bolted, or welded construction in other applications.

1.2 For applications, such as welded bridge construction, where notch toughness is important, notch toughness requirements are to be negotiated between the purchaser and the producer.

1.3 Specification A588/A588M shall not be substituted for Specification A572/A572M without agreement between the purchaser and the supplier.

1.4 The use of columbium (niobium), vanadium, titanium, nitrogen, or combinations thereof, within the limitations noted in Section 5, is required; the selection of type (1, 2, 3, or 5) is at the option of the producer, unless otherwise specified by the purchaser. (See Supplementary Requirement S90.)

1.5 The maximum thicknesses available in the grades and products covered by this specification are shown in Table 1.

1.6 When the steel is to be welded, a welding procedure suitable for the grade of steel and intended use or service is to be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.7 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other, without combining values in any way.

1.8 The text of this specification contains notes or footnotes, or both, that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.9 For structural products produced from coil and furnished without heat treatment or with stress relieving only, the additional requirements, including additional testing requirements and the reporting of additional tests, of Specification A6/A6M apply.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification4 pagesEnglish languagesale 15% off

ABSTRACT

This specification deals with the standard requirements for premium quality alloy steel semifinished rolled or forged blooms and billets for reforging into aircraft and aerospace critical parts such as landing-gear forgings. Covered here are three basic classifications of steel, namely: Class I, steel manufactured by vacuum-induction melting or consumable-electrode vacuum melting process; Class II, air-melted steel manufactured by electric-furnace vacuum degassing process; Class III, air-melted steel manufactured by electric-furnace ladle refining and vacuum degassing processes. Steel materials shall be heat-treated and hot-worked by either hot rolling or forging. Alloy steels shall be examined by heat and product analyses and hardenability tests, and shall conform to chemical composition and maximum annealed Brinell hardness requirements. Quality evaluation tests, such as macrotech, microcleanliness, and nondestructive ultrasonic (both immersion and contact examination) inspection, shall be performed as well.

SCOPE

1.1 This specification2 covers two kinds of rolls used in machinery for producing corrugated paperboard. Rolls are fabricated of forged bodies and trunnions. The trunnions may be bolted or shrink assembled on one or both ends of the body. A seal weld may be made at the body/trunnion interface. Roll shells are made of carbon/manganese, or low alloy steel as hereinafter described, and are heat treated prior to assembly. Pressure rolls may be ordered surface hardened as Condition H, or without surface hardening as Condition S. Provision is made in Supplementary Requirements S1 and S3 for the optional surface hardening of corrugating rolls.

1.2 Corrugating and pressure rolls made to this specification shall not exceed 30 in. [760 mm] in inside diameter. The wall thickness of the roll body shall not be less than 1/12 of the inside diameter or 1 in. [25 mm], whichever is greater, but shall not exceed 4 in. [100 mm]. The wall thickness of the corrugating roll is measured at the bottom of the corrugations in the location of the trunnion fit. The maximum design temperature (MDT) of the roll is 600 °F [315 °C] and the maximum allowable working pressure (MAWP) is 250 psi [1.7 MPa]. The minimum design temperature shall be 40 °F [4 °C] for roll wall thicknesses up to 3 in. [75 mm]. For roll wall thicknesses over 3 in. [75 mm] to 4 in. [100 mm], the minimum design temperature shall be 120 °F [50 °C]. The maximum stresses on the roll bodies from the combined internal and external loading are limited to 18 750 psi [129 MPa] for the Class 2 pressure roll bodies, and 20 000 psi [138 MPa] for Class 1A, 1B, or 5 pressure or corrugating roll bodies in Grades 1 or 2. For the trunnions, the maximum stresses from the combined internal and external loading are limited to 15 000 psi [103.4 MPa] for Classes 3 or 4, or 20 000 psi [138 MPa] for Classes 1A, 1B, or 5 in Grade 2 only. The Grade 1 strength level is not permissible for trunnions.

1.3 Referring to Table 1, material to Classes 1A, 1B, or 5 shall be used for the manufacture of corrugating or pressure roll shells, and Class 2 shall be used only for pressure roll shells. Trunnions shall be made from forgings in Classes 1A, 1B, or 5 in Grade 2 strength level as restricted by Footnote B in Table 2 or in forgings in either Class 3 or 4.

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound units.

1.6 Except as specifically required in this standard, all of the provisions of Specification A788/A788M apply.

1.7 This international standard was de...

- Technical specification4 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers high-carbon bearing-quality steel to be used in the manufacture of anti-friction bearings. Materials shall conform to chemical compositions as specified herein, and to physical size and shape as agreed upon between the manufacturer and purchaser. Steels shall exhibit fine fracture grain size when quenched from normal austenitizing temperatures. Decarburization and surface imperfections shall not exceed the limits also specified herein. When annealing is specified in the order, the steel shall adhere to hardness requirements and have a completely spheroidized microstructure, which shall accordingly be rated and reported as carbide size, carbide network, and lamellar content.

SCOPE

1.1 This specification covers high-carbon bearing-quality steel to be used in the manufacture of anti-friction bearings.

1.2 Supplementary requirements of an optional nature are provided and when desired shall be so stated in the order.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification5 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers high-strength, low-alloy structural steel shapes, plates, and bars for welded, riveted, or bolted construction with atmospheric corrosion resistance. Heat analysis shall be performed wherein the low-alloy structural steel materials shall conform to the required chemical composition for carbon, manganese, phosphorous, sulfur, silicon, nickel, chromium, molybdenum, copper, vanadium, and columbium. Steel samples shall also undergo the tensile test and conform to required values of tensile strength, yield point, and elongation.

SCOPE

1.1 This specification covers high-strength low-alloy structural steel shapes, plates, and bars for welded, riveted, or bolted construction but intended primarily for use in welded bridges and buildings where savings in weight or added durability are important. The atmospheric corrosion resistance of this steel in most environments is substantially better than that of carbon structural steels with or without copper addition (see Note 1). When properly exposed to the atmosphere, this steel is suitable for many applications in the bare (unpainted) condition. This specification is limited to material up to 8 in. [200 mm] inclusive in thickness.

Note 1: For methods of estimating the atmospheric corrosion resistance of low-alloy steels, see Guide G101.

1.2 When the steel is to be welded, a welding procedure suitable for the grade of steel and intended use or service is to be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.3 Units—This specification is expressed in both inch-pound units and in SI units; however, unless the purchase order or contract specifies the applicable M specification designation (SI units), the inch-pound units shall apply. The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other. Combining values from the two systems may result in nonconformances with the standard.

1.4 The text of this specification contains notes, footnotes, or both, that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.5 For structural products produced from coil and furnished without heat treatment or with stress relieving only, the additional requirements, including additional testing requirements and the reporting of additional test results, of Specification A6/A6M apply.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers carbon structural steel shapes, plates, and bars of structural quality for use in riveted, bolted, or welded construction of bridges and buildings, and for general structural purposes. Heat analysis shall be used to determine the required chemical composition for carbon, manganese, phosphorus, sulfur, silicon, and copper. Tensile strength, yield strength, and elongation shall be evaluated using tension test and must conform to the required tensile properties.

SCOPE

1.1 This specification2 covers carbon steel shapes, plates, and bars of structural quality for use in riveted, bolted, or welded construction of bridges and buildings, and for general structural purposes.

1.2 Supplementary requirements are provided for use where additional testing or additional restrictions are required by the purchaser. Such requirements apply only when specified in the purchase order.

1.3 When the steel is to be welded, a welding procedure suitable for the grade of steel and intended use or service is to be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.4 The text of this specification contains notes or footnotes, or both, that provide explanatory material. Such notes and footnotes, excluding those in tables and figures, do not contain any mandatory requirements.

1.5 For structural products produced from coil and furnished without heat treatment or with stress relieving only, the additional requirements, including additional testing requirements and the reporting of additional test results, of Specification A6/A6M apply.

1.6 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system is to be used independently of the other, without combining values in any way.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

- Technical specification3 pagesEnglish languagesale 15% off

ABSTRACT

This specification covers high-strength carbon-manganese steel shapes, plates, and bars of structural quality for use in riveted, bolted, or welded construction of buildings and for general structural purposes. Materials considered here are available in Grades 50 [345] and 55 [380]. Steel specimens shall be killed, and as such, be affirmed in the corresponding test report. Heat and product analysis shall be performed wherein steel materials shall conform to the required chemical compositions of carbon, manganese, phosphorus, sulfur, silicon, copper, columbium, chromium, nickel, molybdenum, and vanadium. Steel specimens shall also undergo tensile tests and shall conform to required values of tensile strength, yield strength, and elongation.

SCOPE

1.1 This specification covers carbon-manganese steel shapes, plates, and bars of structural quality for use in riveted, bolted, or welded construction of buildings and for general structural purposes.

1.2 Material under this specification is available in two grades:

Grade

Yield Strength,

ksi [MPa]

Thickness

50 [345]

50 [345]

Plates to 1 in. [25 mm] thick

to 15 in. [380 mm] wide

Bars to 31/2 in. [90 mm]

Shapes with flange or leg thickness to

11/2 in. [40 mm] inclusive

55 [380]

55 [380]

Plates to 1 in. [25 mm] thick

to 15 in. [380 mm] wide

Bars to 3 in. [75 mm]

Shapes with flange or leg thickness to

11/2 in. [40 mm] inclusive

1.3 When the steel is to be welded, it is presupposed that a welding procedure suitable for the grade of steel and intended use or service will be utilized. See Appendix X3 of Specification A6/A6M for information on weldability.

1.4 The values stated in either inch-pound units or SI units are to be regarded as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Technical specification3 pagesEnglish languagesale 15% off

- Technical specification3 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.