ASTM C1331-01(2012)

(Test Method)Standard Test Method for Measuring Ultrasonic Velocity in Advanced Ceramics with Broadband Pulse-Echo Cross-Correlation Method

Standard Test Method for Measuring Ultrasonic Velocity in Advanced Ceramics with Broadband Pulse-Echo Cross-Correlation Method

SIGNIFICANCE AND USE

4.1 The velocity measurements described in this test method may be used to characterize material variations that affect mechanical or physical properties. This procedure is useful for measuring variations in microstructural features such as grain structure, pore fractions, and density variations in monolithic ceramics.

4.2 Velocity measurements described herein can assess subtle variations in porosity within a given material or component, as, for example, in ceramic superconductors and structural ceramic specimens (2,3).

4.3 In addition to ceramics and ceramic composites, the velocity measurements described herein may be applied to polycrystalline and single crystal metals, metal matrix composites, and polymer matrix composites.

4.4 An alternative technique for velocity measurement is given in Practice E494.

SCOPE

1.1 This test method describes a procedure for measurement of ultrasonic velocity in structural engineering solids such as monolithic ceramics, toughened ceramics, and ceramic matrix composites.

1.2 This test method is based on the broadband pulse-echo contact ultrasonic method. The procedure involves a computer-implemented, frequency-domain method for precise measurement of time delays between pairs of echoes returned by the back surface of a test sample or part.

1.3 This test method describes a procedure for using a digital cross-correlation algorithm for velocity measurement. The cross-correlation function yields a time delay between any two echo waveforms (1).2

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1331 − 01 (Reapproved 2012)

Standard Test Method for

Measuring Ultrasonic Velocity in Advanced Ceramics with

Broadband Pulse-Echo Cross-Correlation Method

This standard is issued under the fixed designation C1331; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E494Practice for Measuring Ultrasonic Velocity in Materi-

als

1.1 Thistestmethoddescribesaprocedureformeasurement

E1316Terminology for Nondestructive Examinations

of ultrasonic velocity in structural engineering solids such as

2.2 ASNT Document:

monolithic ceramics, toughened ceramics, and ceramic matrix

Recommended Practice SNT-TC-1A for Nondestructive

composites.

Testing Personnel Qualification and Certification

1.2 This test method is based on the broadband pulse-echo

2.3 Military Standard:

contactultrasonicmethod.Theprocedureinvolvesacomputer-

MIL-STD-410Nondestructive Testing Personnel Qualifica-

implemented, frequency-domain method for precise measure-

tion and Certification

ment of time delays between pairs of echoes returned by the

2.4 Additional references are cited in the text and at end of

back surface of a test sample or part.

this document.

1.3 This test method describes a procedure for using a

digital cross-correlation algorithm for velocity measurement.

Thecross-correlationfunctionyieldsatimedelaybetweenany

3. Terminology

two echo waveforms (1).

3.1 Definitions of Terms Specific to This Standard:

1.4 This international standard was developed in accor-

3.1.1 back surface—the surface of a test sample which is

dance with internationally recognized principles on standard-

opposite to the front surface and from which back surface

ization established in the Decision on Principles for the

echoes are returned at normal incidence directly to the trans-

Development of International Standards, Guides and Recom-

ducer.

mendations issued by the World Trade Organization Technical

3.1.2 bandwidth—the frequency range of an ultrasonic

Barriers to Trade (TBT) Committee.

probe, defined by convention as the difference between the

lowerandupperfrequenciesatwhichthesignalamplitudeis6

2. Referenced Documents

3 dB down from the frequency at which maximum signal

2.1 ASTM Standards:

amplitude occurs.

B311Test Method for Density of Powder Metallurgy (PM)

3.1.3 broadband transducer—an ultrasonic transducer ca-

Materials Containing Less Than Two Percent Porosity

pableofsendingandreceivingundistortedsignalsoverabroad

C373Test Methods for Determination of Water Absorption

bandwidth, consisting of a thin damped piezocrystal in a

andAssociated Properties byVacuum Method for Pressed

buffered probe (search unit).

Ceramic Tiles and Glass Tiles and Boil Method for

Extruded Ceramic Tiles and Non-tile Fired Ceramic

3.1.4 buffered probe—anultrasonicsearchunitasdefinedin

Whiteware Products

Terminology E1316 but containing a delay line, or buffer rod,

to which the piezocrystal is affixed within the search unit

housing and which separates the piezocrystal from the test

This test method is under the jurisdiction of ASTM Committee E07 on

sample (Fig. 1).

Nondestructive Testing and is the direct responsibility of Subcommittee E07.06 on

Ultrasonic Method. 3.1.5 buffer rod—an integral part of a buffered probe,

Current edition approved Aug. 1, 2012. Published November 2012. Originally

usually a quartz or fused silica cylinder that provides a time

approved in 1996. Last previous edition approved in 2007 as C1331– 01 (2007).

DOI: 10.1520/C1331-01R12.

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

this test method. AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

Standardsvolume information,referto thestandard’sDocumentSummary page on Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098, http://

the ASTM website. www.dodssp.daps.mil.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1331 − 01 (2012)

component, as, for example, in ceramic superconductors and

structural ceramic specimens (2,3).

4.3 In addition to ceramics and ceramic composites, the

velocity measurements described herein may be applied to

polycrystalline and single crystal metals, metal matrix

composites, and polymer matrix composites.

4.4 An alternative technique for velocity measurement is

given in Practice E494.

5. Personnel Qualifications

5.1 It is recommended that nondestructive evaluation/

examinationpersonnelapplyingthistestmethodbequalifiedin

accordance with a nationally-recognized personnel qualifica-

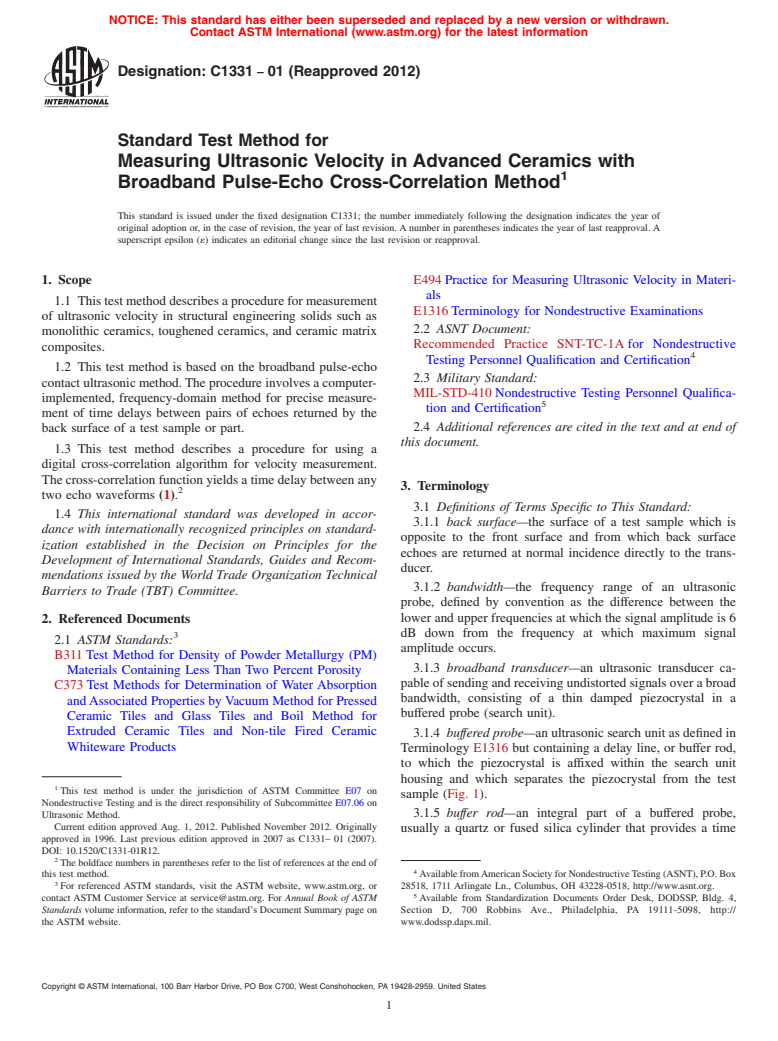

NOTE 1—B and B are first and second back surface echoes,

1 2

tionpracticeorstandardsuchasASNTSNT-TC-1A,MILSTD

respectively, and T is time interval between the echoes.

410, or a similar document. The qualification practice or

FIG. 1 Cross Section of Buffered Ultrasonic Probe (a) and Prin-

standardusedanditsapplicablerevision(s)shouldbespecified

ciple Echoes (b) for Velocity Measurement

in a contractual agreement.

5.2 Knowledge of the principles of ultrasonic testing is

delay between the excitation pulse from the piezocrystal and

required. Personnel applying this test method should be expe-

echoes returning from a sample coupled to the free end of the

riencedpractitionersofultrasonicexaminationsandassociated

buffer rod.

methods for signal acquisition, processing, and interpretation.

3.1.6 cross-correlation function—the cross-correlation

5.3 Personnel should have proficiency in computer signal

function, implemented by a digital algorithm, yields a time

processing and the use of digital methods for time and

delaybetweenanytwo(ultrasonic)echowaveforms.Thistime

frequencydomainsignalanalysis.FamiliaritywithFourierand

is used to determine velocity (1).

associated transforms for ultrasonic spectrum analysis is re-

3.1.7 dispersion—variation of ultrasonic velocity as a func-

quired.

tion of wavelength, that is, frequency dependence of velocity.

3.1.8 front surface—the surface of a test sample to which

6. Apparatus and Test Sample

thebufferrodiscoupledatnormalincidence(designatedastest

6.1 Instrumentation (Fig. 1 and Fig. 2) for broadband

surface in Terminology E1316.

cross-correlation pulse-echo ultrasonic velocity measurement

3.1.9 group velocity—velocity of a broadband ultrasonic

should include the following:

pulse consisting of many different component wavelengths.

6.1.1 Buffered Probe:

3.1.10 test sample—a solid coupon or material part that

6.1.1.1 Thebufferrod,whichisanintegralpartoftheprobe

meets the constraints needed to make the ultrasonic velocity (search unit), should be a right cylinder with smooth flat ends

measurements described herein, that is, a test sample or part

normal to the axis of the probe.

having flat, parallel, smooth, preferably ground or polished 6.1.1.2 The center frequency of the buffered probe should

opposing (front and back) surfaces, and having no discrete

produce a wavelength within the sample that is less than one

flaws or anomalies unrepresentative of the inherent properties

fifth of the thickness of the sample.

of the material.

6.1.1.3 The buffer rod length, that is, time delay should be

three times the interval between two successive back surface

3.1.11 wavelength (λ)—distance that sound (of a particular

echoes.

frequency)travelsduringoneperiod(duringoneoscillation), λ

6.1.1.4 The wave mode may be either longitudinal or shear.

= v/f, where v is the velocity of sound in the material and

6.1.2 Pulser-Receiver,withabandwidththatisatleasttwice

where velocity is measured in cm/µs, frequency in MHz, and

that of the buffered probe. The bandwidth should include

wavelength in cm, herein.

frequencies in the range from 100 kHz to over 100 MHz.

3.2 Othertermsornomenclatureusedinthistestmethodare

6.1.2.1 The pulser-receiver should have provisions for con-

defined in Terminology E1316.

trolling the pulse repetition rate, pulse energy level, pulse

damping, and received signal gain.

4. Significance and Use

6.1.2.2 The pulser-receiver should provide a synchroniza-

4.1 Thevelocitymeasurementsdescribedinthistestmethod

tion pulse and signal output connector.

may be used to characterize material variations that affect

6.1.3 Waveform Digitizing Oscilloscope (A/D Board), bus

mechanical or physical properties.This procedure is useful for

programmable, to window and digitize the echo waveforms.

measuring variations in microstructural features such as grain

6.1.3.1 A minimum 512-element waveform array with a

structure, pore fractions, and density variations in monolithic

maximum data sampling interval of 1.95 ns is recommended.

ceramics.

For better waveform resolution, a 1024-element array with a

4.2 Velocity measurements described herein can assess data sampling interval of 0.97 ns may be needed.

subtle variations in porosity within a given material or 6.1.3.2 Vertical Amplifier, bus programmable module.

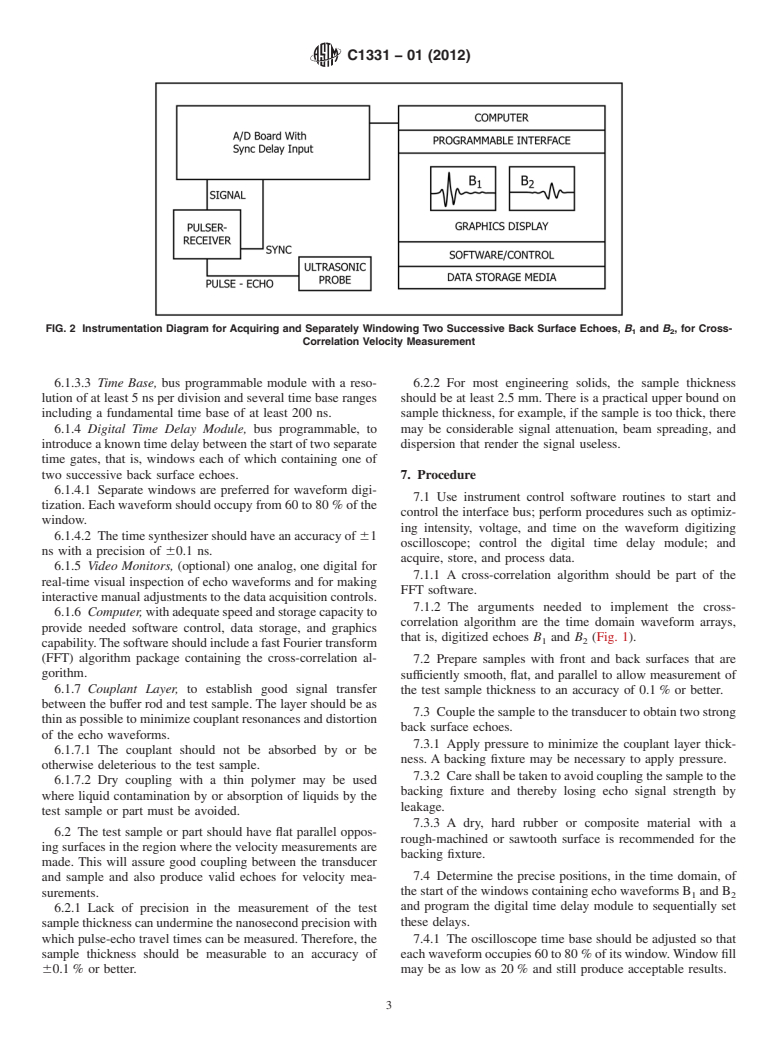

C1331 − 01 (2012)

FIG. 2 Instrumentation Diagram for Acquiring and Separately Windowing Two Successive Back Surface Echoes,B andB , for Cross-

1 2

Correlation Velocity Measurement

6.1.3.3 Time Base, bus programmable module with a reso- 6.2.2 For most engineering solids, the sample thickness

lutionofatleast5nsperdivisionandseveraltimebaseranges should be at least 2.5 mm.There is a practical upper bound on

including a fundamental time base of at least 200 ns. sample thickness, for example, if the sample is too thick, there

6.1.4 Digital Time Delay Module, bus programmable, to may be considerable signal attenuation, beam spreading, and

introduceaknowntimedelaybetweenthestartoftwoseparate dispersion that render the signal useless.

time gates, that is, windows each of which containing one of

two successive back surface echoes. 7. Procedure

6.1.4.1 Separate windows are preferred for waveform digi-

7.1 Use instrument control software routines to start and

tization.Eachwaveformshouldoccupyfrom60to80%ofthe

control the interface bus; perform procedures such as optimiz-

window.

ing intensity, voltage, and time on the waveform digitizing

6.1.4.2 Thetimesynthesizershouldhaveanaccuracyof 61

oscilloscope; control the digital time delay module; and

ns with a precision of 60.1 ns.

acquire, store, and process data.

6.1.5 Video Monitors, (optional) one analog, one digital for

7.1.1 A cross-correlation algorithm should be part of the

real-time visual inspection of echo waveforms and for making

FFT software.

interactivemanualadjustmentstothedataacquisitioncontrols.

7.1.2 The arguments needed to implement the cross-

6.1.6 Computer,withadequatespeedandstoragecapacityto

correlation algorithm are the time domain waveform arrays,

provide needed software control, data storage, and graphics

that is, digitized echoes B and B (Fig. 1).

1 2

capability.ThesoftwareshouldincludeafastFouriertransform

(FFT) algorithm package containing the cross-correlation al-

7.2 Prepare samples with front and back surfaces that are

gorithm.

sufficiently smooth, flat, and parallel to allow measurement of

6.1.7 Couplant Layer, to establish good signal transfer

the test sample thickness to an accuracy of 0.1% or better.

between the buffer rod and test sample.The layer should be as

7.3 Couplethesampletothetransducertoobtaintwostrong

thinaspossibletominimizecouplantresonancesanddistortion

back surface echoes.

of the echo waveforms.

7.3.1 Apply pressure to minimize the couplant layer thick-

6.1.7.1 The couplant should not be absorbed by or be

ness. A backing fixture may be necessary to apply pressure.

otherwise deleterious to the test sample.

7.3.2 Careshallbetakentoavoidcouplingthesampletothe

6.1.7.2 Dry coupling with a thin polymer may be used

backing fixture and thereby losing echo signal strength by

where liquid contamination by or absorption of liquids by the

leakage.

test sample or part must be avoided.

7.3.3 A dry, hard rubber or composite material with a

6.2 The test sample or part should have flat parallel oppos-

rough-machined or sawtooth surface is recommended for the

ingsurfacesintheregionwherethevelocitymeasurementsare

backing fixture.

made. This will assure good coupling between the transducer

7.4 Determine the precise positions, in the time domain, of

and sample and also produce valid echoes for velocity mea-

thestartofthewindowscontainingechowaveformsB andB

surements.

1 2

and program the digital time delay module to sequentially set

6.2.1 Lack of precision in the measurement of the test

these delays.

samplethicknesscanunderminethenanosecondprecisionwith

which pulse-echo travel times can be measured.Therefore, the 7.4.1 The oscilloscope time base should be adjusted so that

sample thickness should be measurable to an accuracy of eachwaveformoccupies60to80%ofitswindow.Windowfill

60.1% or better. may be as low as 20% and still produce acceptable results.

C1331 − 01 (2012)

NOTE 1—Time delay, W, between the two window start times is predetermined. Time interval, T, between echoes B and B is calculated from T =

1 2

W+(T − T ).

2 1

FIG. 3 Separately Windowed and Digitized Back Surface EchoesB andB

1 2

7.7.1.2 The centroid of echo B occurs at time D +T .

2 2 2

7.7.2 If the sample thickness and other constraints are met,

itshouldbepossibletodigitallyoverlapechoes B and B asin

1 2

Fig.4.DispersionhasoccurredifechoB isspreadoutrelative

to B and does not have the same zero crossings as B .Iftoo

1 1

pronounced,dispersionandbeamspreadingmaybeavoidedby

reducing the sample thickness.

7.7.3 The travel time interval T between B and B is given

1 2

by T = C + W , where W = D − D and C is the echo

2 1

displacement time obtained by means of the cross-correlation

algorithm.

7.7.4 The cross-correlation algorithm is applied to the echo

waveforms B and B to provide the value for the echo

1 2

displacement timeC.

7.8 Afteracquiringwaveformrecordsforechoes B and B ,

FIG. 4 Results of Digital Overlap of EchoesB (Solid Line) and 1 2

B (Dotted Line) When Dispersion is Not Present usethecross-correlationalgorithmtoobtaintheechodisplace-

ment time,C, relative to the zero reference.

7.9 Usethecross-correlationalgorithmwhichtransforms B

7.4.2 During data acquisition, the time synthesizer should

and B into the frequency domain, multiplies the complex

sequence through the predetermined time position

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.