ASTM D6264-98(2004)

(Test Method)Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer-Matrix Composite to a Concentrated Quasi-Static Indentation Force

Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer-Matrix Composite to a Concentrated Quasi-Static Indentation Force

SIGNIFICANCE AND USE

Susceptibility to damage from concentrated indentation forces is one of the major weaknesses of many structures made of advanced laminated composites. Knowledge of the damage resistance of a laminated composite material subjected to a concentrated indentation force is useful for product development and material selection.

The QSI test method can serve the following purposes:

5.2.1 To establish quantitatively the effects of stacking sequence, fiber surface treatment, variations in fiber volume fraction, and processing and environmental variables on the damage resistance of a particular composite laminate to a concentrated quasi-static indentation force.

5.2.2 To compare quantitatively the relative values of the damage resistance parameters for composite materials with different constituents. The damage response parameters include d, F1, and Fmax, as well as the F/δ curve.

5.2.3 To place a controlled amount of damage in a specimen for subsequent damage tolerance tests.

5.2.4 To isolate and measure the indentation response of the specimen without bending (rigidly backed configuration).

SCOPE

1.1 A quasi-static indentation (QSI) test method is used to obtain quantitative measurements of the damage resistance of a continuous-fiber-reinforced composite material to a concentrated indentation force (Fig 1). The indentation force is applied to the specimen by slowly pressing a hemispherical indenter into the surface. Procedures are specified for determining the damage resistance for a simply supported test specimen and for a rigidly backed test specimen. The damage resistance is quantified in terms of a critical contact force associated with a single event or sequence of events to cause a specific size and type of damage in the specimen. These tests may be used to screen materials for damage resistance or to inflict damage into a specimen for subsequent damage tolerance testing. This test method is limited to use with composites consisting of layers of unidirectional fibers or layers of fabric. This test method may prove useful for other types and classes of composite materials. Certain interferences, however, have been noted (see 6.7).

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 6264 – 98 (Reapproved 2004)

Standard Test Method for

Measuring Damage Resistance of Fiber-Reinforced Polymer-

Matrix Composite to Concentrated Quasi-Static Indentation

Force

This standard is issued under the fixed designation D6264; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

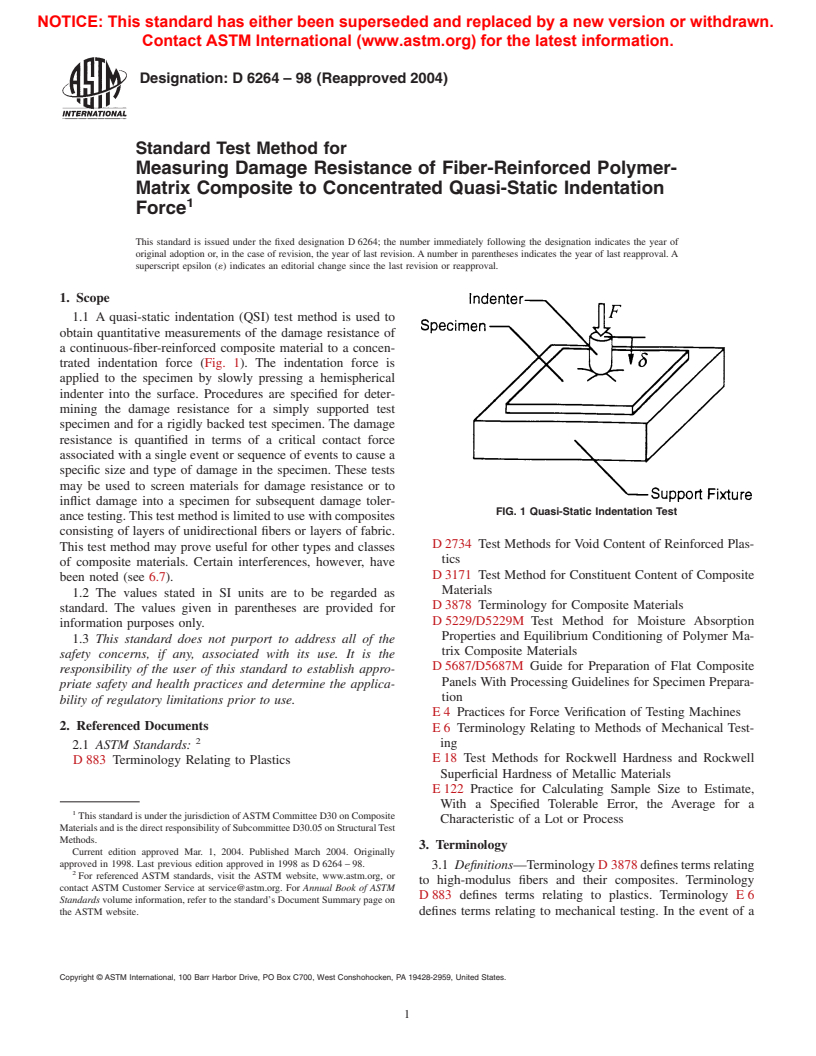

1.1 A quasi-static indentation (QSI) test method is used to

obtain quantitative measurements of the damage resistance of

a continuous-fiber-reinforced composite material to a concen-

trated indentation force (Fig. 1). The indentation force is

applied to the specimen by slowly pressing a hemispherical

indenter into the surface. Procedures are specified for deter-

mining the damage resistance for a simply supported test

specimen and for a rigidly backed test specimen. The damage

resistance is quantified in terms of a critical contact force

associated with a single event or sequence of events to cause a

specific size and type of damage in the specimen. These tests

may be used to screen materials for damage resistance or to

inflict damage into a specimen for subsequent damage toler-

FIG. 1 Quasi-Static Indentation Test

ancetesting.Thistestmethodislimitedtousewithcomposites

consisting of layers of unidirectional fibers or layers of fabric.

D2734 Test Methods for Void Content of Reinforced Plas-

This test method may prove useful for other types and classes

tics

of composite materials. Certain interferences, however, have

D3171 Test Method for Constituent Content of Composite

been noted (see 6.7).

Materials

1.2 The values stated in SI units are to be regarded as

D3878 Terminology for Composite Materials

standard. The values given in parentheses are provided for

D5229/D5229M Test Method for Moisture Absorption

information purposes only.

Properties and Equilibrium Conditioning of Polymer Ma-

1.3 This standard does not purport to address all of the

trix Composite Materials

safety concerns, if any, associated with its use. It is the

D5687/D5687M Guide for Preparation of Flat Composite

responsibility of the user of this standard to establish appro-

Panels With Processing Guidelines for Specimen Prepara-

priate safety and health practices and determine the applica-

tion

bility of regulatory limitations prior to use.

E4 Practices for Force Verification of Testing Machines

2. Referenced Documents

E6 Terminology Relating to Methods of Mechanical Test-

ing

2.1 ASTM Standards:

E18 Test Methods for Rockwell Hardness and Rockwell

D883 Terminology Relating to Plastics

Superficial Hardness of Metallic Materials

E122 Practice for Calculating Sample Size to Estimate,

With a Specified Tolerable Error, the Average for a

ThisstandardisunderthejurisdictionofASTMCommitteeD30onComposite

Characteristic of a Lot or Process

MaterialsandisthedirectresponsibilityofSubcommitteeD30.05onStructuralTest

Methods.

3. Terminology

Current edition approved Mar. 1, 2004. Published March 2004. Originally

approved in 1998. Last previous edition approved in 1998 as D6264–98.

3.1 Definitions—TerminologyD3878definestermsrelating

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

to high-modulus fibers and their composites. Terminology

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

D883 defines terms relating to plastics. Terminology E6

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. defines terms relating to mechanical testing. In the event of a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6264 – 98 (2004)

conflict between terms, Terminology D3878 shall have prece- 4.2 Arecord of the applied contact force/indenter displace-

dence over the other standards. ment (F/d) is recorded on either an X-Y recorder, an equivalent

3.2 Definitions of Terms Specific to This Standard—The real-timeplottingdevice,orstoreddigitallyandpostprocessed.

terms in this test method may conflict with general usage.

5. Significance and Use

Thereisnotyetanestablishedconsensusconcerningtheuseof

these terms. The following descriptions are intended only for 5.1 Susceptibility to damage from concentrated indentation

use in this test method.

forcesisoneofthemajorweaknessesofmanystructuresmade

of advanced laminated composites. Knowledge of the damage

NOTE 1—If the term represents a physical quantity, its analytical

resistance of a laminated composite material subjected to a

dimensionsarestatedimmediatelyfollowingtheterm(orlettersymbol)in

concentrated indentation force is useful for product develop-

fundamental dimension form, using the following ASTM standard sym-

bologyforfundamentaldimensionsshownwithinsquarebrackets:[M]for ment and material selection.

mass,[L]forlength,[T]fortime,[u]forthermodynamictemperature,and

5.2 The QSI test method can serve the following purposes:

[nd] for nondimensional quantities. Use of these symbols is restricted to

5.2.1 To establish quantitatively the effects of stacking

analytical dimensions when used with square brackets, as the symbols

sequence, fiber surface treatment, variations in fiber volume

may have other definitions when used without the brackets.

fraction, and processing and environmental variables on the

−2

3.2.1 contact force, F [MLT ], n—the total force applied

damage resistance of a particular composite laminate to a

normal to the face of the specimen by the indenter.

concentrated quasi-static indentation force.

3.2.2 damage, n—in structures and structural materials,a

5.2.2 To compare quantitatively the relative values of the

structural anomaly in a material or structure created by

damage resistance parameters for composite materials with

manufacturing or service usage.

differentconstituents.Thedamageresponseparametersinclude

3.2.3 damage resistance, n—in structures and structural

d, F , and F , as well as the F/d curve.

1 max

materials, a measure of the relationship between the force,

5.2.3 Toplaceacontrolledamountofdamageinaspecimen

energy, or other parameter(s) associated with an event or

for subsequent damage tolerance tests.

sequence of events and the resulting damage size and type.

5.2.4 Toisolateandmeasuretheindentationresponseofthe

3.2.4 dent depth, d [L], n—residual depth of the depression

specimen without bending (rigidly backed configuration).

formed by an indenter after removal of load. The dent depth

shallbedefinedasthemaximumdistanceinadirectionnormal

6. Interferences

tothefaceofthespecimenfromthelowestpointinthedentto

6.1 The QSI test simulates the force/displacement relation-

the plane of the indented surface that is undisturbed by the

ships of many impacts governed by boundary conditions

dent. 3

(1-7). These are typically relatively large-mass low-velocity

−2

3.2.5 F force, F [MLT ], n—contact force at which the

1 1

hard-body impacts on plates with a relatively small unsup-

force/indenter displacement curve has a discontinuity in force

ported region. This test method does not address wave propa-

or slope.

gationandvibrationsinthespecimen,time-dependentmaterial

3.2.6 indenter displacement, d [L], n—the displacement of

behavior, or inertia-dominated impact events.

the indenter relative to the specimen support.

6.2 The damage response of a specimen is dependent on

−2

3.2.7 maximum force, F [MLT ], n—the maximum

max

many factors, including the indenter geometry and specimen

contactforcealaminatewillresist.Thisforceisobtainedfrom

support conditions. Consequently, comparisons cannot be

the F/d curve after a point is reached where the contact force

made between materials unless identical test configurations,

does not increase with increasing indenter displacement.

identical test conditions, and identical laminates are used.

3.3 Symbols:

Therefore, all deviations from the standard test configuration

should be reported in the results.

6.3 Force F doesnotrepresenttheinitiationofdamage,but

d = dent depth (see 3.2.4).

generally represents when the displacement of the indenter is

F = contact force (see 3.2.1).

affected by large-scale damage formation. Typically, matrix

F = F force (see 3.2.5).

1 1

cracks and small delaminations form before this force.

F = maximum force (see 3.2.7).

max

N = number of ply groups in a laminate’s stacking 6.4 Thedentdepthmay“relax”orreducewithtimeorupon

sequence. exposure to different environmental conditions.

d = indenter displacement (see 3.2.6).

6.5 Treatmentandinterpretationofdelaminationgrowthare

beyond the scope of this test method.

4. Summary of Test Method

6.6 Material and Specimen Preparation—Poor material

4.1 The quasi-static indentation (QSI) test is used to mea-

fabrication practices, lack of control of fiber alignment, and

sure the damage resistance of a uniform-thickness laminated

damage induced by improper coupon machining are known

compositespecimen.Anindentationforceisappliedslowlyby

causes of high material data scatter in composites.

pressing a displacement-controlled hemispherical indenter into

6.7 Application to Other Materials, Lay-Ups, and Architec-

the face of the specimen. The displacement is increased until

tures:

the desired damage state is reached. Procedures are specified

for determining the damage resistance for a simply supported

test specimen and for a rigidly backed test specimen. The

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

damage response is a function of the test configuration. this standard.

D 6264 – 98 (2004)

6.7.1 The QSI test primarily has been used for testing 7.5 Load Versus Indenter Displacement (F Versus d)

carbon-fiber-reinforcedtapeandfabriclaminateswithpolymer Record—An X-Y plotter, or similar device, shall be used to

matrices. For other materials, a quite different response may makeapermanentrecordduringthetestofloadversusindenter

occur. displacement. Alternatively, the data may be stored digitally

and postprocessed.

6.7.2 Nonlaminated, 3D fiber-reinforced, or textile compos-

itesmayfailbydifferentmechanismsthanlaminates.Themost 7.6 Specimen Support—The damage resistance may be

determined for a specimen that is simply supported or rigidly

critical damage may be in the form of matrix cracking or fiber

failure, or both, rather than delaminations. backed. For both configurations, the specimen’s face shall be

held normal to the axis of the indenter.

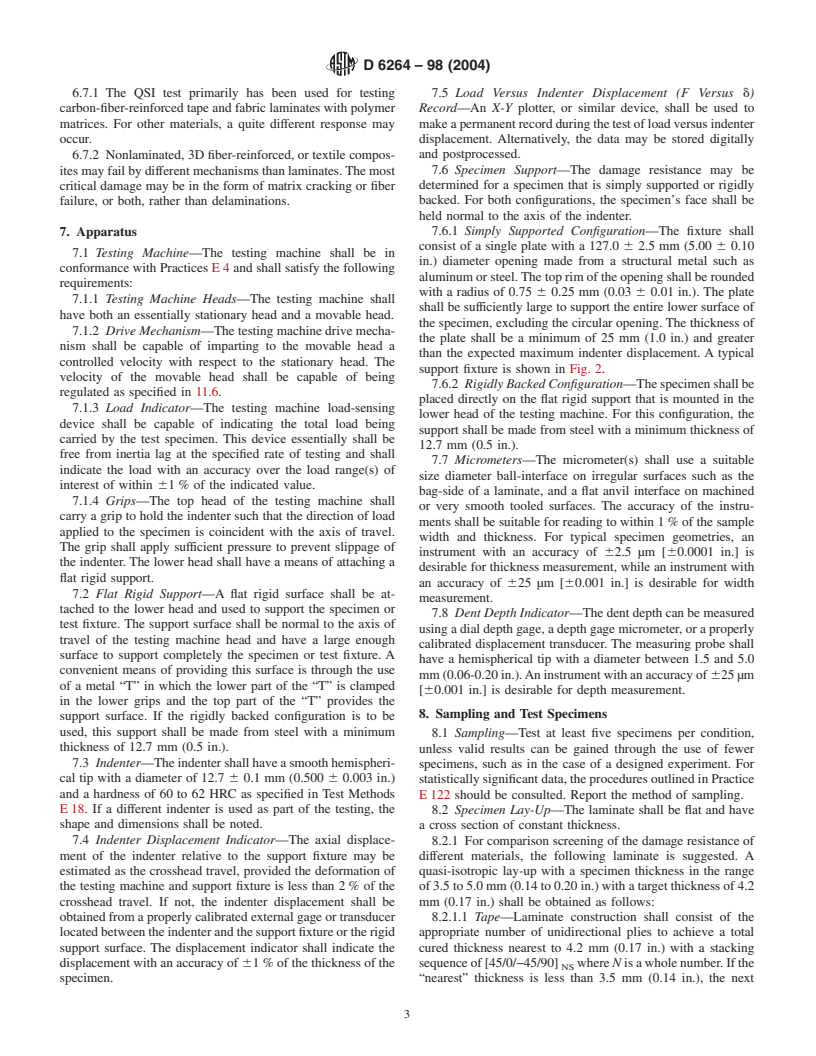

7.6.1 Simply Supported Configuration—The fixture shall

7. Apparatus

consist of a single plate with a 127.0 6 2.5 mm (5.00 6 0.10

7.1 Testing Machine—The testing machine shall be in

in.) diameter opening made from a structural metal such as

conformance with PracticesE4 and shall satisfy the following

aluminumorsteel.Thetoprimoftheopeningshallberounded

requirements:

with a radius of 0.75 6 0.25 mm (0.03 6 0.01 in.). The plate

7.1.1 Testing Machine Heads—The testing machine shall

shall be sufficiently large to support the entire lower surface of

have both an essentially stationary head and a movable head.

the specimen, excluding the circular opening.The thickness of

7.1.2 Drive Mechanism—Thetestingmachinedrivemecha-

the plate shall be a minimum of 25 mm (1.0 in.) and greater

nism shall be capable of imparting to the movable head a

than the expected maximum indenter displacement. A typical

controlled velocity with respect to the stationary head. The

support fixture is shown in Fig. 2.

velocity of the movable head shall be capable of being

7.6.2 Rigidly Backed Configuration—Thespecimenshallbe

regulated as specified in 11.6.

placed directly on the flat rigid support that is mounted in the

7.1.3 Load Indicator—The testing machine load-sensing

lower head of the testing machine. For this configuration, the

device shall be capable of indicating the total load being

support shall be made from steel with a minimum thickness of

carried by the test specimen. This device essentially shall be

12.7 mm (0.5 in.).

free from inertia lag at the specified rate of testing and shall

7.7 Micrometers—The micrometer(s) shall use a suitable

indicate the load with an accuracy over the load range(s) of

size diameter ball-interface on irregular surfaces such as the

interest of within 61% of the indicated value.

bag-side of a laminate, and a flat anvil interface on machined

7.1.4 Grips—The top head of the testing machine shall

or very smooth tooled surfaces. The accuracy of the instru-

carry a grip to hold the indenter such that the direction of load

ments shall be suitable for reading to within 1% of the sample

applied to the specimen is coincident with the axis of travel.

width and thickness. For typical specimen geometries, an

The grip shall apply sufficient pressure to prevent slippage of

instrument with an accuracy of 62.5 µm [60.0001 in.] is

the indenter. The lower head shall have a means of attaching a

desirable for thickness measurement, while an instrument with

flat rigid support.

an accuracy of 625 µm [60.001 in.] is desirable for width

7.2 Flat Rigid Support—A flat rigid surface shall be at-

measurement.

tached to the lower head and used to support the specimen or

7.8 Dent Depth Indicator—Thedentdepthcanbemeasured

test fixture. The support surface shall be normal to the axis of

usingadialdepthgage,adepthgagemicrometer,oraproperly

travel of the testing machine head and have a large enough

calibrated displacement transducer. The measuring probe shall

surface to support completely the specimen or test fixture. A

have a hemispherical tip with a diameter between 1.5 and 5.0

convenient means of providing this surface is through the use

mm(0.06-0.20in.).Aninstrumentwithanaccuracyof 625µm

of a metal “T” in which the lower part of the “T” is clamped

[60.001 in.] is desirable for depth measurement.

in the lower grips and the top part of the “T” provides the

8. Sampling and Test Specimens

support surface. If the rigidly backed configuration is to be

used, this support shall be made from steel with a minimum

8.1 Sampling—Test at least five specimens per condition,

thickness of 12.7 mm (0.5 in.).

unless valid results can be gained through the use of fewer

7.3 Indenter—Theindentershallhaveasmoothhemispheri-

specimens, such as in the case of a designed experiment. For

cal tip with a diameter of 12.7 6 0.1 mm (0.500 6 0.003 in.)

statisticallysignificantdata,theproceduresoutlinedinPractice

and a hardness of 60 to 62 HRC as specified in Test Methods E122 should be consulted. Report the method of sampling.

E18. If a different indenter is used as part of the testing, the

8.2 Specimen Lay-Up—The laminate shall be flat and have

shape and dimensions shall be noted. a cross section of consta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.