ASTM E430-19

(Test Method)Standard Test Methods for Measurement of Gloss of High-Gloss Surfaces by Abridged Goniophotometry

Standard Test Methods for Measurement of Gloss of High-Gloss Surfaces by Abridged Goniophotometry

SIGNIFICANCE AND USE

5.1 The gloss of metallic finishes is important commercially on metals for automotive, architectural, and other uses where these metals undergo special finishing processes to produce the appearances desired. It is important for the end-products, which use such finished metals that parts placed together have the same glossy appearance.

5.2 It is also important that automotive finishes and other high-gloss nonmetallic surfaces possess the desired finished appearance. The present method identifies by measurements important aspects of finishes. Those having identical sets of numbers normally have the same gloss characteristics. It usually requires more than one measurement to identify properly the glossy appearance of any finish (see Refs 3 and 4).

SCOPE

1.1 These test methods cover the measurement of the reflection characteristics responsible for the glossy appearance of high-gloss surfaces. Two test methods, A and B, are provided for evaluating such surface characteristics at specular angles of 20° and 30°, respectively. These test methods are not suitable for diffuse finish surfaces nor do they measure color, another appearance attribute.

1.2 As originally developed by Tingle and others (see Refs 1 and 2),2 the test methods were applied only to bright metals. Recently they have been applied to high-gloss automotive finishes and other nonmetallic surfaces.

1.3 The DOI of a glossy surface is generally independent of its curvature. The DOI measurement by this test method is limited to flat or flattenable surfaces.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E430 − 19

Standard Test Methods for

Measurement of Gloss of High-Gloss Surfaces by Abridged

1

Goniophotometry

This standard is issued under the fixed designation E430; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope ASTM Test Methods

E179 Guide for Selection of Geometric Conditions for

1.1 These test methods cover the measurement of the

Measurement of Reflection and Transmission Properties

reflection characteristics responsible for the glossy appearance

of Materials

of high-gloss surfaces. Two test methods, A and B, are

E284 Terminology of Appearance

provided for evaluating such surface characteristics at specular

E308 Practice for Computing the Colors of Objects by Using

angles of 20° and 30°, respectively. These test methods are not

the CIE System

suitable for diffuse finish surfaces nor do they measure color,

E691 Practice for Conducting an Interlaboratory Study to

another appearance attribute.

Determine the Precision of a Test Method

1.2 As originally developed by Tingle and others (see Refs

E1347 Test Method for Color and Color-Difference Mea-

2

1 and 2), the test methods were applied only to bright metals.

surement by Tristimulus Colorimetry

Recently they have been applied to high-gloss automotive

finishes and other nonmetallic surfaces. 3. Terminology

1.3 The DOI of a glossy surface is generally independent of 3.1 Definitions:

its curvature. The DOI measurement by this test method is 3.1.1 Appearance terms in this test method are in accor-

limited to flat or flattenable surfaces. dance with Terminology E284.

3.1.2 Terms that are defined in Terminology E284, but have

1.4 This international standard was developed in accor-

a specific definition in this method are

dance with internationally recognized principles on standard-

3.1.3 reflectance, p, n—ratio of the reflected radiant or

ization established in the Decision on Principles for the

luminous flux to the incident flux in the given conditions.

Development of International Standards, Guides and Recom-

(Terminology E284)

mendations issued by the World Trade Organization Technical

3.1.3.1 Discussion—The term reflectance is often used in a

Barriers to Trade (TBT) Committee.

general sense or as an abbreviation for reflectance factor. Such

usage is not assumed in this method. The definition may

2. Referenced Documents

3 require that the term be modified by adjectives denoting the

2.1 ASTM Standards:

spectral and geometric conditions of measurement.

D523 Test Method for Specular Gloss

3.2 Definitions of Terms Specific to This Standard:

D2457 Test Method for Specular Gloss of Plastic Films and

3.2.1 reflection haze, H, n—for a specified specular angle,

Solid Plastics

ratio of flux reflected at a specified angle (or angles) from the

E171 Practice for Conditioning and Testing Flexible Barrier

specular direction to the flux similarly reflected at the specular

Packaging

angle by a specified gloss standard.

E177 Practice for Use of the Terms Precision and Bias in

3.2.1.1 Discussion—Modifiers may be used to specify the

angles at which the haze is measured (for example, 2°, –5° or

1

These test methods are under the jurisdiction of ASTM Committee E12 on

15°); whether –H or a logarithmic form is to be stated; or

Color and Appearance and are the direct responsibility of Subcommittee E12.03 on

whether H is to be compensated for the luminance of the

Geometry.

specimen by multiplication by Y /Y , where n denotes the

specimen n

Current edition approved Nov. 1, 2019. Published December 2019. Originally

reference white; or any combination of these.

approved in 1971. Last previous edition approved in 2011 as E430 – 11. DOI:

10.1520/E0430-19.

3.2.2 metallic brightness, n—freedom of a metal surface

2

The boldface numbers in parentheses refer to the list of references at the end of

from diffuse haze or texture.

this method.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.3 ‘with-machine’ direction, n—the axis of a specimen

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

that is parallel to the direction of mill rolling or extrusion, or

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. other surface-finish texture.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

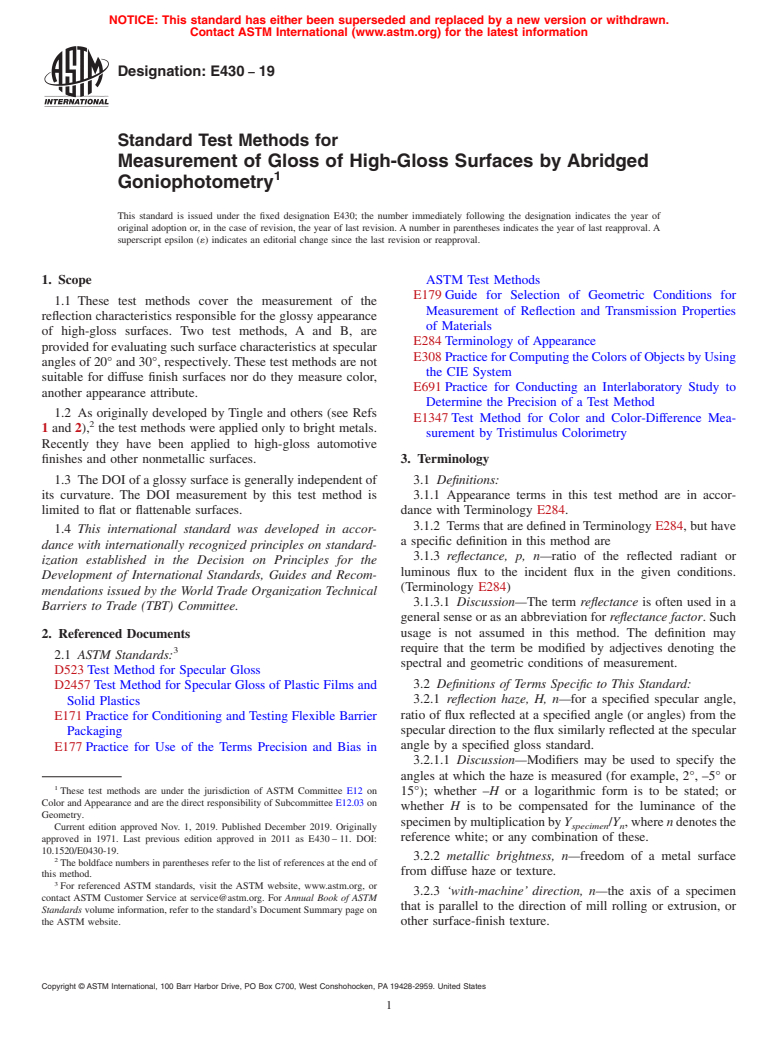

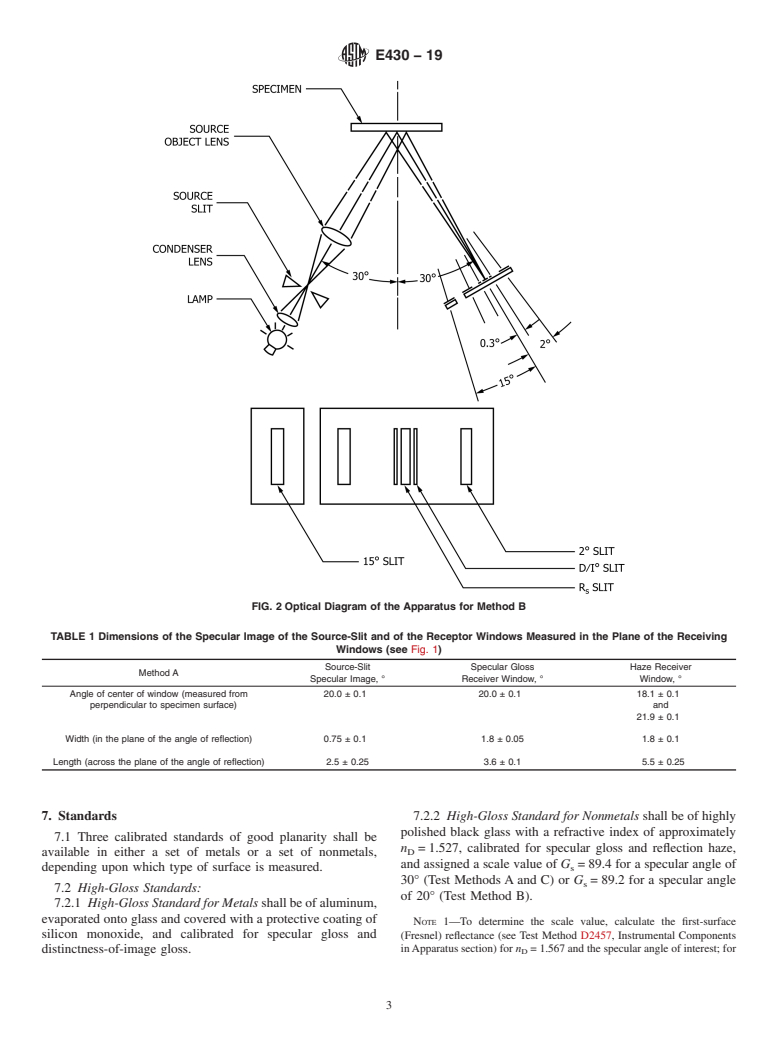

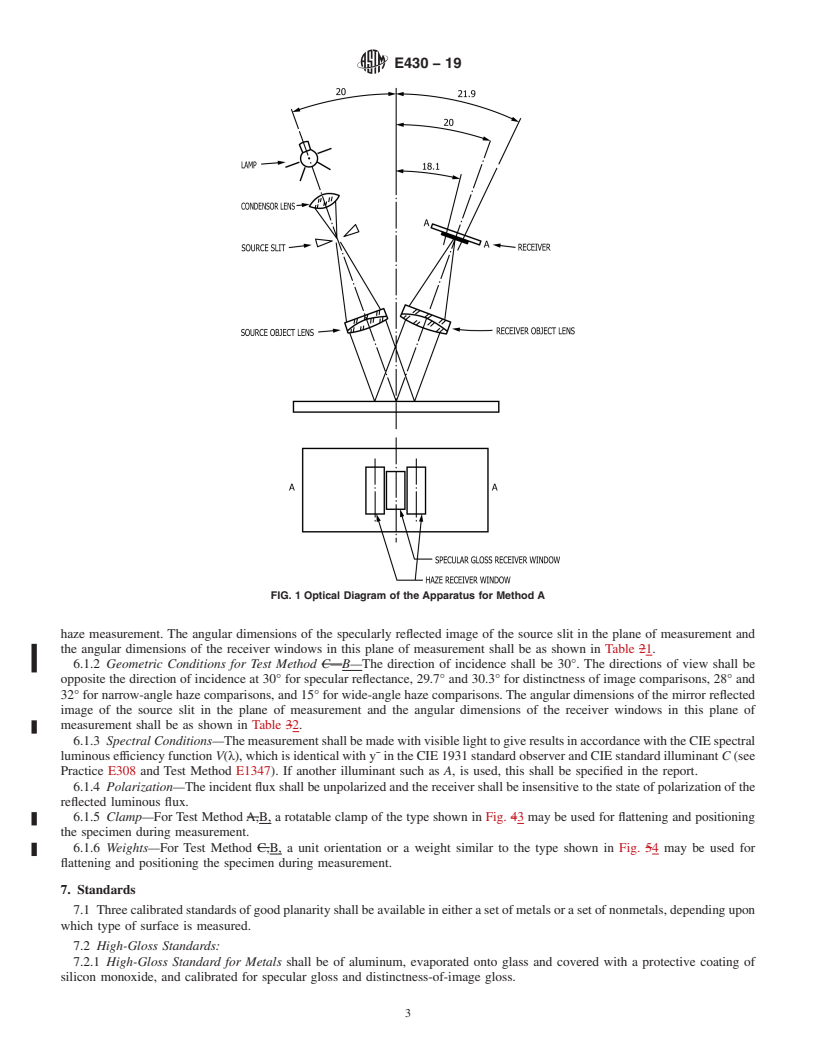

---------------------- Page: 1 ----------------------

E430 − 19

3.2.4 ‘across-machine’ direction, n—the perpendicular to which use such finished metals that parts placed together have

‘with-machine’ direction. the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E430 − 11 E430 − 19

Standard Test Methods for

Measurement of Gloss of High-Gloss Surfaces by Abridged

1

Goniophotometry

This standard is issued under the fixed designation E430; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover the measurement of the reflection characteristics responsible for the glossy appearance of

high-gloss surfaces. ThreeTwo test methods, A, B A and C,B, are provided for evaluating such surface characteristics at specular

angles of 30°, 20° and 30°, respectively. These test methods are not suitable for diffuse finish surfaces nor do they measure color,

another appearance attribute.

2

1.2 As originally developed by Tingle and others (see Refs 1 and 2), the test methods were applied only to bright metals.

Recently they have been applied to high-gloss automotive finishes and other nonmetallic surfaces.

1.3 The DOI of a glossy surface is generally independent of its curvature. The DOI measurement by this test method is limited

to flat or flattenable surfaces.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

D523 Test Method for Specular Gloss

D2457 Test Method for Specular Gloss of Plastic Films and Solid Plastics

E171 Practice for Conditioning and Testing Flexible Barrier Packaging

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E179 Guide for Selection of Geometric Conditions for Measurement of Reflection and Transmission Properties of Materials

E284 Terminology of Appearance

E308 Practice for Computing the Colors of Objects by Using the CIE System

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1347 Test Method for Color and Color-Difference Measurement by Tristimulus Colorimetry

3. Terminology

3.1 Definitions:

3.1.1 Appearance terms in this test method are in accordance with Terminology E284.

3.1.2 Terms that are defined in Terminology E284, but have a specific definition in this method are

3.1.3 reflectance, p, n—ratio of the reflected radiant or luminous flux to the incident flux in the given conditions. ((Terminology

E284)

3.1.3.1 Discussion—

1

These test methods are under the jurisdiction of ASTM Committee E12 on Color and Appearance and are the direct responsibility of Subcommittee E12.03 on Geometry.

Current edition approved June 1, 2011Nov. 1, 2019. Published June 2011December 2019. Originally approved in 1971. Last previous edition approved in 20052011 as

E430 – 05.E430 – 11. DOI: 10.1520/E0430-11.10.1520/E0430-19.

2

The boldface numbers in parentheses refer to the list of references at the end of this method.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E430 − 19

The term reflectance is often used in a general sense or as an abbreviation for reflectance factor. Such usage is not assumed in this

method. The definition may require that the term be modified by adjectives denoting the spectral and geometric conditions of

measurement.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 reflection haze, H, n—for a specified specular angle, ratio of flux reflected at a specified angle (or angles) from the specular

direction to the flux similarly reflected at the specular angle by a specified gloss standard.

3.2.1.1 Discussion—

Modifiers may be used to specify the angles at which the haze is measured (for example, 2°, –5° or 15°); whether –H or a

logarithmic form is to be stated; or whether H is to be compensated for the luminance of the specimen by multiplication by

Y /Y , where n denotes the reference white; or any combination of these.

specimen n

3.2.2 metallic brightness, n—freedom of a metal surface from diffuse

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.